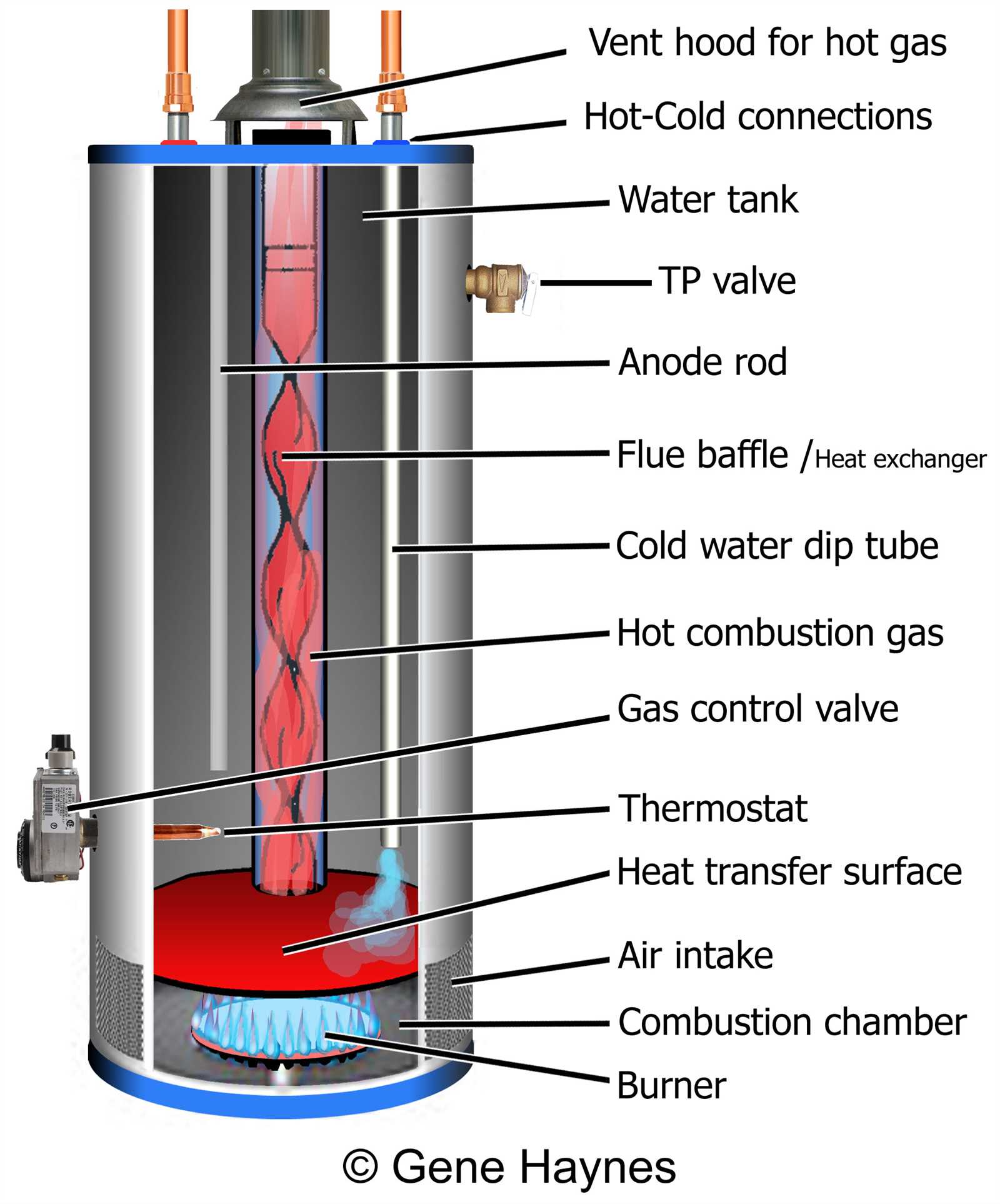

The intricate design of heating appliances involves various essential elements that work together to deliver efficient performance. Each component plays a crucial role in ensuring optimal functionality, contributing to the overall effectiveness of the unit. By familiarizing oneself with these features, users can better comprehend how their system operates and troubleshoot potential issues.

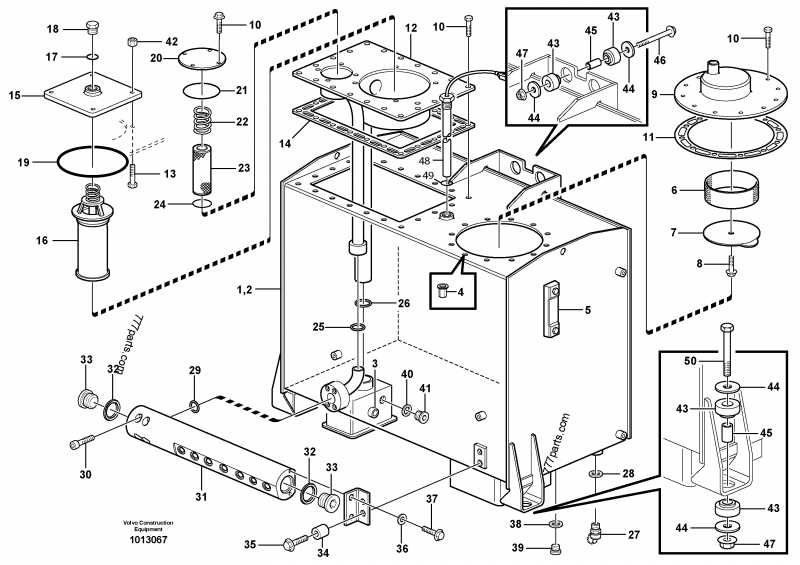

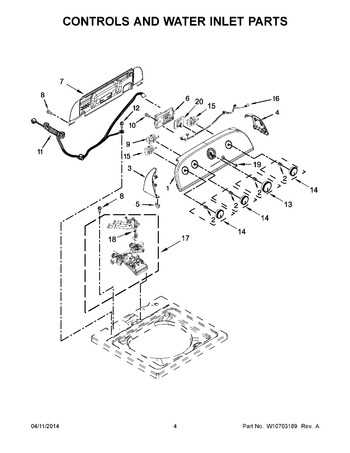

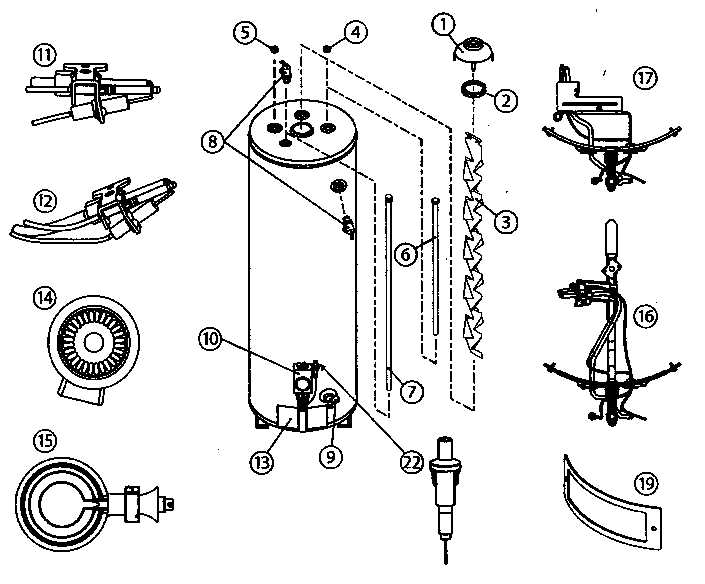

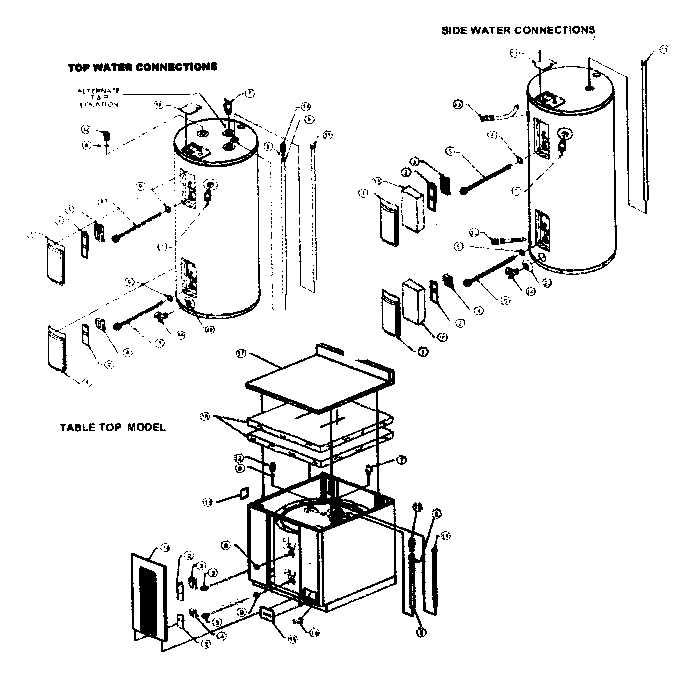

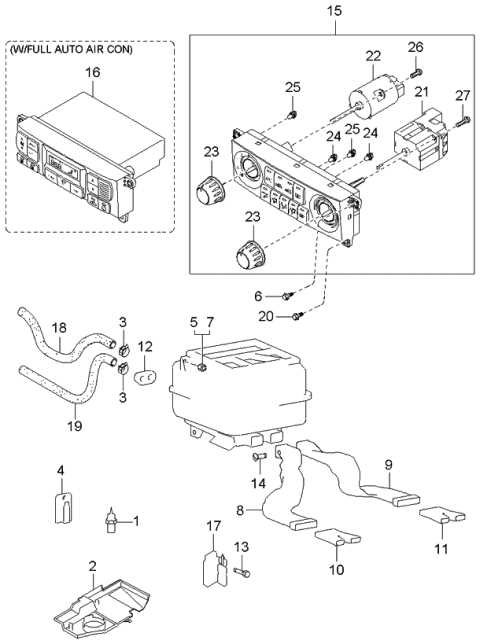

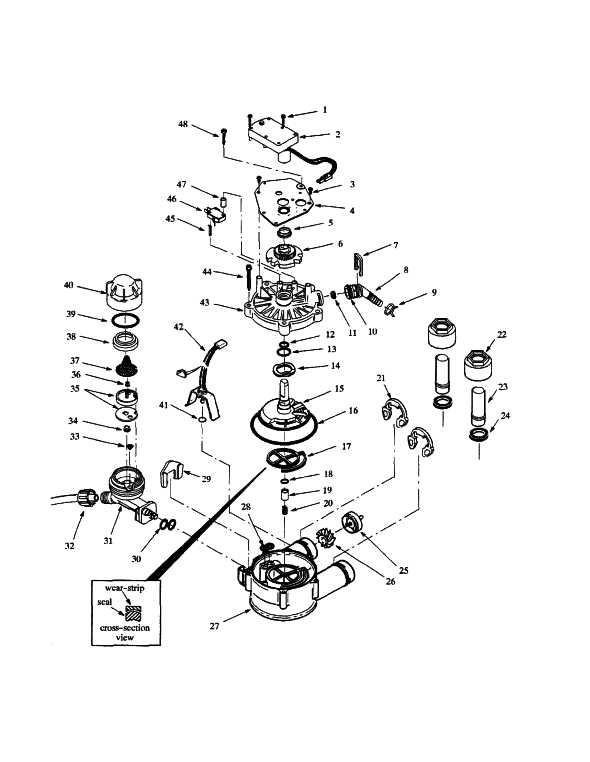

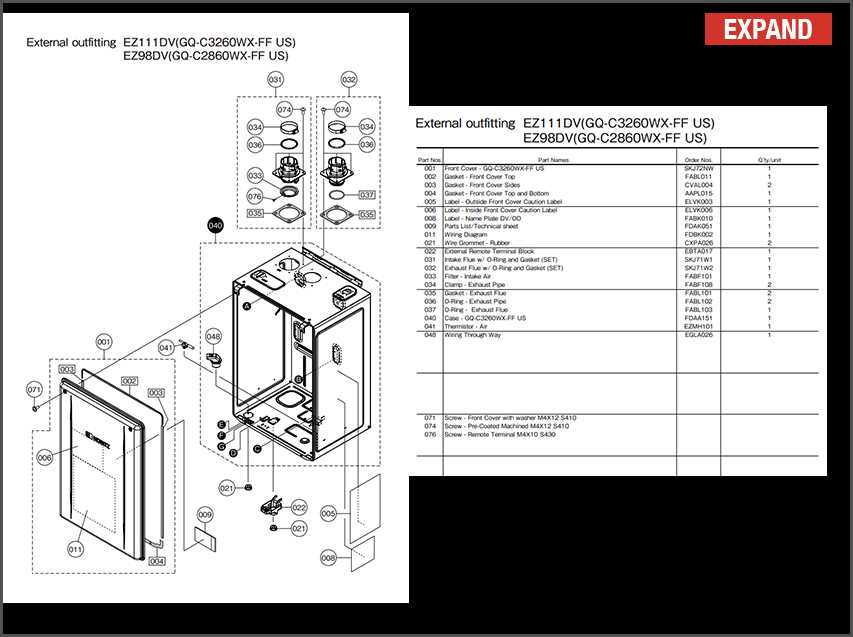

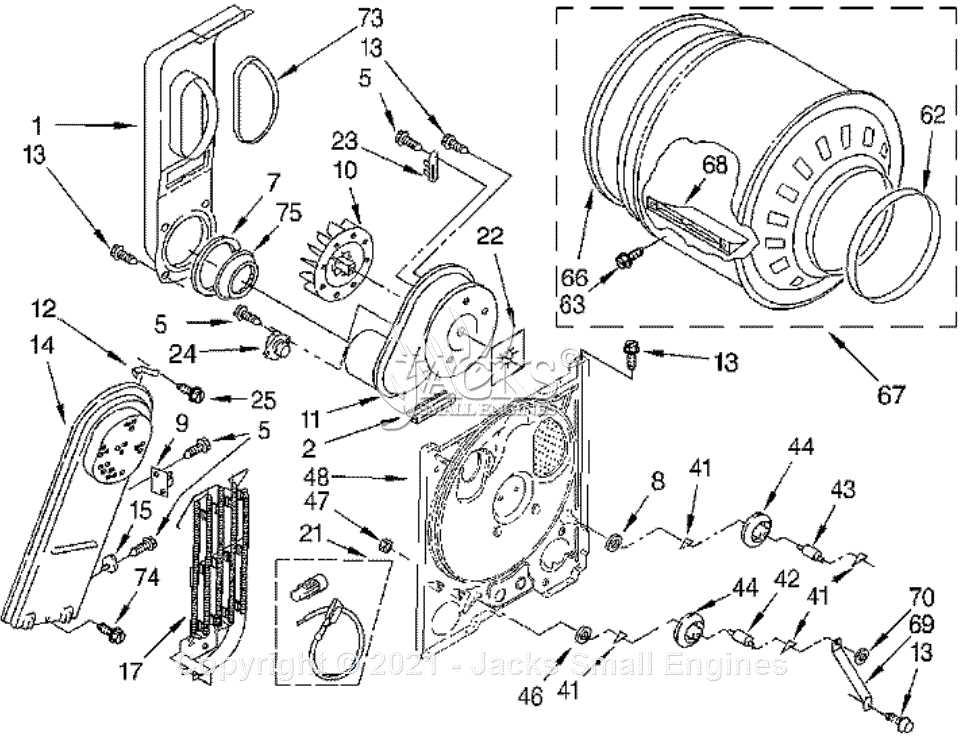

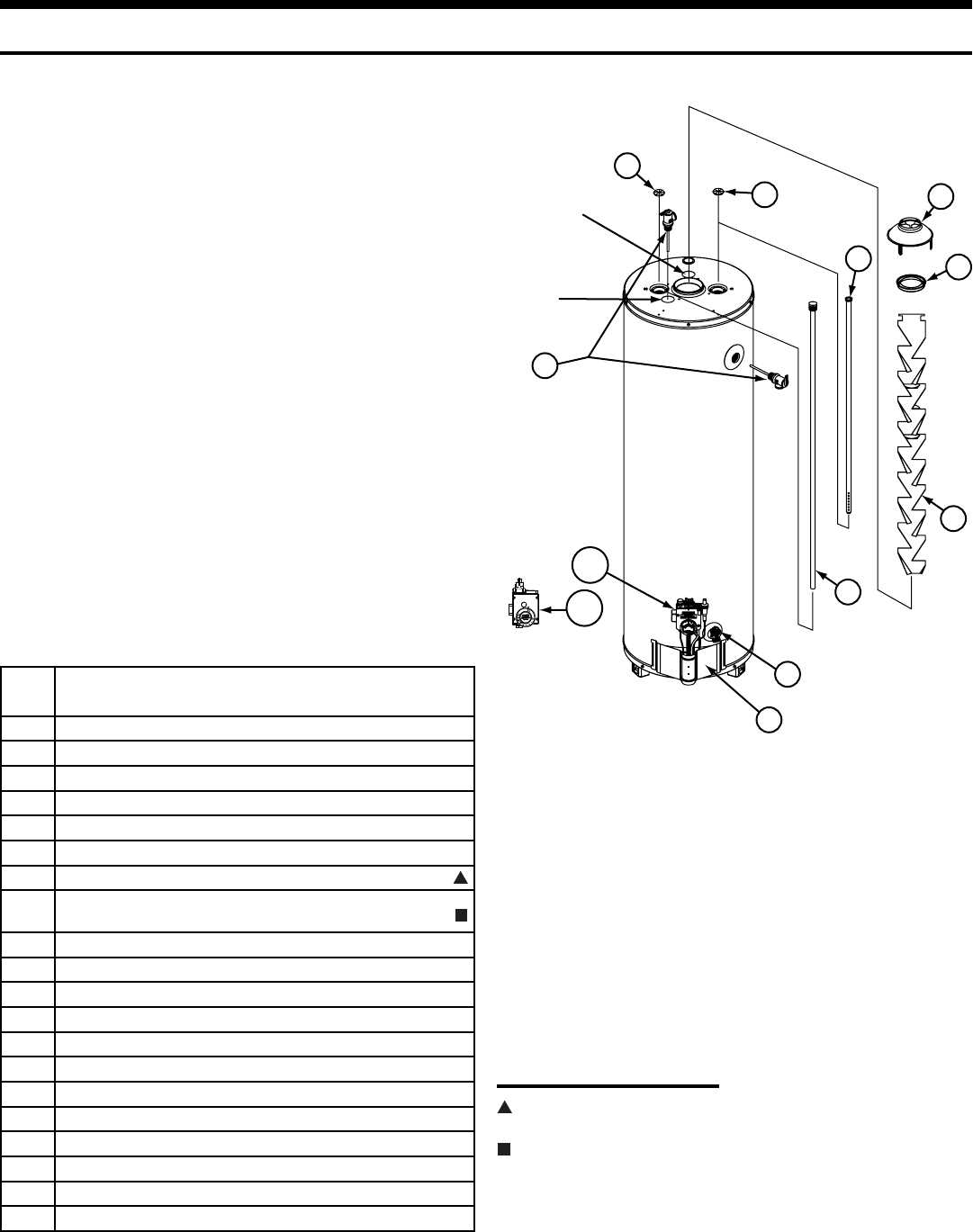

In this section, we will explore a comprehensive representation of the essential elements of these devices. This visual aid will serve as a valuable reference, illustrating the relationship between different components and their respective functions. Gaining insight into this layout will empower users to maintain their systems more effectively and enhance their understanding of the technology at work.

Furthermore, recognizing the significance of each component can lead to more informed decisions regarding repairs or replacements. Users who are well-versed in the structure of their heating apparatus are better equipped to identify problems early and seek appropriate solutions. This knowledge not only fosters confidence in handling maintenance tasks but also ensures a more efficient and reliable performance.

Understanding Whirlpool Water Heater Components

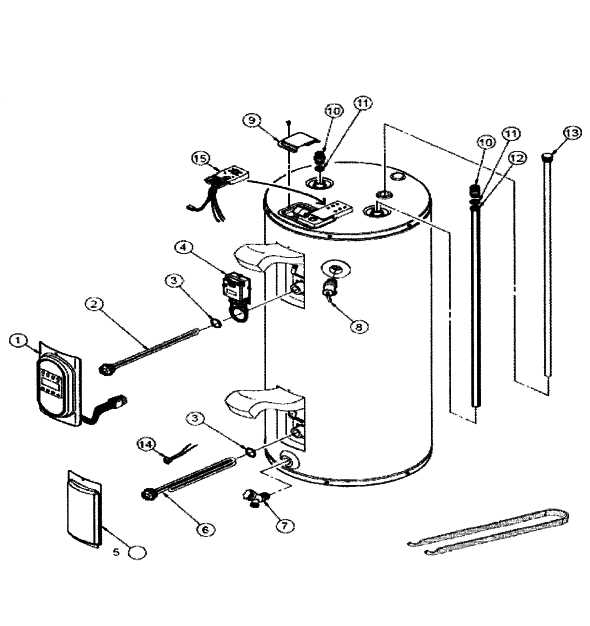

Having a clear grasp of the elements that make up a domestic heating system is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, ensuring that the system operates efficiently and meets the needs of the household. Recognizing these elements allows homeowners to make informed decisions regarding repairs and upgrades.

One of the most vital components is the thermostat, which regulates the temperature of the liquid within the tank. This device ensures that the fluid is heated to the desired level, providing comfort and convenience. Another critical element is the element, responsible for heating the liquid directly. Understanding the operation of this component can aid in diagnosing issues related to inadequate heating.

Additionally, the anode rod plays a significant role in preventing corrosion inside the tank, thereby extending the lifespan of the entire unit. This sacrificial rod attracts corrosive elements, safeguarding the interior surfaces. Regular inspection and replacement of this element are essential for maintaining system integrity.

Lastly, the valve serves as an essential safety mechanism, allowing for the release of excess pressure and ensuring the safe operation of the system. Familiarity with its function is crucial for any homeowner looking to manage their heating apparatus effectively. Overall, understanding these components fosters better maintenance practices and enhances the longevity of the heating system.

Overview of Water Heater Diagrams

Understanding the layout of heating appliances is essential for effective maintenance and troubleshooting. These visual representations provide valuable insights into the components, their functions, and how they interact within the system. A well-constructed illustration can significantly enhance comprehension, enabling users to identify and resolve issues more efficiently.

Importance of Clear Illustrations

Clear visuals are crucial for both professionals and homeowners alike. They facilitate the identification of key elements, allowing for quicker diagnostics and repairs. By depicting the arrangement and relationships among various components, these illustrations simplify complex systems, making them accessible to those without extensive technical knowledge.

Common Features in Schematic Representations

Typically, these layouts include symbols and notations that signify different functionalities. Color coding often helps distinguish between various sections, while labels provide essential information about each component’s role. Familiarizing oneself with these characteristics can empower individuals to approach any maintenance task with confidence.

Key Parts of Whirlpool Models

This section provides an overview of essential components found in various models. Understanding these elements is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring optimal performance and efficiency.

- Heating Element: This component is responsible for raising the temperature of the fluid, allowing it to be used for various applications.

- Thermostat: A crucial element that regulates the temperature by turning the heating element on and off as needed.

- Tank: The main storage unit where the heated fluid is held, designed to maintain heat for extended periods.

- Drain Valve: Located at the bottom of the storage unit, this valve allows for easy removal of the liquid during maintenance or replacement.

- Anode Rod: A sacrificial component that prevents corrosion within the tank by attracting harmful elements.

- Insulation: A critical feature that minimizes heat loss, ensuring energy efficiency and effective temperature retention.

- Control Panel: The user interface that allows for easy adjustments of temperature settings and operational modes.

Familiarity with these components empowers users to make informed decisions regarding repairs and upgrades, enhancing the longevity of their appliances.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of essential home appliances requires regular care and attention. Neglecting these practices can lead to diminished performance, increased energy consumption, and ultimately, costly repairs or replacements. Understanding the significance of proper upkeep is vital for any homeowner aiming to maximize their investments.

Benefits of Regular Upkeep

- Enhanced Efficiency: Consistent maintenance helps keep systems running at optimal levels, reducing energy costs and improving performance.

- Extended Lifespan: By addressing minor issues before they escalate, homeowners can prolong the life of their equipment.

- Safety Assurance: Routine checks can identify potential hazards, ensuring a safe environment for all household members.

- Cost Savings: Preventive care is often less expensive than emergency repairs, saving money in the long run.

Key Maintenance Practices

- Conduct regular inspections to identify wear and tear.

- Clean components as per the manufacturer’s guidelines to prevent buildup and corrosion.

- Replace worn parts promptly to maintain overall efficiency.

- Consult professionals for periodic servicing to ensure thorough care.

By prioritizing regular maintenance, homeowners can enjoy peace of mind knowing their equipment operates safely and efficiently while avoiding unnecessary expenditures.

Common Issues and Troubleshooting Tips

When dealing with home appliances, various challenges may arise that can hinder their optimal performance. Understanding these frequent problems and knowing how to address them is essential for maintaining efficiency and prolonging the lifespan of the unit.

Insufficient Heat Production: One prevalent issue is the inability to generate adequate warmth. This can stem from a malfunctioning thermostat or sediment buildup within the tank. To troubleshoot, ensure that the temperature setting is appropriate and consider flushing the tank to remove any debris.

Unusual Noises: Hearing strange sounds can indicate underlying problems. Rattling or popping noises often signify sediment accumulation, while humming may point to electrical issues. Regular maintenance, including periodic flushing, can help prevent these disturbances.

Leakage: Water pooling around the base is a concerning sign. Leaks can originate from various sources, including loose connections or corroded components. Inspect the fittings and replace any damaged parts to resolve the issue.

Pilot Light Problems: For units relying on a pilot light, failure to ignite can be frustrating. Check the gas supply and ensure the pilot light is clean and unobstructed. If the problem persists, the thermocouple may need replacement.

Being proactive in identifying these issues and implementing the appropriate solutions can enhance performance and ensure reliable operation of your appliance.

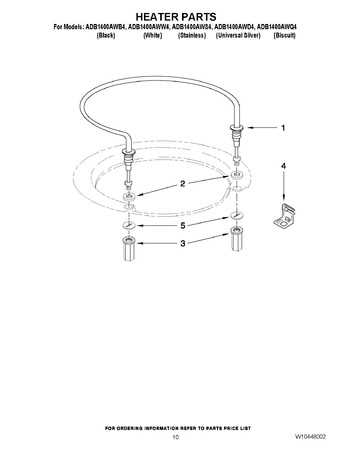

How to Replace a Heating Element

Replacing a heating component in your appliance can be a straightforward task with the right knowledge and tools. This guide outlines the essential steps to safely remove the old element and install a new one, ensuring efficient performance and longevity of the device.

Necessary Tools and Materials

Before starting the replacement process, gather the following tools and materials:

| Tool/Material | Purpose |

|---|---|

| Screwdriver | To remove screws securing the cover |

| Wrench | For loosening the nuts on the heating component |

| Replacement heating element | New part to install |

| Multimeter | To test for electrical continuity |

| Safety gloves | To protect hands during installation |

Step-by-Step Replacement Process

Follow these steps to successfully replace the heating element:

- Disconnect the appliance from its power source to ensure safety.

- Remove the access cover by unscrewing the screws.

- Locate the old heating element and disconnect the electrical connections.

- Using the wrench, loosen the nuts securing the element in place.

- Carefully remove the old component from its housing.

- Install the new heating element, tightening the nuts securely.

- Reconnect the electrical connections, ensuring a secure fit.

- Replace the access cover and secure it with screws.

- Reconnect the appliance to the power source and test the new element.

Identifying the Thermostat Function

The thermostat is a crucial component in regulating temperature within a system. Its primary role involves monitoring and controlling thermal levels, ensuring optimal performance and safety. By accurately sensing the surrounding temperature, it plays a vital part in maintaining consistent conditions.

Understanding the operation of this device is essential for efficient management. It typically features a sensor that detects temperature changes and activates or deactivates the heating mechanism accordingly. This process helps prevent overheating and maintains the desired warmth.

In addition, the thermostat often includes an adjustment feature that allows users to set their preferred temperature. This flexibility is key to enhancing user comfort and energy efficiency, making it an indispensable element in thermal systems.

Water Inlet and Outlet Explained

The flow of fluid into and out of a system is crucial for its overall efficiency and functionality. Understanding these connections allows users to appreciate how different components interact and contribute to the overall performance of the appliance.

Inlet serves as the entry point for the incoming substance, ensuring that it reaches the necessary temperature and quality before it is distributed for use. This connection typically features a valve to control the flow and may include filters to remove impurities.

Outlet, on the other hand, is where the treated substance exits the unit, ready for application. This pathway is designed to deliver the fluid safely and effectively, often incorporating mechanisms to prevent backflow and maintain optimal pressure.

Both connections play an integral role in maintaining system balance and ensuring that operations run smoothly. Proper maintenance and regular inspections of these areas can prevent malfunctions and enhance longevity.

Examining the Anode Rod Role

The anode rod serves as a crucial component in the longevity of a specific appliance, playing a significant part in protecting it from deterioration. By drawing corrosive elements toward itself, this element extends the lifespan of the unit, preventing damage from rust and mineral buildup. Understanding its function is vital for maintaining optimal performance.

This rod is typically composed of magnesium or aluminum, materials selected for their effectiveness in combating corrosion. Over time, the rod will gradually dissolve as it fulfills its protective role. Regular inspection and timely replacement are essential, as a depleted anode rod can lead to costly repairs and a shortened lifespan of the unit.

Ultimately, recognizing the importance of this component can save users both time and money. Ensuring that the anode rod is in good condition contributes significantly to the overall efficiency and durability of the appliance, making it a key focus in routine maintenance practices.

Understanding Pressure Relief Valves

Pressure relief valves are critical components that play a vital role in ensuring safety and efficiency in various systems. They serve to maintain optimal functioning by preventing excess pressure buildup, which can lead to potentially hazardous situations. Understanding their operation and significance is essential for both maintenance and troubleshooting.

Functionality of Pressure Relief Valves

The primary function of pressure relief valves is to release excess pressure in a system, thereby safeguarding it from damage. When the pressure reaches a predetermined limit, the valve opens, allowing fluid to escape and reducing the pressure within the system. This process can be broken down into several key points:

- Monitoring pressure levels continuously.

- Automatically activating when pressure exceeds safe limits.

- Ensuring safe operation of the entire system.

Types of Pressure Relief Valves

There are various types of pressure relief valves, each designed for specific applications. Here are some common types:

- Spring-Loaded Valves: Utilize a spring mechanism to maintain pressure settings.

- Pneumatic Valves: Operated by air pressure, suitable for systems requiring rapid response.

- Hydraulic Valves: Use fluid pressure for operation, ideal for heavy-duty applications.

Understanding these types helps in selecting the right valve for a particular application, ensuring efficiency and safety in operation.

Connecting Electrical Wiring Safely

Ensuring the safe connection of electrical components is crucial for both functionality and user safety. Proper practices and precautions must be adhered to in order to prevent hazards such as short circuits, fires, or electrical shocks. Understanding the essentials of electrical wiring is the foundation of any installation or maintenance task, and following the right procedures can greatly mitigate risks.

Before beginning any electrical work, it is essential to gather the necessary tools and components. Here are some key items you may need:

| Tool/Component | Description |

|---|---|

| Insulated Wire Strippers | Used to remove insulation from wires without damaging the metal. |

| Voltage Tester | Helps determine whether a wire is live or not. |

| Wire Nuts | Used to connect multiple wires securely and safely. |

| Electrical Tape | Provides insulation and protection for wire connections. |

| Safety Goggles | Protects your eyes while working with electrical components. |

Before commencing work, always turn off the power at the circuit breaker. This simple step significantly reduces the risk of electrical shock. After ensuring that the power is off, carefully prepare the wires by stripping them to expose enough metal for a secure connection. It is important to twist wires together tightly and cover them with wire nuts, ensuring no exposed metal is visible.

Additionally, double-check connections by using a voltage tester after completing the wiring process but before restoring power. This will help confirm that everything is correctly installed and safe for use. Finally, once you have verified that all connections are secure, restore power gradually while monitoring for any unusual signs.

Evaluating Insulation and Efficiency

Assessing thermal barriers and energy performance is essential for optimizing the functionality of any heating system. Effective insulation plays a critical role in maintaining desired temperatures while minimizing energy consumption. By examining the components responsible for thermal retention, users can enhance system efficiency and reduce operational costs.

Understanding Thermal Barriers

Insulation serves as the first line of defense against heat loss. Different materials provide varying levels of resistance to heat transfer. Evaluating these materials’ effectiveness is crucial in determining how well they minimize energy loss. Properly installed thermal barriers not only enhance performance but also contribute to longevity by preventing wear and tear on internal components.

Impact on Energy Consumption

Energy efficiency is significantly influenced by the quality of insulation. Systems with superior thermal barriers require less energy to maintain optimal temperatures, leading to lower utility bills. Furthermore, investing in high-quality insulation can lead to a quick return on investment through savings and improved performance.

When to Call a Professional

Understanding when to seek expert assistance is crucial for maintaining the efficiency and safety of your appliance. Certain situations indicate that a skilled technician is needed to diagnose and resolve complex issues that could pose risks or lead to further damage if not handled properly.

Signs That Require Expert Attention

Paying attention to specific symptoms can help you determine when to reach out for help. Here are some key indicators:

| Symptom | Explanation |

|---|---|

| Unusual Noises | Strange sounds such as banging or hissing may signal underlying problems that need immediate inspection. |

| Inconsistent Temperature | Fluctuations in heating efficiency can suggest malfunctioning components that should be evaluated by a professional. |

| Leaks | Any signs of moisture or water pooling around the unit indicate potential failure and require prompt attention. |

| Increased Utility Bills | A sudden spike in energy costs may imply inefficiency, warranting an expert assessment of your system’s performance. |

Professional Evaluation Benefits

Engaging a qualified specialist ensures accurate diagnostics and repairs, reducing the risk of recurring issues and extending the lifespan of your appliance. By addressing concerns early, you can avoid costly repairs down the line and maintain optimal functionality.