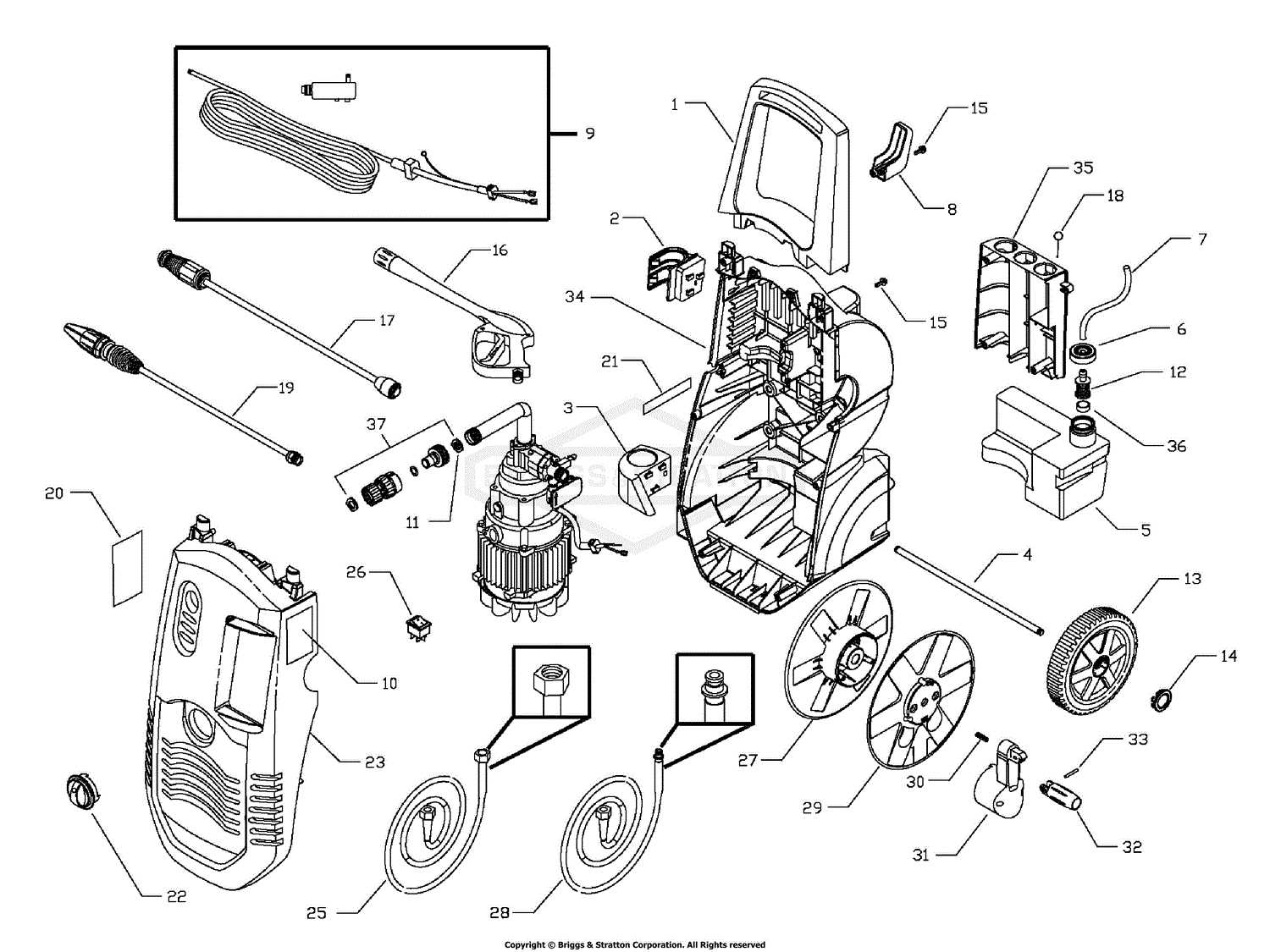

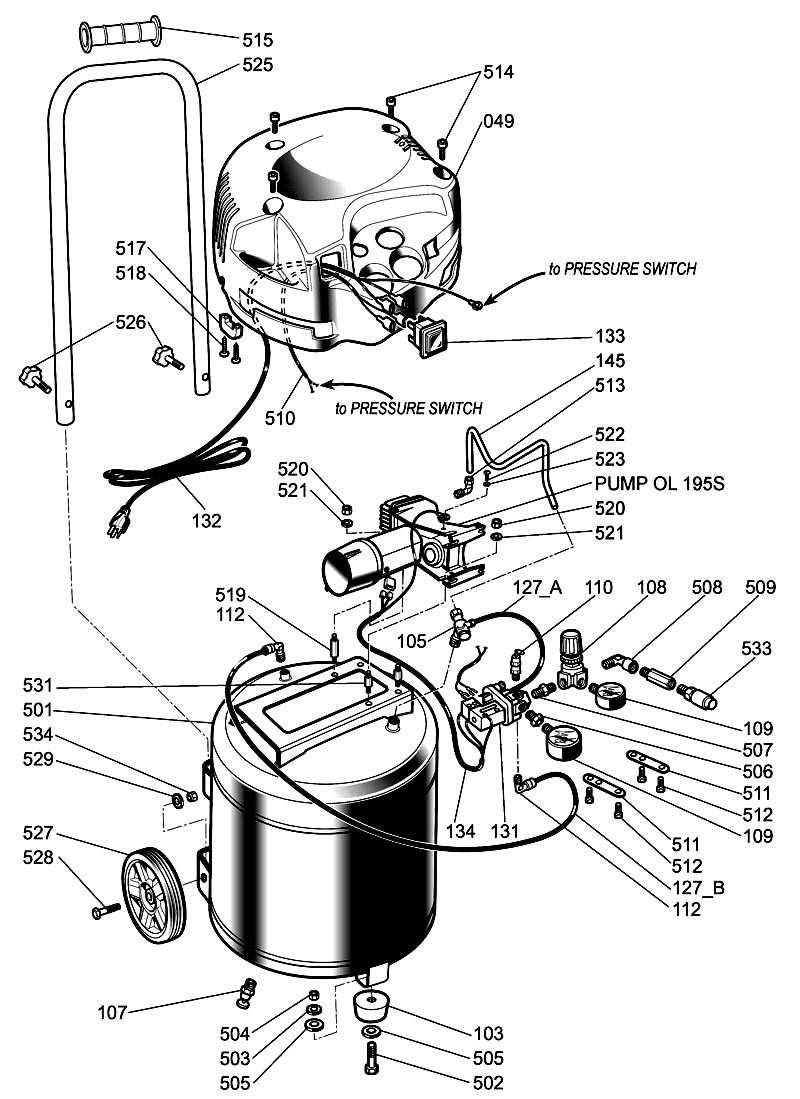

Maintaining and troubleshooting your cleaning device can be a straightforward task when you have a clear visual representation of its components. Such illustrations can greatly enhance your understanding of how the various elements work together to ensure optimal performance. By familiarizing yourself with the layout and functions of these parts, you can effectively manage repairs and maintenance.

Each component plays a critical role in the overall functionality of the machine, and recognizing these parts can save you time and resources. Whether you are looking to replace a worn-out section or simply seeking to improve your equipment’s efficiency, having a reference guide is invaluable.

In this guide, you will discover a detailed overview that simplifies the complexities of your device’s inner workings. By following this structured representation, you will gain insights that empower you to keep your equipment in top shape.

Understanding Husky Pressure Washer Components

This section explores the various elements that make up a cleaning device, highlighting their functions and importance. Recognizing these components is essential for effective maintenance and troubleshooting.

Each segment plays a crucial role in the overall operation, ensuring optimal performance and longevity of the equipment. Familiarity with these parts can aid in identifying issues and making informed decisions during repairs.

| Component | Description |

|---|---|

| Motor | Provides the necessary power to drive the machine, ensuring efficient operation. |

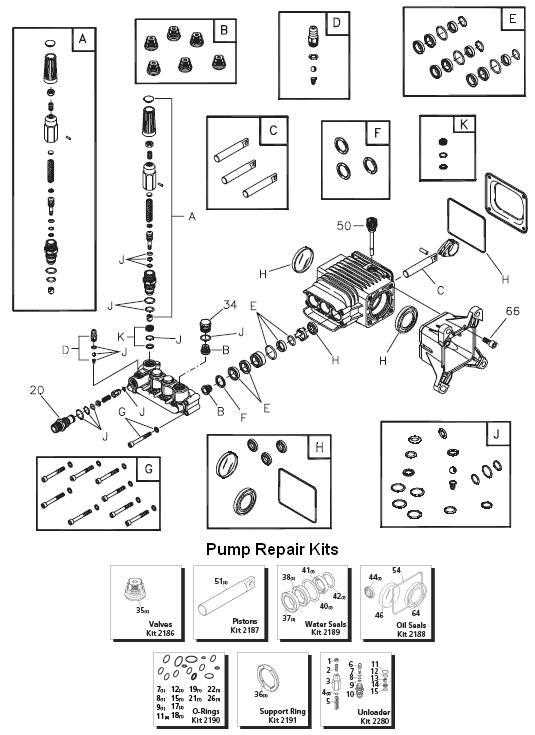

| Pump | Generates the pressure required for effective cleaning, utilizing water flow. |

| Hose | Delivers water from the unit to the cleaning nozzle, designed to withstand high pressure. |

| Nozzle | Controls the spray pattern, allowing for different cleaning techniques based on the task. |

| Trigger | Engages and disengages the water flow, providing user control during operation. |

Key Parts of Pressure Washers

Understanding the essential components of cleaning devices is crucial for effective maintenance and optimal performance. Each element plays a significant role in ensuring that the equipment operates efficiently, providing the desired results for various cleaning tasks.

Motor and Pump

The motor serves as the powerhouse, generating the necessary energy to drive the system. The pump, in turn, pressurizes the water, allowing it to be expelled forcefully. Together, these components are vital for achieving the high performance expected from these machines.

Spray Nozzle and Hose

The spray nozzle is responsible for directing the flow of water, with various types designed for specific cleaning applications. The hose connects the device to the water source and must be durable enough to withstand the pressure generated during operation. Proper selection and maintenance of these elements enhance the overall effectiveness of the equipment.

How to Read Parts Diagrams

Understanding technical illustrations can enhance your maintenance experience. These visuals serve as guides, simplifying the identification and organization of various components in a device. Familiarity with the layout and symbols used is essential for effective interpretation.

To effectively decode these visuals, focus on the following aspects:

| Element | Description |

|---|---|

| Labels | Indicate the name or number of each element, aiding in quick identification. |

| Lines | Connect different components, showing how they relate or fit together. |

| Keys | Provide explanations for symbols used in the illustration, clarifying their meaning. |

| References | May point to further documentation or specifications for deeper understanding. |

By mastering these elements, you can navigate illustrations with confidence and effectively manage your equipment.

Common Issues with Pressure Washers

Many users encounter various challenges when using high-powered cleaning devices. Understanding these frequent problems can help enhance performance and prolong the lifespan of the equipment.

Low Water Pressure: This is a common complaint, often caused by a clogged filter or hose. Regular maintenance is essential to prevent this issue.

Inconsistent Spray Pattern: If the spray is uneven, it may indicate a blocked nozzle. Cleaning or replacing the nozzle can resolve this problem effectively.

Overheating: Overuse or lack of adequate cooling can lead to overheating. It’s important to allow the machine to rest periodically during extended use.

Leaks: Water leaks can arise from worn-out seals or loose connections. Regularly inspecting and tightening components can help mitigate this issue.

Maintenance Tips for Optimal Performance

To ensure your cleaning equipment operates at its best, regular upkeep is essential. Proper maintenance not only extends the lifespan of your device but also enhances its efficiency. Implementing a routine care regimen can prevent common issues and ensure optimal results during use.

1. Regular Cleaning: Keep the exterior and components free from debris and buildup. A clean surface promotes better performance and reduces wear.

2. Inspect Components: Routinely check essential parts for signs of damage or wear. Addressing minor issues early can prevent major repairs later.

3. Fluid Checks: Ensure that all fluids are at the correct levels and replace any that are contaminated. Proper lubrication is crucial for smooth operation.

4. Seasonal Maintenance: Prepare your equipment for seasonal changes. Store it in a dry place and protect it from extreme temperatures to avoid deterioration.

5. Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance recommendations and adhere to suggested schedules.

By following these guidelines, you can maintain your cleaning apparatus effectively, ensuring it remains reliable and efficient for all your tasks.

Identifying Replacement Parts Easily

Finding the right components for your equipment can often seem challenging. However, by utilizing clear illustrations and comprehensive guides, you can simplify the process significantly. Understanding the layout of your device will allow you to identify necessary elements quickly and efficiently.

Utilizing Visual Guides

Visual aids are essential when it comes to recognizing individual components. Diagrams can help illustrate the location and function of each item, making it easier to pinpoint what needs replacing. By cross-referencing these visuals with your equipment, you can ensure that you are choosing the correct parts.

Understanding Component Functionality

It’s also important to familiarize yourself with the functionality of each element within your system. Knowing how each part interacts with others will aid in troubleshooting issues and selecting appropriate replacements. This knowledge empowers you to maintain your device in optimal working condition.

Exploring Pressure Washer Attachments

Attachments enhance the functionality of cleaning machines, allowing for a versatile range of tasks. These tools can dramatically improve efficiency and effectiveness, tailoring the experience to meet specific needs.

Types of Attachments

- Spray Nozzles: Varying pressure and spray patterns for different surfaces.

- Brushes: Ideal for scrubbing stubborn grime from various surfaces.

- Extension Wands: Reach high or distant areas without straining.

- Surface Cleaners: Provide a broader cleaning area, perfect for flat surfaces.

Benefits of Using Attachments

- Increased versatility for different cleaning tasks.

- Enhanced cleaning efficiency, reducing time spent on chores.

- Ability to tackle a wider variety of materials and surfaces.

Safety Features in Pressure Washers

Ensuring user protection is paramount in high-performance cleaning equipment. Various mechanisms and design elements are implemented to minimize risks during operation, making the experience safer and more efficient.

Automatic Shutdown Mechanism

This feature activates when the unit is not in use, preventing accidental activation. It helps to conserve energy and reduce wear on components, ultimately extending the lifespan of the device.

Ergonomic Design

A well-thought-out design enhances control and reduces strain on the user. Features such as comfortable handles and balanced weight distribution allow for easier handling, which significantly decreases the likelihood of accidents.

Essential Tools for Repairing Washers

Having the right equipment is crucial for maintaining and fixing cleaning devices. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed effectively and safely. Understanding the necessary tools can empower users to tackle repairs with confidence.

Basic Hand Tools

Common hand tools like screwdrivers, wrenches, and pliers are fundamental for any repair job. Flathead and Phillips screwdrivers are essential for removing various screws, while adjustable wrenches help manage different sizes of nuts and bolts. Pliers can assist in gripping and twisting components as needed.

Specialized Equipment

In addition to standard hand tools, specialized equipment can enhance repair efficiency. Socket sets provide the versatility required for various fasteners, while multimeters are invaluable for diagnosing electrical issues. Investing in a pressure gauge can also be beneficial for ensuring optimal functionality.

Comparing Different Husky Models

This section explores various models offered by a renowned brand, highlighting their unique features and specifications. By examining these options, users can better understand which model best suits their needs.

Model Features Overview

Each model in the lineup comes with distinct functionalities that cater to different applications. From compact versions designed for light tasks to robust options built for heavy-duty use, there is something for everyone. Assessing the capabilities of each unit helps in making an informed choice.

Performance and Efficiency

When it comes to performance, different units exhibit varying levels of efficiency. Some models prioritize speed, while others focus on delivering optimal results with lower energy consumption. Evaluating these aspects is essential for users seeking to maximize their investment.

Upgrading Components for Efficiency

Enhancing the functionality of your cleaning equipment can significantly improve its performance and longevity. By focusing on key components, you can achieve better results and reduce operational costs.

Assessing Current Features is the first step in identifying areas for improvement. Evaluate the existing elements to determine which ones may be underperforming or outdated. This will help you prioritize upgrades that will yield the most benefit.

Choosing Quality Replacements is essential. Opt for high-quality materials and parts that offer superior durability and efficiency. Investing in reliable components can lead to better cleaning performance and a longer lifespan for your equipment.

Regular Maintenance should not be overlooked. Keeping all upgraded components in optimal condition ensures they function effectively. Implementing a routine maintenance schedule can prevent wear and tear, maximizing the efficiency of your cleaning tasks.

By upgrading components thoughtfully and maintaining them properly, you can enhance the overall efficiency of your cleaning system, leading to satisfying results and reduced workload.

Wiring Diagram Overview for Repairs

This section provides a comprehensive understanding of electrical schematics essential for effective maintenance. Familiarity with these visuals aids in troubleshooting and ensures that all connections are correctly made, enhancing the longevity of the equipment.

By analyzing the layout, users can identify the placement of wires and components, making it easier to pinpoint issues during repairs. This knowledge empowers individuals to approach fixes with confidence and precision, minimizing downtime and enhancing operational efficiency.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for ensuring optimal performance and longevity. There are several reliable sources to explore, each offering various options to meet your needs.

Authorized retailers often stock original items directly from the manufacturer, guaranteeing quality and compatibility. Additionally, online marketplaces may provide a wide selection, but it’s essential to verify the seller’s reputation to avoid counterfeit products.

Local repair shops frequently have access to genuine supplies and can offer expert advice on selection and installation. Joining online forums or community groups can also yield valuable recommendations and insights from fellow users.