The intricate layout of various mechanical components can be quite challenging to understand without a detailed visual guide. This section aims to provide a clear understanding of how essential parts of the equipment are organized and interact with one another. It focuses on ensuring the smooth operation of the machinery by highlighting the structure and connectivity of its elements.

Understanding the Arrangement of Key Elements is crucial for maintaining and repairing the equipment effectively. A well-structured overview of the internal mechanisms helps to identify potential issues and improve performance. With the right knowledge, even complex machinery becomes easier to manage and sustain in top working condition.

In the following section, we will break down the positioning of critical components to give a clearer view of how they contribute to the functionality of the machine. Whether you’re performing routine maintenance or troubleshooting, this guide will assist in navigating the equipment’s structure efficiently.

Component Overview for Garden Cultivator

The machine used for soil preparation is composed of several key elements, each contributing to its efficient operation. These components are designed to ensure durability, functionality, and ease of use when cultivating the soil in a garden or field setting. Understanding how these pieces work together can help in maintaining the device and improving performance.

Engine System

The core of the machine’s power lies in the engine. This part drives the movement of the entire unit and ensures that it can handle tough soil. Regular maintenance of the engine is crucial for long-lasting performance.

- Fuel tank – stores the necessary fuel for engine operation.

- Air filter – protects the engine from dust and debris.

- Exhaust system – reduces emissions and controls noise levels.

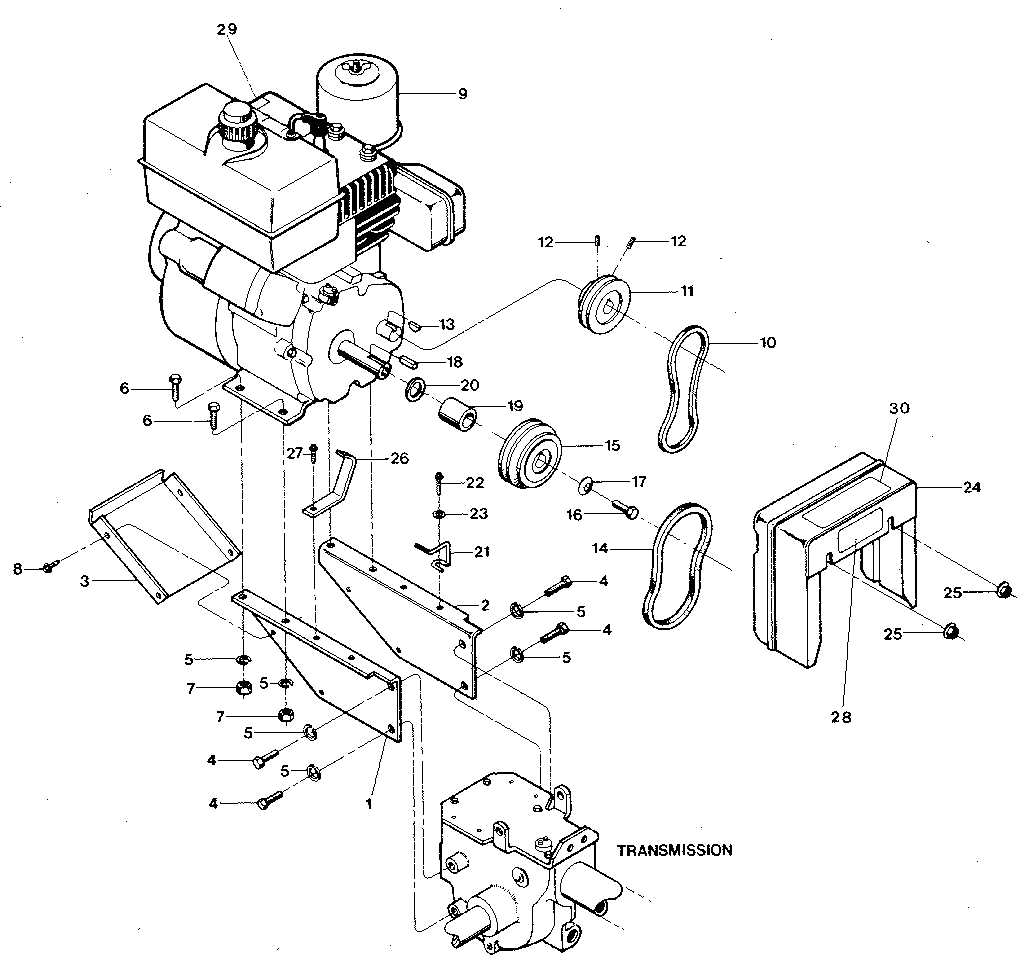

Transmission and Drive Mechanism

This section transfers the power from the engine to the wheels and blades. Proper functioning of this system ensures smooth operation and effective soil tilling.

- Gearbox – controls speed and torque.

- Drive belt – connects the engine to the transmission system.

- Axle and wheels – support movement and stability on different surfaces.

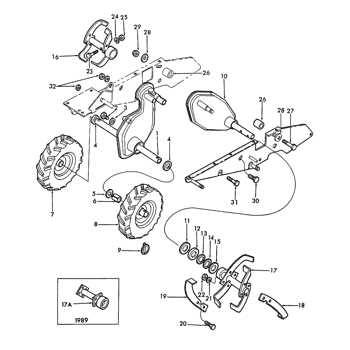

Main Frame Structure and Assembly

The primary construction of the central framework involves numerous components designed to ensure durability and efficient operation. The assembly process focuses on aligning these elements to maintain stability and provide a solid foundation for the entire machine.

Key Components of the Frame

- Main support bars that form the backbone of the structure

- Cross braces for enhanced stability

- Mounting points for various attachments

Steps for Assembly

- Begin by connecting the support bars to the base using appropriate fasteners.

- Attach the cross braces to the frame for added strength.

- Ensure all components are tightly secured before adding any additional parts.

Following these steps ensures that the frame is properly assembled, providing the necessary support for further attachments and systems.

Engine Parts and Maintenance Tips

The core of any garden machine relies heavily on the proper functioning of its engine. To ensure smooth and long-lasting operation, it’s important to focus on regular upkeep and to understand the key components that keep the device running efficiently. Below are essential insights into engine care and advice for maintenance.

Key Engine Components

The engine consists of several crucial parts that work together to provide power and efficiency. These components require attention to ensure optimal performance:

| Component | Function |

|---|---|

| Carburetor | Mixes fuel with air for combustion. |

| Spark Plug | Ignites the air-fuel mixture to power the engine. |

| Air Filter | Prevents dust and debris from entering the engine. |

| Fuel Tank | Stores fuel for the engine’s operation. |

Maintenance Guidelines

Maintaining the engine is vital for its longevity. Start by checking the oil level regularly and replace it when necessary. Clean or replace the air filter

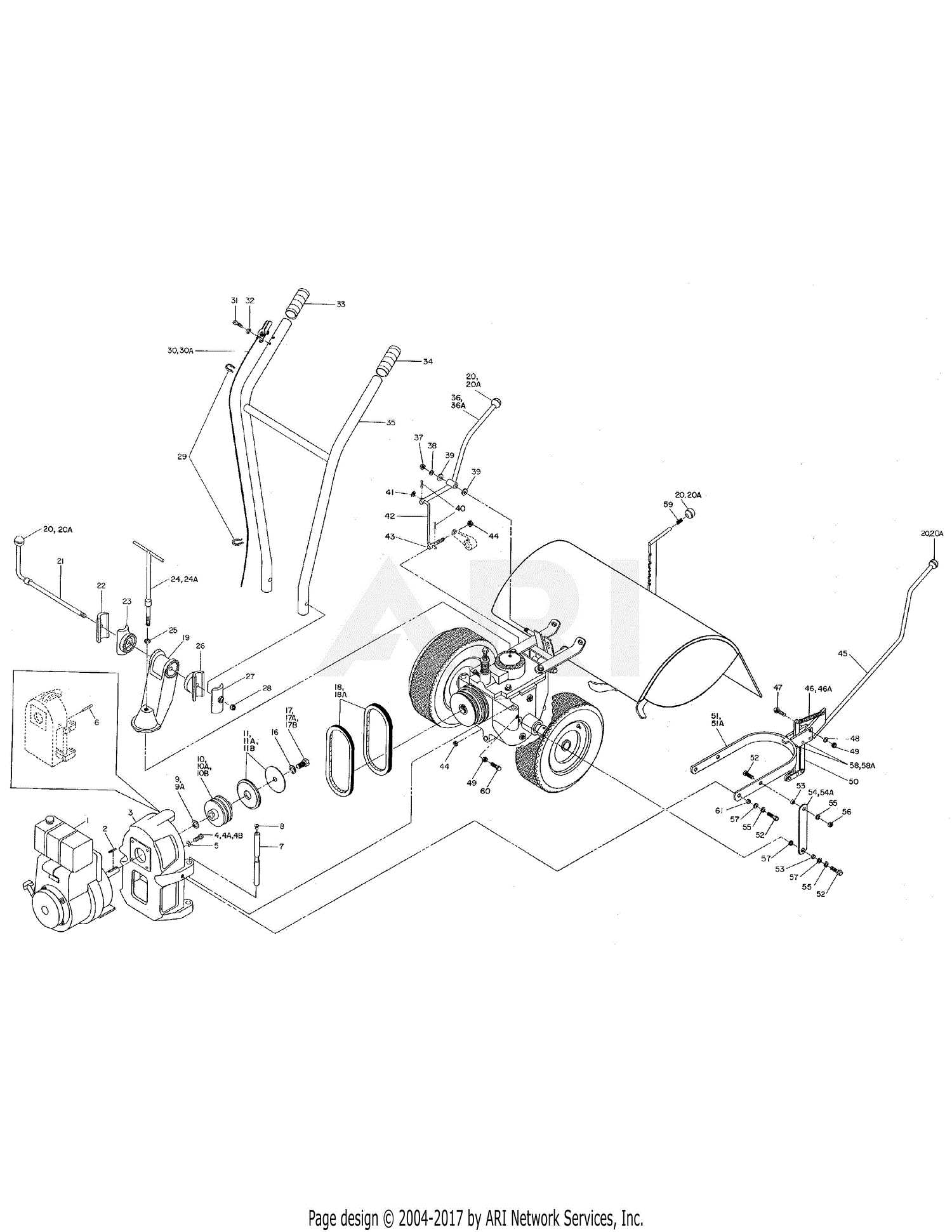

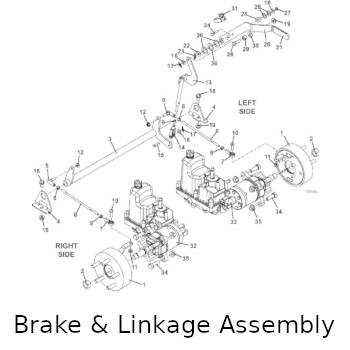

Belt System Configuration Explained

The belt system is a crucial component that ensures the smooth operation of the machine, allowing for effective power transfer between various mechanical parts. This system regulates the movement and functioning of the different elements, ensuring they work in harmony to achieve optimal performance.

Typically, the configuration involves multiple belts that connect key sections of the engine and transmission. Each belt plays a role in transferring energy, which is essential for the overall mechanics of the equipment. Understanding how these belts are aligned and interact is important for maintenance and troubleshooting.

By examining the layout of the belt system, users can identify which belts may need adjustment or replacement over time. Proper alignment and tensioning are vital to preventing wear and ensuring the longevity of the machinery.

Handlebars and Control Mechanisms

The steering system and control components are crucial for the effective management and operation of the machine. These elements ensure smooth navigation and allow the operator to maintain full command over the unit during use.

- Handlebars: The primary interface between the user and the machine, the handlebars are designed to offer comfort and stability during operation. Adjustable in some models, they can be adapted for user height and posture.

- Throttle Lever: This component regulates the speed of the machine, allowing for precise adjustments as needed. A well-positioned throttle enhances control and reduces operator fatigue.

- Gear Shift: Located near the handlebars for easy access, the gear shift allows the operator to change speed settings efficiently. Depending on the model, multiple speed settings can be selected for different tasks.

- Safety Controls: These include features like the stop button or lever, which halts the machine immediately in case of emergency. They are positioned within easy reach of the operator for quick action.

Each of these control mechanisms plays a pivotal role in ensuring the machine performs its tasks efficiently while keeping the operator safe and in control.

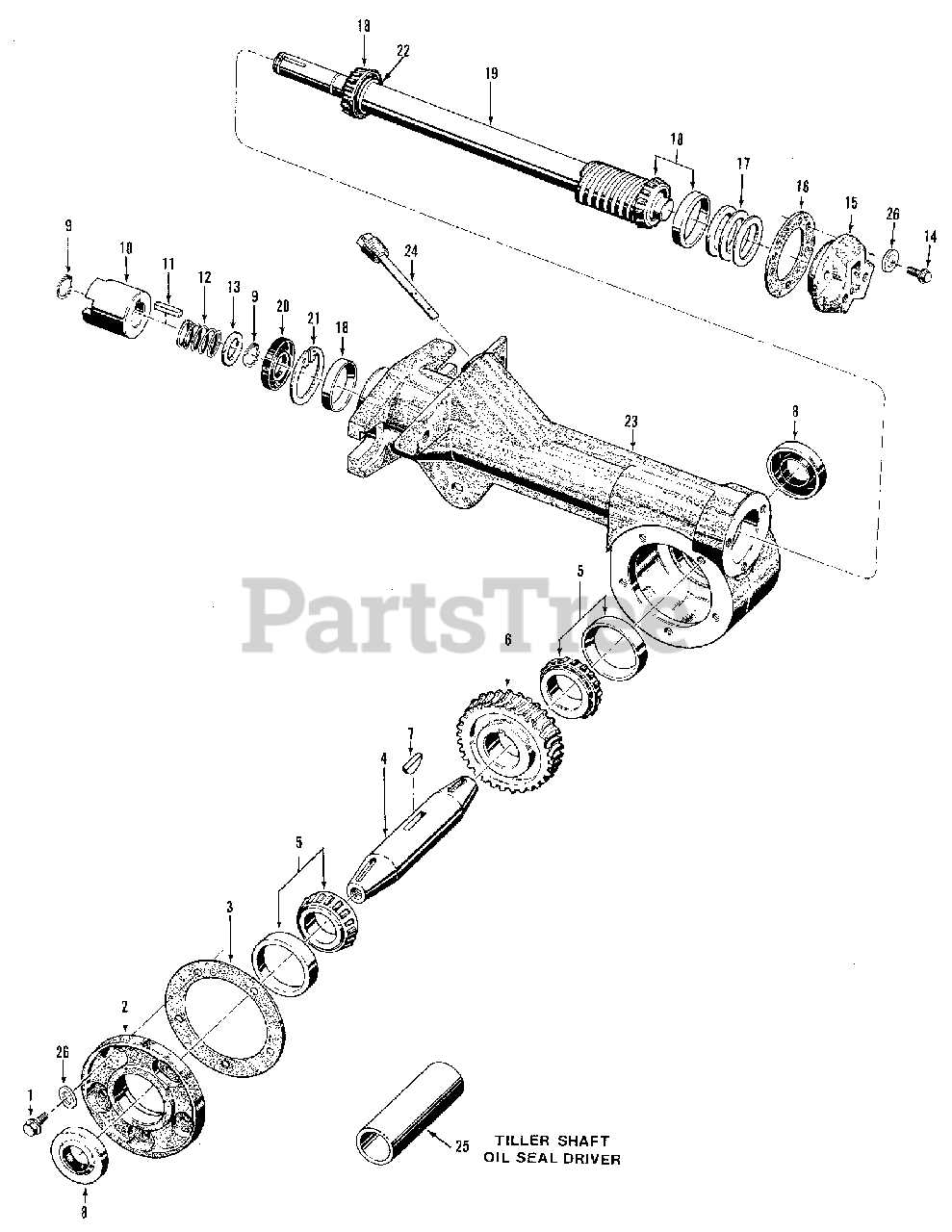

Transmission and Gearbox Details

The transmission and gearbox play a crucial role in the functionality of gardening equipment, providing the necessary power and torque for optimal performance. Understanding these components is essential for proper maintenance and efficient operation.

The transmission is responsible for controlling the speed and direction of the machine. It typically consists of a series of gears and belts that work together to transfer power from the engine to the wheels. Adjusting the settings can enhance maneuverability and efficiency during operation.

The gearbox, on the other hand, houses the gears that modify the torque and speed delivered to the working parts of the equipment. It is vital for converting the rotational power into usable force, allowing the machine to perform various tasks effectively. Regular inspection of the gearbox ensures smooth operation and longevity of the equipment.

Overall, maintaining the transmission and gearbox is essential for achieving the desired performance and reliability in gardening tasks. Proper care can significantly extend the lifespan of these critical components, ensuring that the equipment remains in excellent working condition.

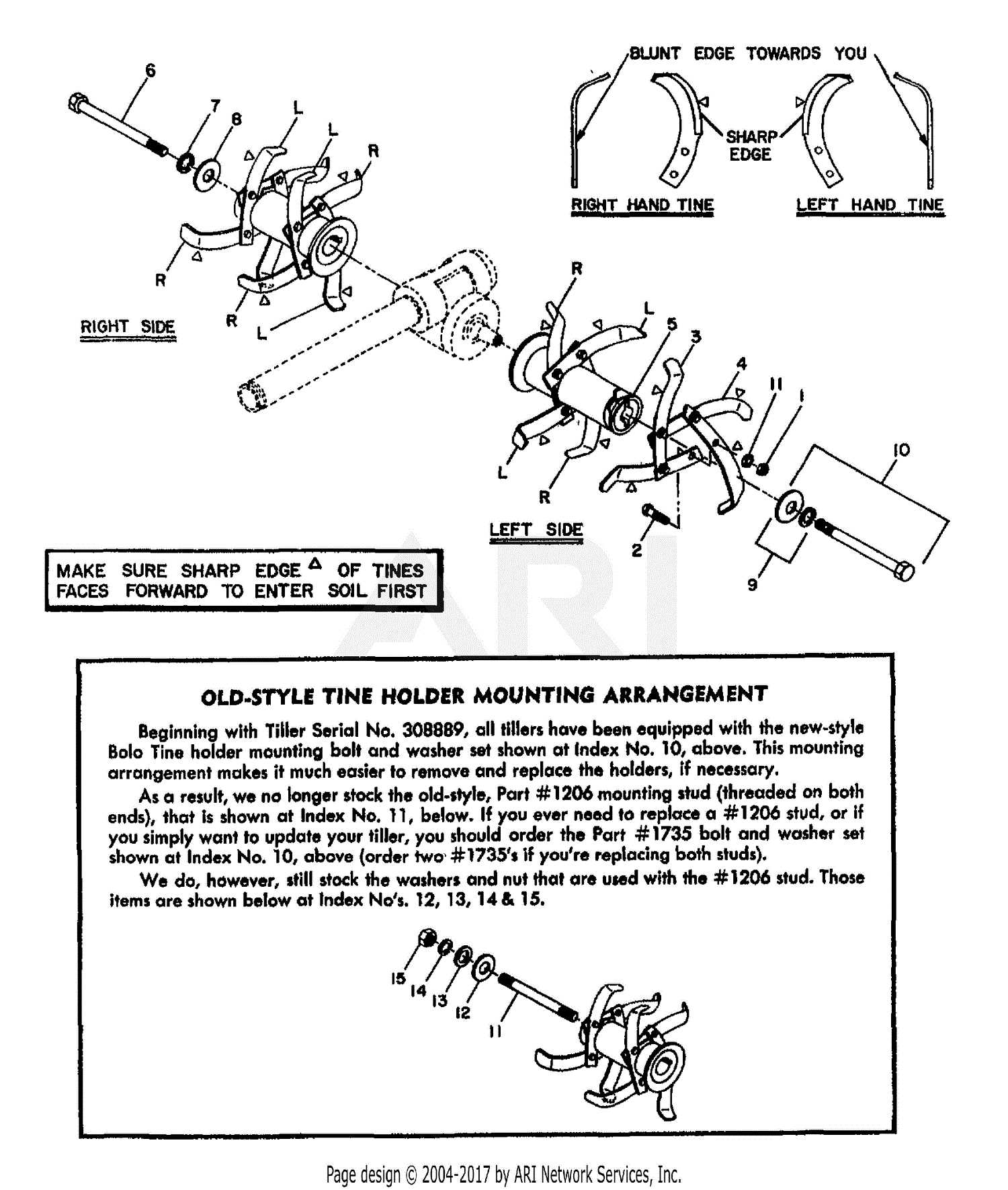

Blades and Tines: Key Features

The efficiency of soil cultivation largely depends on the quality and design of the cutting tools. These essential components are responsible for breaking up the earth, allowing for optimal aeration and nutrient absorption. Understanding their characteristics can significantly enhance performance and ease of use.

Material Composition: The durability of the cutting implements is often determined by the materials used in their construction. High-grade steel is commonly favored due to its strength and resistance to wear. This ensures that the tools remain effective over extended periods of use.

Design Variations: Different designs cater to specific soil types and cultivation techniques. For instance, curved or straight edges can influence the depth and width of the tillage. Choosing the right shape is crucial for achieving desired results in various gardening scenarios.

Adjustability: Many models offer adjustable features that allow users to modify the angle and depth of the blades. This adaptability ensures that the implements can be tailored to different tasks, from light tilling to more intensive cultivation.

Maintenance Requirements: Regular upkeep is essential for optimal performance. Users should be aware of how to properly clean and sharpen the blades to prolong their lifespan and effectiveness. This attention to maintenance contributes to consistent and reliable operation.

Wheels and Tire Replacement Guide

Proper maintenance of wheeled equipment is crucial for optimal performance and longevity. Over time, tires may wear out or become damaged, necessitating timely replacements. This section offers guidance on how to effectively replace wheels and tires to ensure smooth operation and improved efficiency.

Before starting the replacement process, gather all necessary tools and parts, including new tires, appropriate wrenches, and a jack. Ensure that the replacement tires are compatible with your equipment’s specifications, as this will affect performance and safety. It’s advisable to consult the user manual for details on tire size and type.

Begin by safely lifting the equipment using a jack, ensuring it is stable. Remove the old tire by loosening the lug nuts in a star pattern to avoid warping the wheel. Once the nuts are removed, take off the tire and inspect the wheel for any damage. If the wheel is in good condition, proceed to attach the new tire.

Align the new tire with the wheel and press it into place, ensuring it fits snugly. Replace the lug nuts by hand to avoid cross-threading, and then tighten them in the same star pattern. Once all nuts are secure, lower the equipment and check for any unusual sounds or vibrations during operation.

Regularly checking tire pressure and tread wear can prevent premature failures and improve handling. By following these guidelines, you can maintain your equipment in top condition, ensuring reliable performance throughout its use.

Fuel System Layout and Parts

The fuel system is a vital component in ensuring the efficient operation of garden machinery. It encompasses various elements that work together to deliver the necessary fuel to the engine, allowing for optimal performance. Understanding the arrangement and functionality of these components is essential for effective maintenance and troubleshooting.

- Fuel Tank: This is the reservoir that stores fuel until it is needed by the engine.

- Fuel Lines: These are the tubes that transport fuel from the tank to the engine. They must be free of leaks to maintain pressure.

- Fuel Filter: A crucial element that removes impurities from the fuel before it reaches the engine, ensuring clean operation.

- Fuel Pump: This component draws fuel from the tank and sends it through the fuel lines to the engine, maintaining the necessary flow and pressure.

- Carburetor: Responsible for mixing the right amount of air and fuel, facilitating efficient combustion in the engine.

- Choke: Used to restrict airflow during startup, enriching the fuel mixture to ease starting in cold conditions.

Each of these components plays a significant role in the overall efficiency and reliability of the machinery. Regular checks and maintenance of the fuel system can help prevent issues and prolong the lifespan of the equipment.

Ignition System Components Breakdown

The ignition system is crucial for the efficient operation of small engines, ensuring proper combustion and performance. Understanding the various elements within this system can help in diagnosing issues and performing maintenance effectively.

- Ignition Coil: This component transforms low voltage from the battery into high voltage, which is necessary for creating a spark at the spark plug.

- Spark Plug: Responsible for igniting the air-fuel mixture, the spark plug generates a spark that initiates combustion within the engine cylinder.

- Flywheel Magnet: This part plays a vital role in generating the electrical current needed for the ignition coil. As the engine runs, the flywheel rotates, creating a magnetic field.

- Ignition Module: The ignition module controls the timing of the spark and ensures that it occurs at the right moment during the engine’s cycle.

- Wiring Harness: This network of wires connects all ignition components, allowing them to communicate and function as a cohesive system.

Regular inspection and maintenance of these components can significantly enhance engine reliability and performance.

Throttle and Cable Connections

The proper functioning of any gardening equipment relies heavily on the intricate relationships between various components. Among these, the connections that manage speed and control are crucial for optimal performance. Understanding these connections enhances not only operational efficiency but also the longevity of the machine.

Understanding the Mechanism

The throttle mechanism plays a vital role in regulating the engine’s performance. This system allows users to adjust the engine speed according to the task at hand, providing better control over the machine’s operation. Flexible cables connect the throttle lever to the engine, enabling this crucial functionality.

Maintenance and Adjustment

Regular inspection of these connections is essential to prevent wear and tear. Ensure that the cables are free of kinks and frays. Periodic adjustments may be necessary to maintain the appropriate tension, ensuring smooth operation and responsiveness. By keeping these components in good condition, users can ensure reliable and efficient performance for their gardening tasks.

Muffler and Exhaust System Details

The muffler and exhaust assembly play a crucial role in regulating engine performance and reducing noise levels. Understanding their components and functionality is essential for maintaining optimal operation and compliance with environmental regulations.

Key Components

- Muffler: This device minimizes sound produced by the engine, allowing for quieter operation.

- Exhaust Pipes: These tubes channel exhaust gases away from the engine and direct them to the rear of the machine.

- Manifold: The manifold collects exhaust gases from the engine cylinders and sends them into the exhaust system.

- Gaskets: These seals prevent leaks at the joints between components, ensuring efficient gas flow.

Maintenance Tips

- Regularly inspect the muffler for rust or damage that could affect performance.

- Check exhaust pipes for any obstructions or leaks that could hinder gas flow.

- Ensure all connections are secure and gaskets are in good condition to avoid leaks.

- Clean the exhaust system periodically to remove carbon buildup and improve efficiency.

Safety Shields and Protective Covers

In agricultural machinery, safety shields and protective covers play a vital role in ensuring the well-being of the operator and the equipment. These components are designed to minimize the risk of injury by preventing access to moving parts and shielding sensitive areas from debris and contaminants. Their proper installation and maintenance are crucial for the safe operation of any agricultural tool.

Importance of Protective Components

Utilizing shields and covers is essential for maintaining a safe working environment. They help to keep harmful materials away from operators, reducing the likelihood of accidents. Additionally, these protective elements can prolong the lifespan of machinery by preventing wear and tear from environmental factors.

Types of Shields and Covers

There are various types of safety shields and protective covers designed for different applications. Understanding the options available can help operators choose the most suitable components for their needs.

| Type | Description |

|---|---|

| Side Shields | Protect the operator from debris while allowing visibility of the working area. |

| Rear Covers | Prevent materials from entering the back of the machine, reducing the risk of blockages. |

| Foot Guards | Shield the operator’s feet from moving parts and falling objects, enhancing safety. |

| Engine Covers | Protect internal components from dirt and moisture, ensuring reliable operation. |