Grooming tools, like many other devices, consist of various elements that work together to provide optimal performance. Each of these components plays a crucial role in the overall functionality and efficiency of the device, ensuring that it performs as expected. Whether it’s precision cutting, smooth operation, or durability, understanding the inner workings of such tools is essential for maintaining and repairing them.

In this guide, we will explore the essential features and elements that form the backbone of grooming devices. From the intricate mechanisms responsible for movement to the structural pieces that hold everything in place, we will break down each aspect in detail, helping you gain a better understanding of how these tools operate.

With a focus on the key mechanical and electrical elements, this detailed look will help you identify and understand how each component contributes to the overall functionality. Whether you’re looking to improve performance, troubleshoot issues, or simply gain a deeper appreciation for the craftsmanship behind these devices, this guide offers valuable insights into the inner workings of modern

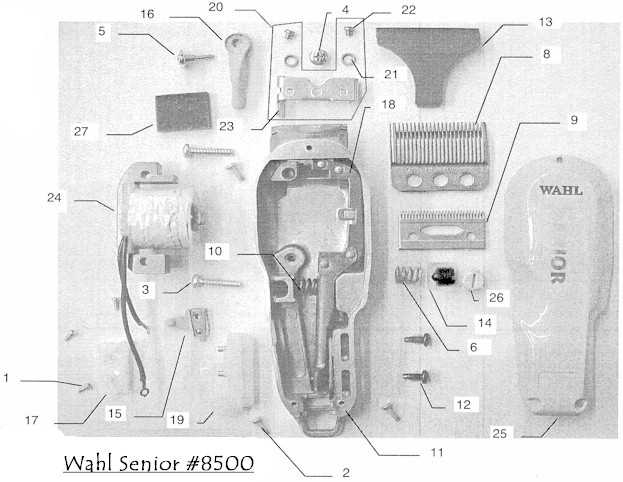

Wahl Trimmer Components Overview

Understanding the various elements that make up a grooming tool is essential for maintaining its efficiency and performance. Each component plays a vital role in the smooth operation of the device, ensuring precision and ease during grooming sessions. In this section, we will examine the key elements that form the structure and functionality of such tools, highlighting their importance and interactions.

Blade Assembly

The sharp cutting mechanism is the heart of the grooming device. It consists of two primary components that move against each other to trim hair effectively. These blades are often made of durable metals, providing a sharp edge for precision trimming. Proper alignment and regular maintenance of the cutting elements ensure that the tool performs optimally.

Motor and Internal Mechanism

The driving force behind the

Key Elements of a Wahl Trimmer

Every grooming tool is composed of essential components that work together to ensure smooth operation and optimal performance. These elements are specifically designed to provide precision, control, and efficiency during grooming tasks. Understanding how these core pieces interact can help maintain the tool’s longevity and functionality.

Motor plays a crucial role in powering the device, enabling the blades to move at the necessary speed. A powerful engine ensures consistent cutting action without lagging or interruptions, crucial for effective grooming.

The cutting mechanism is another integral aspect. This consists of sharp, durable blades designed to handle a range of grooming tasks. Their precision is essential for achieving smooth results, and they typically require regular maintenance, such as cleaning and oiling, to keep them sharp and efficient.

Adjustable features, such as length settings, allow users to tailor the tool’s operation to

How the Motor Powers the Trimmer

The driving force behind any grooming device lies in its internal mechanism, which converts electrical energy into mechanical movement. This core system is responsible for generating the motion necessary to operate efficiently. Understanding how this conversion happens helps reveal the seamless operation of the tool, ensuring precision and reliability during its use.

Energy Conversion

At the heart of the device, the motor receives electrical power from the power source, whether from a battery or direct connection. Once activated, this current flows into the motor’s winding, creating a magnetic field. This magnetic field interacts with the rotor, causing it to spin. The speed and torque of the rotor are essential for the consistent performance of the device.

Transferring Motion to Blades

As the motor spins, its rotation is transferred to the blade assembly through a series of gears and mechanisms. This transfer transforms the rotational motion into a reciprocating action, allowing the cutting

Blade Assembly and Functionality

The cutting mechanism is one of the most critical components in grooming devices, as it ensures precision and efficiency. The way the blades are constructed and operate plays a significant role in achieving smooth and accurate results. Understanding how this system functions can help in maintaining optimal performance.

The cutting system typically consists of multiple pieces working together to create a sharp, fast-moving interface that easily handles a variety of hair textures. These parts include the stationary and moving blades, which are designed to move in synchronization to provide clean, swift cuts. Each component in this mechanism is precisely engineered to maintain alignment, ensuring that the cutting process remains consistent.

Maintenance of the cutting system is essential for longevity and efficiency. Regular cleaning and lubrication help to reduce friction and prevent wear, ensuring the blades remain sharp and perform their task without interruption. Proper care also minimizes the risk of malfunction, keeping the

Internal Wiring and Electrical Connections

The internal wiring and electrical connections of any device play a critical role in ensuring its efficient operation. These connections link various internal components, allowing electrical power to flow seamlessly throughout the system. Understanding how these connections work can help in maintaining, repairing, or upgrading the device’s functionality.

Electrical Pathways and Component Integration

Within the system, electrical pathways are established to connect key components such as motors, switches, and circuit boards. These pathways are designed to handle specific voltage levels and current flows, ensuring each part receives the necessary power without overloading the system. Proper integration of these elements is vital for optimal performance and longevity.

Importance of Insulation and Safety

Insulation and safety measures are crucial aspects of internal wiring. Wires are typically coated with protective layers to prevent short circuits and minimize electrical hazards. These layers not only protect the internal components but also ensure user safety during operation. Attention to detail in wiring design can significantly

Understanding the Battery and Power Source

The power supply plays a crucial role in ensuring the smooth operation of any grooming device. It is important to recognize the components that provide energy and how they affect the performance of the tool. A reliable power system ensures that the device operates efficiently, without interruptions, and delivers consistent results over time.

Battery technology is at the heart of many modern grooming tools. Rechargeable batteries offer convenience and portability, allowing for cordless use. However, the longevity and performance of the device depend on the type of battery used, its capacity, and the charging system. Regular maintenance and proper care of the battery can extend its lifespan and maintain optimal performance.

Power management systems are designed to regulate the flow of electricity within the device. They prevent overcharging, ensure safety during use, and protect sensitive internal circuits. Understanding how the power source works, along with any associated controls, is essential for maximizing the efficiency and lifespan of the grooming device.

Role of the Switch in Operation

The switch plays a crucial role in the functionality of personal grooming devices. It acts as the control interface, allowing the user to manage the device’s power and operational modes. A well-designed switch ensures that the device can be easily powered on and off, facilitating a seamless user experience. Without a reliable switch, the device’s overall performance and usability would be compromised.

Control and Efficiency

The switch ensures that energy is delivered efficiently to the internal components, regulating the power supply. It enables smooth transitions between different operational settings, contributing to the device’s versatility. A malfunctioning switch can lead to inconsistent power delivery, reducing the effectiveness of the tool.

Durability and User Experience

A durable switch not only enhances the lifespan of the device but also impacts the user experience. High-quality switches are designed to withstand repeated usage without wear or degradation. As a result, users can rely on the device for consistent performance, even after extensive use.

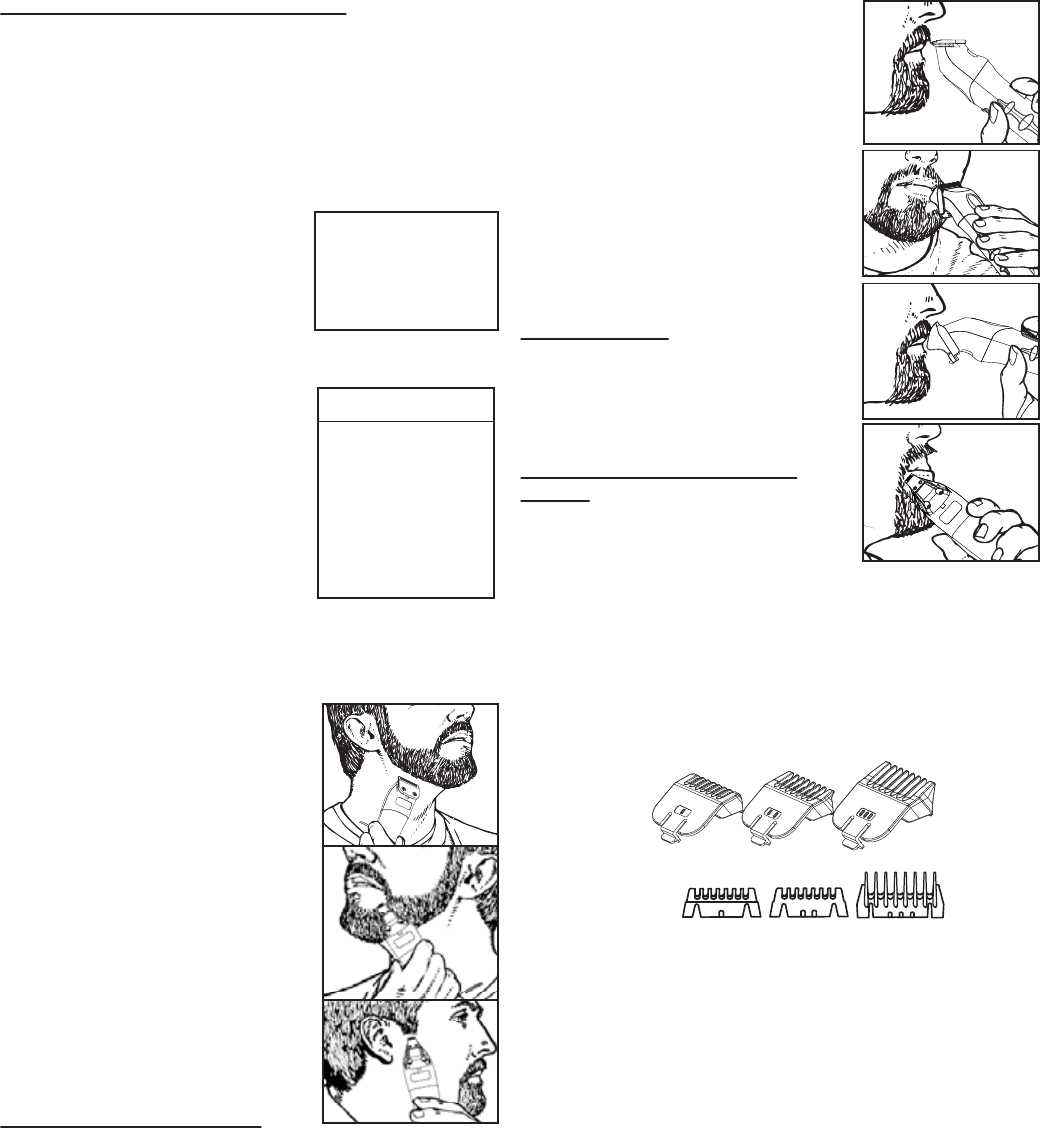

Attachment Comb Variations and Uses

Attachment combs offer versatility and precision in grooming, allowing for various cutting lengths and styles. These accessories come in a range of designs, each suited to different tasks, from trimming hair to shaping beards. Understanding the differences between combs can significantly enhance the grooming experience, providing optimal results based on individual needs.

- Standard Comb: Ideal for regular haircuts, this comb provides a uniform cutting length, ensuring smooth and even results across the scalp.

- Coarse-Toothed Comb: Designed for thicker or coarser hair types, this variation helps manage bulk while maintaining a precise finish.

- Fine-Toothed Comb: Perfect for shorter trims or delicate hair types, this comb allows for more detailed work and finer adjustments in length.

- Long Comb: Used for longer hairstyles or larger sections of hair, providing extended reach for a more consistent trim over a larger surface area.

- Precision Comb: This comb is designed for detailed and intricate work, such as beard shaping or outlining specific areas of the hairline.

Each comb offers a unique functionality, catering to different hair textures, lengths, and grooming preferences. Selecting the right comb attachment can enhance the overall outcome, giving users the flexibility to create both bold and refined looks.

Maintenance Tips for Blade Sharpness

Proper care and maintenance of cutting tools are essential to ensure their efficiency and longevity. Keeping the blades sharp enhances performance, reduces strain on the motor, and delivers a cleaner, more precise cut. Regular attention to the sharpness of the blades will not only improve the quality of your work but also prolong the lifespan of your equipment.

Regular Cleaning: Accumulated hair, debris, or other residues can dull the edges quickly. After every use, clean the blades thoroughly using a small brush or compressed air to remove particles. Keeping the blades free of buildup ensures smoother operation and maintains sharpness for a longer period.

Lubrication: Applying a few drops of oil to the blades helps reduce friction during use, preventing excessive wear. This also aids in keeping the cutting surfaces sharp and functioning optimally. Always ensure the blades are lightly lubricated before each use, but avoid over-oiling as it can attract dirt and debris.

Regular Inspection: Periodically check the blades for signs of dullness or damage. If the cutting action becomes uneven or less effective, it may be time to sharpen the blades. A dull blade can cause discomfort and uneven cuts, leading to a less satisfactory outcome.

Professional Sharpening: While regular maintenance helps, there comes a time when professional sharpening is needed. Having the blades professionally sharpened ensures they return to their optimal condition, reducing the need for frequent replacements and ensuring precision in every cut.

Housing and Outer Shell Construction

The outer structure of a grooming device plays a crucial role in ensuring both durability and ease of use. It is designed to offer protection to the internal components while providing a comfortable grip for the user. This enclosure not only safeguards sensitive parts from external damage but also contributes to the overall aesthetic and functional appeal of the device.

The construction typically involves a combination of materials, with high-quality plastics being the most common choice. These materials are selected for their strength, resistance to wear, and ability to withstand moisture. In addition to the material choice, the shape and texture of the housing are designed to fit the hand comfortably, promoting a secure grip during operation.

The outer shell often includes strategically placed vents or openings to allow proper ventilation, preventing overheating of internal components during extended use. The design may also feature ergonomically positioned buttons and switches for easy access, ensuring the device can be operated efficiently while maintaining a sleek and modern appearance.

Common Issues with Grooming Tools

In everyday use, grooming tools can experience various challenges that affect their performance. These challenges may stem from wear and tear, improper maintenance, or the accumulation of debris. While these devices are designed for long-term use, certain components are prone to malfunction over time. Understanding the common issues can help users troubleshoot and maintain their devices more effectively, ensuring they continue to function optimally.

Blade Dullness and Poor Cutting Performance

One of the most frequent problems encountered is the dullness of the cutting elements. As these components are used repeatedly, their sharpness diminishes, leading to inefficient trimming. A dull blade may pull or snag hair instead of providing a smooth cut. Regular cleaning and occasional sharpening of these elements can help prolong their lifespan and maintain optimal performance.

Motor Malfunctions

The motor is the driving force behind the cutting mechanism, and any issues with it can result in reduced power or complete failure. Overheating, excessive use, or internal component damage can hinder the motor’s functionality. Keeping the device well-ventilated and allowing it to cool between uses can prevent motor strain and extend its service life.