The efficient functioning of any lawn maintenance equipment relies on a well-organized system of interconnected elements. These elements work together to ensure smooth performance and precise control. Knowing how each component fits within the larger framework can help in maintaining, repairing, or optimizing the machine for various conditions.

When it comes to ensuring proper operation and extending the lifespan of such equipment, having a clear understanding of its mechanical structure is essential. Each individual part plays a unique role in the overall system, contributing to its ability to handle various terrains and user needs. By familiarizing yourself with these elements, you can improve the performance and longevity of your machine.

This guide will provide a detailed breakdown of the key elements, illustrating how they work together to deliver effective results. Whether you’re looking to troubleshoot an issue or simply better understand the structure of your equipment, this overview will serve as a helpful reference.

Understanding the Toro Personal Pace System

The mechanism behind this advanced self-propelling system provides an intuitive approach to lawn care. The design focuses on adapting to the user’s natural movement, allowing effortless control without the need for constant adjustments. By adjusting automatically to the speed of the operator, this system enhances ease of use, reducing physical strain and increasing efficiency during operation.

How the System Adapts to Movement

At the core of this feature is its ability to match the operator’s walking pace. As the user walks faster, the machine responds instantly by increasing its speed, and as the user slows down, it gently adjusts. This automatic response creates a seamless mowing experience, where manual intervention becomes unnecessary.

Benefits of Using a Responsive System

The responsive nature of the propulsion ensures that mowing large or uneven areas becomes significantly easier. Comfort and efficiency are prioritized, as the system minimizes user effort and maximizes performance by continuously adapting to changing conditions.

Key Components of the Mower Drive

The drive mechanism is a crucial part of any machine, ensuring smooth and efficient movement during operation. Understanding the key elements of this system helps in maintaining optimal performance and prolonging the life of the equipment. Below is an overview of the fundamental components that make up the propulsion system, which work together to deliver reliable functionality.

Transmission plays a pivotal role in converting engine power into forward motion. It regulates the speed and movement, allowing for smooth transitions between different speeds and terrains.

Drive Belt connects the motor to the wheels, transferring energy that powers the movement of the machine. Regular inspection and maintenance of the belt are essential to prevent wear and ensure continuous operation.

Wheels and Axles form the core of the motion system. The wheels provide traction, while the axles ensure the correct rotation and alignment. These components must be kept in good condition to avoid operational issues.

In summary, keeping the drive system in optimal shape is essential for maintaining efficiency. Regular maintenance of these components will ensure the machine operates smoothly and consistently across various conditions.

Blade Assembly and Its Functions

The structure responsible for cutting vegetation is a key component in any machine designed for maintaining outdoor spaces. Its sharp edges ensure efficient trimming, while the overall design contributes to smooth and consistent operation. Understanding its composition and how each part interacts is crucial for both performance and longevity.

Below is a breakdown of the main elements within this system and their specific roles:

| Component | Function |

|---|---|

| Blade | Performs the primary cutting action, slicing through grass with sharp precision. |

| Mounting Bolt | Secures the blade to the machine, ensuring stability and proper alignment during operation. |

| Blade Adapter | Connects the blade to the motor shaft, allowing efficient transfer of power for optimal rotation. |

| Spacer | Maintains proper distance between the blade and the deck, ensuring safe and effective operation. |

Each component plays a vital role in ensuring the efficiency and durability of the system, making routine maintenance essential for peak performance.

Exploring the Engine Mounting Parts

The foundation of any machinery’s operation is supported by a reliable connection between the engine and its frame. Understanding the components responsible for securing the engine in place ensures a stable and efficient system. These elements contribute to minimizing vibration and maintaining optimal alignment during use.

Brackets and fasteners play a critical role in anchoring the engine to the main structure. Each component must be precisely aligned to distribute the weight evenly, ensuring the machine operates smoothly.

Another essential component is the vibration dampening system, which is designed to absorb movement and reduce wear on the connecting elements. By doing so, it extends the lifespan of both the engine and the surrounding parts.

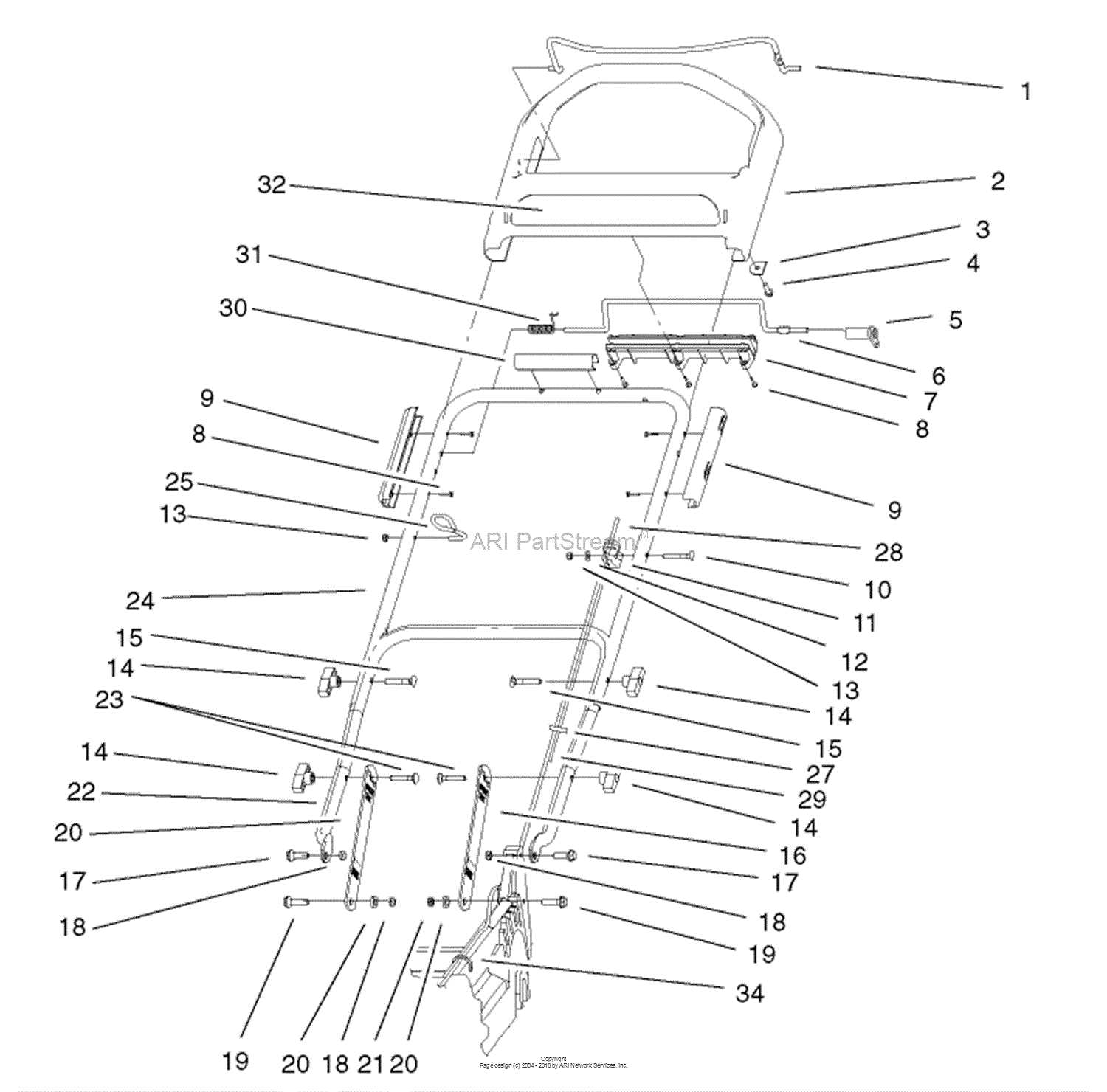

Handlebar and Control Mechanisms Overview

The steering and control elements are essential components for operating this equipment. They provide the user with a way to guide, maneuver, and control various functions. A well-designed system ensures a smooth and efficient operation, minimizing physical effort while maximizing control.

Main Handle Features

- Adjustable grip for enhanced comfort and control

- Ergonomically positioned levers for easy access

- Durable material designed for long-lasting use

Control System Functions

Several key mechanisms work together to ensure optimal performance. These systems allow the operator to engage or disengage movement, adjust speed, and maintain stability during operation.

- Throttle control for regulating engine speed

- Brake lever for halting movement quickly

- Clutch mechanism ensuring smooth transitions during operation

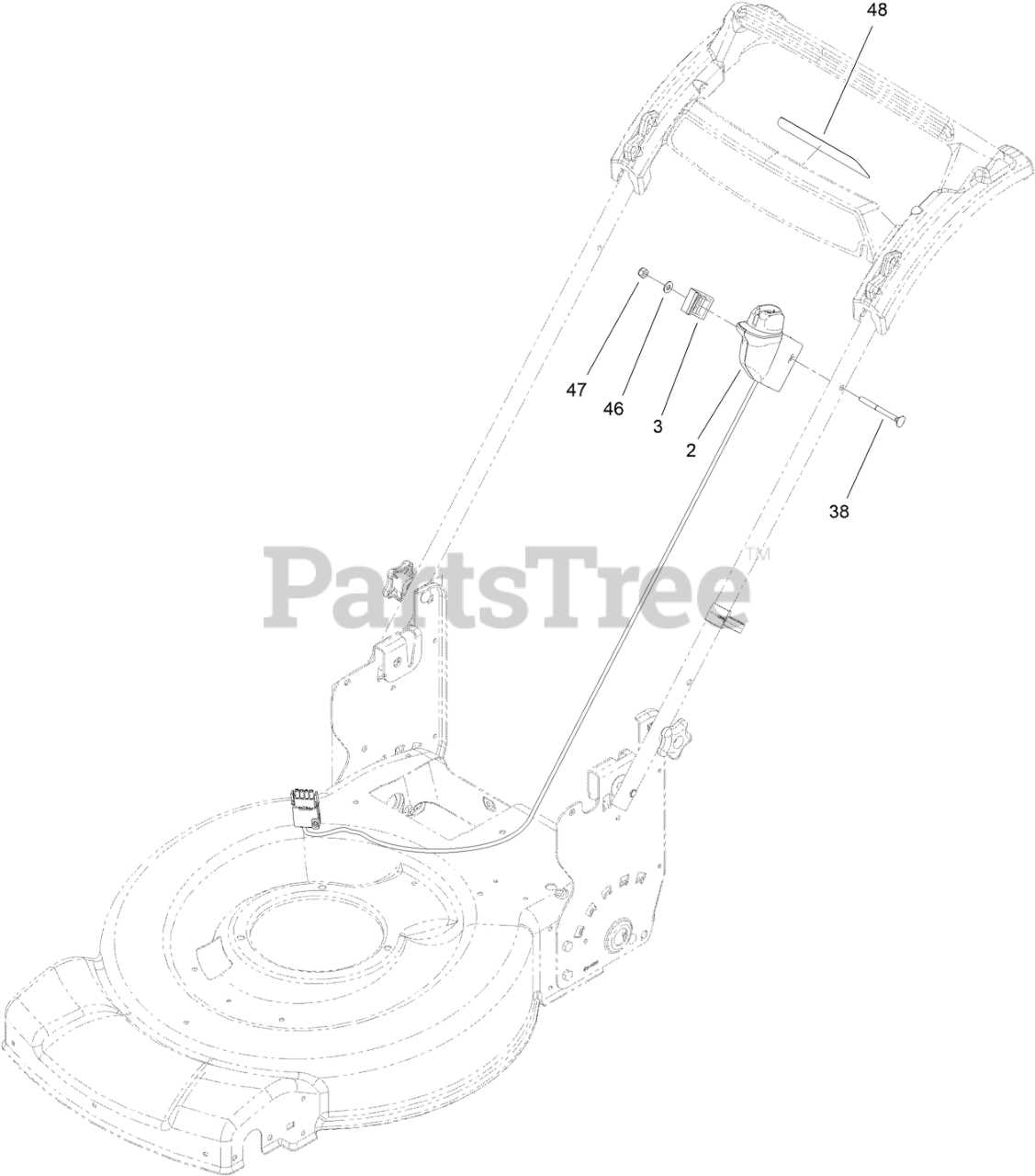

Self-Propelled Drive Belt Diagram

This section focuses on the mechanism responsible for providing motion in lawn maintenance equipment, emphasizing the role of the flexible band that transfers power from the engine to the wheels. Understanding this system is crucial for proper maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Components of the Drive System

The primary elements that constitute the drive system include:

- Engine: The power source that drives the entire mechanism.

- Drive Belt: The flexible band that transfers energy from the engine to the drive wheels.

- Pulleys: Components that guide the belt and facilitate its movement.

- Gear Assembly: Helps to control the speed and torque delivered to the wheels.

Installation and Maintenance Tips

To ensure the proper function of the propulsion mechanism, consider the following recommendations:

- Regularly inspect the condition of the flexible band for signs of wear or damage.

- Ensure proper tension on the band to prevent slippage or excessive strain.

- Lubricate moving parts as needed to facilitate smooth operation.

- Replace any worn or damaged components promptly to maintain performance.

Fuel System Components Layout

This section provides an overview of the essential elements that constitute the fuel delivery system in lawn maintenance equipment. Understanding the arrangement and functionality of these components is crucial for efficient operation and maintenance.

The fuel system is designed to ensure a reliable supply of fuel to the engine, which is vital for optimal performance. Each component plays a specific role, from storage to delivery, facilitating the necessary flow and pressure required for efficient combustion.

| Component | Description |

|---|---|

| Fuel Tank | Holds the fuel supply, ensuring a steady reserve for operation. |

| Fuel Pump | Transports fuel from the tank to the engine, maintaining adequate pressure. |

| Fuel Filter | Cleanses the fuel by removing impurities before it reaches the engine. |

| Fuel Line | Conveys the fuel between the tank, pump, filter, and engine. |

| Carburetor | Mixes fuel with air in the correct ratio for combustion in the engine. |

Throttle and Control Cable Setup

The proper configuration of the throttle and control cables is essential for achieving optimal performance in lawn care equipment. These components play a critical role in regulating the engine’s speed and ensuring that the operator can manage the machine effectively. An accurate setup not only enhances usability but also contributes to the longevity of the device.

Understanding the components involved in the throttle system is the first step. Cables typically connect the control lever to the engine, enabling smooth acceleration and deceleration. Regular inspection for wear or damage is necessary to maintain efficient operation. If any signs of fraying or kinks are present, replacing the cables promptly is advised.

Installation should be conducted with attention to detail. Ensure that the cables are routed correctly, avoiding sharp bends that could impede movement. The adjustments must be precise, allowing for immediate response when the control lever is engaged. Following the manufacturer’s guidelines will help in achieving the desired setup, enhancing both safety and effectiveness during use.

Wheels and Axle Structure Breakdown

This section delves into the intricate components that support mobility in cutting equipment. The configuration and design of these elements play a crucial role in ensuring smooth operation and stability during use.

Understanding the various parts involved can enhance maintenance practices and improve overall performance. Here, we explore the key components:

- Wheels: These elements facilitate movement across diverse terrains and are designed to withstand wear and tear.

- Axles: Acting as the central shafts, axles connect the wheels and allow for rotation, contributing to the equipment’s agility.

- Bearings: These components reduce friction between moving parts, ensuring a smooth and efficient rotation of the wheels.

- Spindles: Serving as the connection points for the wheels, spindles are vital for maintaining alignment and support.

Regular inspection and maintenance of these components are essential for optimal functionality. Consider the following practices:

- Check for any signs of wear on the wheels and replace them if necessary.

- Inspect axles for any damage that may affect performance.

- Ensure bearings are well-lubricated to prevent overheating.

- Examine spindles for tightness and alignment.

By familiarizing yourself with the wheel and axle system, you can ensure that your cutting equipment operates efficiently and reliably.

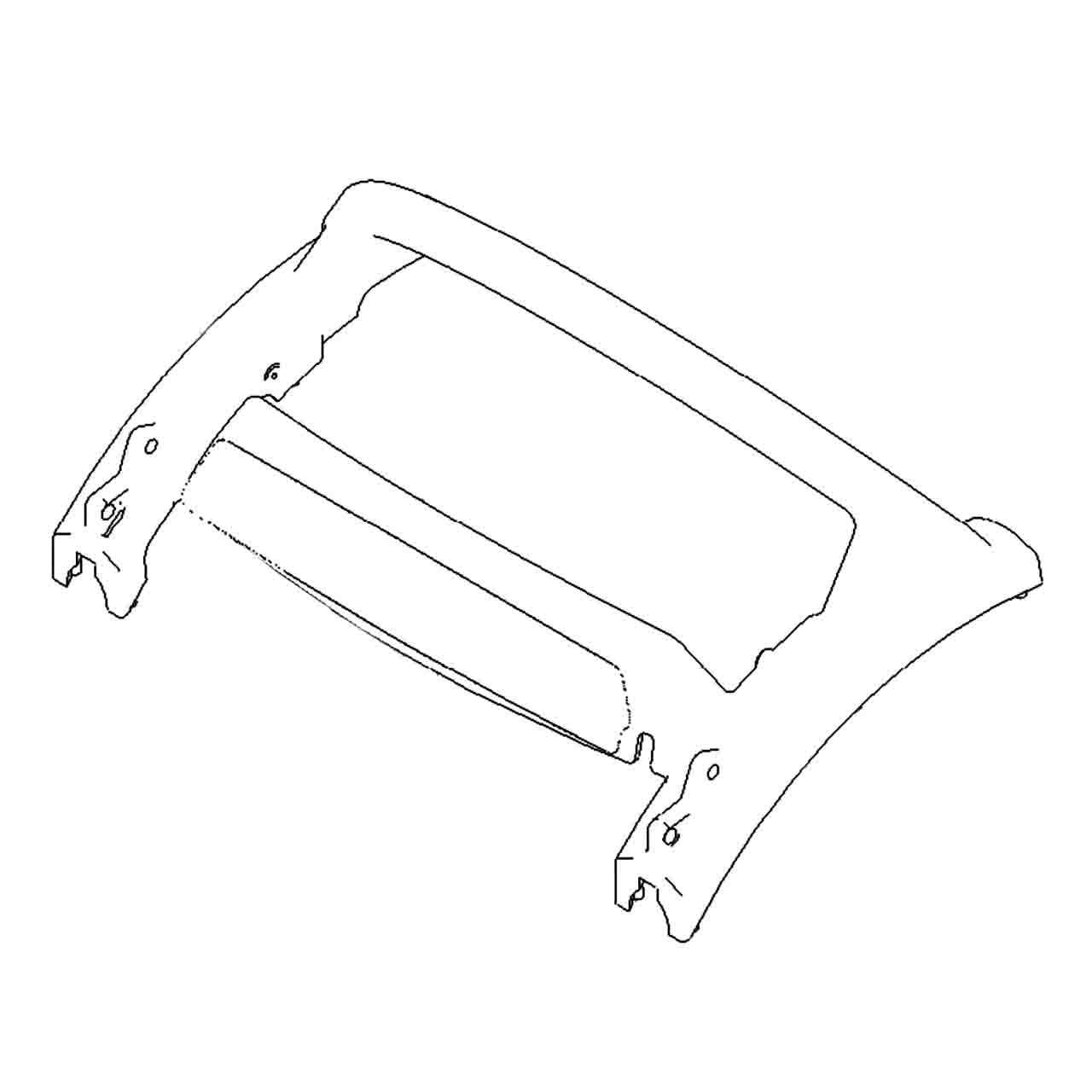

Deck Design and Cutting Adjustments

The design of the cutting platform and the ability to modify the height of the blades are crucial for achieving an optimal cutting experience. This section explores the various elements involved in the structure and functionality of the cutting mechanism, highlighting how these factors influence performance and results.

Key Features of Cutting Platform Design

- Shape and Material: The configuration and composition of the cutting platform can significantly impact durability and efficiency.

- Blade Arrangement: The positioning of the blades determines the effectiveness of the cutting process, allowing for uniform grass length and health.

- Airflow Dynamics: Proper airflow enhances grass discharge and minimizes clumping, resulting in a cleaner cut.

Adjusting Cutting Heights

Modifying the height of the cutting blades is essential for adapting to varying grass types and conditions. Users can achieve the desired length by following these steps:

- Locate the adjustment lever or mechanism.

- Choose the appropriate height setting based on the desired grass length.

- Ensure that all blades are set to the same height for an even cut.

By understanding the intricacies of deck design and making necessary adjustments, users can enhance their mowing efficiency and ensure a well-maintained lawn.

Transmission and Speed Control Parts

This section delves into the components responsible for the transmission and regulation of velocity within the equipment. Understanding these elements is crucial for ensuring optimal functionality and performance during operation. Each component plays a significant role in facilitating smooth movement and enhancing the user experience.

Key Components

- Gearbox Assembly: This unit is vital for converting engine power into usable torque.

- Drive Belt: A crucial element that connects the engine to the transmission, allowing for efficient power transfer.

- Speed Control Lever: This component enables the user to adjust the pace of operation according to specific needs.

- Transmission Control Cable: It links the speed control lever to the transmission, facilitating the transmission of user commands.

Maintenance Tips

- Regularly inspect the drive belt for signs of wear and replace if necessary.

- Ensure the gearbox is adequately lubricated to prevent overheating and wear.

- Check the transmission control cable for fraying or damage to maintain smooth operation.

- Periodically test the speed control lever for responsiveness to ensure precise adjustments.

Maintenance Tips for Key Parts

Proper upkeep of essential components is vital for ensuring the longevity and efficiency of your equipment. By regularly inspecting and servicing these crucial elements, you can prevent potential issues and enhance overall performance.

Regular Cleaning

Keeping key components free from debris and dirt is essential. Here are some tips:

- Utilize a soft brush or cloth to remove dust and grime.

- Inspect air filters regularly and clean or replace them as needed.

- Ensure that ventilation areas are unobstructed to promote airflow.

Periodic Inspections

Routine checks can help identify wear and tear before it becomes a significant problem. Consider the following:

- Examine belts and cables for fraying or damage.

- Check fluid levels and top them off to avoid overheating.

- Assess blades for sharpness; dull blades can lead to uneven cutting.

Common Issues with Toro Mowers

Owners of residential lawn maintenance machines often encounter a variety of challenges that can affect performance and usability. Understanding these frequent concerns can help users address them more effectively and maintain their equipment in optimal condition.

1. Engine Performance Problems: One of the most prevalent issues involves engine troubles, such as stalling or difficulty starting. This can stem from various factors, including fuel quality, spark plug condition, or air filter blockage.

2. Cutting Quality Concerns: Another common complaint is uneven cutting, which may result from dull blades, improper height adjustments, or uneven terrain. Regular blade maintenance and adjustments can significantly improve the cutting experience.

3. Drive System Issues: Users may also face difficulties with the drive mechanism, such as reduced traction or slipping. These problems can be linked to worn belts or malfunctioning drive wheels, necessitating timely inspections and replacements.

4. Electrical System Failures: Malfunctions in the electrical components can lead to starting issues or failure of operational features. Checking the battery and wiring connections is crucial for ensuring reliable performance.

5. Clogging and Debris Buildup: Accumulation of grass clippings and debris can impede the machine’s functionality. Regular cleaning and maintenance of the undercarriage help prevent clogs and promote efficient operation.