In the realm of home appliances, comprehending the intricate workings of your equipment is essential for optimal performance and maintenance. Familiarity with each element allows users to troubleshoot issues effectively and enhance the lifespan of their devices. This exploration delves into the key components that contribute to functionality and efficiency.

Every device is comprised of a variety of essential elements, each playing a crucial role in the overall operation. Recognizing these individual parts and their interactions can demystify common problems, empowering users to take control of their home care routine. From mechanical mechanisms to electronic systems, a clear understanding fosters a more informed approach to maintenance.

In this guide, we will provide an insightful look into the layout and function of each component, allowing users to identify potential issues and make informed decisions regarding repairs and replacements. By equipping yourself with this knowledge, you can ensure that your appliance operates smoothly and efficiently for years to come.

Understanding the Whirlpool Cabrio Washing Machine

This section aims to provide insights into the functionality and design of a popular laundry appliance. By exploring its components and how they interact, users can gain a better understanding of its efficiency and operation. Knowledge of the inner workings enhances troubleshooting and maintenance, ensuring longevity and optimal performance.

Key Features

The appliance boasts several innovative attributes that set it apart from traditional models. Its unique design facilitates improved water usage and energy efficiency, contributing to both environmental sustainability and cost savings. Below is a summary of these essential characteristics:

| Feature | Description |

|---|---|

| Energy Efficiency | Designed to minimize power consumption while delivering excellent cleaning results. |

| Load Sensing | Automatically adjusts water levels based on the size of the load for optimal cleaning. |

| Quiet Operation | Engineered to operate with reduced noise, enhancing the user experience. |

| Custom Cycles | Offers various washing programs tailored to different fabric types and soil levels. |

Maintenance Tips

Regular upkeep is essential for sustaining the performance of the unit. Users should consider the following recommendations to ensure it remains in top condition:

- Check and clean filters regularly to prevent clogs.

- Run cleaning cycles to eliminate residue buildup.

- Inspect hoses for wear and replace as necessary.

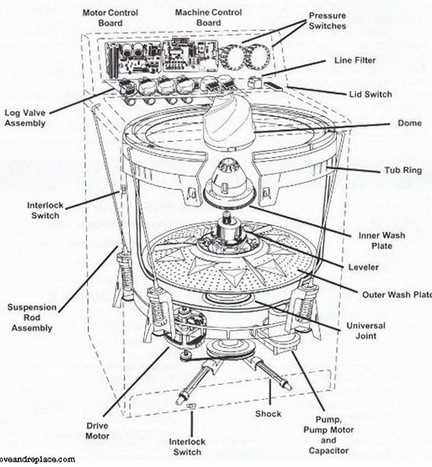

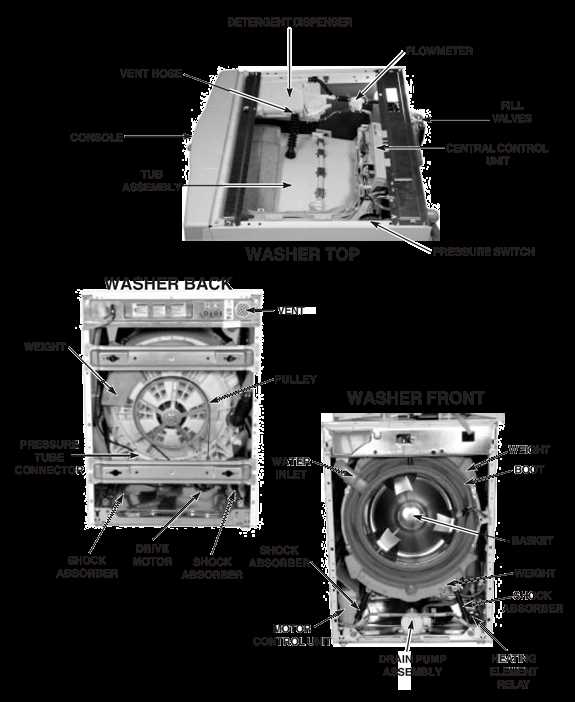

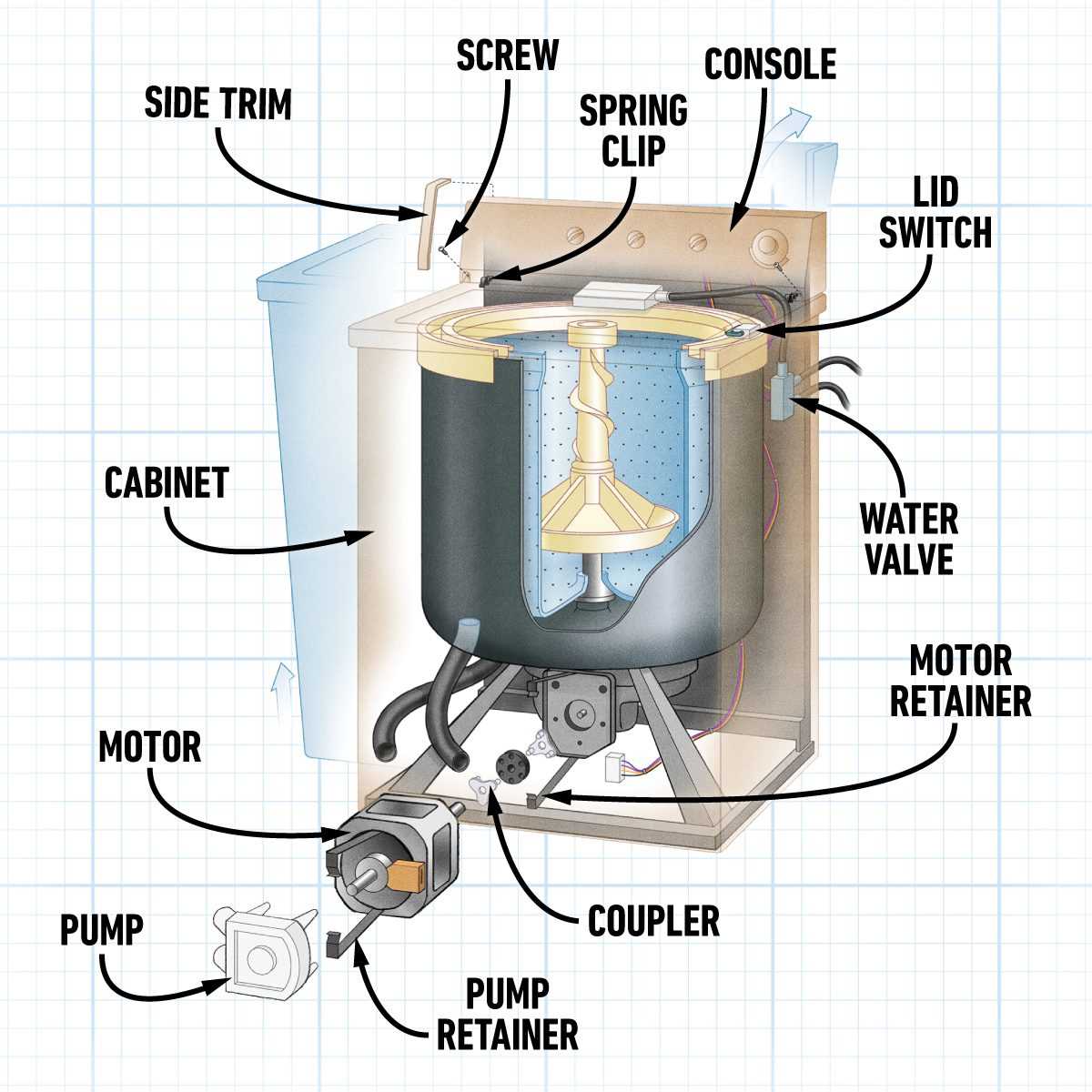

Key Components of the Cabrio Model

This section explores the essential elements that contribute to the functionality and efficiency of this innovative appliance. Understanding these components can enhance user experience and maintenance practices.

- Drum: The central part where items are placed for cleaning, designed for optimal movement and water circulation.

- Control Panel: The interface for selecting cycles and settings, equipped with various options for convenience.

- Water Inlet Valve: Regulates the flow of water into the system, ensuring proper filling during operation.

- Drain Pump: Essential for removing water post-cycle, preventing overflow and ensuring efficiency.

- Agitator: Provides movement to the load, ensuring thorough cleaning by effectively displacing items.

By delving into each of these crucial elements, users can gain a deeper appreciation for the design and engineering that drives performance.

Common Issues and Troubleshooting Tips

Understanding frequent challenges and their solutions can significantly enhance the lifespan and efficiency of your appliance. By identifying typical problems and applying straightforward fixes, users can ensure optimal performance and prevent future complications.

No Power: If the unit fails to start, check the power source and ensure the outlet is functional. Inspect the cord for any visible damage.

Water Not Draining: This issue may stem from a clogged hose or pump. Examine the drain path for any obstructions and clean as necessary.

Unusual Noises: Strange sounds can indicate foreign objects lodged in the drum. Inspect the interior and remove any items that shouldn’t be there.

Leaks: Leaking fluids often result from worn seals or improperly connected hoses. Carefully examine these areas and replace parts if needed.

Cycle Not Completing: If the program halts prematurely, ensure the door is securely closed and check for any error codes on the display.

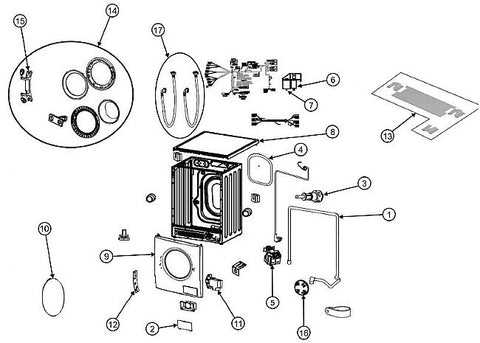

How to Access Internal Parts

Accessing the internal components of your appliance is essential for effective maintenance and troubleshooting. This process often requires careful disassembly, allowing users to reach various elements that may need repair or replacement. Understanding the correct approach ensures safety and efficiency.

Preparation Steps

Before starting, gather the necessary tools such as screwdrivers and pliers. Ensure the appliance is unplugged to avoid electrical hazards. Reviewing the user manual can provide valuable insights into the specific layout and assembly of the device.

Disassembly Process

Begin by removing the exterior panels, typically secured with screws. Once the outer casing is detached, you will have access to the internal framework. Take note of the arrangement of components, which will aid in reassembly. Handle all parts with care to prevent damage.

Importance of Regular Maintenance

Routine care is essential for ensuring longevity and optimal performance of household appliances. By attending to regular upkeep, one can prevent potential issues and enhance efficiency, ultimately saving time and resources.

Neglecting maintenance can lead to various complications, from reduced functionality to complete breakdowns. Understanding the key aspects of upkeep helps in identifying potential problems early and addressing them promptly.

| Benefits of Regular Care | Consequences of Neglect |

|---|---|

| Increased Lifespan | Frequent Repairs |

| Enhanced Efficiency | Higher Utility Bills |

| Consistent Performance | Unexpected Breakdowns |

| Safety Assurance | Potential Hazards |

Ultimately, investing time in proper maintenance routines can lead to significant benefits, ensuring appliances operate smoothly and efficiently for years to come.

Replacing the Control Board Explained

When your appliance experiences operational issues, one common culprit could be the electronic control unit. This component orchestrates various functions and processes, ensuring optimal performance. If malfunctions occur, replacing this unit may be necessary to restore functionality.

Before proceeding with the replacement, it’s crucial to gather the right tools and ensure safety. Disconnect the power source to avoid any risk of electric shock. Familiarize yourself with the layout and connections of the control unit, as this knowledge will simplify the replacement process.

| Step | Description |

|---|---|

| 1 | Turn off the appliance and unplug it from the power source. |

| 2 | Access the control unit by removing the necessary panels or covers. |

| 3 | Carefully disconnect the wiring harness attached to the control board. |

| 4 | Unscrew the control board from its mounting and remove it from the appliance. |

| 5 | Install the new control board by reversing the removal steps. |

| 6 | Reconnect the power source and test the appliance to ensure proper functionality. |

By following these steps, you can effectively replace the control unit and enhance the performance of your appliance, ensuring it operates smoothly for years to come.

Diagnosing Drainage Problems Effectively

Understanding how to identify and resolve drainage issues can save time and prevent further complications. By methodically examining the system, one can pinpoint the root of the problem and implement effective solutions.

Here are some common steps to follow:

- Check the drainage hose for kinks or blockages.

- Inspect the filter for debris that may hinder flow.

- Examine the pump for proper operation; listen for unusual noises.

- Ensure that the water level is appropriate; too high or low can affect drainage.

Additionally, consider these troubleshooting tips:

- Look for leaks around seals and connections.

- Verify that the drainage system is correctly installed and at the right height.

- Run a diagnostic cycle to check for error codes.

By following these steps, one can effectively delve into the underlying issues and work toward a resolution.

Visual Guide to Wiring Connections

This section provides an insightful overview of the electrical linkages found within a common household appliance, focusing on the intricate relationships between various components. Understanding these connections is crucial for effective troubleshooting and maintenance, enabling users to navigate potential issues with confidence.

Color Codes: Familiarize yourself with the standard color coding used in wiring. Each hue signifies specific functions, such as grounding or power, making it easier to identify and follow connections.

Connection Points: Pay attention to the designated terminals on each component. These points are critical for ensuring proper electrical flow, and any disconnection or misalignment can lead to operational failures.

Diagrams: Utilize visual aids to help clarify the layout of connections. Diagrams serve as invaluable tools, providing a clear representation of how different elements interconnect, enhancing your understanding of the overall system.

In conclusion, mastering the wiring connections is vital for anyone seeking to delve deeper into appliance repair and maintenance, ultimately leading to more efficient usage and longevity of the device.

Identifying Belt and Motor Functions

Understanding the roles of the drive components is essential for effective maintenance and troubleshooting. These elements work together to ensure smooth operation, providing the necessary power for various cycles and functionalities.

Drive Belt Overview

The drive belt is a crucial component that transfers power from the motor to the drum assembly. A well-functioning belt enables the rotation needed for effective cleaning. Signs of wear, such as fraying or cracking, should prompt immediate attention to prevent further complications.

Motor Responsibilities

The motor serves as the heart of the operation, generating the force required for both agitation and spin cycles. Its efficiency directly impacts performance; therefore, unusual noises or inconsistent behavior can indicate potential issues. Regular checks can help maintain its ultimate effectiveness.

Understanding the Suspension System

The suspension system plays a crucial role in maintaining stability and performance in laundry appliances. It is designed to absorb vibrations and ensure that the unit operates smoothly during cycles. By keeping the internal components secure, this system helps to prevent excessive wear and tear, thereby extending the lifespan of the appliance.

There are several key components within the suspension framework, each contributing to its overall effectiveness. Understanding these parts can aid in diagnosing issues and ensuring optimal functionality.

| Component | Function |

|---|---|

| Springs | Provide support and absorb shocks during operation. |

| Dampers | Control the movement of the drum to reduce vibrations. |

| Mounting Brackets | Secure the drum to the chassis, maintaining alignment. |

| Shock Absorbers | Minimize movement and stabilize the inner workings. |

By ensuring each element functions correctly, the suspension assembly enhances both performance and durability, making it an integral part of any laundry system.

Detailed Look at the Agitator Assembly

The agitator assembly is a crucial component in the functionality of a laundering device, playing a significant role in the cleaning process. It is designed to create movement within the wash tub, facilitating the effective interaction of water and detergent with garments. Understanding the structure and operation of this assembly can enhance your knowledge of how to maintain and troubleshoot your appliance.

Components of the Agitator Assembly

This assembly typically consists of several key elements that work together to ensure efficient performance. Each part contributes to the overall functionality and can impact the cleaning results if not functioning properly.

| Component | Description |

|---|---|

| Agitator Shaft | The central rod that provides the necessary motion to the upper section of the assembly. |

| Agitator Dogs | Small, tooth-like mechanisms that allow the upper part to rotate in one direction, enabling effective cleaning. |

| Upper Agitator | The portion that moves back and forth, creating agitation within the wash tub. |

| Lower Agitator | This part helps to maintain stability and provides additional motion to the clothing items. |

Importance of Maintenance

Parts List for DIY Repairs

Engaging in home repairs can be rewarding, especially when you have a clear inventory of essential components. Understanding each element and its function can significantly enhance your ability to troubleshoot and fix issues effectively.

- Drive Belt

- Water Inlet Valve

- Drain Pump

- Agitator

- Control Board

- Hoses and Connectors

- Suspension Springs

- Door Lock Assembly

Having access to a comprehensive list not only simplifies repairs but also helps you become familiar with the inner workings of your appliance.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions help create a secure environment, allowing for efficient work without unnecessary risks.

- Always disconnect the power source before starting any repairs.

- Use appropriate tools designed for the task at hand.

- Wear protective gear, such as gloves and safety glasses.

- Ensure the work area is clean and free of hazards.

- Keep children and pets away from the repair site.

Following these guidelines can greatly minimize potential dangers and lead to a smoother repair experience.