For anyone keen on maintaining their outdoor spaces, the intricacies of a high-performance cleaning tool can be pivotal. Having a comprehensive grasp of its components not only enhances its functionality but also prolongs its lifespan. Whether you’re tackling stubborn stains or routine maintenance, knowledge of the inner workings is essential.

In this section, we will explore the essential elements that make up your cleaning device, focusing on their roles and how they interconnect. By breaking down the various components, we can delve into the ultimate strategies for effective use and troubleshooting.

Moreover, understanding these elements allows users to navigate repairs and replacements with confidence. This knowledge empowers you to ensure optimal performance, ensuring your investment continues to serve you well for years to come.

Understanding the Worx Pressure Washer

Maintaining a clean and tidy environment is essential, and one effective way to achieve this is through the use of powerful cleaning devices. These tools utilize high-pressure water streams to remove dirt, grime, and stubborn stains from various surfaces, making them invaluable for both residential and commercial applications.

Key Features of the Device

- High-efficiency motor that delivers exceptional cleaning results.

- Adjustable pressure settings for different surfaces and tasks.

- Compact design for easy storage and transportation.

- Eco-friendly options that reduce water consumption without compromising performance.

Benefits of Using the Device

- Enhances the lifespan of surfaces by preventing wear and tear from built-up dirt.

- Improves the aesthetic appeal of homes and outdoor areas.

- Reduces the time and effort required for cleaning tasks.

- Offers versatility for various applications, including vehicles, patios, and driveways.

Components of a Pressure Washer

Understanding the essential elements of a high-performance cleaning machine is crucial for effective maintenance and operation. Each component plays a significant role in delivering powerful cleaning capabilities and ensuring the longevity of the unit.

Main Elements

- Motor or Engine: Powers the entire system, providing the necessary energy to create high-pressure output.

- Pump: Transforms the motor’s energy into hydraulic energy, pressurizing the water for effective cleaning.

- Nozzle: Directs the flow of water, allowing for various spray patterns to suit different cleaning tasks.

- Hose: Facilitates the movement of water from the pump to the nozzle, usually reinforced for durability.

- Water Inlet: Connects to a water source, allowing the machine to draw in water for the cleaning process.

Additional Features

- Trigger Gun: Enables the operator to control the flow of water, enhancing safety and precision.

- Accessories: Various attachments such as brushes and extension wands to increase versatility.

- Frame: Provides structural support and houses various components, ensuring stability during operation.

- Filter: Protects the internal parts by preventing debris from entering the system.

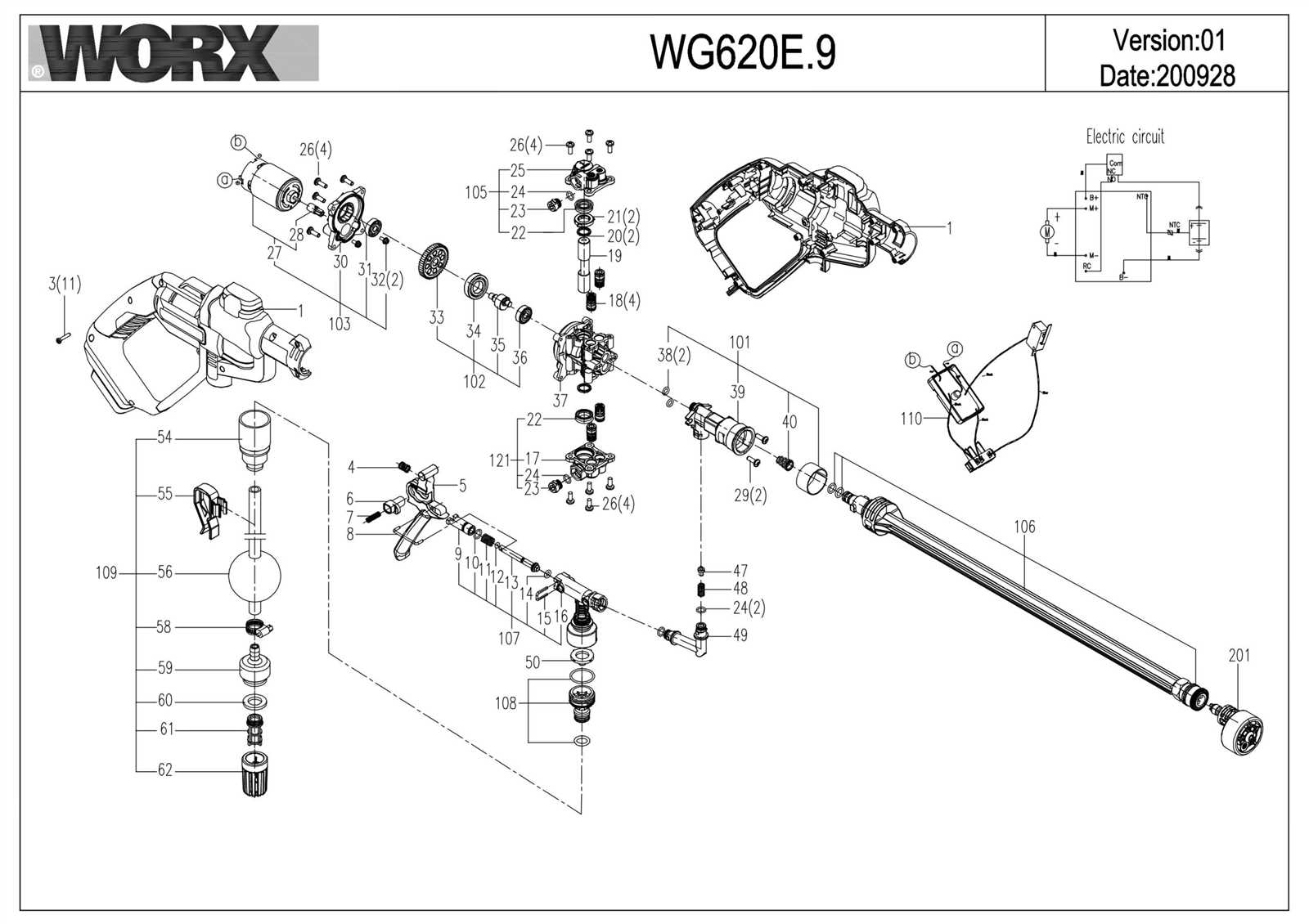

Importance of a Parts Diagram

Understanding the layout and components of any equipment is crucial for efficient maintenance and repair. A visual representation not only simplifies the identification of each element but also aids in recognizing how they interact with one another. This knowledge is essential for both novice users and experienced technicians.

Enhanced Troubleshooting

Having a visual guide allows for quicker diagnosis of issues. When you can see where each component fits, it’s easier to pinpoint problems and determine the ultimate solution, saving both time and resources.

Streamlined Repairs

With an organized illustration, finding the right replacement parts becomes a straightforward task. This clarity helps in minimizing errors during repairs, ensuring that the equipment runs efficiently once reassembled.

Identifying Major Parts in Diagrams

Understanding the layout of essential components in visual representations is crucial for effective maintenance and troubleshooting. Recognizing each element not only enhances operational efficiency but also aids in identifying potential issues.

Key Components to Look For

- Motor: The driving force behind the entire mechanism.

- Handle: Provides control and maneuverability.

- Hose: Facilitates fluid movement throughout the system.

- Nozzle: Directs and adjusts the flow of the fluid.

Understanding Functional Relationships

By delving into the interactions between these critical elements, users can gain a clearer understanding of how the system operates as a whole. This knowledge ultimately empowers individuals to make informed decisions during maintenance and repairs.

Common Issues with Pressure Washers

When it comes to cleaning equipment, users often encounter a variety of challenges that can hinder performance. Understanding these common complications can lead to more efficient use and maintenance. Here, we will explore some frequent problems and their potential solutions.

Performance Problems

Many users report inadequate output, which can stem from several factors. Issues may include blockages in hoses or nozzles, improper settings, or low fluid levels. Regular checks can help identify and rectify these concerns.

Operational Difficulties

Equipment may also face difficulties during operation, such as starting issues or unexpected shutdowns. These problems can often be traced back to fuel quality, battery condition, or mechanical wear. Addressing these areas promptly ensures longevity and reliability.

| Issue | Possible Cause | Solution |

|---|---|---|

| Poor output | Blockages | Clean hoses and nozzles |

| Starting issues | Poor fuel quality | Use fresh fuel |

| Unexpected shutdown | Battery problems | Check and replace battery |

How to Use the Diagram Effectively

Understanding how to interpret a visual representation of components can greatly enhance your ability to maintain and repair equipment. This guide will help you navigate the illustration efficiently and utilize it to your advantage.

- Familiarize Yourself: Before diving in, take a moment to get acquainted with the layout and key features of the representation.

- Identify Key Sections: Break down the illustration into sections for easier comprehension.

- Refer to Labels: Pay attention to annotations and labels that highlight specific elements and functions.

By following these steps, you can delve deeper into the intricacies of the equipment and ultimately enhance your troubleshooting skills.

Replacing Worn-Out Components

Maintaining the efficiency of your cleaning device is essential for optimal performance. Over time, certain elements may wear down, leading to decreased functionality and reliability. Addressing these issues promptly can enhance the lifespan of your equipment and ensure it operates at its best.

Identifying the signs of wear is the first step in this process. Common indicators include unusual noises, reduced output, and visible damage. Once these issues are noted, it’s crucial to delve into the specific components that may require replacement. This not only restores functionality but also provides an opportunity to upgrade to more durable options.

When replacing elements, always opt for high-quality replacements that are compatible with your device. This will ensure that you achieve the ultimate performance and durability. Regular maintenance checks can prevent future wear, allowing you to enjoy uninterrupted service.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure that your equipment operates efficiently and lasts longer. By following a few key practices, you can enhance its performance and reduce the likelihood of unexpected issues.

Routine Checks

Conducting periodic inspections is crucial. Look for wear and tear, and ensure that all components are functioning properly. Addressing small problems early can prevent major repairs later.

Cleaning Practices

Keeping your equipment clean not only improves efficiency but also extends its lifespan. Remove any debris after each use and clean filters regularly to maintain optimal operation.

| Maintenance Task | Frequency |

|---|---|

| Inspect hoses and connections | Monthly |

| Clean filters | After every use |

| Check oil levels | Weekly |

| Store in a dry place | Always |

Finding OEM Replacement Parts

Locating authentic components is essential for maintaining the longevity and performance of your equipment. These original elements ensure compatibility and reliability, allowing your device to function at its best. By investing in genuine replacements, you avoid potential issues that may arise from using inferior alternatives.

Benefits of Using Authentic Components

Utilizing genuine items guarantees quality and durability. Original manufacturers create these components to meet specific standards, ensuring they fit seamlessly with your machinery. Moreover, using OEM options often preserves the warranty, providing peace of mind for users.

How to Source Authentic Parts

Start by checking official websites or authorized dealers for your equipment. Many manufacturers provide a list of certified vendors, ensuring you receive the correct replacements. Additionally, consider online marketplaces specializing in original components to broaden your search.

Tools Needed for Repairs

When undertaking repairs on your cleaning equipment, having the right tools is essential for efficient and effective work. A well-equipped toolkit can make the process smoother and help you avoid unnecessary complications.

Essential Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for removing and tightening screws.

- Wrenches: Adjustable and socket wrenches are important for loosening or securing nuts and bolts.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small components.

- Multimeter: This tool helps in diagnosing electrical issues by measuring voltage, current, and resistance.

- Replacement parts: Always have compatible components on hand to replace worn or broken items.

Safety Gear

- Gloves: Protect your hands from sharp edges and chemicals.

- Safety goggles: Shield your eyes from debris and other hazards during repairs.

- Mask: A mask can protect you from inhaling dust or fumes.

Having these tools and safety measures in place will prepare you for most repair tasks, allowing for a successful maintenance experience.

Consulting the User Manual

Understanding the intricacies of your equipment is crucial for optimal performance and longevity. The user manual serves as an invaluable resource, offering insights into assembly, operation, and maintenance. Familiarizing yourself with this document can enhance your experience and ensure safety during usage.

Key aspects to look for in the user manual include:

- Assembly Instructions: Step-by-step guidance on how to set up your device correctly.

- Operating Guidelines: Detailed information on how to use the equipment efficiently.

- Maintenance Tips: Recommendations for routine care to extend the lifespan of your unit.

- Troubleshooting Section: Solutions for common issues you may encounter during operation.

- Safety Precautions: Essential information to ensure safe handling and usage.

Consulting the manual not only aids in proper utilization but also empowers you to resolve potential challenges independently. Always keep it accessible for quick reference as you navigate your tasks.

Safety Precautions When Repairing

When engaging in maintenance tasks, prioritizing safety is essential to prevent injuries and ensure a smooth process. Understanding potential hazards and following established guidelines can create a secure environment for both the technician and the equipment.

Before commencing any repair work, it’s important to adhere to the following precautions:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, goggles, and sturdy footwear to shield against debris and splashes. |

| Disconnect Power Sources | Ensure all power supplies are unplugged to avoid electrical shocks during repairs. |

| Work in a Well-Ventilated Area | Ensure proper airflow to reduce the risk of inhaling harmful fumes or dust. |

| Follow Manufacturer Instructions | Refer to the guidelines provided by the manufacturer for safe and effective repairs. |

| Keep a Clean Workspace | Remove clutter and organize tools to minimize the risk of accidents and ensure efficiency. |