In the intricate world of marine engineering, a comprehensive grasp of the various elements that make up a vessel’s propulsion system is essential. Each component plays a critical role in ensuring optimal performance, reliability, and safety on the water. Whether you are a seasoned technician or a boating enthusiast, familiarizing yourself with these elements can significantly enhance your maintenance capabilities and troubleshooting skills.

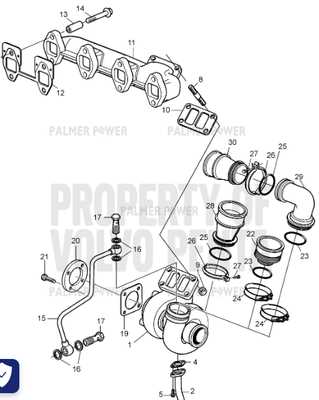

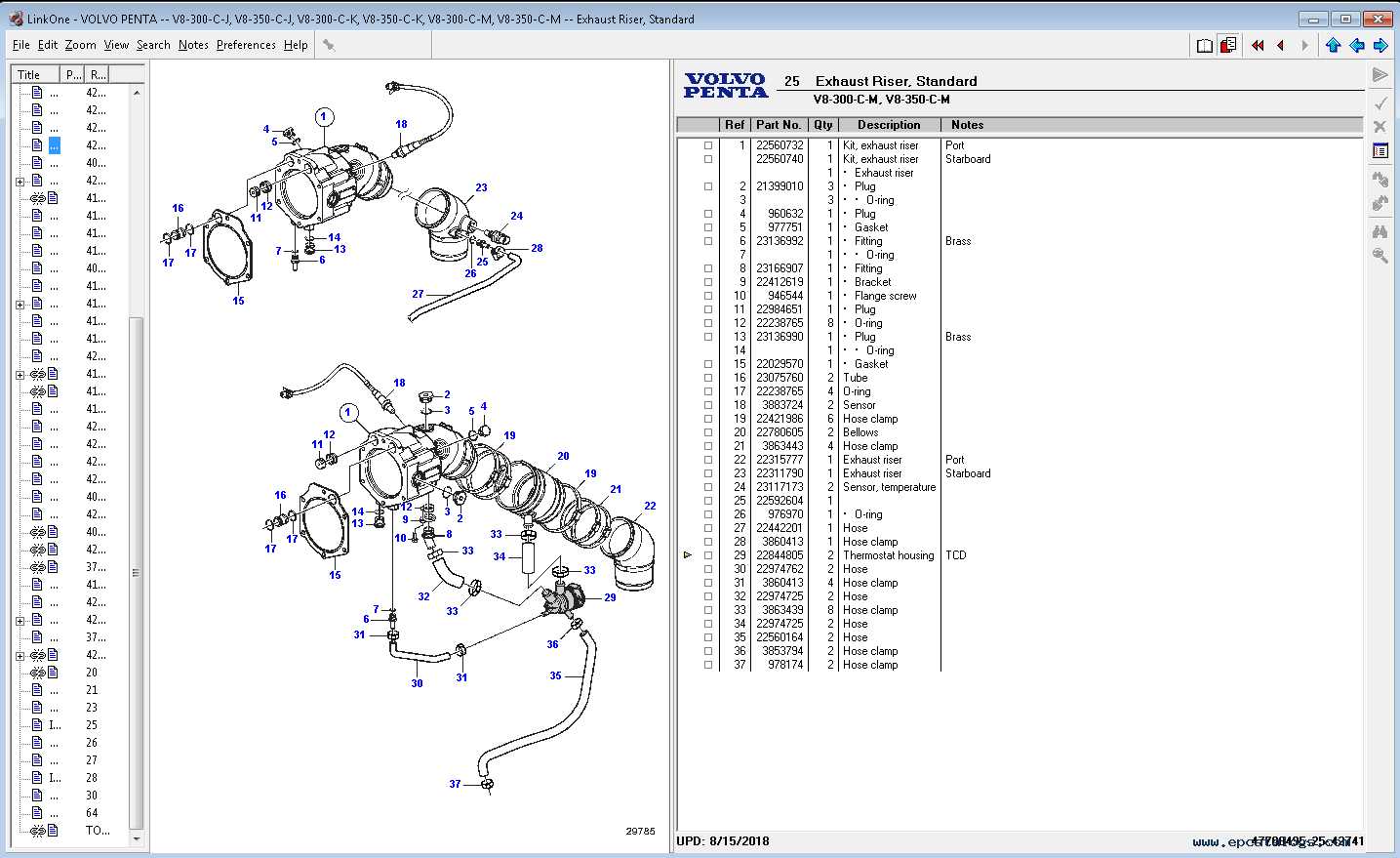

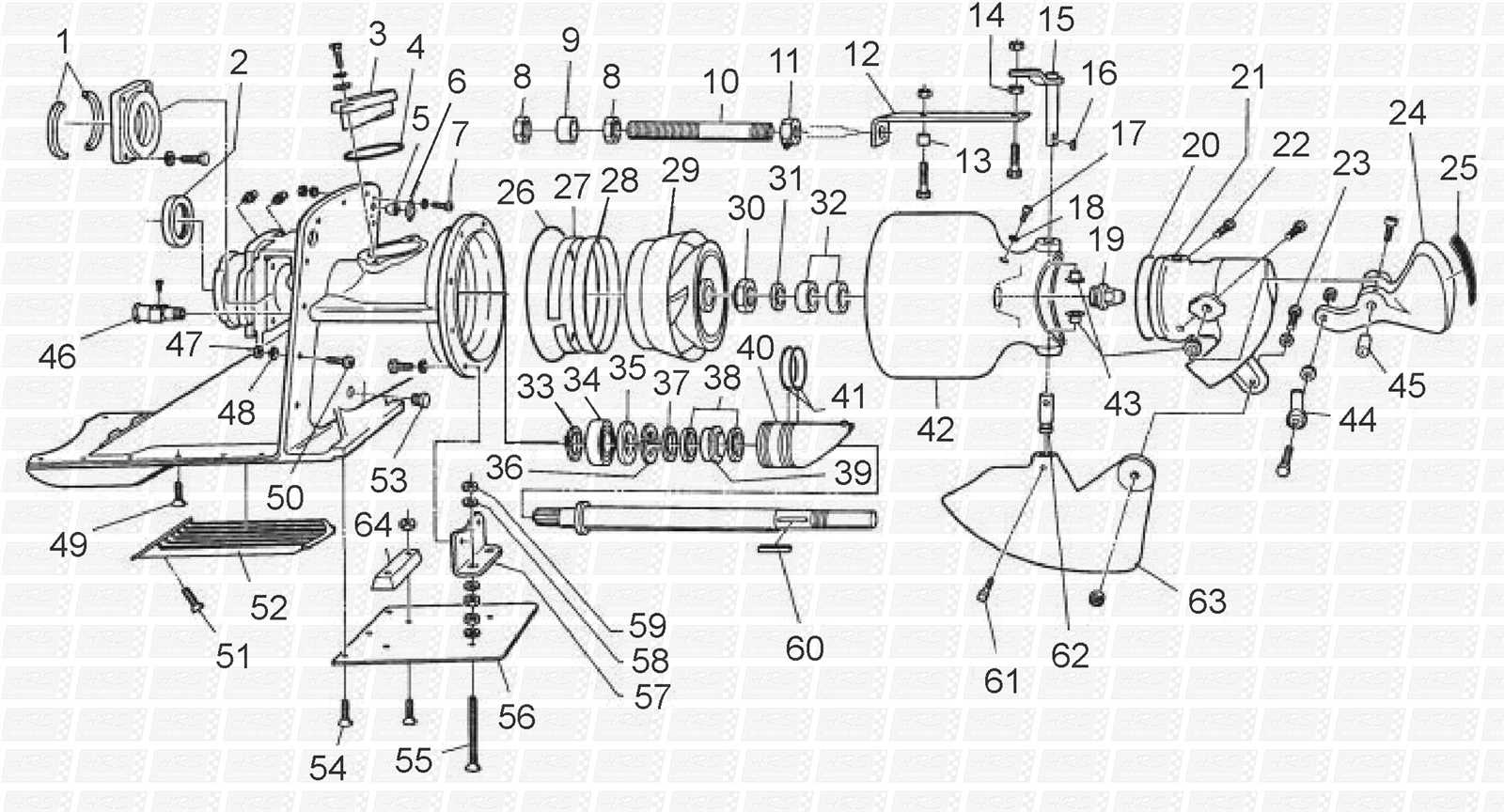

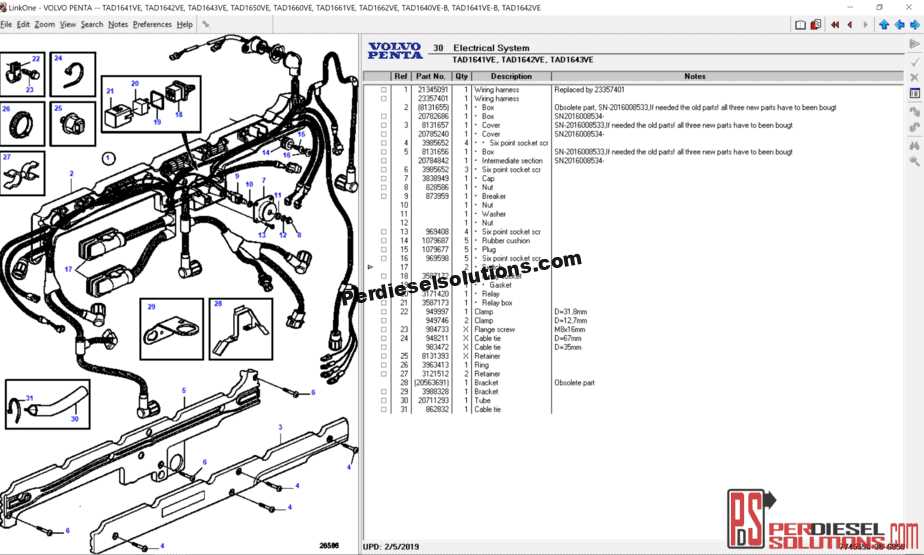

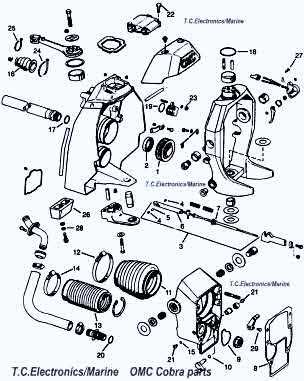

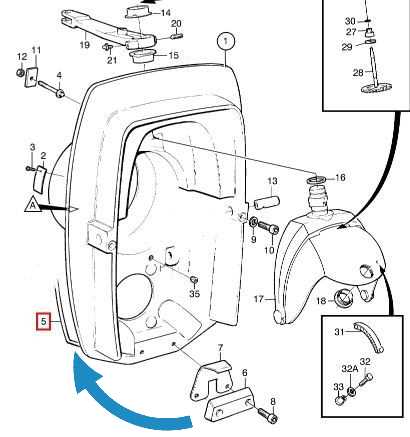

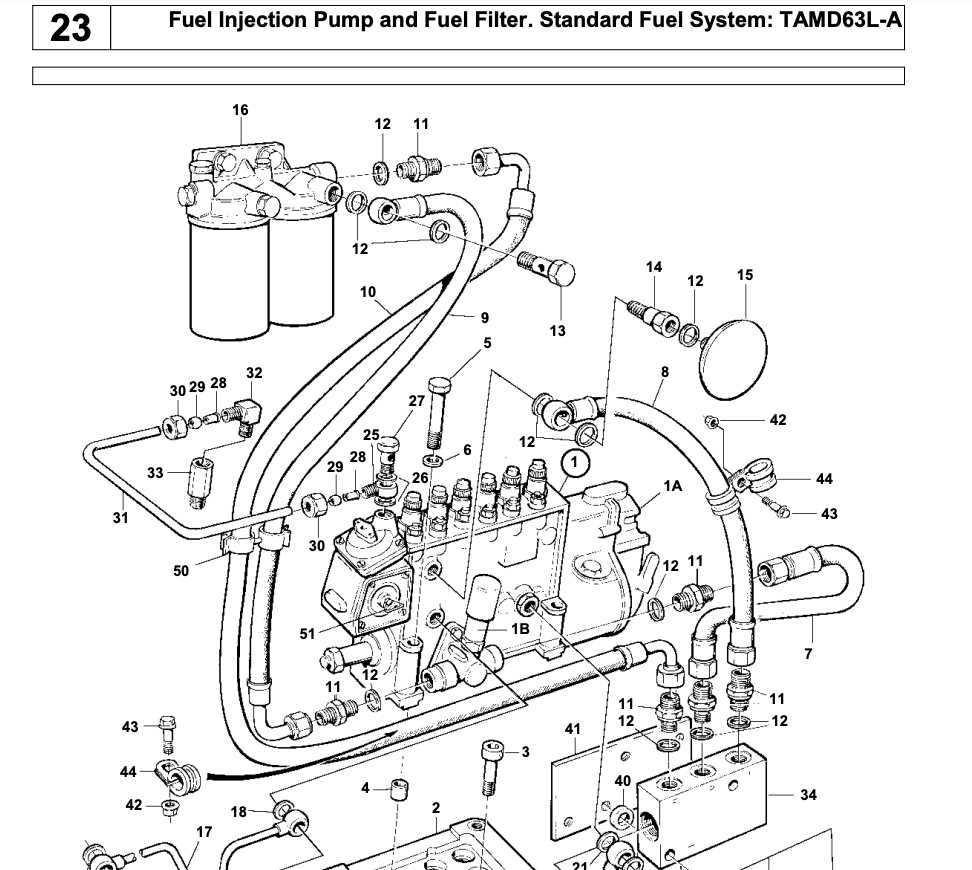

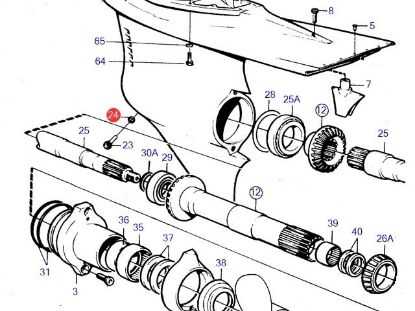

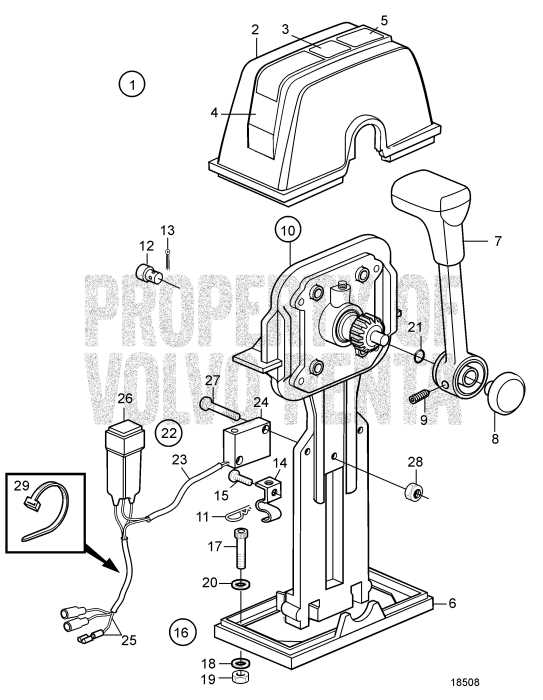

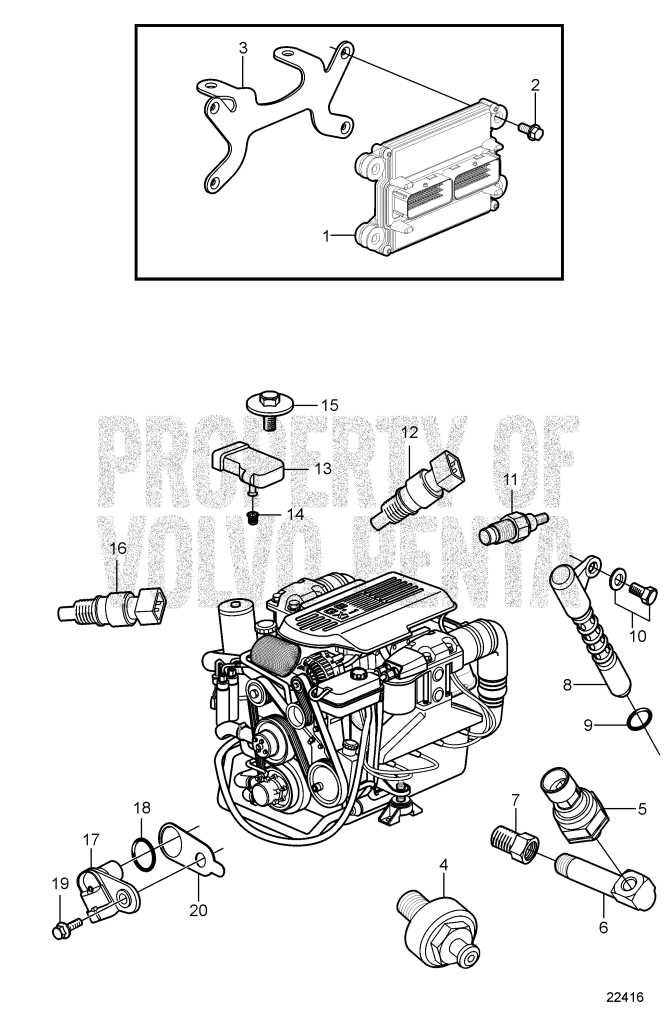

Visual representations of these components offer a valuable resource for anyone looking to deepen their understanding. They serve as an effective guide, allowing users to identify, locate, and comprehend the relationships between different sections of the engine assembly. This knowledge can lead to more efficient repairs and replacements, ultimately extending the lifespan of the equipment.

Additionally, recognizing the unique features and specifications of each component can aid in the selection of appropriate replacements or upgrades. With a well-organized visual reference, users can streamline their decision-making process, ensuring that every part is compatible and enhances overall functionality. Embracing this approach not only empowers individuals but also fosters a greater appreciation for the complexity and craftsmanship involved in marine engineering.

Understanding Volvo Penta Parts Diagrams

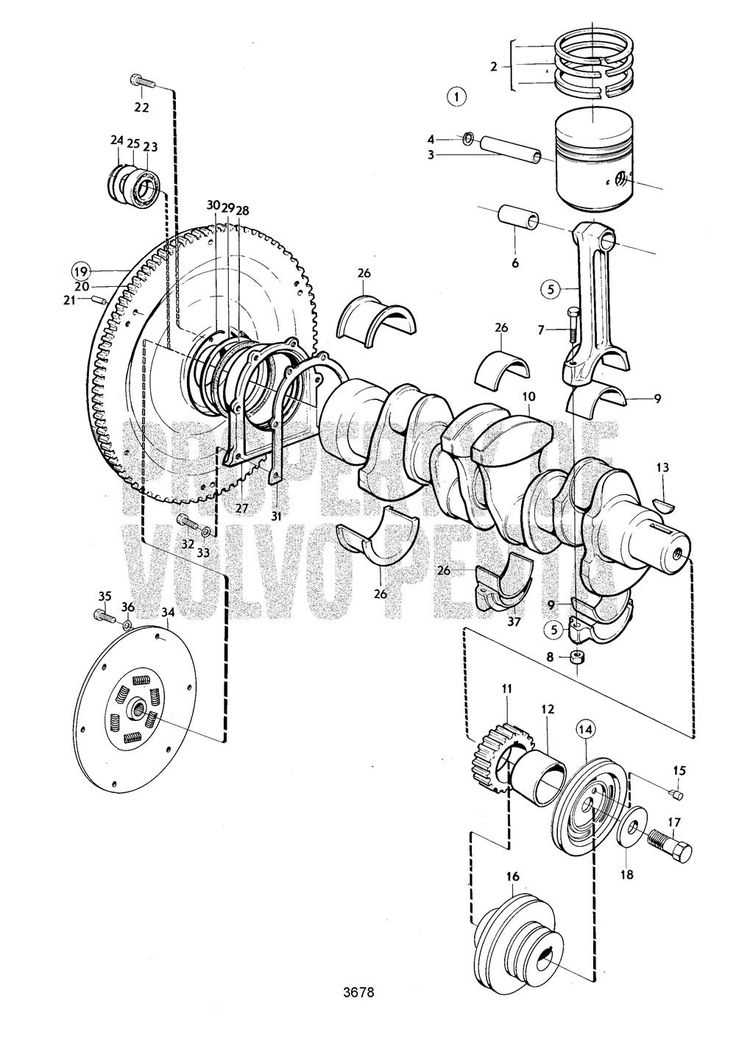

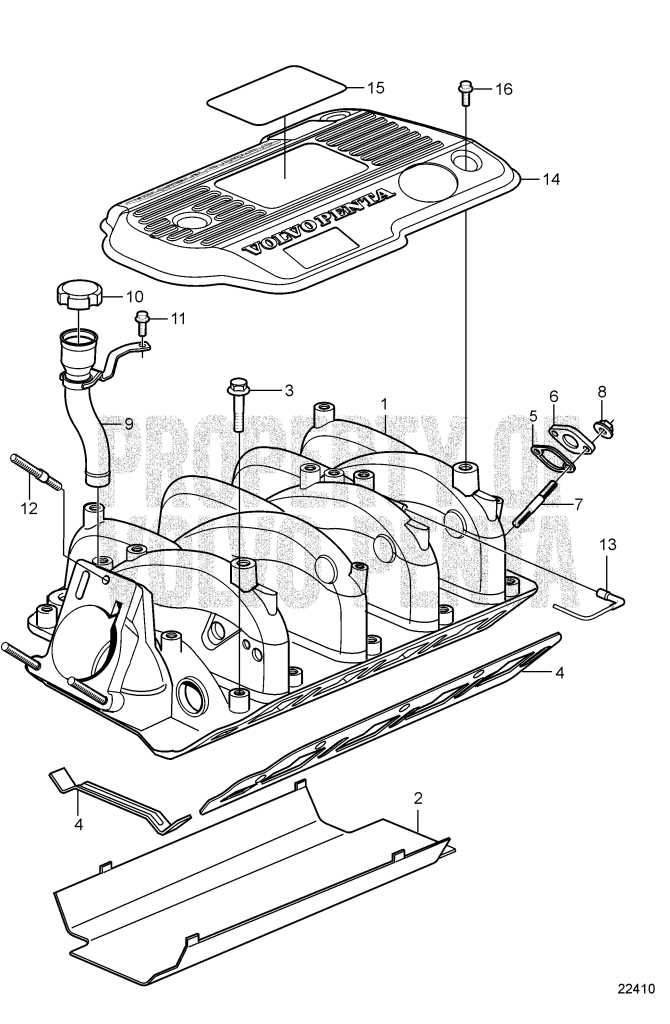

Grasping the intricacies of mechanical schematics is essential for anyone working with marine engines and associated systems. These illustrations serve as a crucial reference, allowing technicians and enthusiasts to identify components, understand their functions, and ensure proper maintenance. A well-organized visual representation can greatly enhance the efficiency of repairs and upgrades.

The Importance of Accurate Representations

Having precise and detailed illustrations is vital for troubleshooting and repairs. These visuals help in pinpointing issues quickly, as they depict the arrangement and relationship between various elements. Understanding how components interact within the overall assembly can save time and reduce the likelihood of errors during repairs.

How to Read and Utilize Schematics

To effectively interpret these illustrations, one should familiarize themselves with common symbols and notations. Many schematics include a legend or key that explains the meaning of various icons, which can be invaluable for deciphering complex assemblies. Additionally, cross-referencing these visuals with manuals can provide further clarity on installation and maintenance procedures.

| Component | Function |

|---|---|

| Engine Block | Houses cylinders and provides structural integrity |

| Fuel Pump | Delivers fuel to the engine |

| Cooling System | Maintains optimal operating temperature |

| Ignition System | Ignites the air-fuel mixture |

Importance of Accurate Parts Identification

Proper identification of components is crucial for the efficient operation and maintenance of any machinery. When every element is correctly recognized, it enhances the reliability and longevity of the equipment.

- Ensures compatibility with existing systems

- Reduces the risk of operational failures

- Simplifies maintenance and repair processes

Inaccuracies can lead to significant downtime and increased costs. Therefore, meticulous attention to detail during identification is essential.

- Accurate identification prevents incorrect replacements.

- It supports effective troubleshooting and diagnostics.

- Enhances safety standards by ensuring proper fit and function.

Ultimately, investing time in precise recognition not only promotes efficiency but also safeguards the overall functionality of the machinery.

Common Components in Volvo Penta Engines

Understanding the essential elements of marine engines is crucial for effective maintenance and performance. These components work in harmony to ensure smooth operation and longevity, making them vital for any vessel’s reliability.

Core Elements

At the heart of these machines are the power units, responsible for generating propulsion. Additionally, the cooling system plays a pivotal role in regulating temperature, while the fuel system ensures optimal energy delivery for efficient operation.

Support Systems

Complementary systems such as exhaust and electrical setups enhance overall functionality. The exhaust mechanism directs emissions safely away, while electrical components power essential features, ensuring the engine runs effectively during all conditions.

How to Read Parts Diagrams Effectively

Understanding technical illustrations can significantly enhance your ability to identify components and their relationships. Mastering this skill is crucial for effective maintenance and repairs.

To interpret these illustrations successfully, consider the following steps:

- Familiarize Yourself with Symbols:

- Study common icons used in schematics.

- Understand the color coding that indicates functionality.

- Identify Key Sections:

- Locate the title and reference numbers for clarity.

- Examine the layout to determine how parts fit together.

- Take Note of Annotations:

- Pay attention to notes that provide additional context.

- Look for measurements and specifications relevant to each element.

- Cross-Reference with Manuals:

- Use manufacturer manuals for detailed descriptions.

- Check for compatibility with various models.

By following these strategies, you can effectively navigate technical illustrations and enhance your understanding of the components involved.

Where to Find Official Diagrams

When it comes to locating precise illustrations for components of your marine engine, there are several reliable sources to consider. Accessing official representations is crucial for ensuring correct installation and maintenance of your machinery.

Manufacturer Websites: The primary destination for authentic schematics is the official website of the engine manufacturer. They typically provide downloadable resources, including detailed charts and manuals that cover various models and assemblies.

Authorized Dealers: Engaging with authorized dealers is another effective method. These retailers often have access to proprietary materials and can assist in obtaining the necessary illustrations specific to your equipment.

Online Forums and Communities: Participating in dedicated online communities can also yield valuable insights. Enthusiasts and professionals frequently share links to useful resources, including official documents, which can enhance your understanding and maintenance capabilities.

Service Centers: If you prefer hands-on assistance, visiting an authorized service center can be beneficial. Technicians there can provide printed versions of technical illustrations and answer any questions regarding your equipment.

Utilizing these sources will ensure that you have the most accurate and helpful information at your fingertips, ultimately supporting the longevity and performance of your machinery.

Comparing Different Volvo Penta Models

When exploring the diverse range of marine engines available, it’s essential to assess the unique features and capabilities of each model. Different variations offer distinct advantages depending on the specific needs of the vessel and its intended use. Understanding these differences can greatly influence performance, efficiency, and overall user satisfaction.

Power Output: One of the most critical aspects to consider is the engine’s power output. Various models provide a spectrum of horsepower options, catering to everything from recreational boats to commercial vessels. The choice of power directly affects speed, towing capacity, and overall handling on the water.

Fuel Efficiency: Another significant factor is fuel consumption. Some engines are engineered for optimal efficiency, allowing for longer journeys with less fuel. This is particularly beneficial for long-distance travel and commercial applications where operating costs are a major concern.

Maintenance and Durability: The longevity and reliability of an engine are paramount for any owner. Different models feature varying maintenance requirements and construction quality. It’s advisable to research which options offer easier servicing and better resistance to wear and tear, especially in challenging marine environments.

Technology Integration: Many modern engines come equipped with advanced technology that enhances performance and user experience. Features like digital displays, integrated diagnostics, and connectivity options can significantly simplify operation and monitoring, making them a worthwhile consideration in the selection process.

In summary, evaluating the distinctions among various engine models is crucial for making an informed choice. By considering power output, fuel efficiency, maintenance needs, and technological advancements, potential buyers can select the best option tailored to their specific maritime endeavors.

Tips for Ordering Replacement Parts

When it comes to acquiring components for your equipment, understanding the process can enhance efficiency and ensure you get the right items. Here are some essential strategies to streamline your ordering experience.

Know Your Specifications

- Gather the model number and serial number of your equipment.

- Identify the specific component you need to replace.

- Consult the manufacturer’s documentation for accurate details.

Choose a Reliable Supplier

- Research suppliers with good reputations in the industry.

- Read reviews to ensure quality service.

- Verify the supplier offers genuine items rather than substitutes.

By following these guidelines, you can navigate the ordering process with confidence and ultimately enhance your maintenance efforts.

Maintenance Best Practices for Longevity

Ensuring the extended lifespan of marine equipment requires a systematic approach to upkeep. Regular attention to maintenance not only enhances performance but also minimizes the likelihood of costly repairs. By implementing best practices, owners can effectively safeguard their investments and promote reliability.

1. Regular Inspections: Conducting frequent checks for wear and tear helps identify potential issues before they escalate. Focus on critical components and replace any worn parts promptly.

2. Cleanliness: Keeping machinery and surrounding areas clean prevents the buildup of harmful substances that can lead to corrosion and inefficiency. Regular washing and drying of surfaces are essential.

3. Lubrication: Applying appropriate lubricants at specified intervals reduces friction and prevents overheating. Always follow the manufacturer’s guidelines for lubricant types and frequencies.

4. Seasonal Preparation: Before storing equipment, prepare it for off-seasons by draining fluids and protecting against environmental factors. This ensures readiness for the next use.

5. Record Keeping: Maintaining a detailed log of maintenance activities aids in tracking performance and identifying recurring issues. This data is invaluable for informed decision-making.

By adhering to these strategies, individuals can delve deeper into the nuances of upkeep, ultimately enhancing the durability and efficiency of their marine systems.

Common Issues and Solutions

Understanding typical challenges that may arise with marine engines is essential for maintaining optimal performance. Addressing these issues promptly can prevent further complications and ensure reliable operation on the water.

Overheating Problems

One frequent concern is engine overheating. This can occur due to a variety of factors, including inadequate coolant flow or a malfunctioning thermostat. Regularly inspecting the cooling system and replacing worn components can significantly reduce the risk of overheating. If the engine does overheat, allowing it to cool down and checking for blockages in the cooling passages are crucial steps.

Starting Difficulties

Another common issue is difficulty starting the engine. This may stem from a weak battery, faulty wiring, or issues with the ignition system. Ensuring that the battery is fully charged and connections are clean can often resolve these problems. Additionally, routine maintenance of the ignition components can help prevent starting issues in the future.

Aftermarket Parts: Pros and Cons

Exploring alternatives in the realm of components can lead to significant advantages and drawbacks. It’s essential to weigh these factors when considering substitutes to original equipment.

Advantages:

- Cost-Effective: Often more affordable than original options, making repairs and upgrades more accessible.

- Variety: A wider selection allows for customization and potentially enhanced performance.

- Availability: Typically easier to find, especially for older models or discontinued items.

Disadvantages:

- Quality Variability: Not all alternatives meet the same standards, which can lead to reliability issues.

- Warranty Concerns: Using substitutes may void warranties on original equipment.

- Compatibility Issues: Some options may not fit or function properly, leading to further complications.

Integrating Diagrams into Repair Processes

Incorporating visual representations into maintenance workflows significantly enhances efficiency and accuracy. These illustrations serve as essential tools, guiding technicians through complex procedures and facilitating a clearer understanding of component interactions.

Benefits of Visual Aids

Utilizing schematics in repair operations offers numerous advantages, including reduced errors, faster diagnostics, and improved communication among team members. By referencing clear visuals, professionals can pinpoint issues more swiftly and apply solutions with greater confidence.

Best Practices for Implementation

To maximize the effectiveness of visual tools, it is crucial to ensure they are easily accessible and regularly updated. Integrating these resources into training programs can also enhance technicians’ skills and familiarity with various systems.

| Advantage | Description |

|---|---|

| Clarity | Enhances understanding of complex systems. |

| Efficiency | Reduces time spent troubleshooting. |

| Collaboration | Improves communication among team members. |

Resources for Further Learning

Expanding your knowledge on marine equipment can significantly enhance your understanding and proficiency in maintenance and repairs. Access to quality resources is essential for anyone looking to deepen their expertise in this area. Here are some valuable materials and platforms to consider for further exploration.

Books and Manuals

- Technical manuals specific to various marine engines.

- Comprehensive guides on marine propulsion systems.

- Books focused on troubleshooting and repair techniques.

Online Platforms

- Websites dedicated to marine engineering and mechanics.

- Forums and community groups for discussing maintenance strategies.

- Video tutorials showcasing repair processes and best practices.

Utilizing these resources can help enhance your skills and confidence in working with marine systems.