When it comes to maintaining your outdoor cleaning tools, a clear comprehension of their individual elements is essential. Knowing how these components function together can enhance efficiency and prolong the lifespan of the equipment. This guide aims to shed light on the intricate relationships between various sections of the unit.

Whether you are a DIY enthusiast or a professional, having access to a visual representation of the essential mechanisms can significantly streamline repairs and maintenance. Each element plays a crucial role in achieving optimal performance, making it vital to grasp their configurations.

By delving into the layout of these crucial components, users can confidently navigate assembly and disassembly, ensuring effective troubleshooting and efficient usage. Let’s explore the ultimate schematic of these elements for better understanding and care.

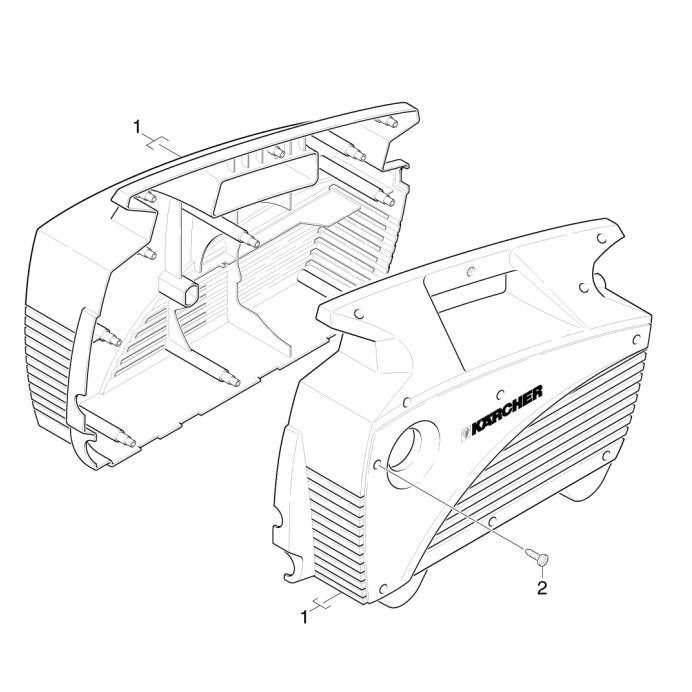

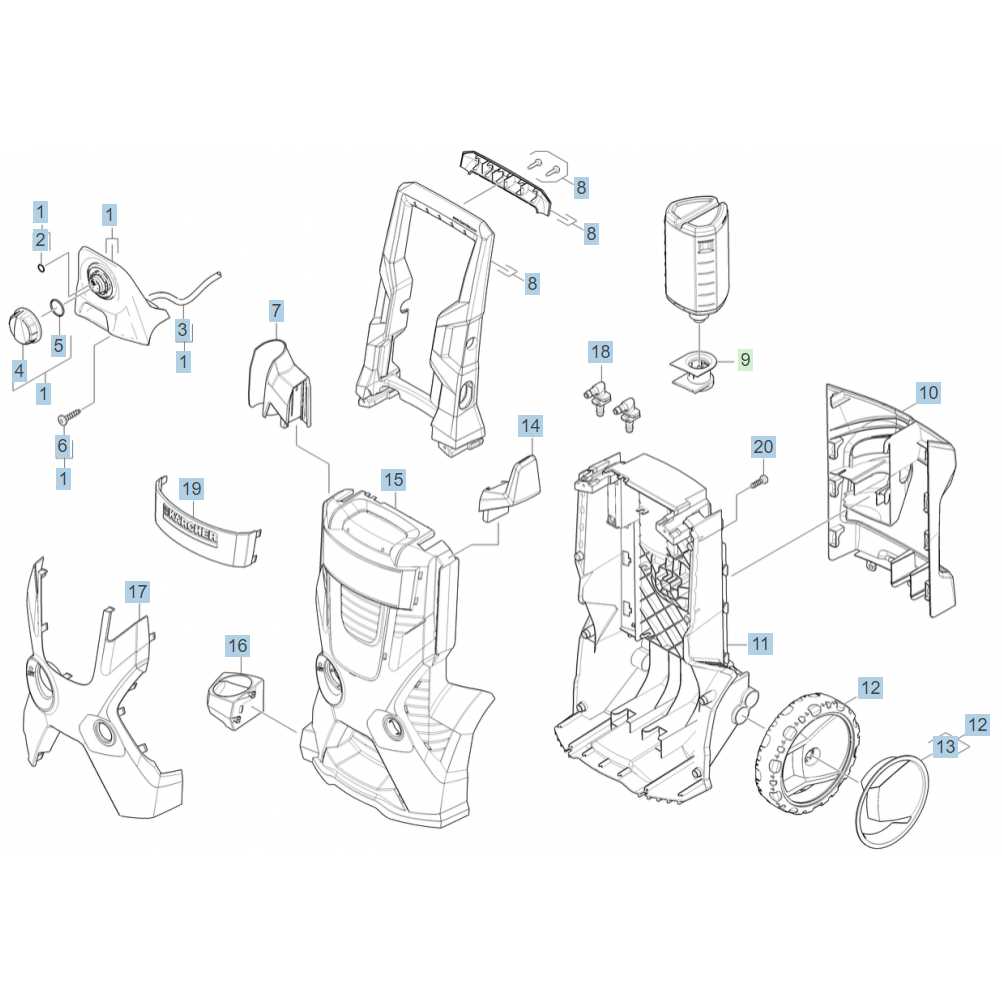

Karcher K5 Pressure Washer Overview

The K5 model represents a powerful solution for tackling outdoor cleaning tasks. Designed for efficiency, it offers a robust performance that meets the demands of both residential and light commercial use. Its user-friendly features make it accessible for anyone looking to achieve professional-level results with minimal effort.

This equipment is equipped with a reliable motor and advanced technology that ensures optimal water flow and pressure, allowing users to remove dirt and grime from various surfaces effectively. The innovative design promotes ease of handling, making it suitable for a wide range of applications, from washing vehicles to cleaning patios.

Overall, the K5 stands out for its combination of power, efficiency, and adaptability, making it an ideal choice for those seeking an effective cleaning solution that simplifies maintenance chores.

Understanding Pressure Washer Components

To effectively utilize any cleaning device, it’s essential to comprehend its fundamental elements and how they interact. Each component plays a crucial role in ensuring optimal functionality, allowing users to achieve desired results efficiently. A deeper understanding can enhance the overall experience and prolong the lifespan of the equipment.

Main Functional Elements

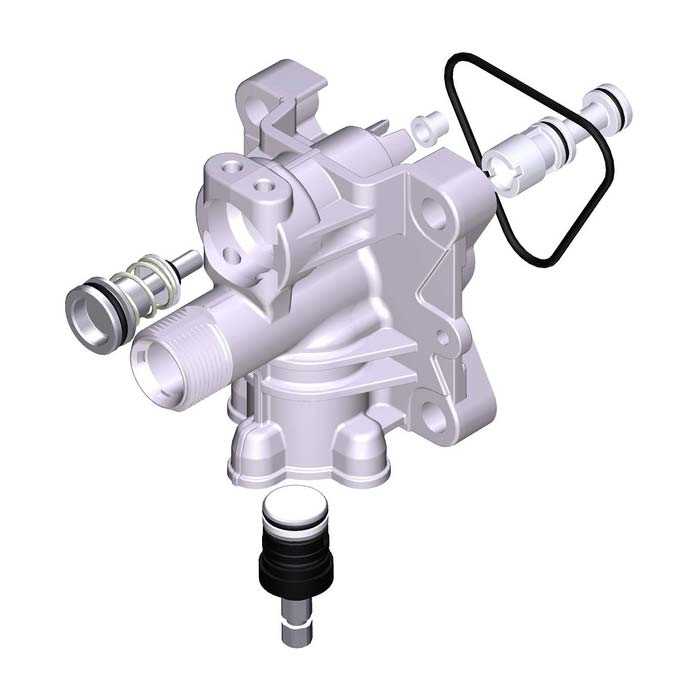

At the heart of the device is the motor, responsible for generating the necessary force. This is complemented by the pump, which amplifies the pressure, enabling the flow of water to effectively tackle various surfaces. The connection between these components is vital, as it dictates the overall performance and efficiency of the system.

Beyond the core elements, additional accessories significantly contribute to versatility. Nozzles offer different spray patterns, adapting to diverse cleaning tasks, while hoses and connectors ensure seamless water flow. Understanding these elements allows users to customize their cleaning experience and optimize the device for specific applications.

Importance of Proper Maintenance

Ensuring optimal performance and longevity of your cleaning equipment is crucial for achieving the best results in your tasks. Regular upkeep not only enhances efficiency but also prevents potential issues that could arise from neglect. A well-maintained device operates smoothly, providing reliable service whenever needed.

Timely inspections play a key role in identifying wear and tear. Components that are regularly checked and maintained are less likely to suffer from unexpected breakdowns. Additionally, replacing worn parts proactively can save time and money in the long run.

Moreover, proper care extends the lifespan of your equipment, allowing you to maximize your investment. By following the manufacturer’s guidelines and performing routine maintenance, you ensure that your cleaning tools remain in excellent condition, ready to tackle any job efficiently.

Common Issues with Karcher K5

Every device may encounter challenges over time, and this model is no exception. Users often report several typical problems that can affect performance and efficiency. Understanding these issues can help in troubleshooting and maintaining the equipment effectively.

- Inconsistent Water Flow: Many users experience fluctuations in water pressure, which can be attributed to clogged filters or hoses.

- Overheating: Extended usage can lead to overheating, especially if the unit is operated continuously without breaks.

- Noisy Operation: Unusual sounds during operation may indicate internal wear or a need for lubrication in moving parts.

- Leaks: Water leakage can occur from connections or seals that have worn out over time.

- Difficulty Starting: Some users find it challenging to start the device, which could be due to electrical issues or a malfunctioning motor.

Regular maintenance and prompt attention to these common problems can extend the lifespan of the equipment and ensure optimal performance.

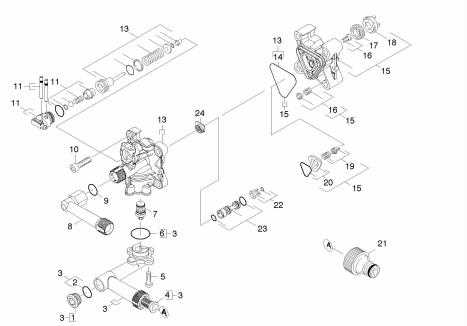

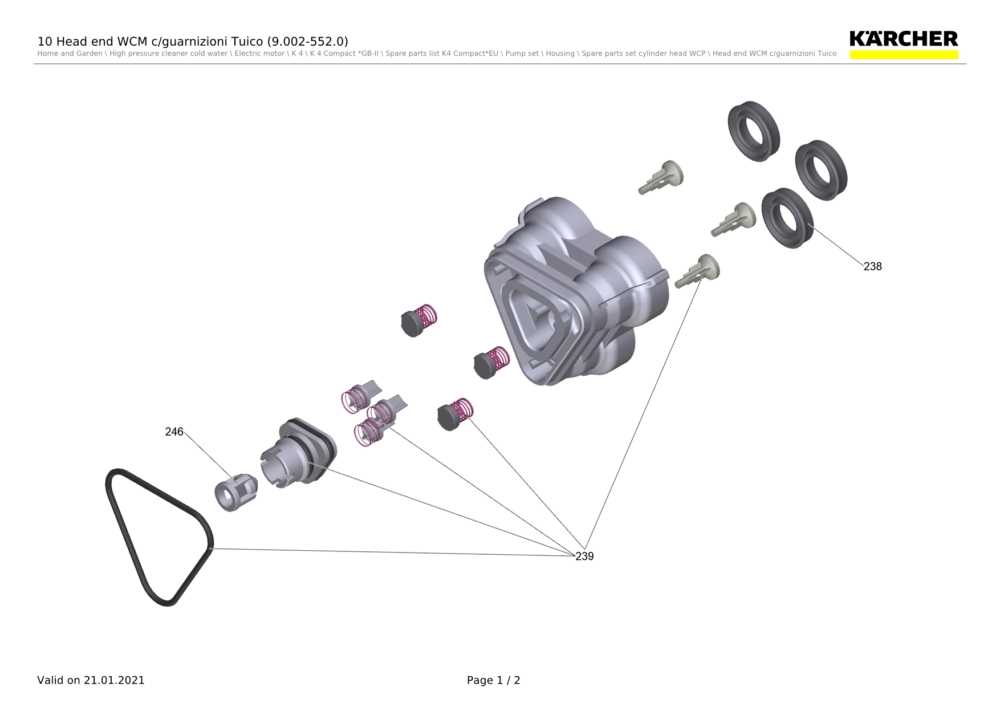

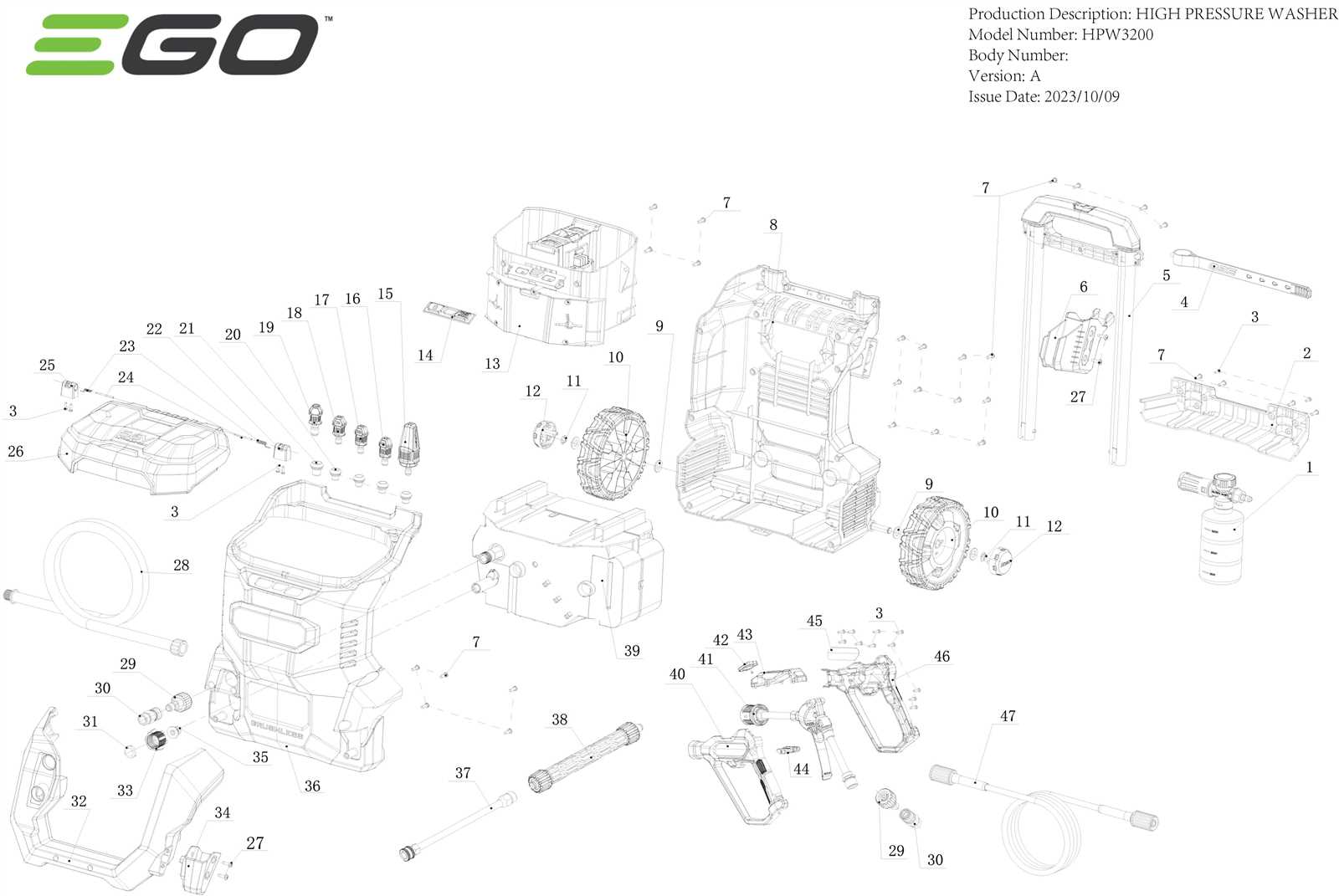

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides, allowing users to identify individual elements and their relationships within a system.

Key Components of Illustrations

- Labels: Each item is usually marked with a unique identifier.

- Legend: This section explains symbols and colors used in the illustration.

- Assembly Sequence: Some diagrams show the order in which components should be assembled or disassembled.

Steps to Interpret Visual Guides

- Start by reviewing the legend to understand symbols.

- Locate the main components to grasp the overall layout.

- Follow the assembly sequence for proper reassembly if needed.

- Cross-reference with a manual for detailed instructions.

Identifying Key Replacement Parts

Understanding the essential components of your cleaning device is crucial for maintenance and optimal performance. Familiarity with each element allows for timely replacements, ensuring that your equipment functions efficiently and effectively. Recognizing the signs of wear and knowing which pieces require attention can prolong the lifespan of your machine and enhance its operational capabilities.

Common elements to focus on include the motor, hose, and nozzles, each playing a significant role in the overall function. The motor is the powerhouse, generating the necessary force for effective cleaning. Hoses, often prone to damage, should be inspected for leaks or cracks. Nozzles, which direct the flow, come in various types and should be chosen based on specific tasks. Ensuring these components are in good condition can significantly impact the results of your cleaning efforts.

Additionally, seals and filters are vital for maintaining performance. Seals prevent leaks and keep internal components protected from debris, while filters ensure that the water used is clean and free from impurities. Regularly checking these items and replacing them when necessary can enhance the efficiency and reliability of your device.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right instruments is essential for a smooth and effective process. These tools not only facilitate the repair but also ensure that the job is done efficiently and safely. Familiarizing yourself with the necessary items can greatly enhance your ability to address any issues that arise.

Commonly required tools include wrenches, screwdrivers, and pliers, which allow you to easily access and manipulate various components. Additionally, a multimeter can be beneficial for diagnosing electrical problems, while lubricants help in maintaining moving parts. A sturdy workbench and good lighting are also important to create an optimal workspace for your repair tasks.

Step-by-Step Repair Guide

This section provides a detailed approach to troubleshooting and restoring your cleaning device. Following these instructions will help you identify common issues and effectively resolve them, ensuring optimal performance and longevity.

Identifying the Problem

Begin by examining the machine for any visible signs of damage or wear. Listen for unusual sounds during operation, which can indicate internal malfunctions. Take note of any leaks or reduced efficiency, as these can guide your diagnosis.

Gathering Necessary Tools

Before starting repairs, collect the essential tools such as screwdrivers, wrenches, and cleaning agents. Having everything on hand will streamline the process and reduce the likelihood of interruptions while you work.

Where to Purchase Spare Parts

When it comes to maintaining your cleaning equipment, finding reliable sources for replacement components is essential. Numerous options are available, ranging from official distributors to online retailers, each providing different advantages in terms of price, availability, and service quality. Identifying the right vendor can help ensure that your equipment remains in top working condition.

Authorized Dealers

Authorized dealers are a great choice for those seeking original components. These vendors guarantee authenticity and compatibility, reducing the risk of installation issues. They often offer warranties, providing peace of mind with your purchase.

Online Marketplaces

Online platforms present a convenient way to browse a wide selection of components. Many sellers offer competitive pricing and customer reviews, helping you make informed decisions. However, it’s crucial to verify the reputation of the seller and the quality of the items.

| Source Type | Advantages | Disadvantages |

|---|---|---|

| Authorized Dealers | Original components, warranty support | Potentially higher prices |

| Online Marketplaces | Wide selection, competitive pricing | Quality variability, seller reputation concerns |

Tips for Efficient Operation

Maximizing the effectiveness of your cleaning equipment involves understanding key techniques and practices. By following a few simple guidelines, you can achieve superior results while extending the lifespan of your device.

Preparation Steps

- Ensure the area is free of obstacles to facilitate easy movement.

- Gather all necessary accessories beforehand to avoid interruptions.

- Inspect the equipment for any damage or wear before starting.

Operational Techniques

- Start with a low setting and gradually increase the intensity as needed.

- Maintain a consistent distance from the surface being cleaned to prevent damage.

- Utilize appropriate nozzles for different surfaces to optimize cleaning power.

- Work from the top down to avoid re-cleaning lower areas.