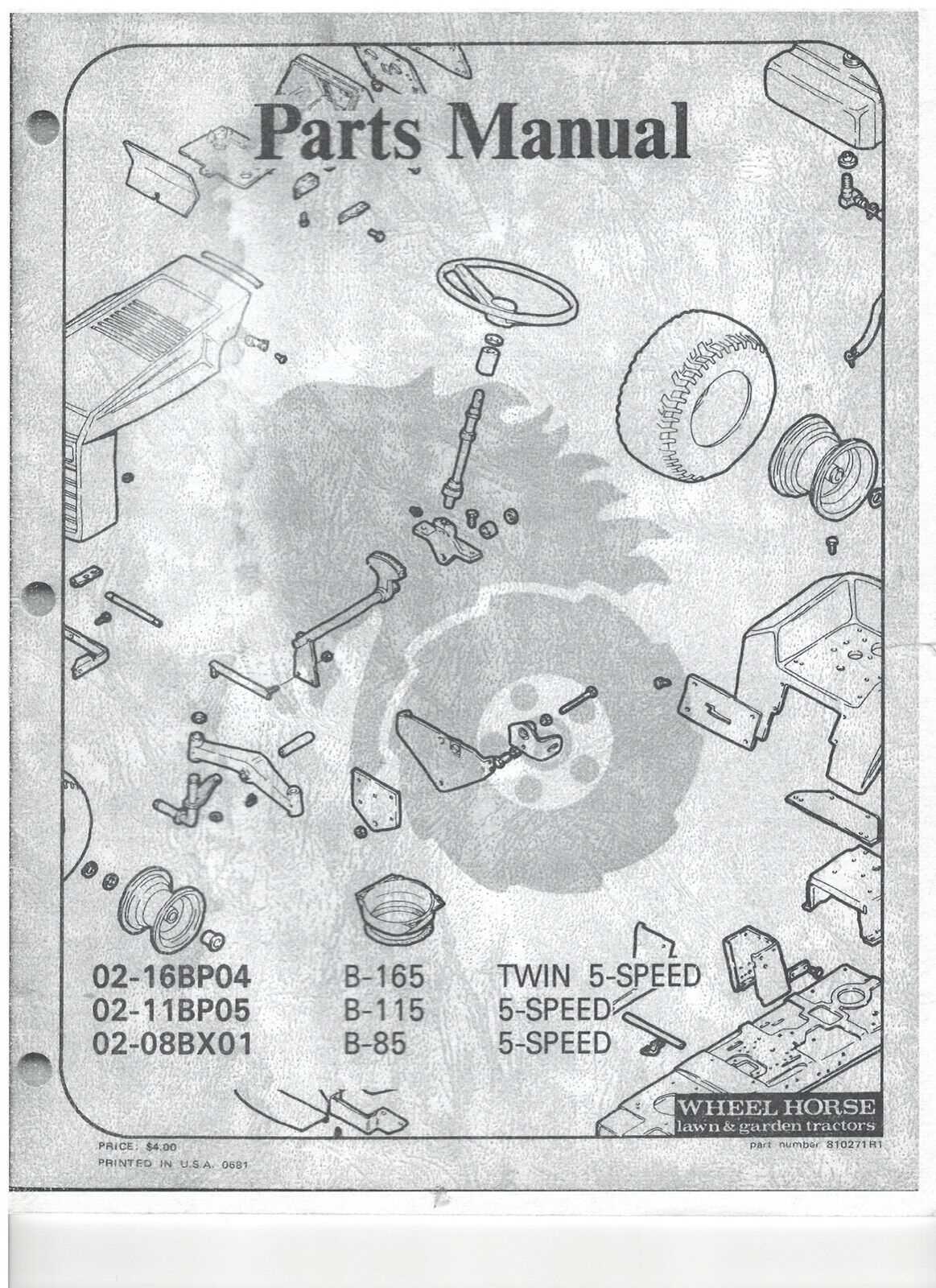

In the world of gardening and landscaping, having a reliable machine can make all the difference. This section delves into the intricate assembly of a particular garden vehicle, exploring its various elements and how they function together. By gaining insight into these components, users can enhance their maintenance and repair skills, ensuring optimal performance and longevity.

Familiarity with the layout of the machine is crucial for effective troubleshooting and repairs. Each element plays a vital role, contributing to the overall efficiency of the equipment. Understanding the configuration allows operators to pinpoint issues quickly, minimizing downtime and maximizing productivity.

Moreover, comprehending the structure empowers users to make informed decisions when seeking replacements or upgrades. Knowledge of each component’s function fosters confidence in handling repairs and maintenance tasks. As a result, this understanding leads to a more satisfying and productive gardening experience.

This section aims to provide a comprehensive overview of the various models produced by the manufacturer, focusing on their unique features, specifications, and common applications. Understanding these models is essential for identifying the right components and maintaining optimal performance.

Model Variations

Several variations exist within the lineup, each designed for specific tasks and environments. These variations can be categorized based on:

- Engine specifications

- Transmission types

- Attachments and accessories

Key Features

Each model showcases distinct characteristics that contribute to its functionality and efficiency. Key features to note include:

- Durability and build quality

- Ease of maintenance

- Operator comfort and ergonomics

Historical Context

Understanding the historical context of these models can provide insight into their evolution and design philosophy. Important factors include:

- Development timelines

- Technological advancements

- Market demands

Common Applications

These models serve a variety of functions, making them popular in different sectors. Common applications include:

- Landscaping and gardening

- Agricultural tasks

- Commercial maintenance

Maintenance Guidelines

Proper maintenance is crucial for prolonging the lifespan of any model. Essential maintenance guidelines include:

- Regular oil changes

- Inspecting belts and hoses

- Sharpening blades and attachments

Replacement Components

Identifying and sourcing replacement components is a vital part of ownership. Important considerations include:

- Compatibility with specific models

- Quality and durability of parts

- Cost and availability

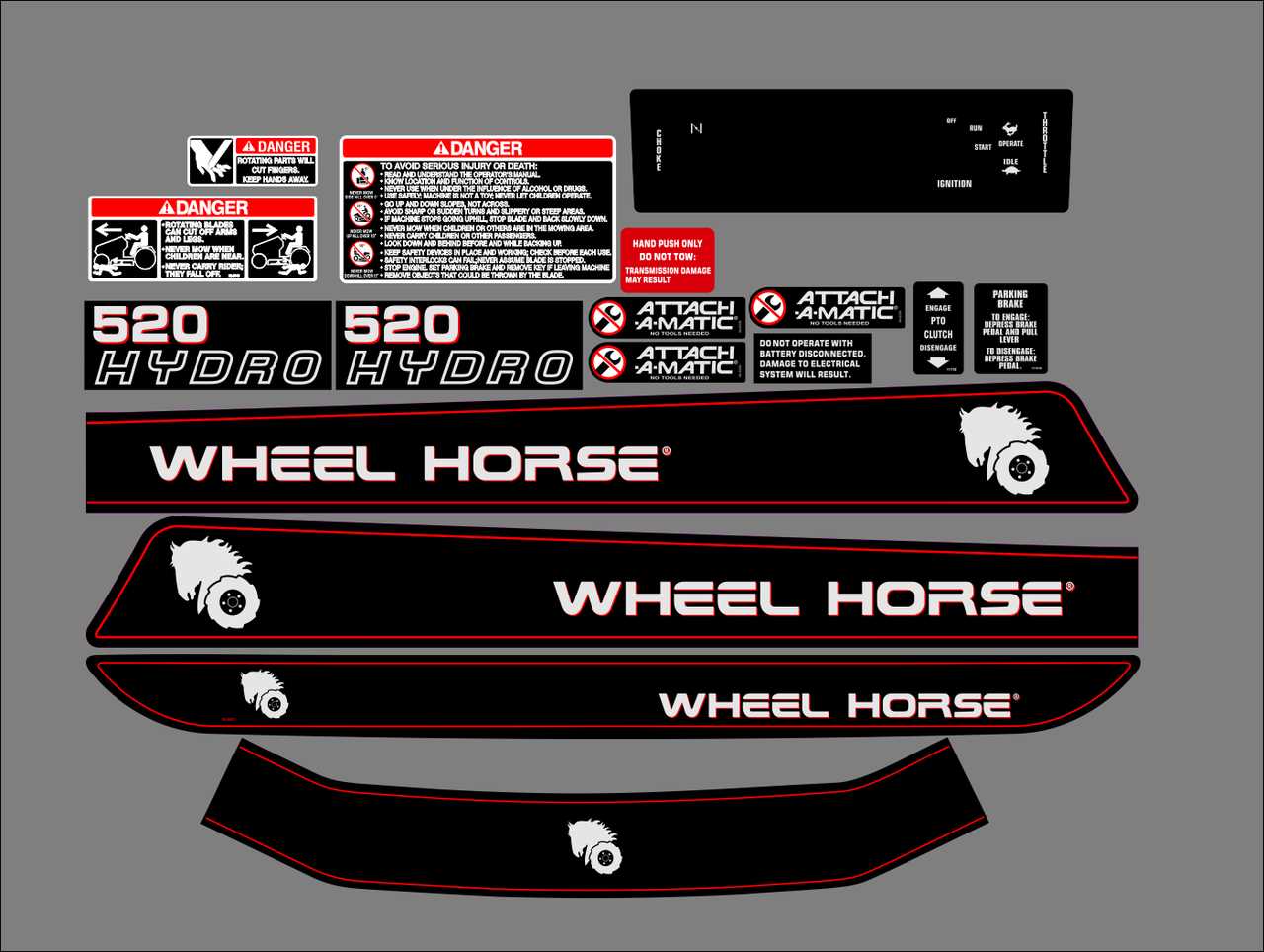

Safety Features

Safety is paramount when operating these machines. Key safety features to be aware of include:

- Operator presence controls

- Emergency shut-off mechanisms

- Protective guards and shields

Performance Metrics

Understanding performance metrics can help users evaluate efficiency. Relevant metrics include:

- Fuel efficiency

- Power output

- Speed and agility

Customer Reviews

Feedback from users can provide valuable insights into the effectiveness of these models. Common themes in reviews include:

- Ease of use

- Reliability

- Value for money

Future Trends

Keeping an eye on future trends can help users anticipate changes in design and technology. Trends to consider include:

- Increased automation

- Eco-friendly innovations

- Enhanced connectivity features

Conclusion

In summary, understanding these models enhances user experience and informs purchasing decisions. By examining various aspects such as features, applications, and maintenance, users can make well-informed choices that align with their needs.

Key Features of Wheel Horse 520H

This section explores the essential characteristics of a versatile garden tractor model known for its durability and performance. These attributes make it a reliable choice for various landscaping tasks, ensuring efficient operation and user satisfaction.

Robust Construction

The machine is designed with sturdy materials that enhance its longevity, allowing it to withstand demanding tasks. The solid frame and high-quality components contribute to its ability to handle various terrains with ease.

Powerful Engine Performance

Equipped with a reliable engine, this model delivers consistent power, ensuring effective performance during operation. Its efficiency not only enhances productivity but also reduces the frequency of maintenance, making it a practical investment for users.

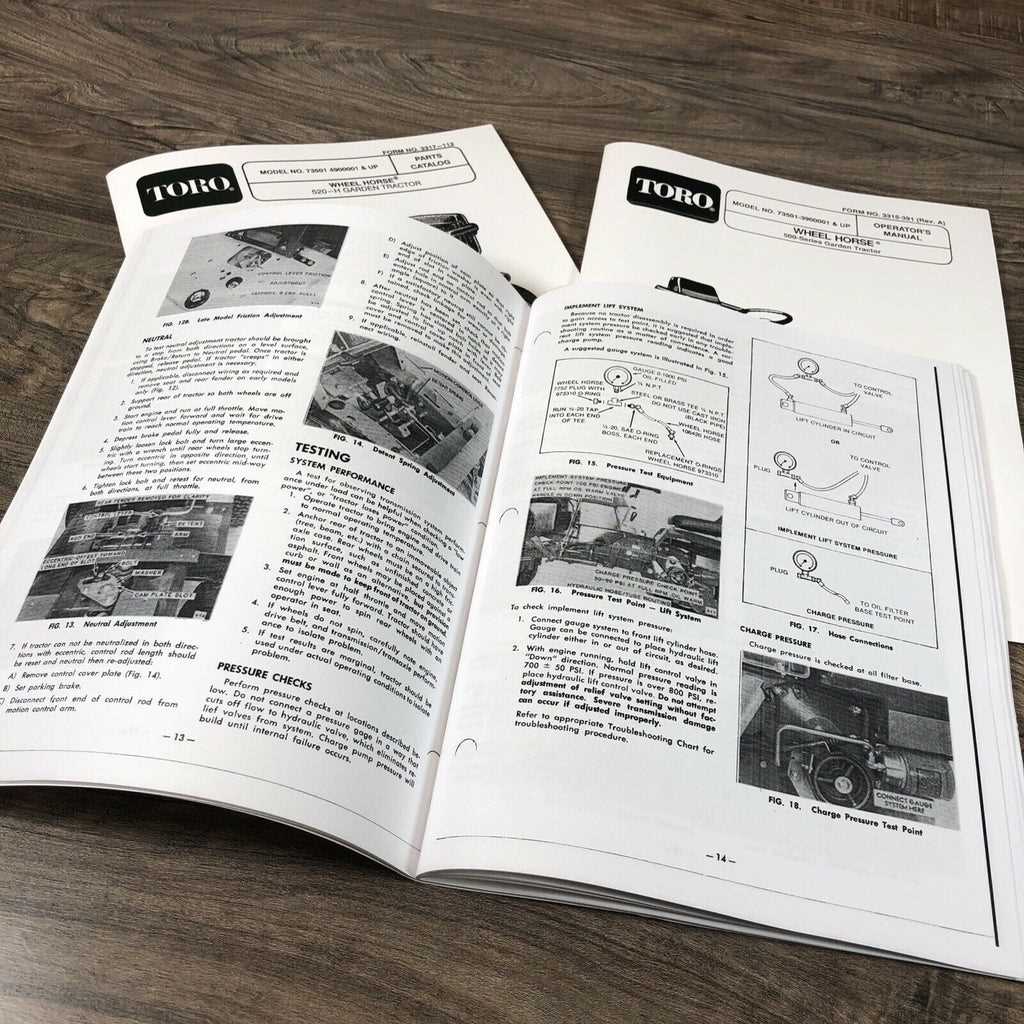

Components Overview of 520H

This section provides a comprehensive look at the essential elements that contribute to the functionality of the 520H model. Understanding these components is crucial for effective maintenance and troubleshooting.

Key Elements

The primary components of the 520H include the engine, transmission, and chassis. Each of these parts plays a vital role in ensuring optimal performance and durability. The engine serves as the powerhouse, while the transmission facilitates smooth power transfer. The chassis, on the other hand, provides structural integrity and stability.

Additional Features

In addition to the core components, various auxiliary systems enhance the overall efficiency of the 520H. These include electrical systems, hydraulic mechanisms, and control interfaces. Each feature is designed to improve user experience and operational effectiveness, making the machine versatile for different tasks.

Identifying Essential Spare Parts

Understanding the critical components required for maintenance and repair is vital for any machinery owner. Recognizing these elements not only ensures the smooth operation of the equipment but also extends its lifespan. Having a clear grasp of which items are necessary helps in timely replacements, reducing downtime and enhancing performance.

Key Components to Consider

When assessing what elements are essential, focus on those that experience the most wear and tear. Commonly, items such as belts, filters, and bearings should be prioritized, as they play a crucial role in the overall functionality. Regular checks and timely replacements can prevent larger issues down the line.

Maintaining an Inventory

Keeping an organized inventory of frequently used components is advisable for efficient operation. This practice allows for quick access to necessary items, facilitating immediate repairs when required. Additionally, documenting the condition and lifespan of each component can help in forecasting future needs, ensuring that replacements are always on hand.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. By following some straightforward maintenance practices, you can significantly extend the life of your machine and improve its efficiency. Regular upkeep not only prevents costly repairs but also enhances the overall user experience.

Routine Inspections

Conducting regular inspections is essential for identifying potential issues before they escalate. Here are some key areas to focus on:

- Check for signs of wear on belts and hoses.

- Inspect fluid levels and look for leaks.

- Examine electrical connections for corrosion or damage.

- Ensure all safety features are functioning properly.

Proper Cleaning

Keeping your machinery clean can prevent dirt and debris from causing malfunctions. Follow these cleaning tips:

- Wipe down surfaces regularly to remove dust and grime.

- Use appropriate solvents for stubborn stains or residues.

- Clear out any buildup from air filters to ensure efficient airflow.

- Store the equipment in a dry, sheltered area to protect it from the elements.

Finding Replacement Parts Easily

Locating suitable components for machinery can often feel daunting, yet it is essential for maintaining functionality and performance. Understanding the different sources and methods available for acquiring these items can streamline the process significantly. By leveraging the right resources, users can ensure they find the appropriate replacements efficiently.

Utilizing Online Resources

The internet offers a wealth of information and options for sourcing components. Websites dedicated to machinery supplies often feature extensive catalogs, detailed specifications, and user reviews. Utilizing search engines effectively can also lead to forums and communities where individuals share insights and recommendations for reliable suppliers.

Consulting Local Dealers

Establishing a relationship with local dealers or repair shops can provide access to specific components that might not be readily available online. These professionals often possess valuable knowledge about compatible items and can assist in identifying the right choices based on individual needs. Engaging with them can result in personalized service and immediate support for any inquiries.

Exploring Aftermarket Parts Options

When maintaining or upgrading outdoor equipment, the availability of alternative components can significantly enhance performance and longevity. These substitutes often provide a cost-effective solution, allowing users to source reliable items without the constraints of original manufacturer offerings. By considering aftermarket alternatives, individuals can tailor their machinery to better suit their specific needs and preferences.

Benefits of Aftermarket Components

Opting for substitute items can result in various advantages. Many aftermarket options are designed to meet or exceed the quality of original items, often at a reduced price. Additionally, the diversity in selection allows for greater customization, ensuring that users can find the best fit for their machinery. This flexibility can lead to improved efficiency and functionality, enhancing the overall user experience.

Finding Quality Alternatives

To ensure the selection of high-quality substitute components, it is essential to research reputable suppliers. Reading customer reviews and seeking recommendations from experienced users can help identify trustworthy sources. Furthermore, checking for warranties and return policies can provide additional assurance of the product’s quality and reliability. Making informed choices when selecting substitutes can lead to successful upgrades and maintenance.

Common Issues and Solutions

This section addresses frequent challenges encountered with specific machinery, providing practical solutions to enhance performance and reliability. Understanding these common difficulties can aid in effective troubleshooting and maintenance.

Identifying Frequent Problems

Operators often face various malfunctions that can hinder the operation of their equipment. Recognizing the symptoms of these issues is the first step toward resolution. Below are some typical concerns:

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Engine Starting Issues | Difficulty in ignition, unusual noises | Check battery connections, inspect starter motor |

| Hydraulic System Failures | Weak lifting power, leaks | Examine fluid levels, inspect hoses for damage |

| Electrical Problems | Inconsistent power supply, blown fuses | Inspect wiring for wear, replace faulty components |

Maintenance Tips

Regular maintenance is essential to prevent issues from arising. Implementing a routine check-up schedule can help identify potential problems early on. Key maintenance practices include:

- Regular oil changes

- Routine filter replacements

- Consistent inspection of belts and hoses

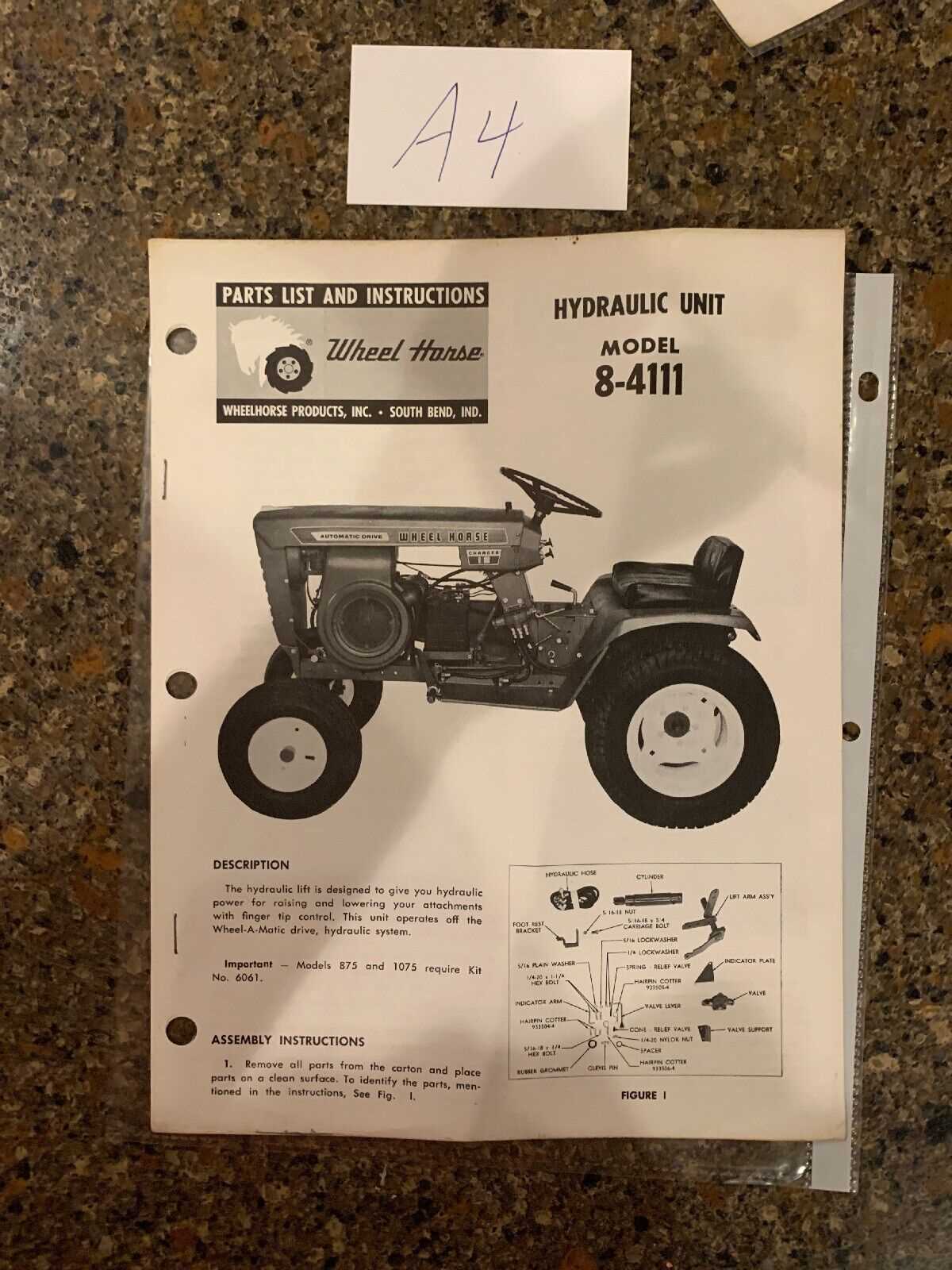

Guidelines for Proper Assembly

Achieving a successful construction process requires attention to detail and a systematic approach. By following established protocols, individuals can ensure that each component is accurately positioned and secured, leading to optimal functionality and performance. This section provides essential recommendations for assembling machinery effectively.

Before starting the assembly, gather all necessary components and tools. Reviewing the assembly instructions thoroughly will facilitate a smoother process. Begin by organizing the components based on their sequence in the assembly process. Ensure that each part is clean and free of debris to prevent complications during installation.

As you proceed with the assembly, take care to follow the recommended torque specifications for bolts and screws. Over-tightening or under-tightening can lead to mechanical failures or operational inefficiencies. It is also beneficial to regularly check the alignment of parts as the assembly progresses, making adjustments as needed to maintain precision.

Finally, once the assembly is complete, conduct a thorough inspection to verify that all components are correctly positioned and secured. Testing the machinery in a controlled environment before regular use will help identify any potential issues early on. Proper assembly not only enhances performance but also extends the lifespan of the equipment.

Tools Needed for Repairs

Having the right tools is essential for effective maintenance and repairs of outdoor machinery. The appropriate instruments not only ensure the job is done efficiently but also enhance safety during the process. Below is a list of commonly required tools that can make repairs easier and more effective.

Basic Hand Tools: A set of wrenches, screwdrivers, and pliers is crucial for various adjustments and repairs. These tools allow you to access different components easily and tighten or loosen parts as needed.

Specialized Equipment: Depending on the specific tasks, you may need specialized tools such as a torque wrench for precise tightening or a multimeter for electrical diagnostics. Having these tools on hand can significantly reduce troubleshooting time.

Safety Gear: Always prioritize safety by wearing appropriate gear, including gloves and safety glasses. This ensures protection from sharp edges and flying debris while working on the machinery.

Being well-prepared with the necessary tools simplifies the repair process and helps maintain the longevity of your equipment.

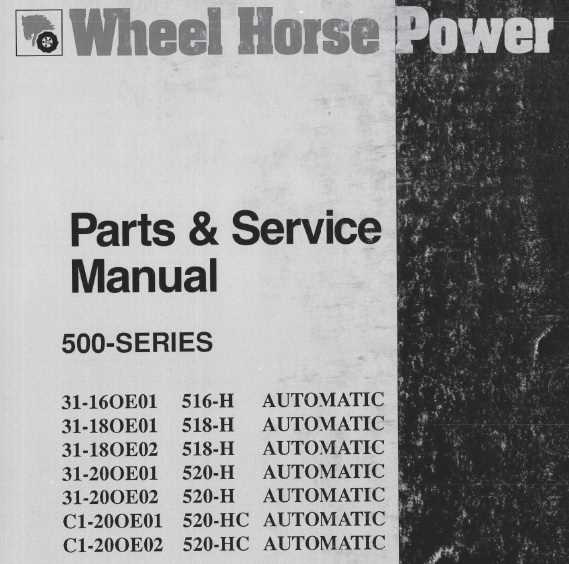

Comparing Models Within the Series

The analysis of various models within a specific lineup reveals significant insights into their distinct features and functionalities. Each variant in the collection has been designed to cater to specific tasks, demonstrating unique strengths that can enhance performance in diverse applications. By examining the nuances among these versions, users can make informed decisions that align with their operational needs.

One of the primary differences among these models lies in their engine specifications. While some versions may focus on power and efficiency, others might prioritize compact design and maneuverability. Furthermore, the availability of optional accessories can also vary, providing users with tailored enhancements that fit their requirements. Understanding these variations not only aids in selecting the right machine but also maximizes productivity across various tasks.

Resources for Further Information

For individuals seeking to enhance their understanding of specific equipment and its components, a variety of resources are available. These materials can provide invaluable insights, from technical specifications to maintenance guidelines, ensuring effective usage and care.

Online forums and communities often host discussions and shared experiences from fellow enthusiasts. Engaging in these platforms can yield practical advice and troubleshooting tips. Additionally, manufacturer websites typically offer comprehensive manuals and schematics that can aid in identifying key features and functionalities.

Moreover, specialized publications and manuals provide detailed information regarding operational procedures and servicing. Investing time in these resources can significantly improve one’s knowledge and confidence in handling machinery.