In the world of marine engineering, the intricate interplay of various elements is crucial for the optimal performance of watercraft. Knowledge of these components not only aids in effective maintenance but also enhances the overall functionality of the vessel. By breaking down these systems, enthusiasts and professionals alike can ensure longevity and efficiency.

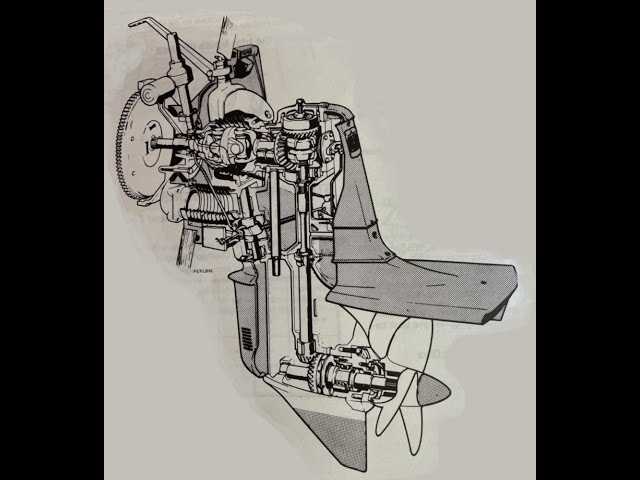

Exploring the schematics of propulsion mechanisms reveals a wealth of information about each individual unit. Identifying these critical components allows for informed decisions regarding upgrades, repairs, and replacements. Moreover, a comprehensive understanding fosters a deeper appreciation for the craftsmanship involved in marine technology.

Whether you are a seasoned technician or a novice boat owner, delving into the specifics of these mechanical structures equips you with the tools necessary for successful troubleshooting. The ultimate goal is to maintain peak performance and safety while navigating the waters.

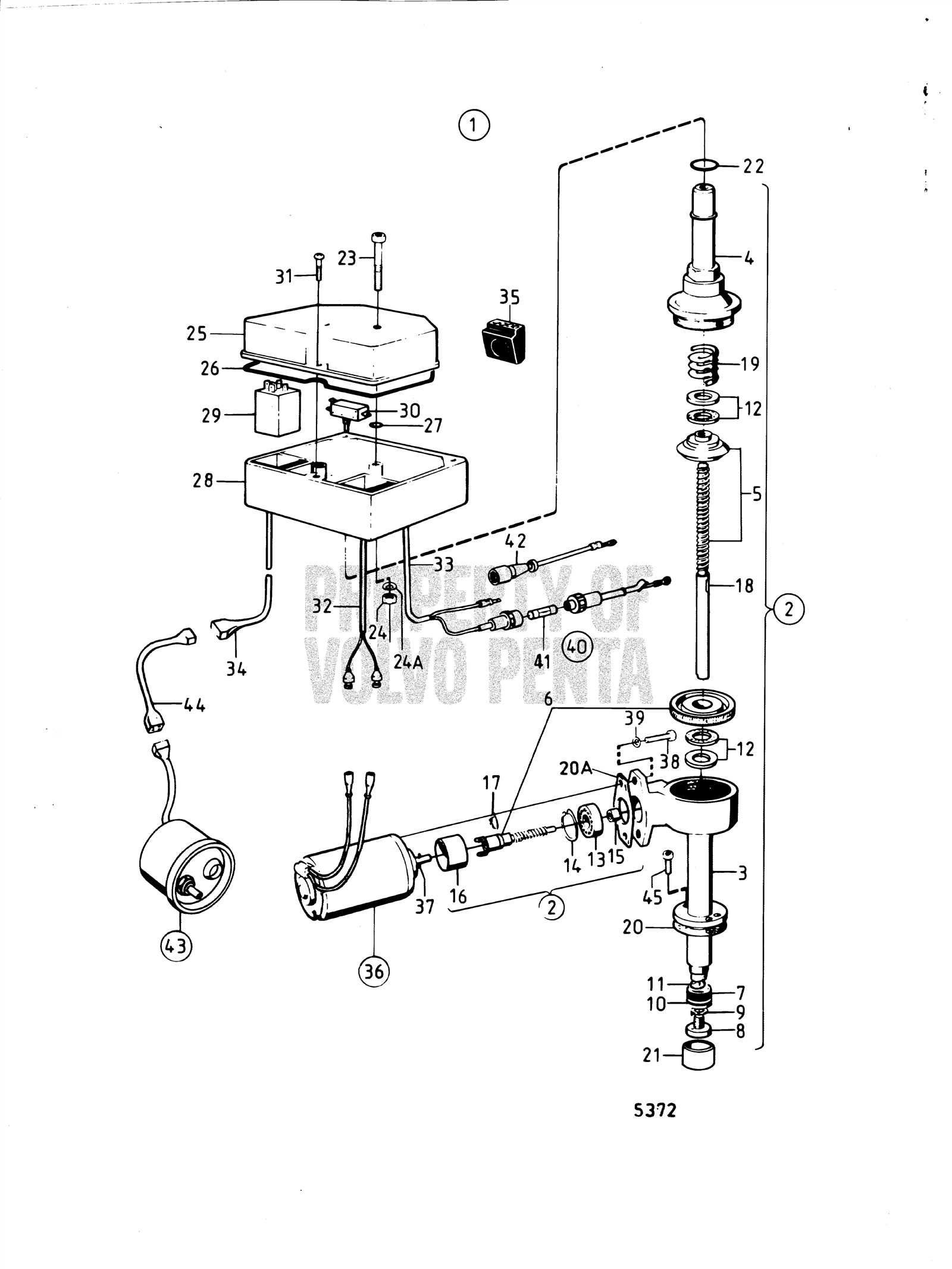

Understanding Volvo Penta 270 Overview

This section provides a comprehensive look into a specific marine engine system, highlighting its components, functionality, and the intricate design that supports its operation. Such systems are crucial for ensuring reliability and efficiency in various aquatic applications.

| Component | Description |

|---|---|

| Engine Block | The core structure that houses vital engine components and provides durability. |

| Transmission | A mechanism that facilitates gear shifting, ensuring optimal power transfer. |

| Cooling System | Maintains the engine temperature, preventing overheating during operation. |

| Fuel System | Handles the delivery of fuel, ensuring efficient combustion within the engine. |

| Exhaust System | Channels exhaust gases away from the engine, enhancing performance and safety. |

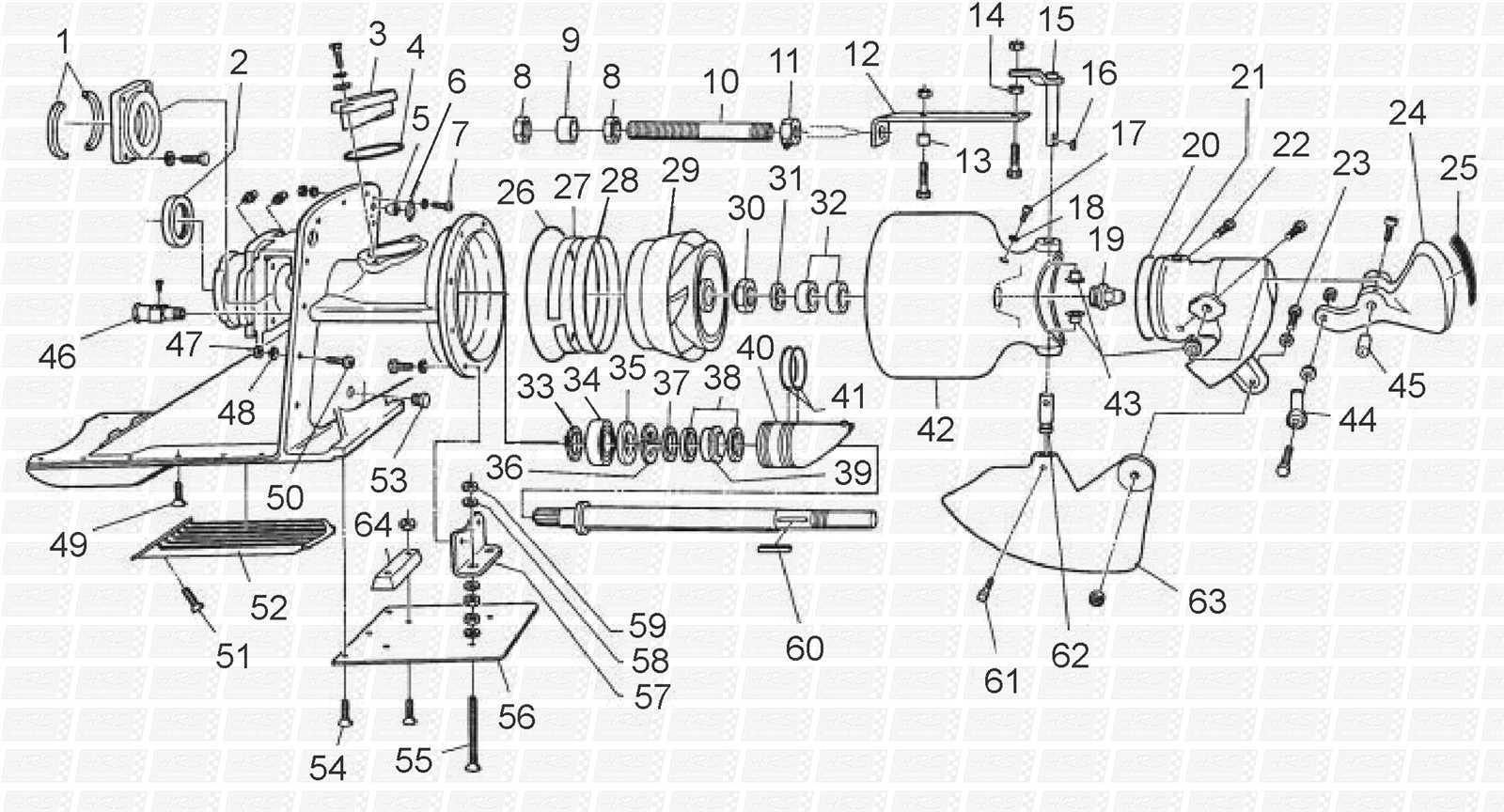

Key Components of the 270 System

The intricate assembly of the marine propulsion unit comprises various essential elements that work in harmony to ensure optimal performance and reliability. Each component plays a significant role in the overall functionality of the system, contributing to smooth operation and effective power transmission.

| Component | Description |

|---|---|

| Drive Unit | The core mechanism that transfers power from the engine to the propeller, enabling movement. |

| Gearbox | This component adjusts the rotational speed and torque, allowing for better control of the vessel. |

| Propeller | The part that converts rotational energy into thrust, propelling the boat forward. |

| Shaft | The connecting element that transfers power between the drive unit and the propeller. |

| Cooling System | Ensures that the engine and other components operate within safe temperature limits, preventing overheating. |

| Steering Mechanism | Facilitates directional control of the vessel, allowing for precise navigation. |

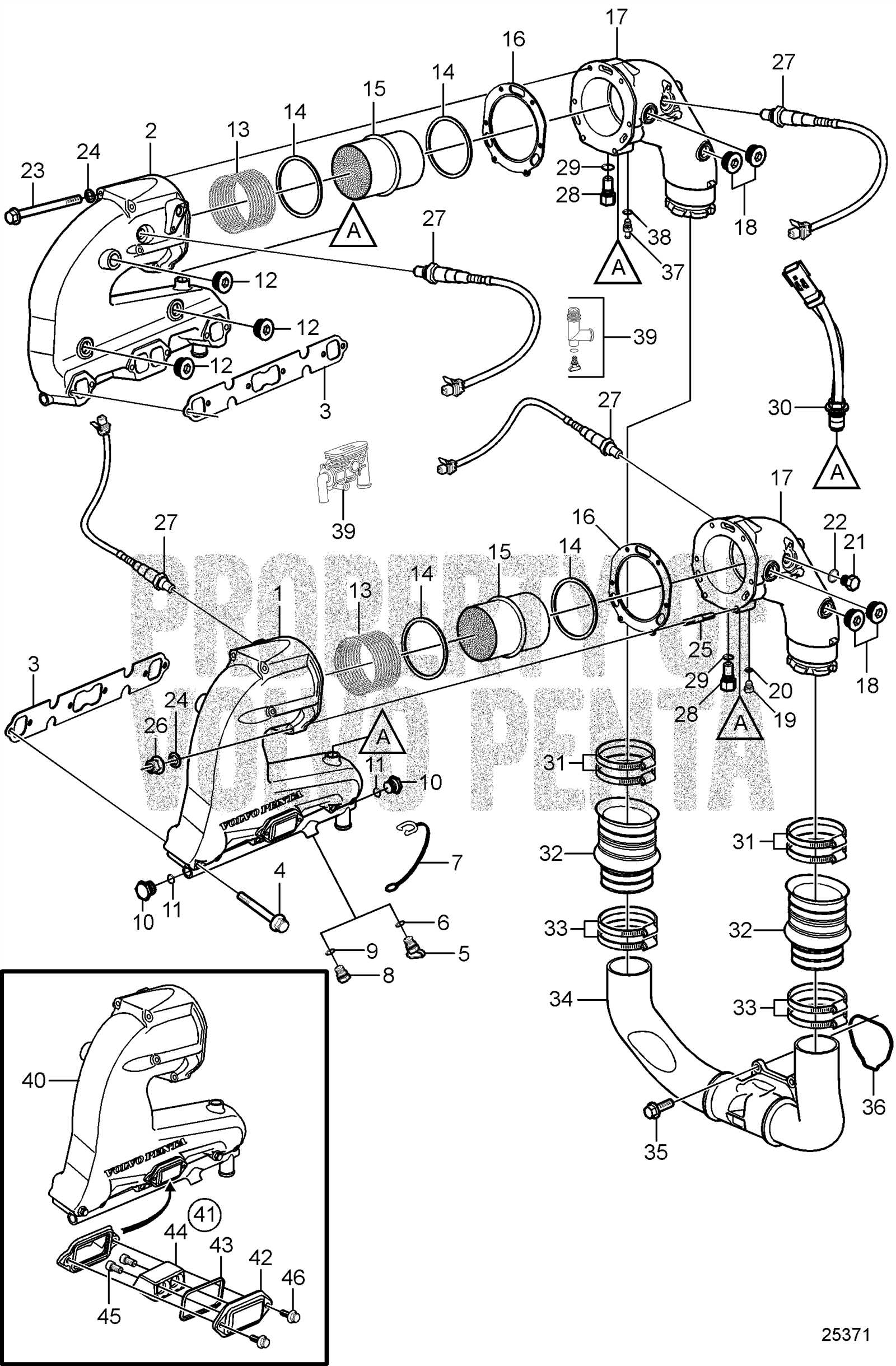

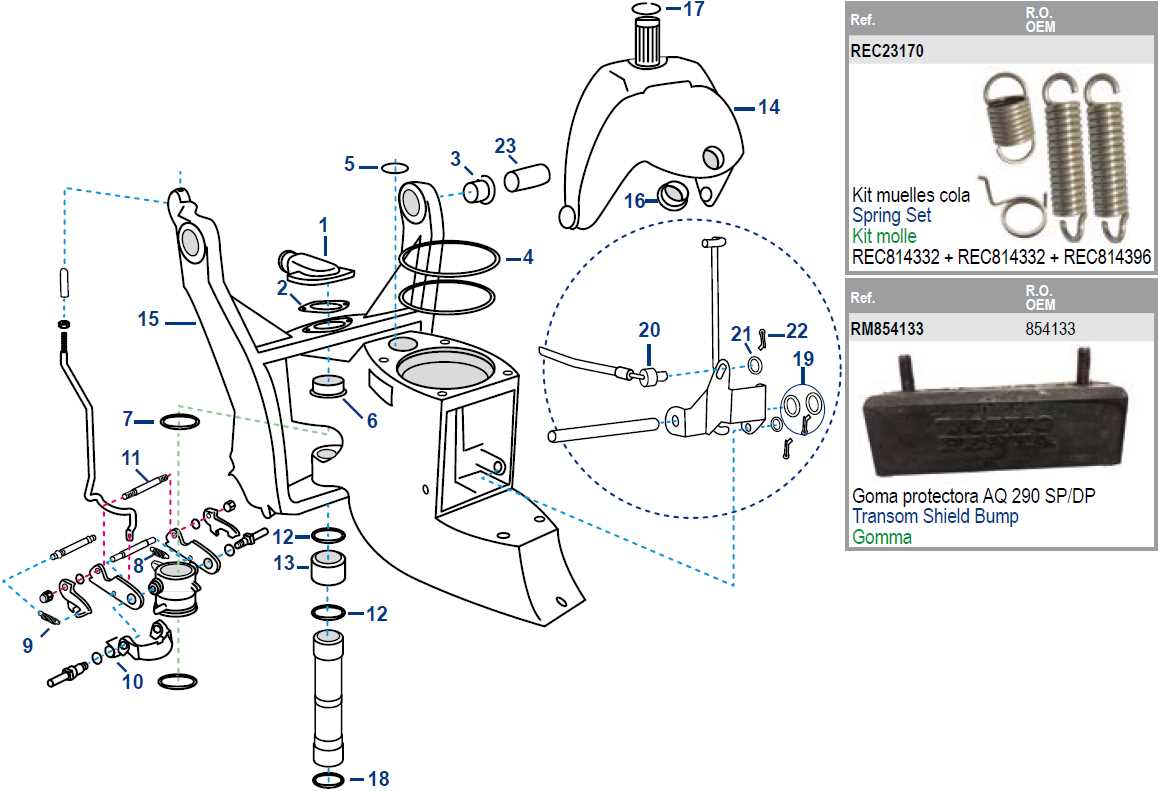

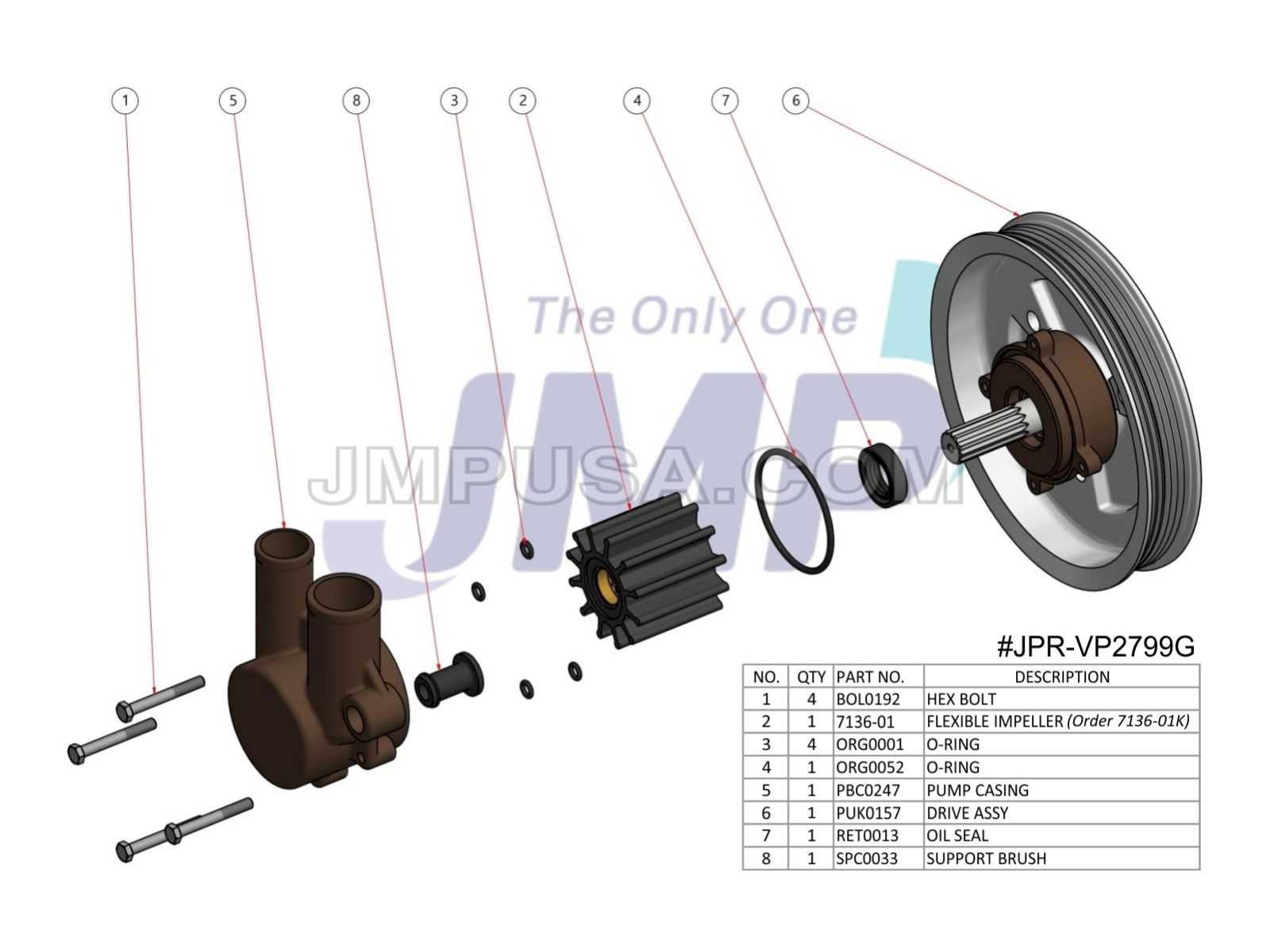

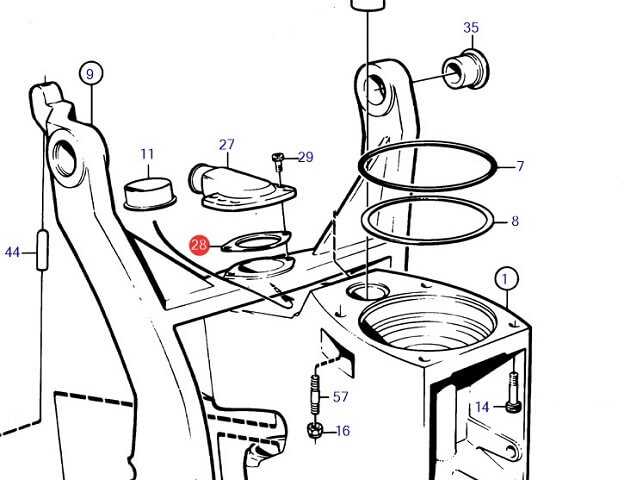

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricacies of machinery. They offer a clear and organized overview, enabling users to quickly identify each element’s function and relationship within a system.

These illustrations serve as essential tools for both maintenance and assembly, allowing technicians to pinpoint specific areas that require attention. Moreover, they facilitate efficient troubleshooting by providing a reference that enhances clarity.

In the long run, having access to accurate schematics can significantly reduce downtime and repair costs, ensuring optimal performance of equipment. Ultimately, these resources empower users to engage with their machinery more confidently and effectively.

Common Issues with Volvo Penta 270

This section addresses frequent challenges encountered with a specific marine propulsion system, focusing on performance and maintenance concerns. Understanding these issues can help operators ensure longevity and reliability in their operations.

Mechanical Failures

Mechanical breakdowns often stem from inadequate lubrication and wear over time. Key components require regular inspection to prevent costly repairs.

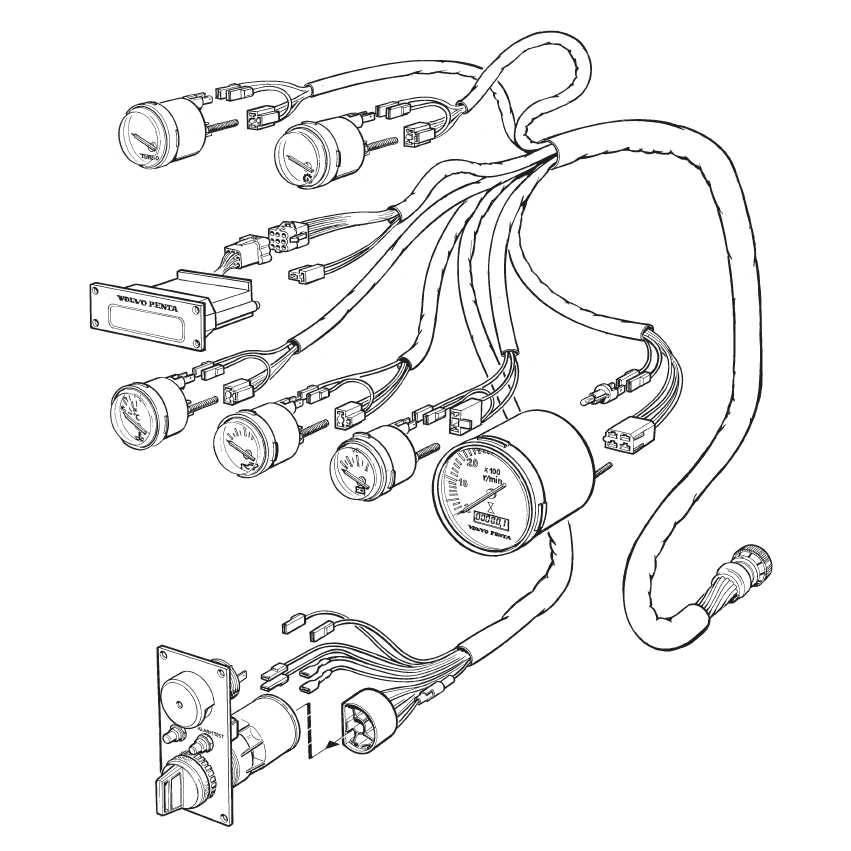

Electrical Problems

Electrical failures can lead to operational disruptions. Common culprits include faulty wiring and corroded connections that affect performance.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat can damage internal parts. | Regularly check coolant levels and impeller condition. |

| Vibration | Unusual movement may indicate misalignment. | Inspect alignment and secure mounting. |

| Fuel Leaks | Leaks can lead to performance issues and safety hazards. | Examine fuel lines and fittings for integrity. |

Where to Find Parts Diagrams

Finding detailed schematics for specific machinery components can greatly enhance repair and maintenance efforts. Various resources are available to assist enthusiasts and professionals in locating these invaluable illustrations. By exploring multiple avenues, users can ensure they have access to accurate information, ultimately aiding in efficient repairs and replacements.

Online databases and official manufacturer websites often house extensive libraries of visual references. Additionally, specialized forums and community groups provide a wealth of shared knowledge, where users can exchange insights and resources. Local dealerships and repair shops also tend to maintain physical copies or can guide individuals toward acquiring them.

Utilizing these channels not only simplifies the search process but also fosters a deeper understanding of the mechanical systems involved. With the right tools at hand, anyone can tackle repairs with confidence, leading to improved functionality and longevity of the equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your marine equipment requires consistent care and attention. Regular maintenance not only enhances performance but also helps in preventing costly repairs in the future. Here are essential practices to keep your system operating smoothly for years to come.

Regular Inspections

Conducting routine checks can help identify potential issues before they escalate. Look for signs of wear, corrosion, or leaks that might affect performance.

Proper Lubrication

Keeping moving parts adequately lubricated reduces friction and wear. Use the manufacturer-recommended lubricants and follow the suggested intervals for application.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for signs of wear or damage. |

| Fluid Levels Check | Bi-weekly | Ensure all fluids are at optimal levels. |

| Filter Replacement | Every 6 months | Replace fuel and oil filters regularly. |

| Propeller Inspection | Annually | Look for nicks or cracks. |

How to Interpret Diagrams Effectively

Understanding visual representations is crucial for grasping complex information quickly. These illustrations often condense detailed concepts into a format that is easier to analyze. By mastering the skill of interpretation, you can enhance your comprehension and improve your ability to troubleshoot issues effectively.

Key Steps for Effective Interpretation

- Familiarize Yourself with Symbols: Each visual representation employs specific symbols and notations. Understanding what these symbols represent is the first step in decoding the information.

- Identify Main Components: Focus on the primary elements depicted. This will help you understand the overall structure and function of the system being illustrated.

- Follow Connections: Analyze the lines and arrows that connect various parts. These often indicate relationships or flows that are crucial to the system’s operation.

- Refer to Legends: Most visuals include a legend or key that explains the symbols used. Always refer to this to gain deeper insights.

- Practice Contextual Analysis: Consider the context in which the illustration is used. Understanding the application can greatly enhance your interpretation skills.

Common Mistakes to Avoid

- Skipping the Legend: Ignoring the key can lead to misunderstandings of the representation.

- Rushing Through: Take your time to carefully analyze each part to avoid missing critical details.

- Overlooking Relationships: Failing to understand how components interact can lead to incorrect conclusions.

By following these guidelines, you can improve your ability to interpret visuals accurately and efficiently, ultimately enhancing your understanding of complex systems.

Benefits of Using Genuine Parts

Utilizing authentic components for your machinery ensures optimal performance and longevity. These original elements are designed to meet specific standards, providing reliability that aftermarket options may lack.

- Quality Assurance: Genuine components undergo rigorous testing to guarantee their durability and efficiency.

- Perfect Fit: They are engineered to fit seamlessly, minimizing the risk of installation issues.

- Enhanced Performance: Authentic parts contribute to the overall effectiveness of your equipment.

- Warranty Protection: Many manufacturers offer extended warranties when genuine components are used.

- Increased Resale Value: Using original elements can boost the resale price of your machinery.

Ultimately, investing in authentic components can lead to significant long-term savings and peace of mind.

Replacement Procedures for Critical Components

Ensuring the reliability and performance of marine machinery often hinges on the timely replacement of vital elements. Understanding the necessary steps for swapping out these components is crucial for maintaining optimal functionality and safety. This section outlines essential procedures for replacing significant parts, focusing on best practices and common pitfalls to avoid.

Before initiating any replacement, it is imperative to gather all required tools and components, ensuring compatibility with the existing system. Proper preparation minimizes downtime and enhances efficiency during the process. Always consult the manufacturer’s specifications to confirm the correct procedures and torque settings.

Once ready, carefully remove the old component, paying close attention to any fasteners or seals that may require special handling. Cleaning the surrounding area before installation helps prevent debris from causing future issues. After positioning the new part, ensure that all connections are secure and test the system thoroughly to verify proper operation.

Documentation of the replacement process, including any anomalies encountered, can provide valuable insights for future maintenance. Regular reviews of these procedures contribute to a deeper understanding of the machinery and support ongoing performance optimization.

Differences Between Volvo Penta Models

When exploring the variations among marine engine systems, it becomes evident that each model possesses unique characteristics tailored to specific performance needs. These distinctions can greatly influence the overall efficiency, power output, and adaptability of the engines, catering to various types of vessels and operational conditions.

Engine Design: Different models often feature variations in design architecture, which impacts their horsepower and torque delivery. For instance, some configurations prioritize high torque for heavy-duty applications, while others focus on achieving maximum speed.

Fuel Efficiency: Variability in fuel consumption is another critical aspect. Certain systems are engineered to optimize fuel usage, making them ideal for long-distance cruising, while others may prioritize power over efficiency, suited for performance-driven applications.

Maintenance Requirements: The maintenance needs can also differ significantly. Some engines are designed with accessibility in mind, allowing for easier servicing and lower operational costs, while others may require more frequent and complex maintenance interventions.

Technological Features: Advancements in technology also differentiate models. Certain systems may come equipped with cutting-edge electronics and diagnostic tools, enhancing user experience and operational reliability, while others might rely on more traditional mechanisms.

Understanding these differences is essential for boat owners and operators in selecting the right engine that meets their specific requirements and enhances their overall maritime experience.

Upgrades and Performance Enhancements

Enhancing the capabilities of your marine engine can lead to significant improvements in efficiency and power. Whether you’re seeking better fuel economy or increased speed, various modifications can optimize performance. Understanding the options available will help you make informed choices that align with your boating needs.

Common Upgrade Options

Numerous components can be upgraded to achieve better performance. These modifications can range from simple replacements to more complex installations. Here are some popular choices:

| Upgrade Type | Description |

|---|---|

| Propeller | Switching to a high-performance propeller can improve speed and handling. |

| Exhaust System | Upgrading to a freer-flowing exhaust can enhance engine efficiency and sound. |

| Fuel System | Improving fuel injectors or adding a performance carburetor can increase power output. |

| Ignition System | Upgrading the ignition system can lead to better combustion and improved throttle response. |

Performance Tuning

Beyond physical upgrades, performance tuning is essential for maximizing your engine’s potential. Adjusting parameters such as fuel mixture and timing can provide noticeable benefits. Collaborating with a professional tuner can yield optimal results, ensuring your engine runs smoothly while delivering enhanced power and efficiency.

Resources for Troubleshooting Problems

When encountering issues with marine propulsion systems, having access to reliable resources is crucial for effective problem-solving. These materials can guide you through diagnosing and resolving a variety of mechanical challenges, ensuring optimal performance and safety on the water.

One of the most valuable tools is the user manual, which provides detailed instructions and specifications. Online forums and communities often feature discussions where enthusiasts share experiences and solutions to common issues. Additionally, instructional videos can offer visual guidance, making it easier to understand complex repairs.

For those seeking technical support, manufacturer websites frequently host troubleshooting guides and FAQs. Local dealers or service centers may also provide expert assistance, offering insights based on years of experience. Collectively, these resources empower users to maintain their equipment effectively and minimize downtime.

Expert Recommendations for Owners

For individuals who own marine propulsion systems, maintaining optimal performance and longevity is crucial. Following expert guidance can help enhance reliability and ensure safe operation on the water. Here are key recommendations to consider:

- Regular Maintenance:

- Schedule periodic inspections to identify wear and tear.

- Replace fluids and filters according to the manufacturer’s guidelines.

- Use Quality Components:

- Opt for original equipment or high-quality aftermarket components.

- Avoid counterfeit parts that may compromise performance.

- Monitor Performance:

- Keep an eye on fuel consumption and engine temperatures.

- Address any unusual noises or vibrations promptly.

- Stay Informed:

- Follow updates from reputable sources regarding recalls or service bulletins.

- Join forums or groups dedicated to your specific model for shared experiences and tips.

- Professional Assistance:

- Consult a qualified technician for complex repairs or upgrades.

- Invest in training for yourself or crew to handle routine checks effectively.

By adhering to these expert recommendations, owners can ensure their systems remain efficient and safe, allowing for enjoyable experiences on the water.