The functionality and efficiency of a lawn maintenance implement rely heavily on its various components. A thorough examination of these elements is crucial for ensuring optimal performance and longevity. By familiarizing oneself with the intricate details of the assembly, users can better maintain their equipment and troubleshoot any issues that may arise.

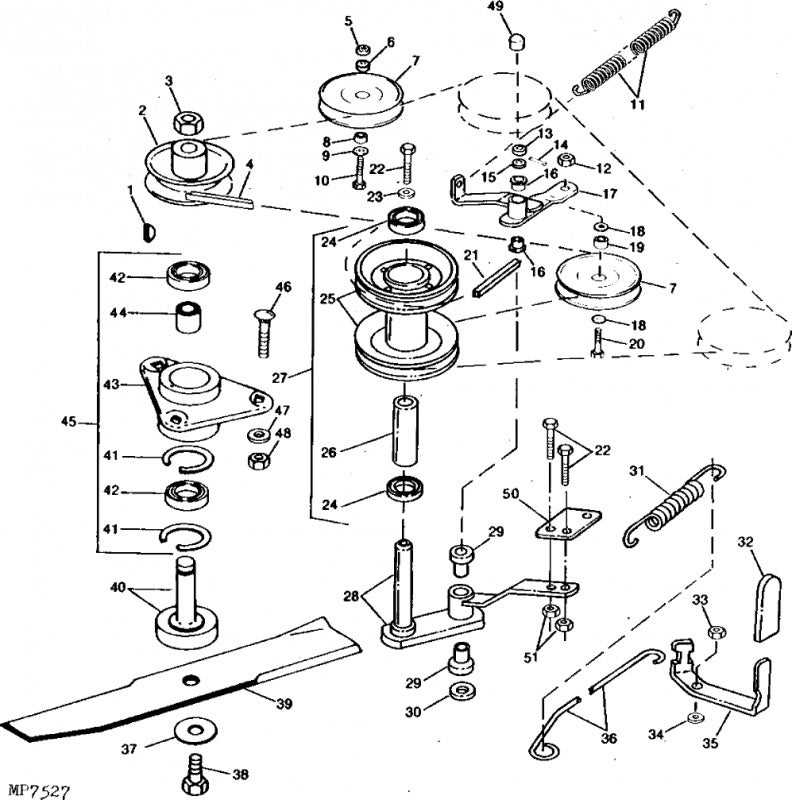

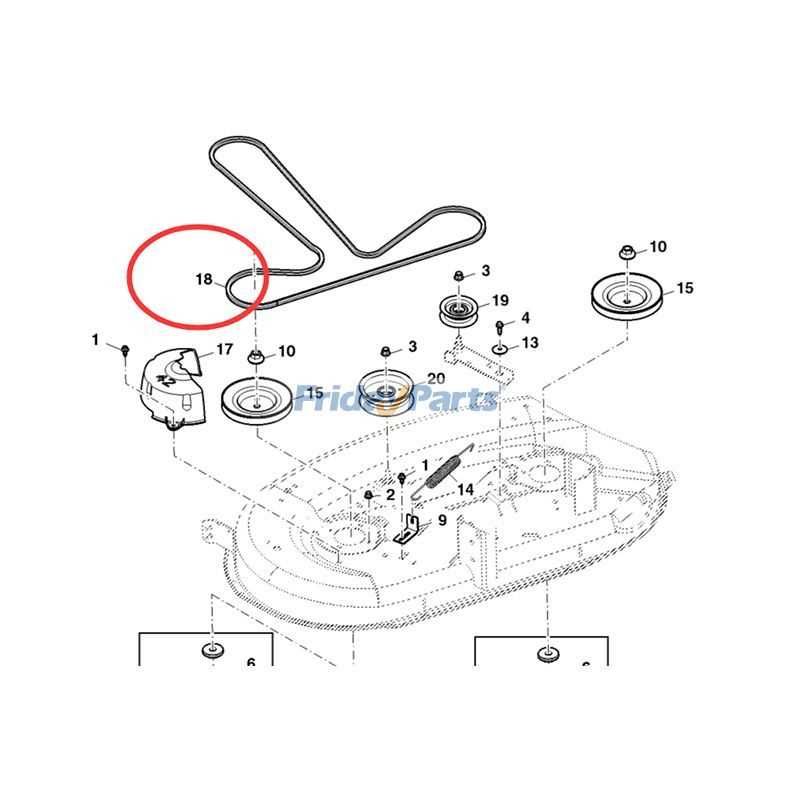

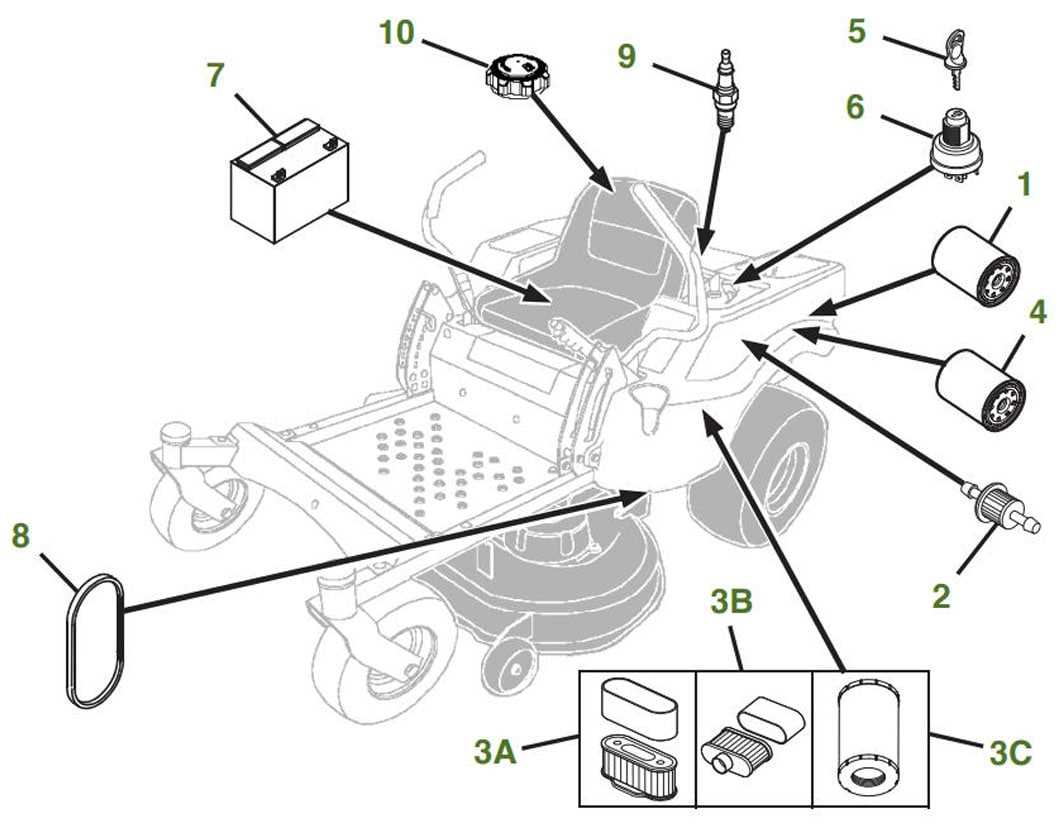

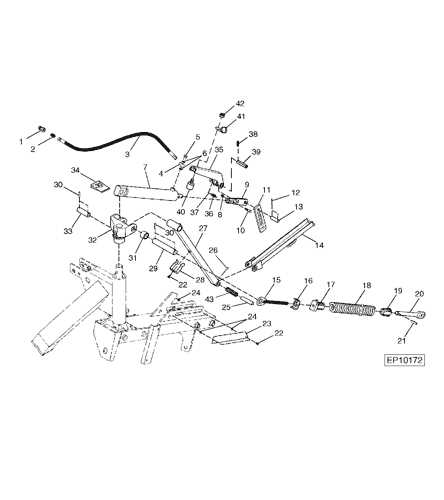

Detailed schematics serve as invaluable resources for understanding how each component interacts within the overall system. These illustrations offer insights into the configuration and alignment of individual elements, allowing operators to grasp the importance of each part in achieving effective operation. With this knowledge, users are empowered to undertake necessary repairs and adjustments with confidence.

Moreover, comprehending the arrangement of these components can enhance one’s ability to optimize performance. Knowledge of how parts work together enables individuals to make informed decisions regarding maintenance practices and potential upgrades. This understanding not only contributes to a more efficient experience but also promotes a deeper appreciation for the engineering that underpins modern lawn care technology.

Proper upkeep of your equipment is essential for ensuring its durability and optimal performance over time. By following a few key practices, you can extend the lifespan of your machinery and enhance its efficiency.

- Regular Inspection: Conduct frequent checks for any signs of wear or damage. This includes looking at blades, belts, and other components that may require attention.

- Cleaning: After each use, remove debris and dirt from the machine to prevent rust and corrosion. Pay special attention to hard-to-reach areas.

- Lubrication: Apply lubricant to moving parts as recommended in the user manual. Proper lubrication reduces friction and wear.

- Sharpen Blades: Keep blades sharp to ensure clean cuts and minimize strain on the engine. Dull blades can lead to excessive wear and poor performance.

- Storage: Store the equipment in a dry and sheltered area to protect it from the elements. Using a cover can help keep it safe from dust and moisture.

- Check Fluids: Regularly inspect and change fluids as needed, including oil and fuel. Clean, fresh fluids contribute to smoother operation.

By adhering to these guidelines, you can promote the longevity of your machinery and ensure reliable performance for many seasons to come.

Identifying Replacement Parts

When it comes to maintaining your equipment, understanding how to recognize and source components is essential for ensuring optimal performance. Accurately identifying necessary elements can save time and reduce costs associated with repairs. This section aims to provide guidance on how to effectively pinpoint what you need for your specific machinery.

Common Types of Components

- Blades: Essential for cutting and require periodic replacement to maintain efficiency.

- Belts: Vital for transmitting power; worn or damaged belts can affect performance.

- Filters: Crucial for keeping the engine and other systems clean from debris.

- Spindles: Important for rotating blades; a malfunctioning spindle can hinder operation.

Steps to Identify Components

- Refer to the owner’s manual for a comprehensive list of necessary components.

- Inspect the existing items for any visible signs of wear or damage.

- Consult online resources or diagrams that outline various elements and their functions.

- Contact local suppliers or online retailers for assistance in sourcing the correct replacements.

How to Access Mower Deck Parts

Gaining entry to the essential components of your cutting apparatus is a fundamental step in ensuring its optimal performance. This process allows for thorough inspection, maintenance, and replacement of various elements, contributing to the longevity of your equipment.

Follow these steps to access the vital components efficiently:

- Gather necessary tools, including a wrench set, screwdriver, and safety gloves.

- Ensure the machine is on a flat surface and the engine is turned off for safety.

- Disconnect the power source to prevent accidental activation.

Once safety precautions are in place, proceed as follows:

- Locate the securing bolts or clips that hold the cover in place.

- Carefully remove these fasteners using the appropriate tools.

- Lift or detach the cover to reveal the internal components.

- Inspect each section for wear and damage, making notes of any parts that may require replacement.

After completing the inspection, reassemble everything by reversing the steps, ensuring all fasteners are securely tightened. Regular access to these critical elements will enhance your machine’s efficiency and performance.

Tools Required for Repairs

When undertaking maintenance tasks on outdoor machinery, having the right instruments is crucial for ensuring effective and efficient repairs. Each tool serves a specific purpose, making it easier to perform various adjustments, replacements, and inspections.

Below is a list of essential instruments needed for performing repairs:

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening nuts and bolts. |

| Screwdriver Set | Required for removing and securing screws of different sizes. |

| Socket Set | Ideal for reaching fasteners in tight spaces. |

| Pliers | Useful for gripping, bending, and cutting wires or components. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Cleaning Brushes | Essential for removing debris and dirt from components. |

| Safety Goggles | Protective eyewear to safeguard against debris and particles. |

Having these tools on hand will streamline the repair process, allowing for safer and more efficient maintenance of your equipment.

Assembly Instructions for Deck Parts

This section provides essential guidance for the proper assembly of components related to the cutting apparatus. Ensuring correct installation is crucial for optimal performance and longevity.

Begin by organizing all elements and fasteners required for assembly. Familiarize yourself with each component, as understanding their functions will facilitate a smoother process. Carefully review the user manual for any specific recommendations or warnings that may apply to your model.

Start with the foundation piece, securing it firmly to the frame. Utilize the appropriate tools to ensure that all connections are tight yet not over-tightened, as this could lead to damage. Proceed by attaching the blades, ensuring they are oriented correctly to achieve the desired cutting height and efficiency.

Finally, double-check all connections for stability and alignment. Test the assembly by manually rotating the blades to ensure there is no obstruction and that movement is fluid. Proper assembly will enhance both the functionality and safety of the equipment.

Safety Precautions During Maintenance

Ensuring a safe working environment is crucial when performing upkeep on outdoor machinery. Adhering to recommended safety practices helps prevent accidents and promotes the longevity of the equipment. By following established guidelines, users can efficiently maintain their equipment while minimizing the risk of injury.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect the power source before beginning any maintenance tasks to avoid unintentional start-up.

- Keep the work area clean and free from obstructions to ensure easy movement and access to tools.

Proper Tool Handling

- Use tools that are in good condition and suitable for the specific task at hand.

- Store tools properly after use to prevent accidents and ensure they are readily available for future maintenance.

- Always follow the manufacturer’s instructions for tool operation and maintenance.

Where to Purchase Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing suitable components is crucial for ensuring optimal performance. There are various options available for obtaining high-quality replacements that cater to your specific needs.

Authorized Dealers

One of the most reliable sources for acquiring replacements is through authorized dealers. These retailers provide:

- Genuine components that meet manufacturer standards

- Expert advice on compatibility and installation

- Warranty options for peace of mind

Online Retailers

The convenience of shopping online has transformed how consumers access equipment components. Several reputable platforms offer:

- A wide variety of choices from multiple brands

- User reviews to help guide your selection

- Competitive pricing and promotional deals

Whether opting for local dealers or online marketplaces, ensuring the quality and compatibility of components is essential for maintaining your machinery.

FAQs About Mower Deck Parts

This section aims to address common inquiries regarding components related to cutting apparatus for lawn care. Understanding the various elements involved can enhance maintenance and improve overall performance.

What are the key components of a cutting apparatus?

The essential elements typically include the housing, blades, and drive system. Each part plays a crucial role in ensuring efficient operation and durability. Regular inspection of these components can prevent potential issues and extend the lifespan of the equipment.

How often should I replace the blades?

Blade replacement is recommended at least once a year or more frequently if signs of wear appear, such as dullness or nicks. Keeping the edges sharp promotes a clean cut and minimizes damage to the grass, leading to healthier growth.

For those looking to optimize their equipment, understanding these fundamental aspects is key to effective upkeep and performance enhancement.