The intricate world of marine propulsion systems requires a deep understanding of various elements that contribute to the overall functionality and efficiency of the vessel. A well-organized reference for these components can greatly enhance maintenance practices and repair efforts, ensuring that enthusiasts and professionals alike can navigate the complexities of their machinery.

By exploring the structure and relationships between different engine elements, users can gain valuable insights into how each component interacts within the system. This knowledge is essential for troubleshooting, as well as for making informed decisions during the selection of replacement pieces and upgrades.

Whether you’re a seasoned technician or a boat owner keen on self-maintenance, having access to a comprehensive visual representation of these components is invaluable. Such resources not only simplify the identification process but also foster a deeper appreciation for the engineering that keeps our vessels on the water.

Understanding Volvo Penta 280 Components

Gaining insight into the various elements of a marine propulsion system is essential for any enthusiast or professional. Each component plays a crucial role in ensuring optimal performance and reliability. A thorough comprehension of these parts can significantly enhance maintenance efforts and troubleshooting capabilities.

Key Components: The heart of any propulsion unit lies in its engine, where power is generated and transmitted. Coupled with this are the transmission mechanisms that facilitate smooth operation. Additionally, various attachments, such as cooling systems and exhaust components, are vital for efficient functionality.

Maintenance Insights: Regular checks and replacements of wear-prone parts can prevent unexpected failures. Understanding the layout and interconnections between these elements allows for proactive management, ensuring longevity and safety in marine operations.

Key Features of the 280 Model

The 280 series is recognized for its remarkable engineering and performance capabilities, making it a popular choice among enthusiasts and professionals alike. This model incorporates several advanced features that enhance both functionality and reliability.

- Durable Construction: Crafted from high-quality materials, ensuring longevity and resistance to wear and tear.

- Efficient Power Output: Designed to deliver optimal performance with minimal fuel consumption, promoting eco-friendliness.

- Sleek Design: Features an aerodynamic shape that not only improves aesthetics but also enhances maneuverability.

- Advanced Cooling System: Equipped with an efficient cooling mechanism to prevent overheating during operation.

- Easy Maintenance: Engineered for straightforward upkeep, reducing downtime and service costs.

These characteristics contribute to the overall effectiveness of the unit, making it a top choice in its category.

Common Issues and Solutions

When it comes to marine engines, several challenges can arise during operation and maintenance. Identifying these problems promptly can save time and resources, ensuring smooth performance on the water. This section explores typical issues encountered, along with effective solutions to mitigate them.

One frequent concern is overheating, which can lead to severe engine damage if not addressed. This issue often stems from a blocked cooling system or insufficient coolant levels. To resolve it, regularly inspect the cooling system for obstructions and ensure that coolant is topped up as needed.

Another common problem is poor fuel efficiency, which can be caused by a variety of factors including clogged filters or improper fuel mixture. To improve fuel economy, check and replace fuel filters regularly, and ensure the fuel mixture is within the recommended specifications.

Starting difficulties can also plague operators, often resulting from battery issues or faulty ignition components. Regularly test the battery and inspect all electrical connections to ensure a reliable start every time.

Lastly, unusual noises during operation may indicate mechanical issues such as wear on moving parts. Routine maintenance and inspections can help identify and rectify these problems before they escalate into more significant repairs.

Benefits of Using Original Parts

Utilizing authentic components for your machinery ensures optimal performance and longevity. These specialized elements are designed to meet the precise specifications of your equipment, ultimately enhancing reliability and efficiency.

Quality Assurance

- Manufactured to strict standards

- Superior materials for durability

- Extensive testing for performance

Cost-Effectiveness

- Reduced need for frequent replacements

- Lower maintenance costs over time

- Enhanced resale value of equipment

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your marine equipment requires regular attention and care. By implementing consistent maintenance practices, you can enhance performance and extend the life of your machinery.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Inspect Fluid Levels | Monthly | Check oil and coolant levels regularly; top up as needed. |

| Clean Filters | Every 6 Months | Replace or clean air and fuel filters to ensure optimal performance. |

| Check Belts and Hoses | Quarterly | Look for wear and tear; replace any damaged components immediately. |

| Inspect Electrical Systems | Yearly | Test batteries and connections for corrosion and secure fit. |

Where to Find Replacement Parts

Finding suitable components for your marine equipment can be a straightforward process if you know where to look. Reliable sources often include specialized retailers, online marketplaces, and authorized dealers that cater specifically to boating needs. Understanding these options will ensure you can obtain the right items efficiently.

Online Retailers

Numerous online platforms offer an extensive selection of components. Websites dedicated to boating supplies typically provide detailed descriptions and images, making it easier to identify the correct items. Customer reviews can also guide your decision-making process, ensuring you select quality components.

Local Dealers and Salvage Yards

Local distributors and salvage yards can be treasure troves for hard-to-find items. They often stock both new and used options, allowing for budget-friendly choices. Building a relationship with these local sources can lead to valuable insights and recommendations for specific needs.

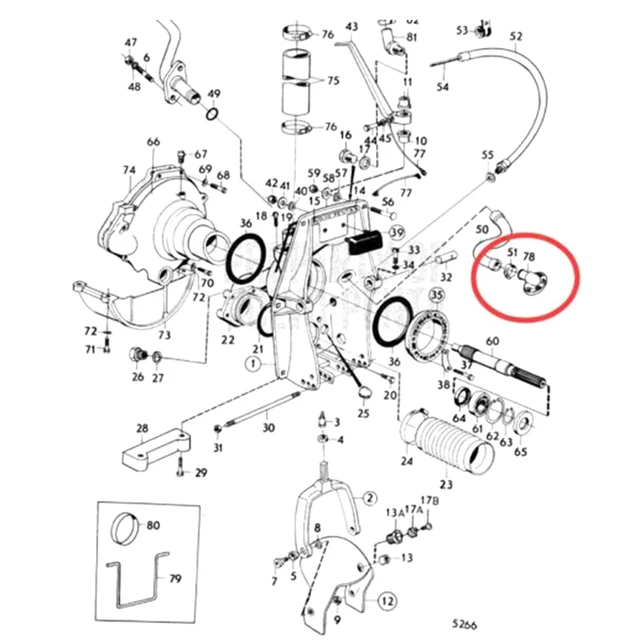

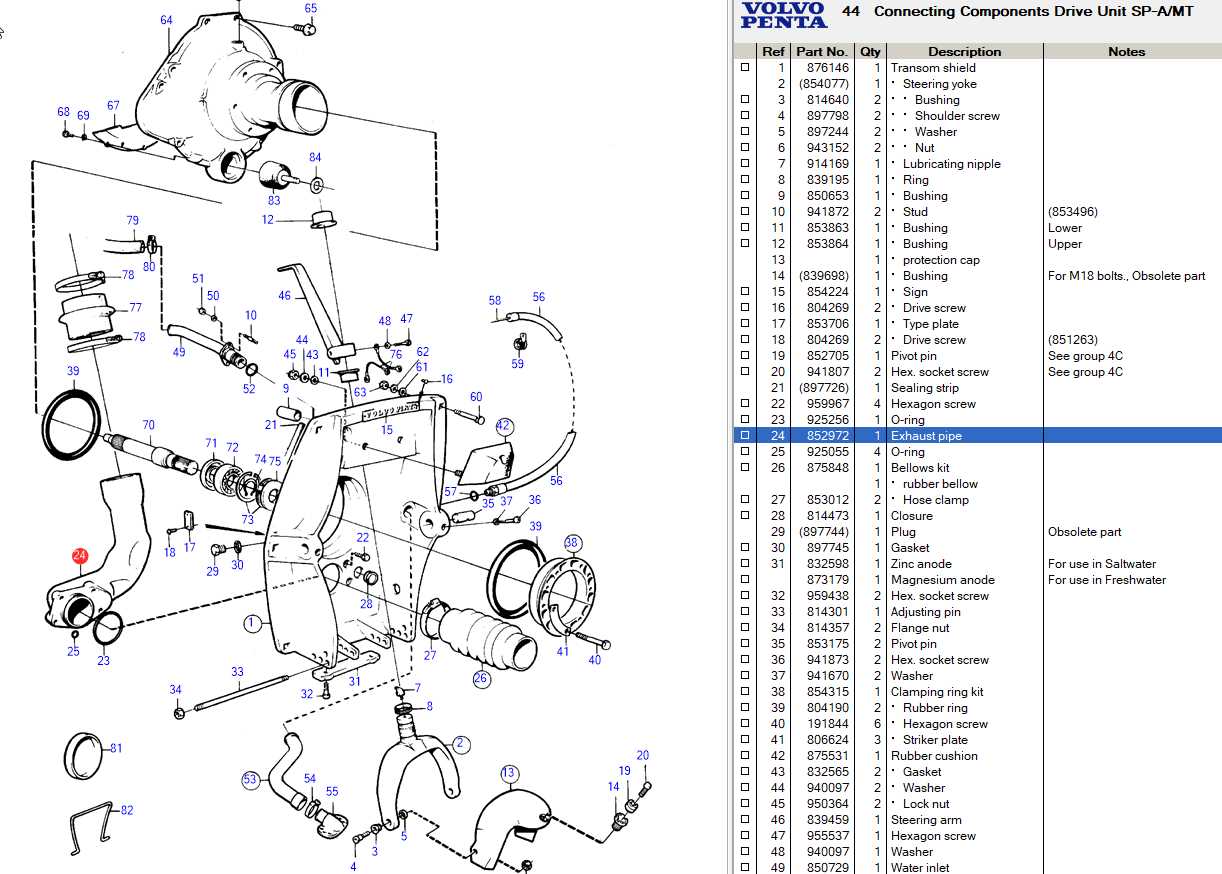

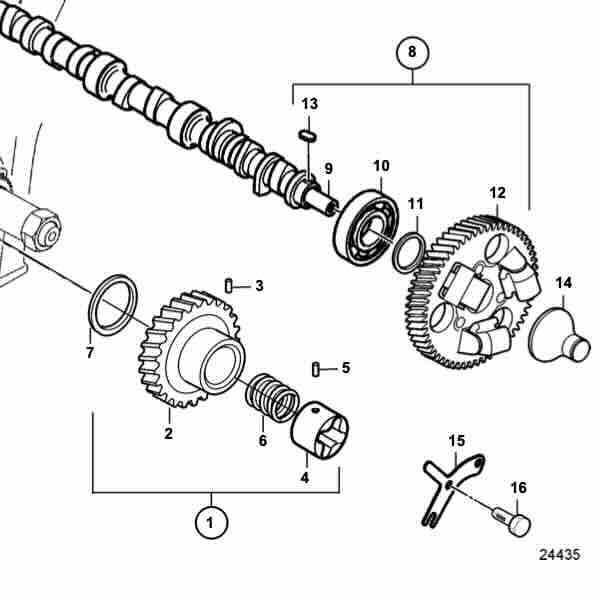

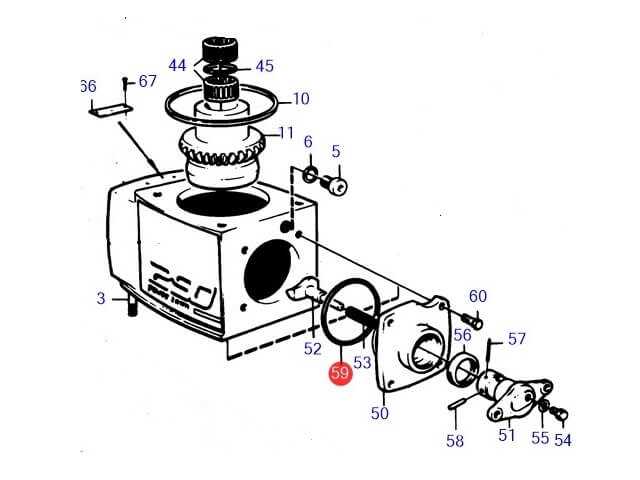

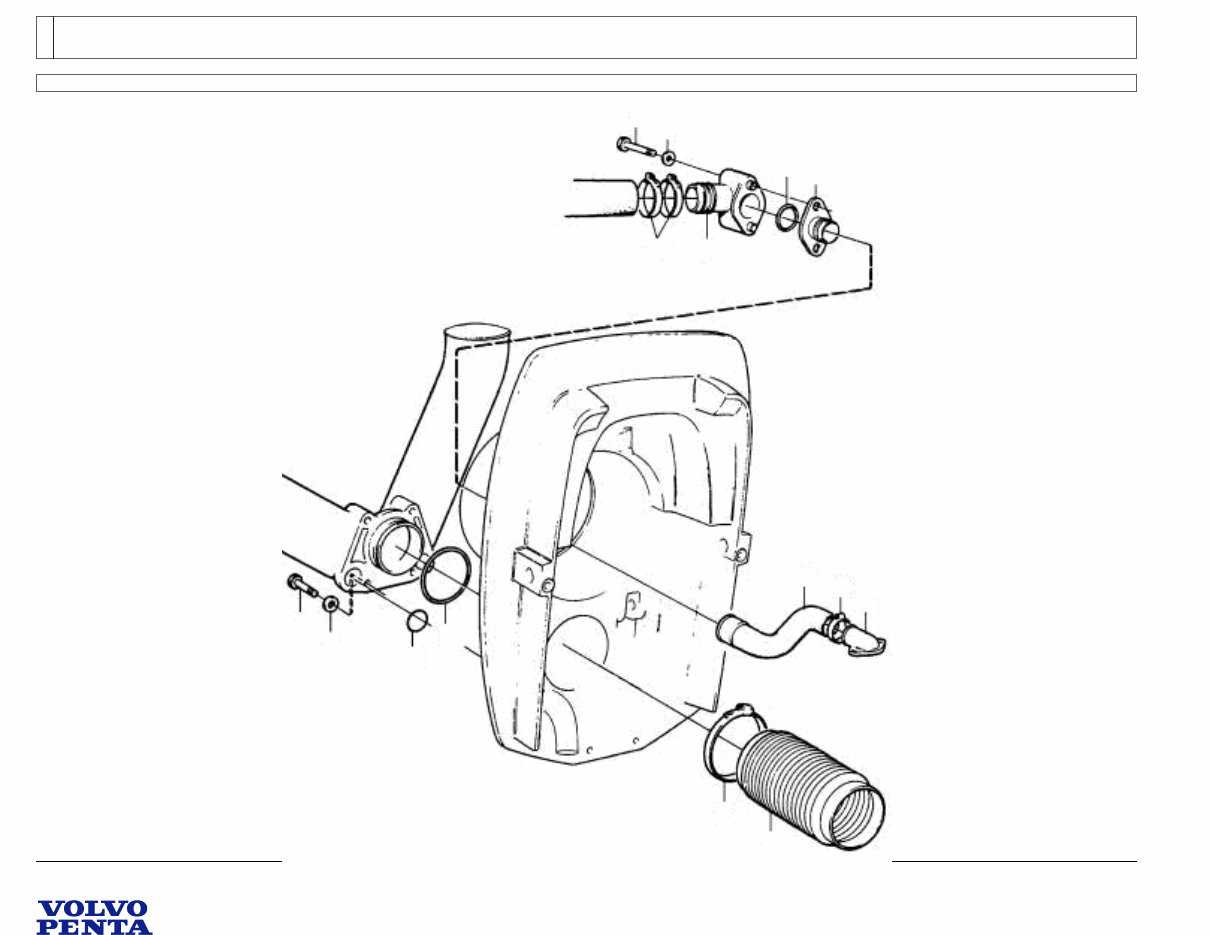

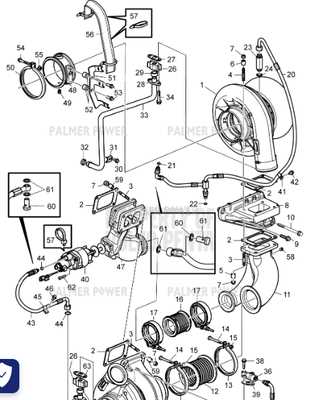

Importance of Accurate Diagrams

Precise visual representations play a crucial role in the maintenance and assembly of mechanical systems. They provide a clear understanding of components, ensuring that technicians can effectively identify and address issues, leading to enhanced performance and longevity of the machinery.

Facilitating Repairs and Maintenance

When technicians refer to accurate visuals, they can quickly locate necessary elements, reducing downtime. Effective schematics eliminate guesswork, allowing for streamlined processes that save both time and resources.

Enhancing Communication

Accurate visuals serve as a universal language among professionals, fostering collaboration and knowledge sharing. This clarity helps ensure that everyone involved is on the same page, minimizing errors and improving overall efficiency.

Upgrading Your 280 Engine System

Enhancing the performance and efficiency of your engine system can significantly impact your overall experience on the water. By focusing on various components and making thoughtful improvements, you can ensure a smoother, more powerful operation while extending the lifespan of your vessel.

Key Components for Enhancement

When considering upgrades, it’s essential to focus on critical areas such as fuel delivery, ignition systems, and exhaust efficiency. Each component plays a vital role in the overall functionality of the engine.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Fuel System | High-performance injectors | Improved fuel efficiency and power |

| Ignition | Advanced spark plugs | Better combustion and response |

| Exhaust | Performance manifolds | Enhanced flow and reduced emissions |

Final Considerations

Ultimately, each upgrade should align with your specific performance goals and boating needs. Carefully assess options and consult with experts to achieve the best results for your engine system.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining and repairing marine engines, the choice between original equipment and alternative solutions often arises. Each option presents unique benefits and potential drawbacks that can influence both performance and cost. Understanding these differences is essential for making informed decisions that impact the longevity and reliability of your vessel.

Quality and Performance

Original components are typically manufactured by the same company that produced the engine, ensuring a precise fit and compatibility. They often undergo rigorous testing and adhere to strict quality standards, providing peace of mind regarding performance and durability. In contrast, alternative solutions can vary significantly in quality. While some may offer comparable performance at a lower price, others might lack the same level of reliability, leading to potential long-term issues.

Cost Considerations

Cost is a significant factor for many boat owners. Original equipment tends to be more expensive due to the brand’s reputation and the assurance of quality. However, alternative options can be more budget-friendly, allowing for substantial savings. It is crucial to weigh these savings against the potential risks associated with quality and performance discrepancies.

Ultimately, the decision between original and alternative solutions should consider individual circumstances, including budget, intended use, and the importance of reliability in your maritime activities.

Installation Guide for New Components

This section provides a comprehensive approach to integrating new elements into your marine system. Proper installation is crucial for optimal performance and longevity, ensuring that all components function harmoniously.

Before beginning the installation process, gather the necessary tools and components. Familiarize yourself with the specifications of each item to ensure compatibility.

| Step | Description |

|---|---|

| 1 | Review the installation manual for detailed instructions specific to the component. |

| 2 | Prepare the workspace by cleaning the area and organizing tools for easy access. |

| 3 | Carefully remove the old component, taking note of the connections and positioning. |

| 4 | Install the new component, ensuring it is secured and aligned correctly. |

| 5 | Reconnect any wiring or hoses as per the original configuration. |

| 6 | Conduct a thorough inspection and test the system to verify proper functionality. |

Following these steps will help you achieve a successful installation, enhancing the overall efficiency of your equipment.

Tools Required for Repair Tasks

When embarking on maintenance or repair activities, having the right equipment is crucial for efficiency and success. This section outlines essential instruments that facilitate various procedures, ensuring that each task is executed with precision and ease.

Basic Hand Tools

Fundamental hand tools are indispensable for any repair task. These include items that assist in disassembly, adjustment, and reassembly of components.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For tightening or loosening screws of various sizes. |

| Wrench Set | Used for gripping, fastening, and turning nuts and bolts. |

| Pliers | Helpful for gripping and manipulating small parts. |

Specialized Equipment

In addition to basic tools, certain specialized equipment may be required for more intricate tasks. These tools enhance the capability to tackle specific challenges effectively.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specification. |

| Multimeter | Used for electrical testing and diagnostics. |

| Socket Set | Ideal for working with various sizes of fasteners. |

Resources for Further Information

For those seeking additional insights and guidance on marine engine components and their maintenance, a variety of valuable resources are available. These can assist enthusiasts, professionals, and hobbyists alike in deepening their understanding and ensuring optimal performance.

- Manufacturer Websites: Official sites often provide comprehensive manuals, troubleshooting guides, and updates regarding specific models.

- Online Forums: Communities dedicated to marine engines can be excellent places to ask questions, share experiences, and learn from fellow users.

- YouTube Tutorials: Video content can offer visual instructions on repairs, installations, and maintenance practices.

- Local Dealers and Service Centers: Consulting with local experts can provide tailored advice and access to original components.

- Technical Manuals: Printed or digital manuals are invaluable for detailed diagrams, specifications, and step-by-step procedures.

By utilizing these resources, individuals can enhance their knowledge and effectively address various challenges related to marine machinery.