In the realm of automotive technology, a comprehensive grasp of the various components that contribute to a vehicle’s functionality is essential. This knowledge not only enhances one’s appreciation of engineering but also aids in effective maintenance and troubleshooting. By delving into the intricate workings of specific models, enthusiasts and professionals alike can cultivate a deeper understanding of how these complex systems interact.

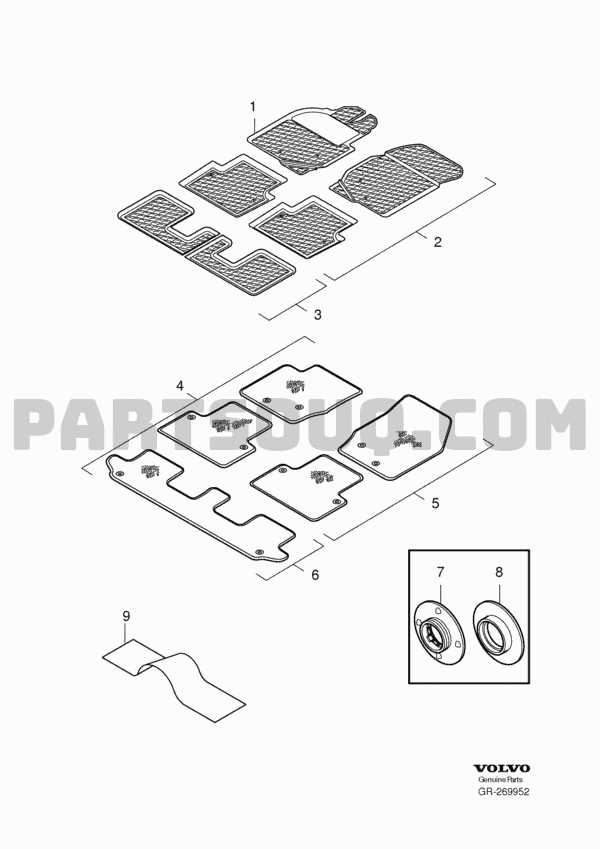

Visual representations serve as invaluable tools for illustrating the relationships and placements of different elements within a vehicle’s structure. These schematics allow for easier navigation through the multitude of parts that work in concert to ensure optimal performance. Whether you are a mechanic, a student, or simply a curious individual, familiarizing yourself with these layouts can greatly enhance your mechanical literacy.

As we explore the intricate network of components, we will highlight key elements that contribute to overall performance and reliability. This guide aims to simplify the complexities involved, breaking down barriers for those looking to enhance their knowledge and skills in automotive care and repair.

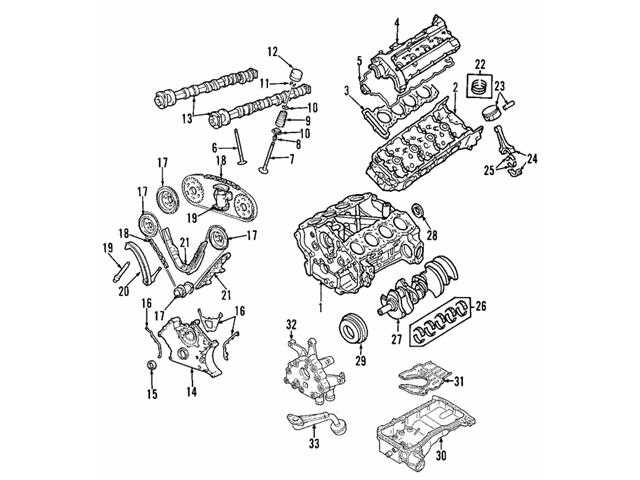

Understanding Volvo XC90 Engine Components

This section aims to explore the various elements that contribute to the functioning of a powerful vehicle. Each component plays a crucial role in ensuring optimal performance, efficiency, and reliability.

Core Elements

The heart of any automobile relies on its primary components, including the block, pistons, and crankshaft. These essential parts work together in harmony to convert fuel into motion, delivering the ultimate driving experience.

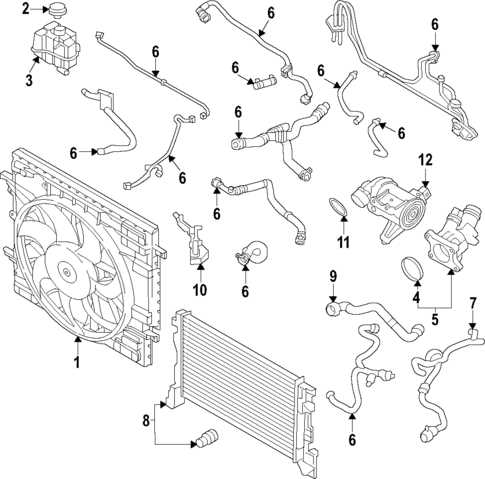

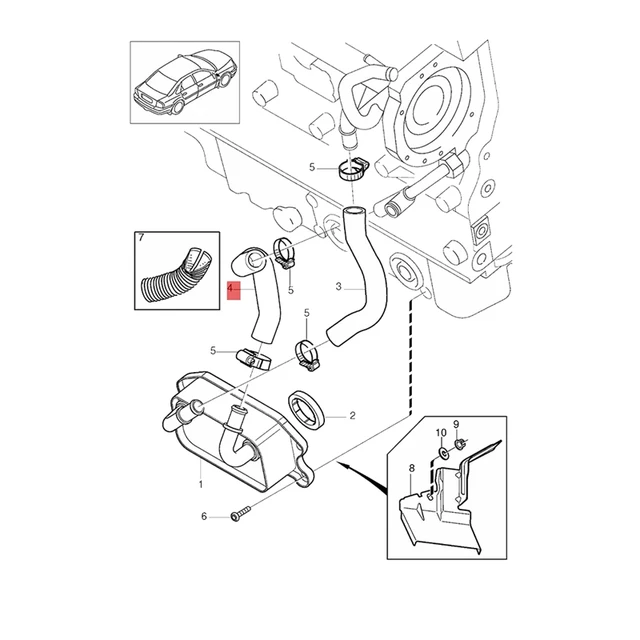

Supporting Systems

In addition to the core elements, various supporting systems enhance overall functionality. The intake and exhaust systems, along with cooling and lubrication mechanisms, are vital for maintaining performance under different conditions. Understanding these systems can help in diagnosing issues and ensuring longevity.

Overview of Engine Parts Functionality

This section explores the essential components that contribute to the overall performance of a vehicle’s power unit. Each element plays a specific role, ensuring optimal operation and efficiency. Understanding these functionalities is crucial for maintaining and troubleshooting any issues that may arise.

The following list highlights key components and their respective functions:

- Crankshaft: Transforms linear motion from pistons into rotational motion, driving the vehicle’s wheels.

- Pistons: Move within the cylinders, compressing the air-fuel mixture for ignition.

- Camshaft: Regulates the opening and closing of valves, controlling airflow in and out of the combustion chamber.

- Valves: Manage the entry of the air-fuel mixture and the exit of exhaust gases.

- Fuel Injector: Delivers a precise amount of fuel into the combustion chamber for optimal combustion.

- Oil Pump: Circulates lubricant throughout the system, reducing friction and preventing wear.

- Timing Belt: Ensures synchronization between the crankshaft and camshaft, allowing for precise valve timing.

Each of these components is integral to the overall functionality and efficiency of the vehicle’s power unit. Regular maintenance and understanding of their roles can lead to better performance and longevity.

Key Specifications of the XC90 Engine

This section explores the essential characteristics of the power unit that drives this premium SUV. Understanding these specifications is crucial for evaluating performance, efficiency, and overall capability.

Displacement: The capacity of the combustion chambers significantly influences power output and torque delivery.

Horsepower: A vital measure of the vehicle’s ability to accelerate and perform under various conditions.

Torque: This metric indicates the twisting force available, impacting towing capacity and responsiveness.

Cylinders: The number of cylinders affects smoothness and performance dynamics, playing a role in both efficiency and power.

Fuel Type: The choice of fuel can affect both performance and environmental impact, shaping the driving experience.

Transmission: The type of transmission influences gear shifts and overall driving comfort, enhancing the relationship between driver and machine.

Efficiency Ratings: These figures provide insight into the balance between power and fuel consumption, crucial for long journeys.

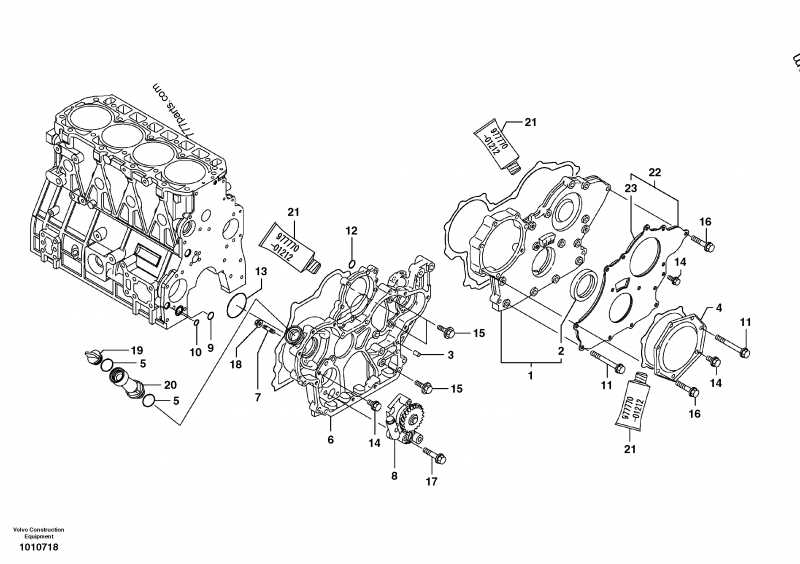

Visual Guide to Engine Parts Diagram

This section offers an insightful overview of the components that make up a motor’s functionality. Understanding these elements is essential for anyone interested in the mechanics behind automotive performance. By exploring these features visually, readers can gain a clearer perspective on their roles and interconnections.

Key Components

- Cylinder Head

- Crankshaft

- Pistons

- Connecting Rods

- Timing Belt

Understanding the Layout

- Identify each element’s function.

- Examine how they work together.

- Consider potential maintenance needs.

Common Issues with XC90 Engine Parts

Understanding the frequent complications that arise within the motor system can greatly assist in maintaining optimal performance. Various components are prone to wear and tear, leading to a range of operational challenges that drivers may encounter over time.

One prevalent concern involves overheating, often due to coolant leaks or a malfunctioning thermostat. Additionally, irregular oil consumption can signify wear in piston rings or valve seals, resulting in decreased efficiency. Electrical failures may also disrupt functionality, particularly with sensors and wiring harnesses, leading to performance issues.

Furthermore, unusual noises could indicate problems with timing belts or pulleys, necessitating timely inspections. Addressing these concerns promptly can prevent more severe damage and ensure longevity in performance.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s core components is essential for optimal performance and reliability. Regular upkeep not only enhances efficiency but also extends the lifespan of critical systems. Implementing a few straightforward practices can make a significant difference in maintaining overall functionality.

1. Regular Fluid Changes: Keeping fluids fresh is vital. Regularly replacing oil, coolant, and other vital liquids helps reduce wear and tear on internal mechanisms, ensuring smooth operation.

2. Monitor Temperature: Overheating can lead to severe damage. Always keep an eye on temperature levels, and address any cooling system issues promptly to prevent costly repairs.

3. Inspect Filters: Air and fuel filters play a crucial role in maintaining performance. Regularly checking and replacing these components can prevent contaminants from causing harm.

4. Routine Checks: Frequent inspections of belts, hoses, and connections can identify potential problems before they escalate. Early detection is key to avoiding major breakdowns.

5. Drive Smoothly: Adopting a gentle driving style can minimize stress on components. Avoiding rapid acceleration and hard braking helps prolong the life of various systems.

6. Use Quality Parts: When replacements are necessary, opt for high-quality components. Using superior materials ensures better performance and longevity compared to cheaper alternatives.

By following these simple yet effective strategies, you can significantly enhance the reliability and lifespan of your vehicle’s vital systems, ensuring a smoother journey for years to come.

Comparative Analysis of Engine Models

This section explores the diverse variations of powertrains, focusing on their functionalities, efficiencies, and performance metrics. Understanding these differences allows for informed decisions when selecting a suitable model for specific requirements.

Key Features

- Fuel Efficiency: Assessment of consumption rates across different systems.

- Power Output: Comparison of horsepower and torque capabilities.

- Emissions: Analysis of environmental impact and regulatory compliance.

Performance Metrics

- Acceleration: Evaluation of response times and speed capabilities.

- Durability: Insights into lifespan and maintenance needs.

- Adaptability: How well each type integrates with varying driving conditions.

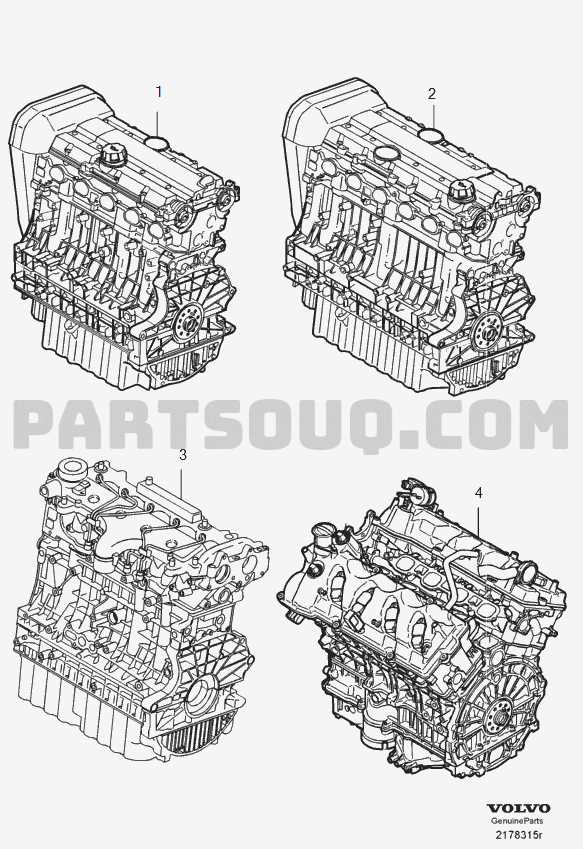

Importance of Genuine Replacement Parts

Using authentic components in any mechanical system is crucial for maintaining optimal performance and reliability. Substituting with inferior alternatives can lead to a range of issues, ultimately compromising safety and functionality. Genuine items are designed to meet strict standards, ensuring seamless integration and longevity.

Quality Assurance: Original components undergo rigorous testing and quality checks, which counterfeit or generic versions often lack. This assurance translates into enhanced durability and reduced likelihood of failures over time.

Compatibility: Authentic elements are specifically engineered to fit and work seamlessly with your vehicle’s architecture. This compatibility minimizes the risk of operational disruptions and costly repairs down the line.

Performance: Utilizing original replacements ensures that your vehicle performs as intended, delivering the power and efficiency that you expect. Non-genuine components may not provide the same level of performance, leading to diminished driving experiences.

Warranty Protection: Many manufacturers offer warranties on their vehicles, which can be voided if non-authentic components are used. Sticking to genuine items helps maintain warranty coverage and provides peace of mind.

In summary, investing in original replacements is essential for preserving your vehicle’s integrity, enhancing its performance, and ensuring a safer driving experience.

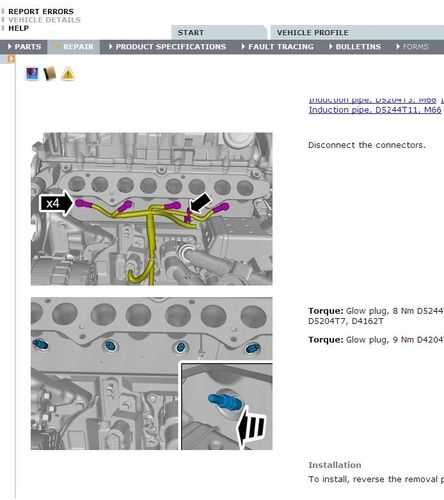

Step-by-Step Engine Assembly Process

Assembling a complex mechanical unit requires precision and a systematic approach. Each component plays a critical role in the overall functionality, and understanding the order of assembly is essential for achieving optimal performance.

The following table outlines the essential steps in the assembly process, detailing key actions and considerations:

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools to ensure a smooth assembly. |

| 2 | Begin with the base structure, securing it firmly to prevent movement. |

| 3 | Install critical internal mechanisms, ensuring proper alignment and fit. |

| 4 | Attach auxiliary systems, verifying each connection is secure and functional. |

| 5 | Perform a thorough inspection of all assembled elements for any discrepancies. |

| 6 | Finalize the assembly by integrating external casings and systems, ensuring completeness. |

Aftermarket vs. OEM Engine Components

When it comes to selecting replacement components for your vehicle, enthusiasts often face a choice between two main categories: original equipment manufacturer options and those produced by third-party suppliers. Each of these choices presents unique benefits and potential drawbacks that can significantly impact performance, longevity, and cost.

Quality and Performance

OEM offerings are designed to meet the exact specifications set by the manufacturer, ensuring a precise fit and optimal performance. This consistency can be crucial for maintaining the integrity of your vehicle. In contrast, aftermarket alternatives may vary widely in quality. While some third-party products can exceed OEM standards, others might not deliver the same reliability. It’s essential to research each option carefully, especially if you are looking for enhanced performance or specific features.

Cost Considerations

One of the most significant differences lies in pricing. OEM components typically come at a premium due to their guaranteed compatibility and quality assurance. Aftermarket products, on the other hand, can offer substantial savings, but this can sometimes come at the cost of reliability. When evaluating your choices, consider not just the initial purchase price but also the potential long-term effects on your vehicle’s maintenance and overall value.

Tools Required for Engine Repairs

Undertaking repairs on a vehicle requires a specific set of instruments to ensure efficiency and safety. Having the right tools not only streamlines the process but also enhances the overall quality of the work done.

- Wrenches

- Screwdrivers

- Socket set

- Torque wrench

- Pliers

- Jack and jack stands

- Oil filter wrench

Each tool serves a unique purpose, enabling one to access and manipulate various components effectively. Here are additional essentials:

- Diagnostic scanner

- Wire brush

- Funnel

- Safety goggles

- Mechanic’s gloves

Equipping oneself with these instruments will greatly improve the likelihood of a successful repair and ensure that all tasks are completed with precision.

Expert Recommendations for Upgrades

Enhancing the performance and efficiency of your vehicle can be an exciting journey. With the right modifications, you can improve handling, increase power output, and elevate overall driving enjoyment. This section provides insights into strategic enhancements that can transform your automotive experience.

Performance Enhancements

- Consider upgrading the intake system. A high-flow air intake can improve airflow, resulting in better combustion and increased horsepower.

- Invest in a performance exhaust system. This not only enhances sound but also reduces back pressure, allowing for improved engine efficiency.

- Explore tuning options. Reprogramming the engine control unit (ECU) can optimize fuel delivery and ignition timing, leading to significant performance gains.

Handling and Stability Improvements

- Upgrade suspension components for better handling. Performance shocks and struts can enhance ride quality and responsiveness.

- Install high-performance tires. Selecting tires with better grip can improve traction and stability during turns.

- Consider adding sway bars. These can reduce body roll and provide a more planted feel when navigating corners.

These recommendations serve as a foundation for elevating your vehicle’s capabilities. Carefully consider each option to achieve the best results tailored to your driving style and preferences.

Understanding Engine Performance Metrics

Analyzing the effectiveness of a power unit is essential for optimizing vehicle dynamics and enhancing driving experience. Various indicators provide insights into how well the machinery operates under different conditions, reflecting its capability and efficiency.

Torque is a crucial metric that represents the rotational force produced, influencing acceleration and overall performance. Higher torque often correlates with better towing capacity and responsiveness.

Horsepower quantifies the power output, impacting top speed and acceleration. Understanding this measurement helps in comparing the vigor of different power sources.

Fuel efficiency, often expressed in miles per gallon or liters per 100 kilometers, indicates how effectively the system converts fuel into motion. Enhancing this aspect is vital for reducing operational costs and environmental impact.

By delving into these metrics, one can achieve a deeper comprehension of the capabilities and limitations of the machinery, guiding choices for upgrades or maintenance to reach ultimate performance levels.