When it comes to maintaining the efficiency and longevity of your cleaning equipment, a comprehensive grasp of its internal mechanisms is essential. This knowledge not only helps in troubleshooting issues but also facilitates better care and maintenance practices. Familiarity with the various elements that make up the machinery can significantly enhance your cleaning experience and ensure optimal performance.

In this section, we will delve into a detailed overview of the different sections and functionalities of your device. By examining the arrangement and purpose of each component, users can quickly identify areas that may require attention or replacement. This understanding empowers owners to carry out routine checks and repairs, ultimately saving time and money.

Furthermore, visual aids such as schematics serve as invaluable tools for both novice and experienced users. They provide clarity on how components interact, allowing for a more intuitive approach to maintenance. Whether you are troubleshooting a minor issue or planning a significant overhaul, having access to a clear representation of the machinery’s layout can be immensely beneficial.

Understanding Simoniz 2000 Pressure Washer

This section provides a comprehensive overview of a popular cleaning device designed for high-efficiency tasks. It highlights the key components that contribute to its functionality, ensuring effective performance in various applications. Grasping the essential elements involved will empower users to maintain and troubleshoot the equipment effectively.

When examining the intricacies of this machine, it’s important to recognize its primary elements that work in harmony to deliver optimal results. Familiarity with these components allows for informed decisions regarding maintenance and repairs, ultimately prolonging the life of the device.

| Component | Description |

|---|---|

| Motor | Drives the entire system, providing the necessary power for operation. |

| Pump | Pressurizes the water, enabling it to flow at high speeds for effective cleaning. |

| Nozzle | Regulates the water flow and pressure, allowing for different spray patterns. |

| Hose | Connects the device to the water source, facilitating fluid movement. |

| Handle | Provides user control and maneuverability during operation. |

Understanding these fundamental components will enhance user experience and efficiency, paving the way for successful cleaning endeavors.

Importance of Pressure Washer Parts

Understanding the components of a cleaning device is crucial for maintaining its efficiency and longevity. Each element plays a specific role, contributing to the overall functionality and effectiveness of the equipment. By ensuring that every component is in good working order, users can achieve optimal results in their cleaning tasks.

Functionality and Performance

The individual elements of a cleaning system are designed to work together harmoniously. When any part is compromised, it can lead to decreased performance, making it harder to achieve the desired level of cleanliness. Regular checks and timely replacements are essential to maintain peak functionality and ensure the machine operates smoothly.

Safety and Reliability

Properly functioning components are also vital for safety during operation. Faulty or worn-out elements can lead to malfunctions that pose risks to the user. Regular maintenance and understanding the importance of each part not only enhance performance but also ensure that the equipment remains safe and reliable over time.

Common Issues with Simoniz 2000

When utilizing any cleaning device, users may encounter a range of common challenges that can affect performance and efficiency. Identifying and addressing these issues promptly is essential for maintaining optimal functionality and extending the lifespan of the equipment.

Performance Problems

One frequent concern is a noticeable decrease in cleaning efficiency. This can stem from various factors, including clogged nozzles or worn-out seals. Regular maintenance and inspections can help alleviate these issues, ensuring that the device operates at peak performance. Users should also pay attention to water flow and pressure settings, as improper adjustments can lead to unsatisfactory results.

Starting Difficulties

Another common issue is trouble starting the device. This can be attributed to various elements, such as fuel supply problems, electrical malfunctions, or battery failures. Checking connections and ensuring that all components are in good condition can often resolve these starting difficulties. Additionally, users should regularly maintain the motor to prevent future issues.

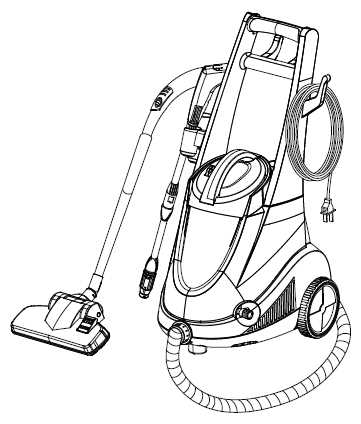

Parts Diagram Overview

This section provides a comprehensive look at the components and their arrangement in a specific cleaning device. Understanding the layout and function of each element is crucial for effective maintenance and troubleshooting.

Each component plays a vital role in the overall operation, ensuring efficiency and reliability. By examining the illustration, users can easily identify parts that may require attention or replacement.

Key benefits of reviewing the component layout include improved familiarity with the unit, easier identification of issues, and enhanced ability to perform repairs. Additionally, this knowledge facilitates better decision-making when sourcing replacements.

In summary, a thorough understanding of the assembly not only aids in maintenance but also promotes optimal performance and longevity of the equipment.

Identifying Key Components

Understanding the essential elements of your cleaning device is crucial for effective maintenance and troubleshooting. By familiarizing yourself with these components, you can ensure optimal performance and longevity of the equipment.

Here are the primary components you should recognize:

- Motor: This is the heart of the machine, providing the necessary power to operate the system.

- Pump: Responsible for generating the flow of water, it creates the pressure needed for cleaning.

- Hose: The flexible tube that directs the water from the pump to the nozzle.

- Nozzle: This attachment controls the water stream, allowing for various cleaning tasks by altering the spray pattern.

- Trigger Gun: The handheld device that controls the flow of water; it’s essential for user convenience and safety.

- Wheels: Facilitating mobility, they allow for easy maneuvering of the equipment during use.

Recognizing these components will help you better understand the functionality of your cleaning unit and aid in effective troubleshooting and repairs.

How to Read the Diagram

Understanding a technical illustration is essential for effective maintenance and troubleshooting. This guide will help you navigate through the visual representation, enabling you to identify various components and their interconnections. By familiarizing yourself with the key elements of the illustration, you’ll be better equipped to perform repairs and enhancements.

Identifying Key Components

Start by looking for labeled sections that indicate specific parts. These labels often use abbreviations or symbols. Take note of any accompanying numbers, as they usually correspond to a list that details each element. Familiarize yourself with the terminology used, as this will facilitate easier reference when consulting manuals or seeking replacement items.

Understanding Connections and Functions

Next, examine how each part interacts with others. Arrows or lines typically illustrate connections and flow paths. This information is crucial for understanding how the system operates as a whole. Pay attention to any indications of directional flow or operational sequences, as these details are vital for ensuring optimal performance during use.

Replacement Part Options Available

When it comes to maintaining your cleaning equipment, having access to a variety of replacement components is essential. Ensuring that each part is functioning optimally can significantly enhance performance and longevity. This section will explore the diverse options available for sourcing these vital elements, enabling users to make informed decisions for their maintenance needs.

Numerous retailers offer an extensive selection of compatible elements, ranging from essential internal mechanisms to external fittings. Online platforms frequently provide detailed catalogs that facilitate easy navigation and comparison. It’s advisable to consider factors such as compatibility, quality, and warranty when selecting replacement items to ensure optimal performance.

Local hardware stores and specialized service centers often carry a range of components as well. Engaging with knowledgeable staff can lead to valuable insights and recommendations tailored to specific equipment. Additionally, many manufacturers provide direct access to their components through official channels, ensuring authenticity and reliability.

For those who prefer a DIY approach, various instructional resources are available. These guides can assist in identifying the necessary components and provide step-by-step instructions for installation. This empowerment allows users to take control of their equipment maintenance efficiently and effectively.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your cleaning equipment requires regular care and attention. Implementing a consistent maintenance routine not only enhances performance but also extends the lifespan of your machine.

Here are essential tips to keep your device in top shape:

- Regular Cleaning: After each use, clean the exterior and any removable components to prevent the buildup of dirt and grime.

- Check for Wear: Inspect hoses and connectors for signs of wear or damage, replacing them as necessary to avoid leaks.

- Fluid Levels: Regularly monitor and replenish necessary fluids, ensuring optimal operation and preventing overheating.

- Storage Conditions: Store the equipment in a dry and temperature-controlled environment to prevent corrosion and damage.

By adhering to these guidelines, you can significantly improve the longevity and reliability of your cleaning apparatus, ensuring it remains effective for years to come.

Tools Needed for Repairs

When it comes to fixing your cleaning equipment, having the right tools on hand is crucial for a successful repair. The following section outlines the essential instruments that will aid you in the maintenance and restoration processes, ensuring efficiency and effectiveness in your tasks.

Essential Instruments

Before starting any repair job, gather these vital tools:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and tighten screws of various sizes. |

| Wrench Set | For loosening and tightening nuts and bolts. |

| Pliers | To grip, twist, or cut wires and other materials. |

| Multimeter | For checking electrical connections and diagnosing issues. |

| Replacement Parts | Necessary components to replace worn or damaged items. |

Additional Supplies

Besides basic tools, consider these additional supplies to enhance your repair experience:

| Supply | Purpose |

|---|---|

| Lubricant | To ensure smooth operation of moving parts. |

| Cleaning Supplies | To clean components before reassembly. |

| Safety Gear | To protect yourself during repair activities. |

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring functionality to your cleaning device. By following a systematic process, you can identify and resolve common issues effectively. Each step is designed to be clear and concise, ensuring that even those with minimal experience can tackle the repairs confidently.

Identifying the Problem

Begin by observing the unit for any signs of malfunction. Common issues may include unusual noises, leaks, or a lack of performance. Take note of any symptoms, as this information will be crucial in diagnosing the root cause.

Gathering Necessary Tools

Before commencing repairs, ensure you have all required tools at hand. Typical instruments might include wrenches, screwdrivers, and replacement components. Organizing your workspace will facilitate a smoother repair process and minimize potential disruptions.

Where to Buy Replacement Parts

Finding suitable components for your cleaning equipment can be a straightforward task if you know where to look. Numerous resources are available, both online and offline, that cater specifically to those in need of quality replacements. This section will guide you through various options to ensure your machine operates efficiently once again.

Online Retailers: The internet is a treasure trove of options. Major e-commerce platforms offer a wide selection of components, often accompanied by customer reviews and ratings. This can help you make informed decisions about quality and reliability.

Manufacturer Websites: Many original manufacturers maintain an online presence where you can purchase official replacements. These sites usually provide detailed information about compatibility, ensuring you find exactly what you need.

Local Hardware Stores: Don’t overlook your local shops. Many hardware stores carry a variety of replacement items and can offer personalized assistance. This can save you shipping time and costs, allowing you to get back to work faster.

Specialty Suppliers: There are suppliers who focus solely on cleaning equipment. These businesses often have extensive inventories and knowledgeable staff who can help you locate the right items for your specific needs.

Regardless of where you choose to shop, ensure that you verify the compatibility of the components with your equipment. Doing so will help you avoid any inconveniences and ensure a seamless restoration process.

Frequently Asked Questions

This section aims to address common inquiries regarding the components and functionality of various cleaning devices. Whether you are seeking information about maintenance, troubleshooting, or replacement, we’ve compiled a list of frequent concerns to assist you.

General Inquiries

- What are the essential components of a typical cleaning device?

- How can I identify if a component needs replacement?

- What maintenance practices should I follow to ensure longevity?

Troubleshooting Issues

- If the machine won’t start, what steps should I take?

- How can I fix low performance issues?

- What should I do if there’s a leak?