When exploring the intricate world of cleaning machines, it becomes essential to familiarize oneself with the various elements that contribute to their functionality. Each component plays a pivotal role, ensuring that these devices operate at their ultimate efficiency. A comprehensive grasp of these parts can enhance maintenance practices and extend the lifespan of your equipment.

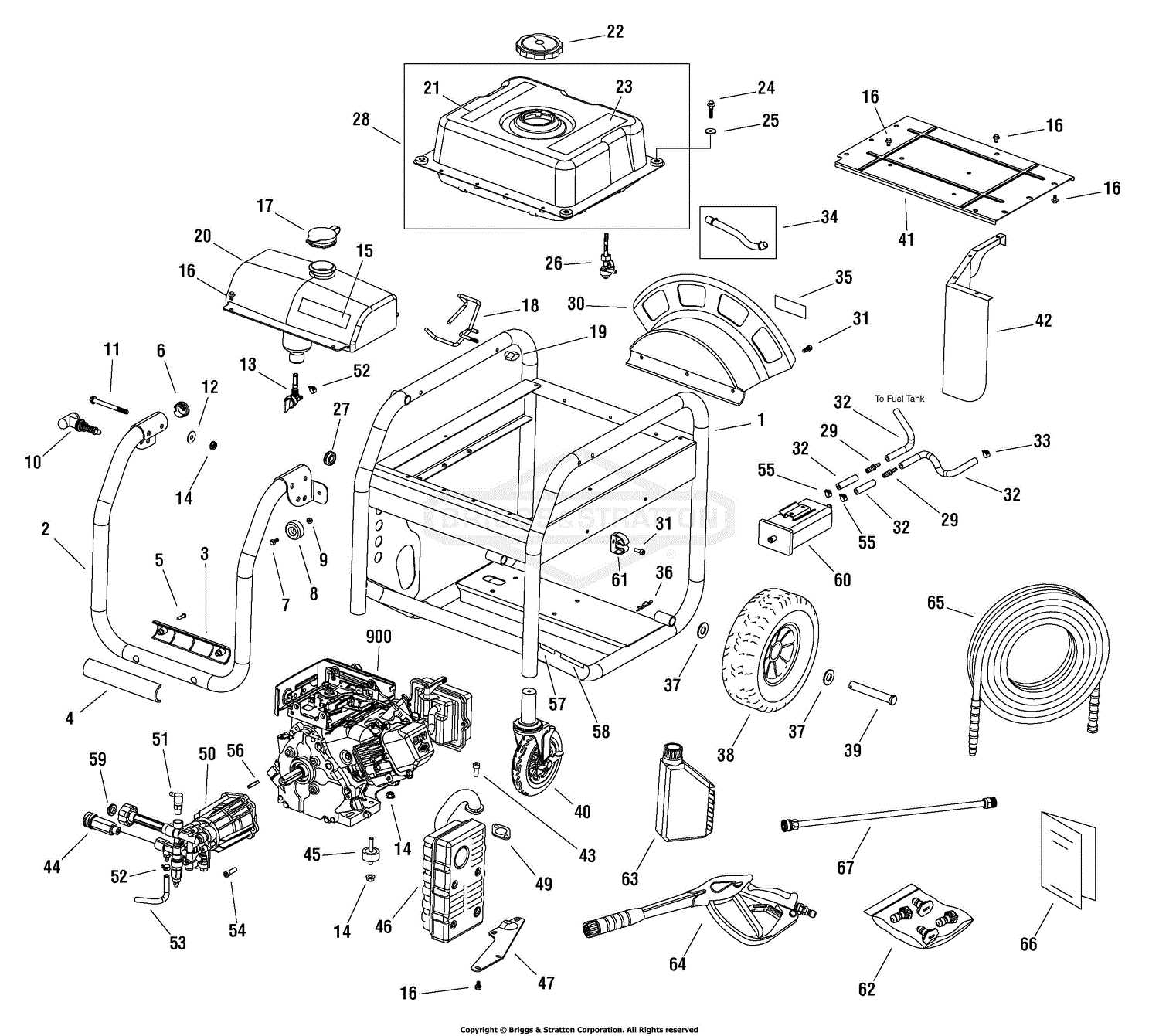

Visual aids are invaluable tools for anyone looking to delve deeper into the mechanics of these machines. By examining a detailed illustration of each segment, users can gain insights into how different pieces interact and function cohesively. This knowledge empowers owners to perform repairs and upgrades with confidence.

Whether you are a seasoned professional or a DIY enthusiast, understanding the architecture of your cleaning apparatus can transform your approach to maintenance. With the right information at hand, troubleshooting becomes less daunting, allowing for more effective solutions to common issues.

Understanding Husqvarna PW 3200 Parts

When it comes to maintaining and optimizing the performance of your cleaning machine, having a clear grasp of its individual components is essential. Each element plays a crucial role in ensuring the efficient operation of the equipment. Familiarity with these elements can lead to better troubleshooting, effective repairs, and informed upgrades.

Key components include the motor, pump, and various attachments, each contributing to the overall functionality. Recognizing how these elements interact can enhance your understanding of potential issues and maintenance needs. For example, if the pressure output is inconsistent, the pump might be the culprit, requiring a thorough inspection or replacement.

Additionally, accessories such as hoses, nozzles, and filters also deserve attention. Regular checks and timely replacements of these accessories can significantly improve cleaning efficiency and prolong the lifespan of the device. By prioritizing the upkeep of both major and minor components, you can ensure that your equipment remains in optimal condition.

Overall, gaining insight into the various elements that constitute your cleaning machine not only aids in effective usage but also empowers you to make knowledgeable decisions regarding repairs and upgrades.

Overview of Pressure Washer Components

A pressure washing device consists of various essential elements that work together to deliver powerful cleaning performance. Understanding these components is crucial for optimal use and maintenance.

- Motor: Powers the pump and generates high pressure.

- Pump: Increases water pressure and controls flow.

- Nozzle: Determines spray pattern and pressure intensity.

- Trigger Gun: Allows user to control water flow and pressure.

- Hose: Transfers water from the pump to the nozzle.

- Frame: Supports all components and enhances portability.

Each part plays a pivotal role, and maintaining them ensures the ultimate efficiency and longevity of the device.

Importance of Accurate Parts Diagram

Understanding the layout and components of equipment is crucial for maintenance and repairs. A precise illustration serves as a vital tool for users, enabling them to identify each element effectively, which ultimately enhances the overall functionality and longevity of the device.

Benefits of Clarity

- Facilitates quick identification of components.

- Reduces the risk of errors during assembly and disassembly.

- Enhances troubleshooting efficiency.

Impact on Performance

- Ensures that all necessary elements are accounted for.

- Promotes optimal operation through correct replacements.

- Minimizes downtime by streamlining repair processes.

Key Features of Husqvarna PW 3200

This powerful cleaning machine is designed to deliver exceptional performance and efficiency for a variety of outdoor tasks. With its advanced features, it stands out as a reliable choice for both residential and commercial use.

- High Pressure Output: Delivers impressive pressure, ensuring thorough cleaning of surfaces.

- Durable Construction: Built with high-quality materials that enhance longevity and resilience.

- Versatile Nozzle Options: Comes with multiple nozzles for different cleaning applications.

- Easy Maneuverability: Equipped with large wheels and a lightweight design for effortless movement.

- Efficient Motor: Features a robust motor that ensures consistent performance with minimal energy consumption.

These attributes make this cleaning machine an ultimate choice for users seeking power and reliability in their cleaning endeavors.

Common Replacement Parts for Maintenance

Regular upkeep of equipment is essential to ensure long-term efficiency and functionality. Over time, certain components may wear out or require adjustment, and timely replacements can help maintain optimal performance. Understanding which elements are most likely to need attention can streamline the maintenance process.

Wear-and-Tear Components

Some elements are prone to natural wear due to frequent use. These include seals, filters, and nozzles, which can degrade or become less effective over time. Replacing these items as part of routine care ensures that the device continues to operate smoothly and without interruptions.

Key Functional Elements

In addition to parts affected by general wear, critical components like hoses and pumps also need periodic evaluation. Ensuring these are in good working order is crucial for preventing major breakdowns. When signs of aging or

How to Read Parts Diagrams

Understanding how to interpret technical illustrations is crucial for anyone looking to repair or maintain equipment. These schematics provide a detailed overview of various components, showing their placement and relationships within the system. By learning how to navigate through these visual guides, you can identify the right components, understand their functionality, and perform tasks with confidence.

Step-by-step analysis involves familiarizing yourself with the layout and symbols used. Typically, these images are organized logically, grouping related components together. Key numbers or letters are often assigned to each item, helping you cross-reference them with an accompanying list. Pay attention to sequence and positioning, as they reflect the order in which components are assembled or interact.

Another essential aspect is to recognize that each component may serve multiple functions depending on its arrangement in the system. Carefully examining the overall structure allows you to anticipate potential connections or dependencies, ensuring more efficient repairs or upgrades. Developing these skills will save time and minimize errors during maintenance tasks.

Identifying Faulty Components Quickly

When dealing with equipment malfunctions, it’s essential to swiftly recognize the problematic parts to avoid prolonged downtime. Efficient troubleshooting involves a systematic approach that can save time and prevent unnecessary replacements.

- Begin by observing any unusual sounds or vibrations during operation, as these often indicate underlying issues.

- Check for visible signs of wear, such as cracks, rust, or deformation on mechanical components.

- Evaluate the connections, ensuring that wires, hoses, and seals are intact and functioning as intended.

- Test moving parts to confirm they operate smoothly without resistance or abnormal friction.

- If necessary, consult diagnostic tools or meters to assess electrical performance, ensuring all readings are within expected ranges.

By following these steps, you can rapidly identify malfunctioning components, enabling quicker repairs and extending the lifespan of your equipment.

Where to Find Replacement Parts

When it comes to maintaining or repairing equipment, locating the correct components is crucial for ensuring optimal performance. Whether you’re looking for small accessories or more complex elements, knowing where to search can save both time and effort. This section will guide you through some effective methods for finding compatible replacements.

Authorized Retailers and Dealers

Your best bet for high-quality components often lies with official vendors and certified distributors. They provide access to original items specifically designed for your machine, guaranteeing a perfect fit and durability. It’s always recommended to check with these sellers first to ensure you receive genuine parts that meet your equipment’s specifications.

Online Marketplaces and Specialty Shops

Another reliable source for finding what you need is through specialized online stores. These platforms often offer a broad range of options, from brand-new to aftermarket alternatives. Make sure to verify seller ratings and reviews to avoid counterfeit products and ensure you’re purchasing reliable and compatible components for your needs.

Benefits of Using Genuine Parts

Choosing original components for maintenance and repairs provides numerous advantages that contribute to the overall performance and longevity of your equipment. High-quality materials and precision engineering ensure that every element fits perfectly, reducing the chances of malfunctions and extending the life of your machine.

Enhanced Durability

Original components are designed to meet specific standards, ensuring that they withstand the stresses and strains of regular use. This increases their lifespan, minimizing the need for frequent replacements and reducing long-term costs.

Optimal Performance

When using authentic components, you can trust that the equipment will operate at its highest efficiency. These parts are created with the exact specifications required, promoting smooth operation and reducing the risk of breakdowns.

| Advantage | Tips for DIY Repairs and Upgrades

Undertaking home repairs and upgrades can be a rewarding way to maintain equipment while saving on professional services. By gaining a basic understanding of the machine’s components and functionality, you can confidently handle various adjustments and repairs with the right approach and tools. Preparing for RepairsBefore beginning any repair, it’s essential to ensure that all necessary tools are on hand. Thoroughly inspect the machine for signs of wear, leaks, or loose connections. Make sure to follow safety guidelines, such as disconnecting power sources and wearing protective gear.

Upgrading ComponentsFor those looking to enhance the machine’s performance, upgrading certain parts can extend its lifespan Safety Precautions During RepairsWhen performing maintenance or addressing mechanical issues, it is essential to prioritize safety at all times. Understanding potential hazards and taking appropriate precautions will help prevent accidents and ensure a smooth repair process. Even the most experienced technicians must remain vigilant and follow best practices to avoid injuries. Before starting any work, always disconnect the equipment from any power source to eliminate the risk of electric shocks. Make sure the surrounding area is clear of obstacles and debris to reduce the chances of slips or falls. Wearing protective gear such as gloves and safety goggles is highly recommended, as it can safeguard against unexpected hazards. Proper use of tools is another key factor. Ensure that all instruments are in good working condition and appropriate for the task at hand. Using damaged or incorrect tools can result in injury or equipment damage. Familiarize yourself with the device’s manual and safety guidelines to minimize risks during repairs. Finally, if you are uncertain about any aspect of the Comparing Models: PW 3200 vs OthersWhen evaluating different high-pressure washers, it’s important to consider various performance factors such as power output, water flow, and overall efficiency. Each model offers distinct advantages that cater to specific needs, whether you’re tackling light maintenance or heavy-duty cleaning tasks. By understanding the unique features of each device, you can make an informed decision on which tool best suits your requirements. Some models excel in delivering superior water pressure for tougher jobs, while others might prioritize ease of use and mobility. Understanding these differences helps you match the machine to the task at hand, ensuring you get the best performance possible for your specific environment and workload. Additionally, certain devices come with enhanced features like customizable nozzles or additional accessories, making them more versatile in handling various surfaces. When comparing these tools, it’s crucial to consider not just raw power but also the level of control Customer Reviews and Feedback Insights

Understanding customer opinions provides valuable insights into the performance and reliability of any product. Through firsthand experiences, users share their perspectives on functionality, ease of use, and durability, offering potential buyers a clearer view of what to expect. Positive feedback often highlights key advantages, including the quality of design and efficiency. Users frequently note how specific features enhance their overall experience, making tasks easier and more manageable. On the other hand, constructive criticism sheds light on areas that may require improvement. Common themes in reviews might touch on aspects such as handling, maintenance, or specific functionalities. This balanced feedback allows future customers to make informed decisions and helps manufacturers refine their offerings. |

|---|