When it comes to maintaining high-performance vessels, knowing the layout and structure of the essential components is crucial. Each element within the power system plays a pivotal role in ensuring smooth and reliable operation, whether you’re out on the open waters or preparing for your next voyage.

A comprehensive view of the various connections and key mechanical elements offers insight into how these systems interact. This understanding helps not only in routine care but also in identifying potential issues before they become significant problems. Navigating the intricacies of such systems is a valuable skill for anyone involved in maritime adventures.

Familiarity with the mechanical framework empowers users to make informed decisions regarding upkeep and repair. By visualizing how individual components are connected, you can effectively troubleshoot and optimize performance, ensuring that every journey is as efficient as possible.

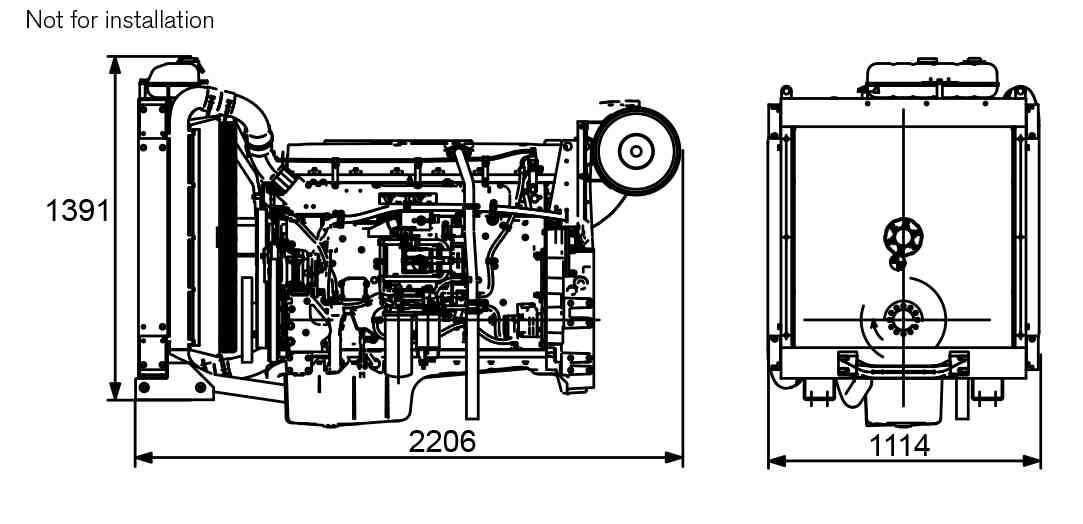

Overview of Volvo Penta Engine Components

In this section, we will explore the essential elements that make up a reliable and efficient power unit. These components work together to ensure smooth operation, durability, and optimal performance, allowing the system to handle various challenges in different environments.

- Power Source: The central unit that generates the necessary force, converting energy to motion.

- Cooling System: A vital mechanism responsible for maintaining optimal temperature during operation, preventing overheating.

- Lubrication System: Ensures all moving parts remain well-oiled to reduce friction and wear, enhancing longevity.

- Fuel Delivery: Manages the flow and proper distribution of fuel, ensuring efficient energy conversion.

- Exhaust System: Channels gases produced during combustion out of the system, ensuring safe and clean operation.

Each of these sections plays a critical role in maintaining the overall functionality and reliability, making the system robust and dependable for prolonged use.

Main Functions of Key Engine Parts

The proper functioning of any mechanical system relies on the cooperation of various components that each have a crucial role. Understanding how these elements interact and contribute to the overall performance is essential for maintaining optimal efficiency. Below is an overview of the fundamental components that work together to power complex machinery.

Core Mechanical Elements

At the heart of the system, several components collaborate to transform energy into motion. Each plays a specific role, whether it’s in controlling movement, ensuring stability, or optimizing fuel efficiency. These elements must be well-coordinated to achieve smooth performance.

Supporting Components

A variety of auxiliary components help regulate temperature, manage fuel flow, and reduce wear and tear. Their presence ensures that the central mechanical processes run without overheating, excessive friction, or other potential issues that might disrupt the system.

| Component | Function |

|---|---|

| Piston | Converts pressure into motion by moving up and down within a cylinder. |

| Crankshaft | Transforms linear movement into rotational force, driving other parts. |

| Cylinder | Provides a chamber where fuel combustion occurs, powering the movement of the piston. |

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber for efficient burning. |

| Cooling System | Prevents overheating by circulating coolant through various components. |

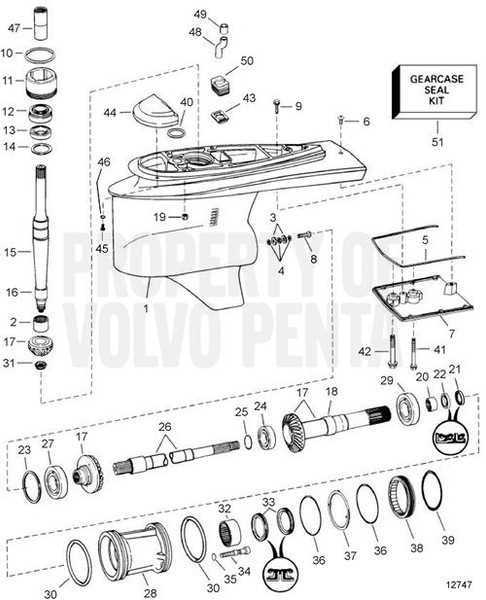

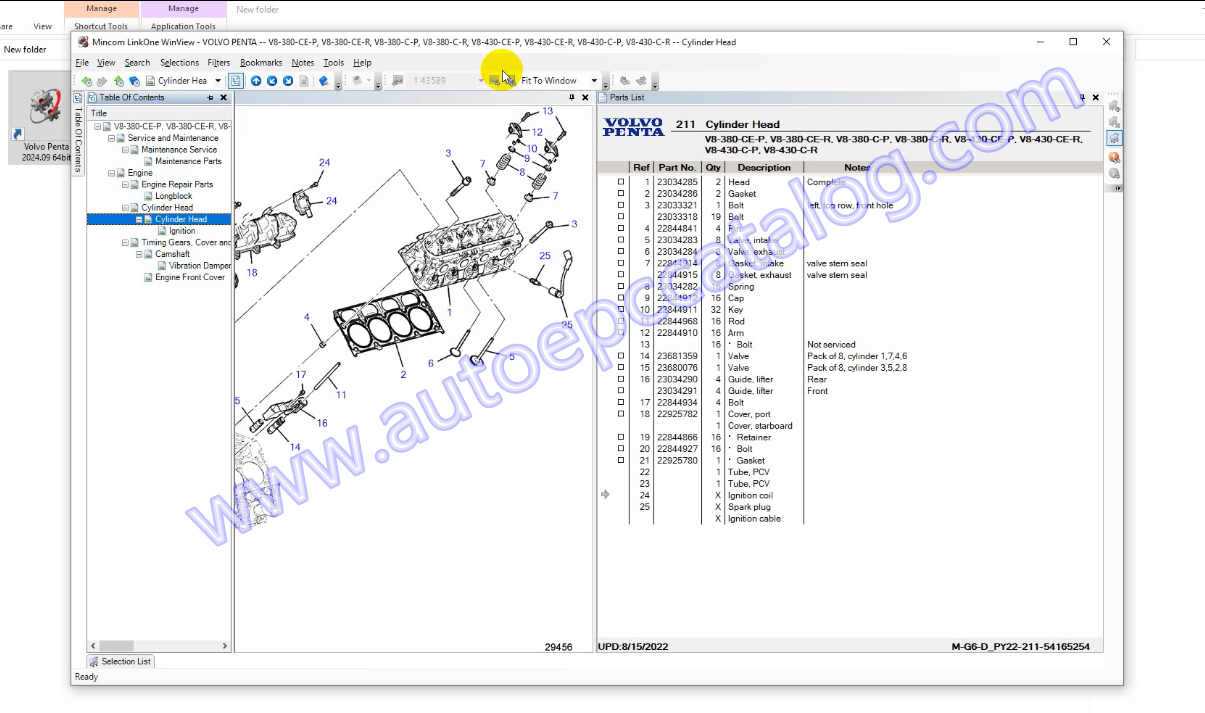

Identifying Critical Elements in the Diagram

Understanding the layout and functionality of mechanical systems requires identifying the key components that contribute to its overall operation. Each element plays a specific role, and recognizing these allows for more efficient maintenance and troubleshooting. The visual representation helps to highlight how these crucial parts interact and ensures a clear view of the system’s core functions.

Key components in the layout are often distinguished by their unique shapes, sizes, or positions within the system. It’s essential to pinpoint these parts to ensure a proper understanding of their role and to facilitate the process of repair or optimization. Additionally, observing the connections and flow between these critical elements can provide insight into the overall mechanics of the system.

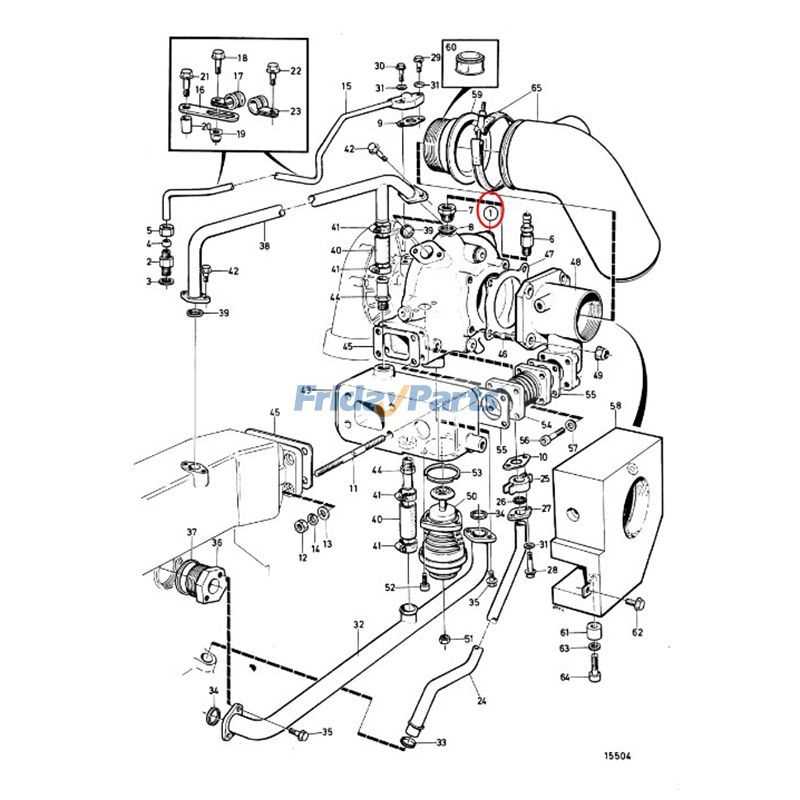

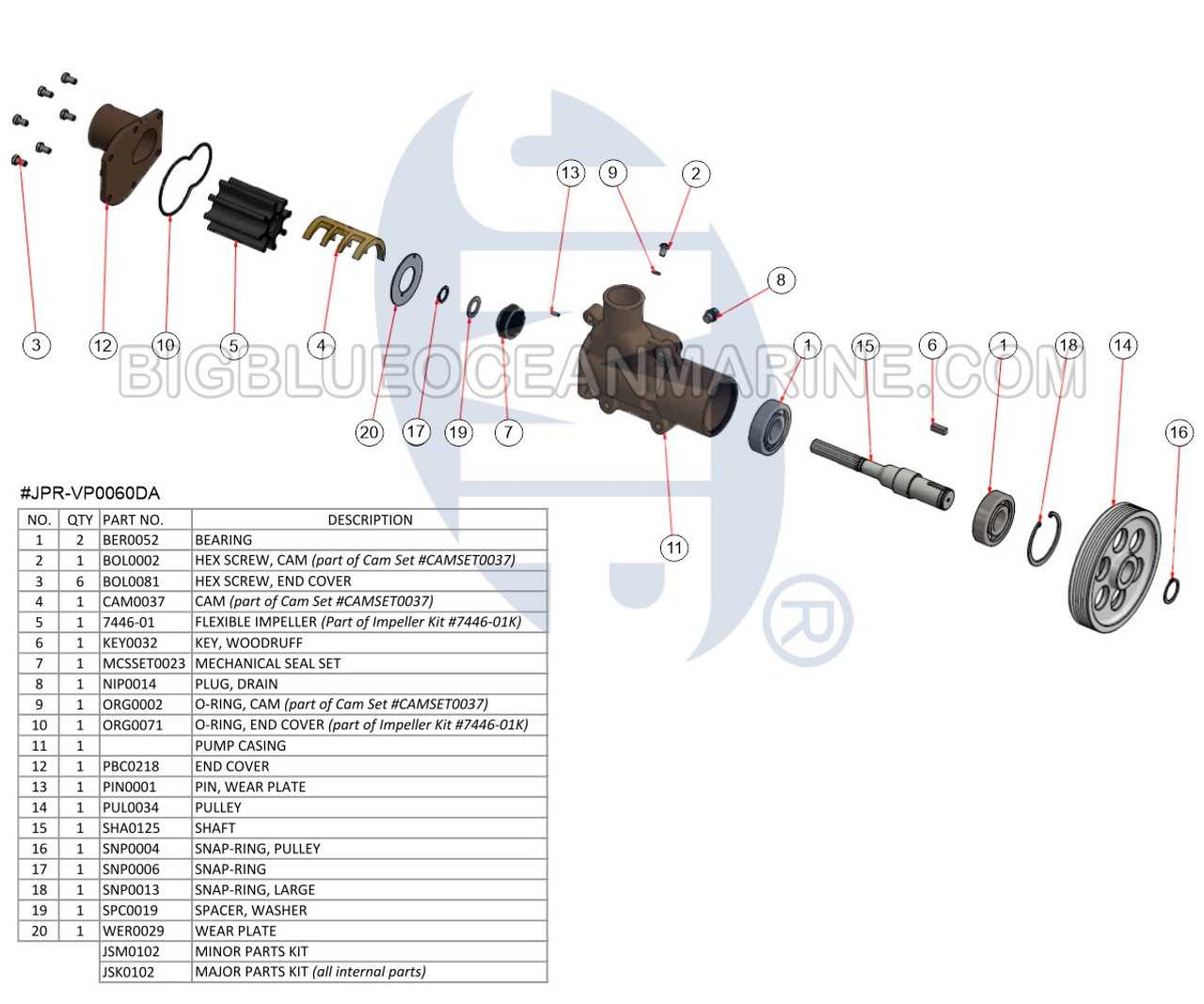

How the Cooling System Operates

The cooling mechanism plays a crucial role in maintaining the temperature within the machinery at an optimal level. Its main function is to prevent overheating by circulating a cooling fluid throughout critical components. This circulation ensures that excess heat is transferred away efficiently, keeping the entire system functioning smoothly even under heavy loads.

Key Components Involved

Several essential elements make up this cooling structure, including a pump, radiator, and thermostat. The pump drives the liquid through various channels, while the radiator dissipates the heat absorbed. The thermostat regulates the flow based on the temperature, ensuring the system remains balanced.

Cooling Process Flow

The process starts with the pump pushing the liquid through passages. As it moves, the fluid absorbs heat from high-temperature areas. Once it reaches the radiator, the heat is released, and the cooled liquid is recirculated to repeat the process. This continuous cycle ensures efficient temperature control.

| Component | Function |

|---|---|

| Pump | Circulates cooling fluid throughout the system |

| Radiator | Dissipates the absorbed heat into the surrounding air |

| Thermostat | Controls the flow of coolant based on temperature |

Understanding Fuel System Connections

Fuel systems play a critical role in ensuring that a machine operates efficiently by delivering the right amount of fuel to the combustion unit. This section explores how various components within the fuel system interact, ensuring smooth flow and proper pressure levels for optimal performance. Knowing how these connections work together helps in troubleshooting and maintaining the overall system.

Main Components of the Fuel System

The fuel system consists of several essential elements, including pumps, filters, and lines that connect the fuel source to the combustion area. These components must function in harmony to maintain a consistent fuel supply. Each part has a specific role, from filtering impurities to pressurizing the fuel for proper atomization.

Key Fuel Line Connections

The connections between the fuel tank, filters, and the injection system are crucial. Proper sealing and alignment ensure that fuel is transferred without leaks or loss of pressure. High-quality materials are often used to withstand heat and pressure, while the arrangement of the lines determines the efficiency of fuel delivery.

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Pump | Pressurizes the fuel and ensures a steady flow to the injectors. | ||||||||||||

| Fuel Filter | Removes contaminants from the fuel to protect the system. | ||||||||||||

| Fuel Lines | Transport fuel from the tank to the injectors.

Lubrication System: Key Parts and FlowThe lubrication system plays a crucial role in maintaining the efficiency and longevity of mechanical machinery. It ensures that moving components are adequately coated with oil, minimizing friction and preventing wear. This section explores the fundamental components of the lubrication mechanism and the flow of lubricating fluid through the system, highlighting their importance in promoting optimal performance. Essential Components of the Lubrication MechanismAt the heart of the lubrication process are various elements that work in harmony to distribute oil throughout the system. The oil pump, often considered the lifeblood of the system, creates the necessary pressure to circulate the lubricant. Filters are also vital, as they remove impurities from the oil, ensuring that only clean fluid reaches critical components. Additionally, oil galleries and passages guide the lubricant to areas where it is needed most, reducing the risk of overheating and mechanical failure. Flow Dynamics of Lubricating FluidThe flow of lubricating fluid is designed to be efficient and effective. Once the oil is drawn from the reservoir by the pump, it travels through filters and into the galleries, where it is directed to various parts. As the fluid lubricates components, it absorbs heat generated by friction, which is then transferred back to the reservoir for cooling. This continuous cycle not only protects components but also enhances the overall efficiency of the machinery, demonstrating the critical nature of a well-functioning lubrication system. Exhaust System and Its Components

The exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. It is responsible for directing harmful gases away from the combustion area while reducing noise and emissions. This system comprises several interconnected components, each serving a specific function to ensure smooth operation and optimal performance.

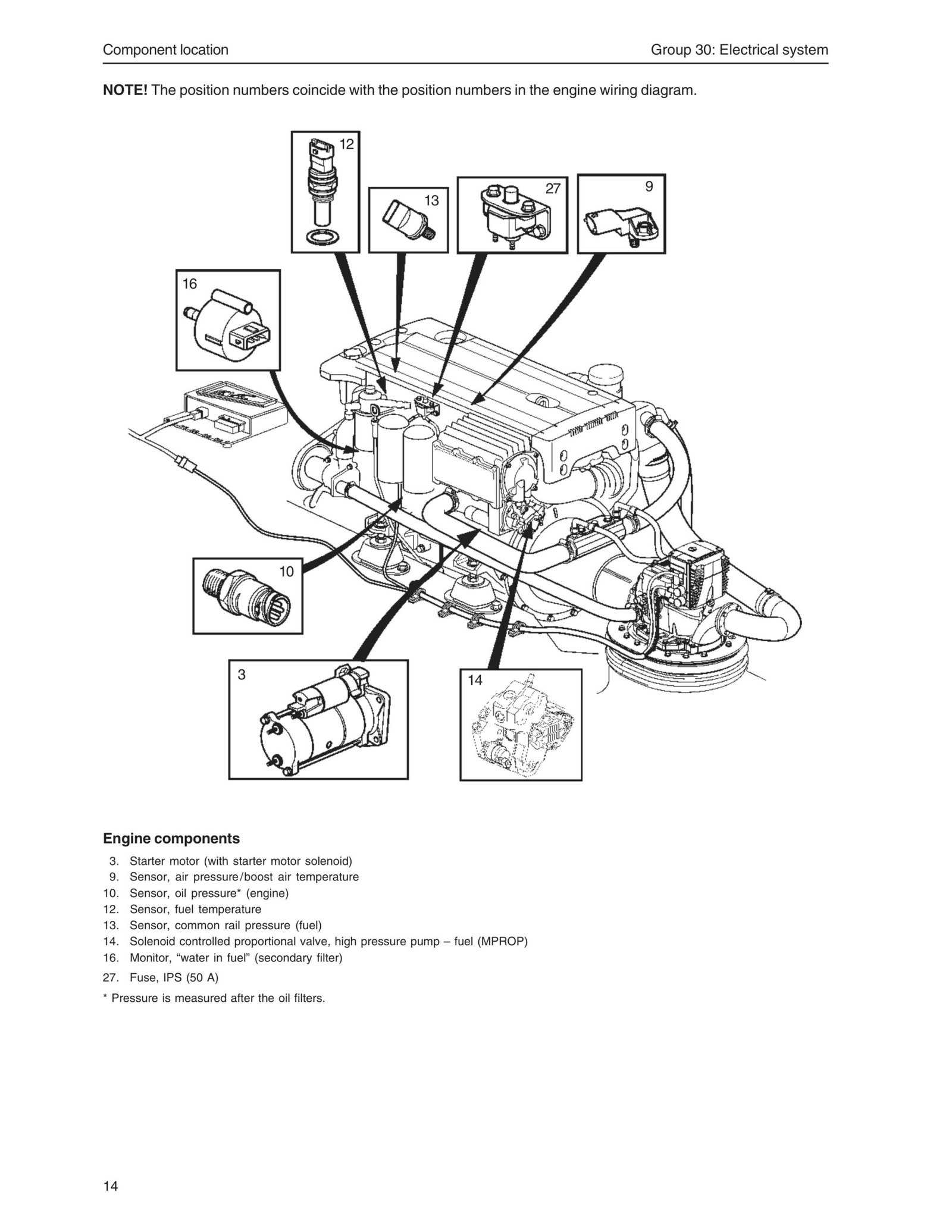

Air Intake and Filtration MechanismsThe systems responsible for air intake and filtration play a crucial role in maintaining optimal performance and longevity of combustion systems. These mechanisms ensure that clean, unrestricted air enters the combustion chamber, promoting efficient operation and reducing the risk of damage from contaminants. Functionality of Air Intake SystemsAir intake systems are designed to draw in air from the environment, directing it towards the combustion chamber. This process involves several components that work together to regulate airflow and pressure. A well-designed intake system enhances the efficiency of the combustion process, leading to improved power output and fuel efficiency. Importance of FiltrationEffective filtration is essential to protect the internal components from dust, debris, and other particulates that can cause wear and tear. The filtration mechanism employs various media to trap harmful particles, ensuring that only clean air enters the combustion chamber. Regular maintenance and replacement of these filters are vital for sustaining performance and extending the lifespan of the system. Electrical Components and Their Roles

The functionality of a marine power unit heavily relies on various electrical components that ensure optimal performance and reliability. These elements play vital roles in the overall operation, contributing to safety and efficiency during navigation.

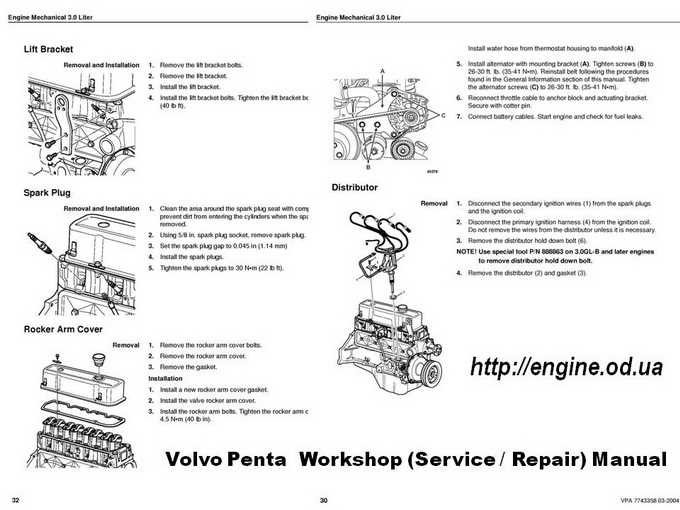

Understanding the roles of these electrical components is crucial for maintaining efficiency and ensuring the longevity of the entire marine system. Diagram Interpretation: Tips for BeginnersUnderstanding visual representations of mechanical systems can be a valuable skill for anyone interested in maintenance and repairs. These illustrations provide a wealth of information, revealing how various components interact and function together. By grasping the basics of these visuals, newcomers can enhance their troubleshooting abilities and overall comprehension of the equipment. 1. Familiarize Yourself with Symbols: Every visual representation uses specific symbols to denote various components. Take time to learn what these symbols mean, as this knowledge will be essential for interpreting the information accurately. 2. Start with the Basics: Focus on the fundamental parts and their relationships before diving into more complex elements. Identifying the primary functions of each component will create a solid foundation for understanding the entire system. 3. Follow the Flow: Many visuals are designed to illustrate the flow of energy or fluids within the system. Pay attention to the arrows and lines, as they indicate how elements connect and interact with one another. Recognizing these connections can clarify the overall functionality. 4. Take Notes: As you study the visual aids, jot down important observations or questions. This practice can help reinforce your understanding and provide a reference for future inquiries. 5. Seek Resources: Don’t hesitate to consult manuals, online tutorials, or forums. Many communities and resources are available to help you decode complex illustrations and provide additional insights. By employing these strategies, beginners can improve their ability to interpret visual representations, making their maintenance and repair efforts more effective and informed. Engine Block: Structure and Design

The foundation of any internal combustion mechanism plays a crucial role in its overall performance and durability. This core component serves as the primary housing for various essential elements, ensuring stability while facilitating effective energy conversion. Understanding its structure and design is vital for appreciating how these systems operate and maintain efficiency. Typically crafted from robust materials, this foundational unit must endure substantial pressure and thermal stress. Its design often incorporates numerous passages and chambers, enabling the circulation of vital fluids such as coolant and lubricants. The configuration of these channels significantly influences the thermal management and lubrication efficiency within the assembly. Furthermore, the integrity of this housing is paramount, as any defects can lead to severe operational failures. Advanced manufacturing techniques and rigorous quality control measures are employed to guarantee that each unit meets the necessary standards for performance and reliability. Additionally, modern designs often prioritize weight reduction without compromising strength, utilizing innovative materials and engineering solutions. In summary, the architecture of this central structure is essential for the seamless functioning of combustion mechanisms. Its careful design contributes not only to the mechanical efficiency but also to the longevity and resilience of the entire system. Transmission and Propulsion Parts Explained

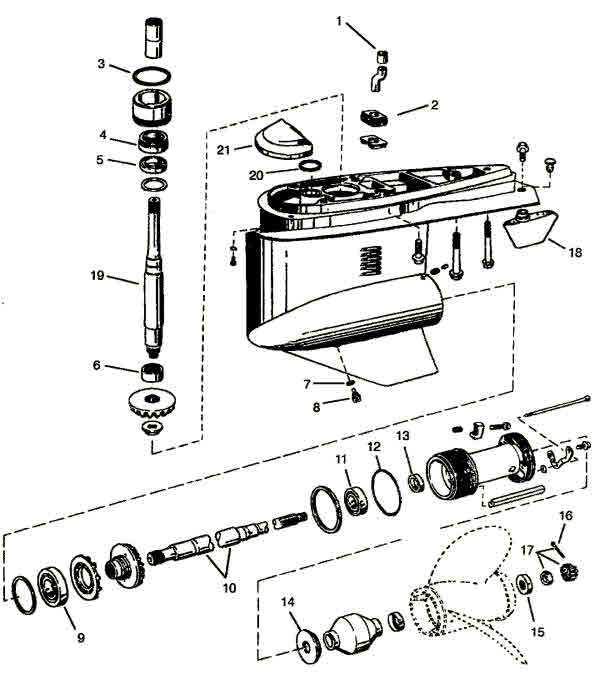

The components responsible for transmitting power and ensuring effective movement play a crucial role in the overall functionality of marine systems. Understanding these elements is essential for maintaining optimal performance and enhancing operational efficiency. This section delves into the key components that facilitate the transfer of energy and enable smooth navigation through water. Key Components of Transmission Systems

Transmission systems comprise various elements that work together to convert the rotational motion from the power source into useful work. The primary components include gearboxes, clutches, and drive shafts. Gearboxes serve to adjust speed and torque, allowing for versatility in different operational conditions. Clutches enable smooth engagement and disengagement, providing control over power transfer. Drive shafts then relay the power to the propulsion units, ensuring reliable movement. Understanding Propulsion Mechanisms

Propulsion mechanisms are essential for creating thrust and ensuring effective maneuverability. These mechanisms typically include propellers, jets, and water intakes. Propellers convert rotational energy into thrust, allowing vessels to move efficiently through water. Jets utilize high-pressure water to propel the vessel forward, providing agile movement and quick response times. Water intakes facilitate the flow of water into the propulsion system, ensuring optimal performance and efficiency. Routine Maintenance Tips for Volvo Penta Engines

Regular upkeep is essential for ensuring optimal performance and longevity of your marine propulsion system. Following a systematic maintenance schedule can prevent potential issues and enhance the overall efficiency of your vessel’s mechanics.

By adhering to these maintenance practices, you can help ensure that your vessel remains reliable and ready for any journey ahead. |