When it comes to maintaining your outdoor equipment, having a clear understanding of its essential elements is crucial for optimal performance. A thorough exploration of each component allows for better troubleshooting and effective repairs, ensuring longevity and efficiency.

Illustrations of these elements serve as valuable resources, simplifying the identification and understanding of how each part interacts with one another. By visualizing the relationships between the components, you can approach maintenance tasks with confidence.

Whether you are a seasoned technician or a DIY enthusiast, delving into the intricacies of your machine can lead to the ultimate improvement in functionality. Familiarity with the assembly will empower you to tackle any issues that arise, making your experience with the equipment much more rewarding.

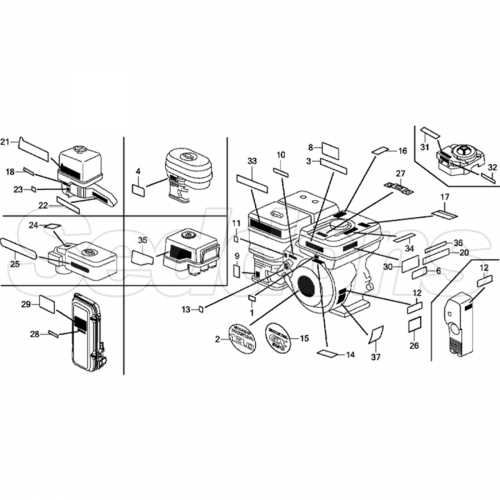

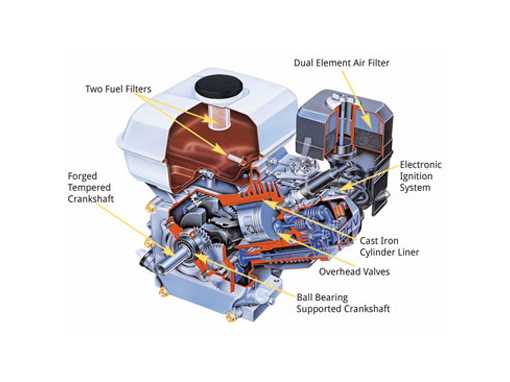

Understanding the Honda GX390

This section aims to provide an in-depth look at a specific engine model renowned for its reliability and performance. Its design and features make it suitable for a variety of applications, showcasing a blend of power and efficiency that meets the demands of both professional and recreational users.

Key Features

One of the standout aspects of this engine is its robust construction, which ensures durability under challenging conditions. It is equipped with advanced technology that optimizes fuel consumption while maintaining high output. Users appreciate the ease of maintenance and the availability of replacement components, which enhance the overall longevity of the unit.

Applications and Benefits

This engine is widely utilized across different sectors, from construction to home improvement. Its versatility allows it to adapt to various tasks, providing significant benefits in terms of time and efficiency. The powerful performance not only improves productivity but also ensures user satisfaction, making it a preferred choice among many operators.

Importance of Pressure Washer Parts

Understanding the components of cleaning machines is essential for optimal performance and longevity. Each element plays a vital role in the overall functionality, ensuring that the device operates efficiently and effectively.

Regular maintenance of these components not only enhances cleaning power but also reduces the risk of breakdowns. When all elements are in good condition, users can achieve the ultimate results in their cleaning tasks.

Investing time in learning about each component allows for better troubleshooting and repair, leading to a smoother operation. Knowledge of how each piece contributes to the whole makes for a more informed user, ultimately enhancing the cleaning experience.

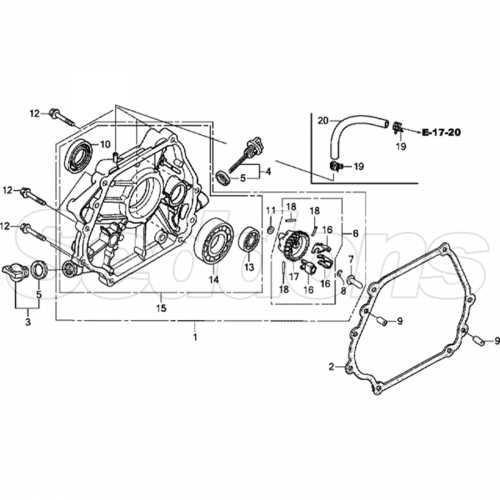

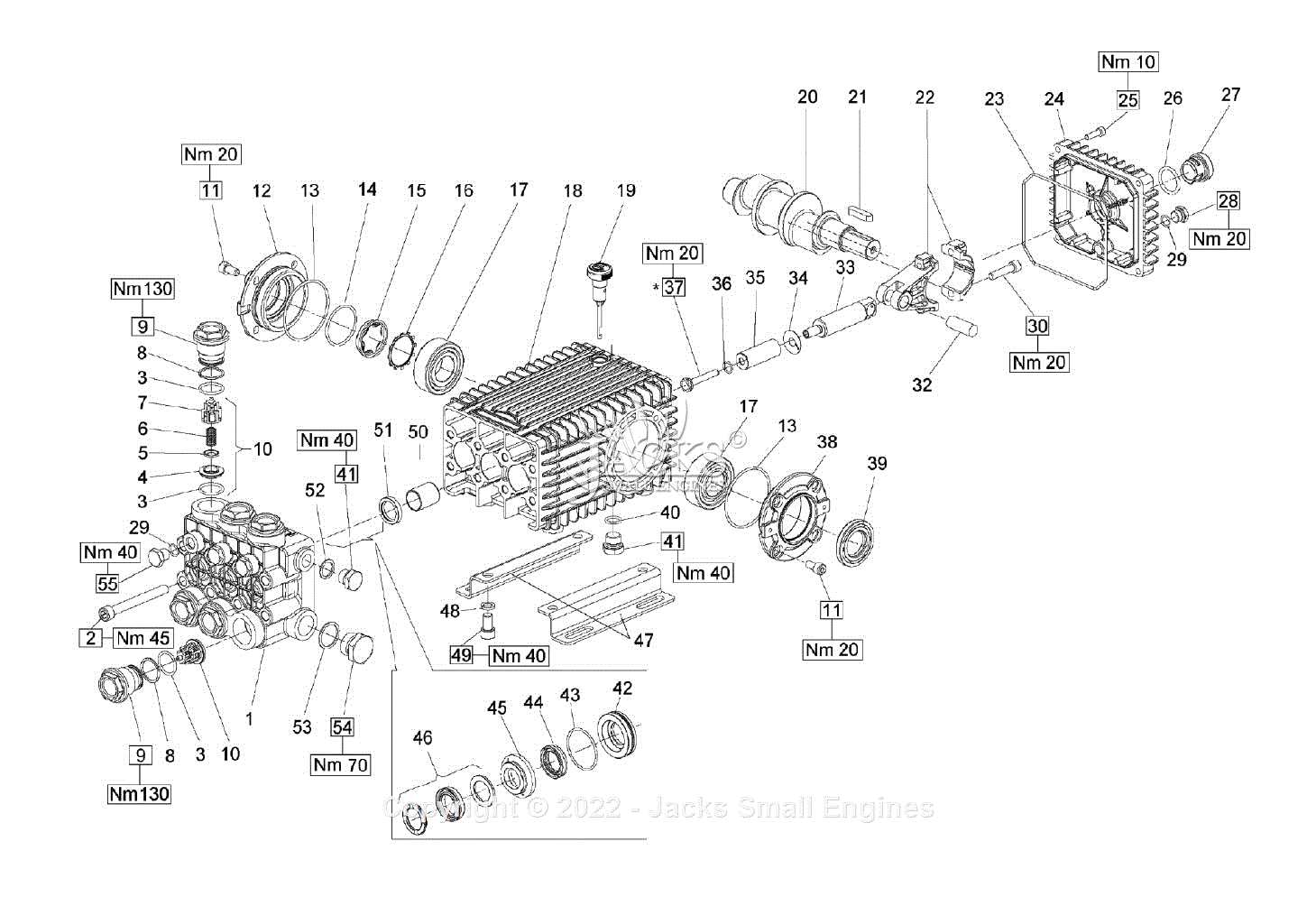

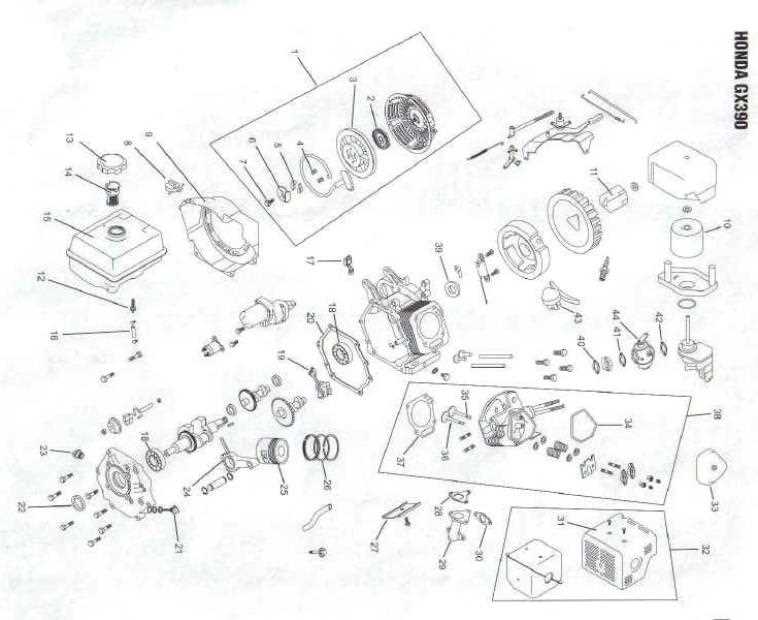

Overview of Parts Diagram

The illustration of components serves as a vital reference for understanding the intricate assembly of equipment. It provides a detailed representation of each element, enabling users to identify and locate individual sections easily. This resource is essential for both maintenance and repairs, ensuring that all parts are correctly positioned and functional.

Importance of Understanding the Components

Grasping the layout of the elements is crucial for effective troubleshooting and upkeep. Knowledge of how each part interacts with others allows for more efficient repairs and enhances overall performance. Furthermore, it helps in preventing potential malfunctions caused by incorrect assembly or misplacement.

Utilizing the Illustration for Maintenance

When engaging in routine care or replacements, the schematic can guide users in selecting the right components. Following the visual guide minimizes errors and saves time, making it an invaluable tool for anyone working with the machinery. It ultimately supports longevity and reliability in operation.

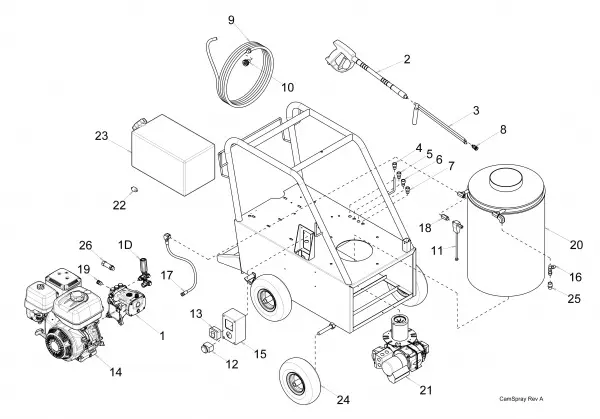

Main Components of GX390 Model

The model in question is equipped with several essential elements that work in harmony to ensure optimal performance and efficiency. Understanding these components is crucial for effective maintenance and troubleshooting.

Engine: The powerhouse of the unit, this component provides the necessary energy to drive all operations. It is designed for durability and reliability, often featuring a robust design to withstand various conditions.

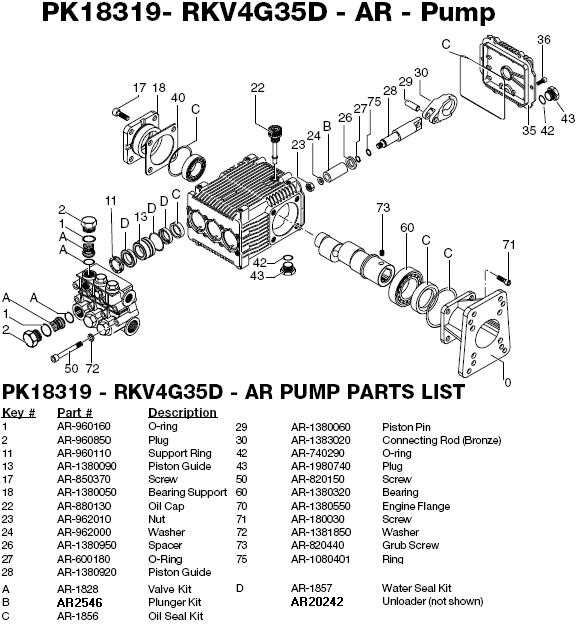

Pump: This integral part is responsible for generating the required flow and pressure of the fluid. It is engineered to deliver consistent performance, making it vital for the overall functionality of the system.

Frame: The structure that houses all components, ensuring stability and support during operation. A sturdy frame contributes to the longevity of the entire assembly.

Hoses: These flexible conduits are essential for transporting the fluid from the pump to the nozzle. Their quality and condition directly impact the effectiveness of the operation.

Nozzle: The outlet that directs the flow, allowing for various patterns and intensities. The design of the nozzle can greatly affect the outcome of the task being performed.

Each of these elements plays a pivotal role in the operation of the model, and regular inspection can enhance performance and extend the lifespan of the equipment.

How to Read the Diagram

Understanding a schematic can significantly enhance your ability to troubleshoot and maintain your equipment. This section will guide you through the essential elements that make up these visual representations, allowing you to interpret them with confidence.

Key Components to Identify

- Symbols: Each symbol represents a specific element or function. Familiarize yourself with these icons to quickly understand what each part does.

- Lines: The connections between symbols indicate how components interact with each other. Pay attention to the types of lines, as they may signify different relationships or functions.

- Labels: Text annotations provide critical information about sizes, specifications, or additional notes that are vital for proper assembly or troubleshooting.

Steps for Effective Reading

- Start from the top: Begin at the top of the diagram and work your way down. This often reflects the flow of operation.

- Follow the connections: Trace the lines between symbols to understand how each component interacts with others.

- Refer to the legend: If a key or legend is provided, consult it to decode any unfamiliar symbols or abbreviations.

- Cross-reference: Use the schematic alongside the user manual or service guide for additional context and details.

Common Issues and Solutions

When using high-powered cleaning machines, users often encounter several typical challenges that can hinder performance. Understanding these issues and their resolutions is essential for maintaining efficiency and extending the lifespan of the equipment.

Low Pressure Problems

One frequent issue is insufficient water pressure. This can stem from clogged filters, damaged hoses, or incorrect nozzle selection. To resolve this, check for any blockages, ensure hoses are in good condition, and use the appropriate nozzle for your task.

Engine Starting Difficulties

Another common concern is trouble starting the engine. This can be caused by stale fuel, a faulty spark plug, or low oil levels. To address this, replace old fuel, check and change the spark plug if necessary, and maintain proper oil levels to ensure smooth operation.

Replacing Worn Out Parts

Maintaining the efficiency of your equipment is crucial for optimal performance. Over time, components can wear down, affecting functionality and reliability. Identifying and replacing these worn elements is essential to ensure your machine operates smoothly.

Signs of Wear and Tear

- Unusual noises during operation

- Decreased performance or output

- Visible damage or corrosion on components

- Leaks or fluid loss

Replacement Steps

- Disconnect the power source for safety.

- Inspect the machine thoroughly to locate worn items.

- Gather necessary replacement components.

- Follow the manufacturer’s instructions for installation.

- Test the equipment to ensure proper function.

Maintenance Tips for Longevity

To ensure the prolonged functionality and reliability of your equipment, regular upkeep is essential. Implementing a few straightforward practices can significantly enhance performance and extend its lifespan.

Regular Inspection: Periodically examine all components for signs of wear and tear. Look for loose connections, cracks, or any other irregularities that could affect operation.

Cleanliness: Keep the machinery free from dirt and debris. A clean environment not only improves efficiency but also prevents potential damage caused by accumulated grime.

Fluid Checks: Regularly monitor and replace fluids as necessary. This includes oil changes and checking fuel quality, as proper lubrication is crucial for optimal performance.

Storage Practices: When not in use, store the equipment in a dry and sheltered location. Covering it will help protect against environmental factors that could cause deterioration.

Follow the Manual: Adhere to the manufacturer’s guidelines for maintenance schedules and procedures. These recommendations are designed to optimize the longevity and functionality of your device.

By implementing these maintenance tips, you can ensure that your equipment remains in excellent working condition for years to come.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing quality components is essential for optimal performance. There are several avenues to explore when searching for replacements, ensuring you find the right items efficiently.

- Authorized Dealers: These outlets offer genuine components that meet manufacturer standards, providing peace of mind regarding quality and compatibility.

- Online Retailers: Websites dedicated to equipment supply often carry a vast selection. Check reviews and ratings to gauge reliability.

- Local Hardware Stores: Many community stores stock a variety of components and can provide personalized assistance in finding what you need.

- Salvage Yards: For those on a budget, salvage yards can be a treasure trove of usable items, though condition varies.

- Manufacturer’s Website: Directly visiting the producer’s site can reveal options for purchasing parts, along with detailed specifications.

By exploring these resources, you can ensure that your equipment remains in excellent condition and continues to operate effectively.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks on machinery, having the right instruments at your disposal is essential for effective and efficient work. This section will outline the necessary tools that will aid in the repair process, ensuring everything runs smoothly.

Essential Hand Tools: A reliable set of wrenches, screwdrivers, and pliers are fundamental. These tools will allow you to manipulate various components with precision.

Power Tools: For more extensive repairs, electric drills and impact wrenches can significantly speed up the process. They provide the ultimate efficiency needed for tough jobs.

Safety Gear: Always prioritize safety by wearing gloves, goggles, and ear protection. This gear is vital to protect yourself while working on any equipment.

Cleaning Supplies: To ensure optimal performance, having brushes, rags, and cleaning solvents on hand will help maintain the integrity of the machine.

By assembling these tools, you will be well-equipped to tackle any repair project confidently and effectively.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is essential to prevent accidents and injuries. Proper precautions should be taken to create a secure environment for both the technician and the equipment being serviced.

Wear Protective Gear

Always use appropriate personal protective equipment (PPE) such as gloves, goggles, and masks. This gear safeguards against potential hazards that may arise during repairs, including sharp objects and harmful substances.

Disconnect Power Sources

Before beginning any repair work, ensure that all power sources are disconnected. This step is crucial to avoid electrical shocks or unintentional activation of the machinery while you are working on it.

FAQs About GX390 Pressure Washers

This section aims to address common inquiries regarding a popular model known for its efficiency and durability. Below are frequently asked questions that can help users better understand its features and maintenance.

- What is the power output of this model?

The engine typically delivers around 13 horsepower, providing ample force for a variety of cleaning tasks.

- What type of fuel is recommended?

Regular unleaded gasoline is usually advised for optimal performance. It is important to avoid using fuel with high ethanol content.

- How often should I change the oil?

It’s generally recommended to change the oil every 50 hours of operation or at least once a year, whichever comes first.

- What maintenance tasks are essential?

- Check and clean the air filter regularly.

- Inspect the spark plug for wear and replace if necessary.

- Ensure that all connections and hoses are secure and free of leaks.

- Can I use different nozzles?

Yes, a variety of nozzles can be utilized to achieve different spray patterns and pressures, making it versatile for various cleaning applications.

- What safety precautions should I take?

- Always wear protective gear, such as gloves and goggles.

- Ensure the work area is clear of obstacles and hazards.

- Never aim the spray at yourself or others.