When it comes to maintaining a pristine outdoor space, understanding the key elements of your grass-cutting equipment is crucial. Each component plays a significant role in ensuring optimal performance and longevity. This section delves into the various integral parts that contribute to the efficiency of your machine, providing clarity on their functions and importance.

Visual aids can greatly enhance your comprehension of these components. By exploring a comprehensive layout, users can easily identify each element, making repairs and maintenance tasks more manageable. This resource aims to equip you with the knowledge needed to keep your equipment running smoothly, empowering you to tackle any challenges that may arise.

Whether you’re a seasoned professional or a weekend warrior, familiarity with your machinery’s anatomy will not only save you time but also improve the overall effectiveness of your lawn care routine. Understanding these aspects can lead to better decision-making when it comes to repairs and upgrades, ensuring your investment stands the test of time.

Understanding the John Deere 445 Mower

This section explores the essential aspects of a well-known landscaping machine, focusing on its functionality, components, and overall significance in maintaining a pristine lawn. By examining its design and capabilities, users can enhance their experience and maximize efficiency during operation.

Key Features and Benefits

The machine boasts an impressive array of features, including robust performance and user-friendly controls. These elements combine to provide an effective solution for homeowners and professionals alike, ensuring a well-manicured outdoor space with minimal effort.

Maintenance and Care

Mower Deck Components Overview

This section provides a comprehensive look at the essential elements that make up the cutting mechanism of a lawn care machine. Understanding these components is crucial for maintenance and troubleshooting, ensuring optimal performance during operation.

- Cutter Blades: The sharp edges that perform the actual cutting of grass, crucial for achieving a clean finish.

- Spindle Assembly: This component houses the blades and is responsible for their rotation, allowing efficient cutting.

- Belt System: A series of belts that transfer power from the engine to the spindle, facilitating movement and speed control.

- Chassis: The frame that supports all components, providing stability and structure to the overall assembly.

- Height Adjustment Mechanism: Allows users to modify the cutting height, accommodating various grass types and desired lengths.

- Skirt or Deflector: This part helps direct clippings away from the cutting area, preventing clogging and promoting an even distribution.

Each of these elements plays a vital role in the effective functioning of the cutting unit, and regular inspection can help identify any issues that may arise over time.

Parts Diagram for 60-Inch Deck

This section provides a comprehensive overview of the components associated with the 60-inch cutting apparatus. Understanding the configuration of these elements is crucial for effective maintenance and repair. Each item plays a significant role in the overall functionality and efficiency of the machine.

Key Components: The assembly consists of various essential elements including the cutting blades, belts, and brackets. These parts work in harmony to ensure optimal performance and longevity.

Maintenance Tips: Regular inspection and timely replacement of worn components can enhance the lifespan of the equipment. Familiarity with the layout will facilitate easier repairs and upgrades.

Common Issues with Mower Decks

When it comes to maintaining your lawn equipment, certain challenges often arise that can affect performance and efficiency. Understanding these common problems is essential for effective troubleshooting and maintenance.

- Uneven Cutting: One of the most frequently encountered issues is uneven grass cutting. This can result from various factors, including blade height adjustments, dull blades, or improper tire inflation.

- Clogging: Grass buildup can lead to clogs, particularly in damp conditions. Regular cleaning after use can prevent this problem from escalating.

- Vibration: Excessive shaking during operation often indicates a misalignment of components or damaged blades. Regular inspections can help identify and rectify these issues early.

- Noise: Unusual sounds can signal mechanical problems, such as loose bolts or worn bearings. Prompt attention to these noises can avert further damage.

- Streaking: If the equipment leaves uncut strips of grass, it may be a sign of dull blades or inadequate overlap during cutting passes. Ensuring sharp blades and proper technique is key.

lessCopy code

Regular maintenance and prompt attention to these issues can significantly enhance the lifespan and efficiency of your lawn equipment, ensuring a well-kept lawn with minimal effort.

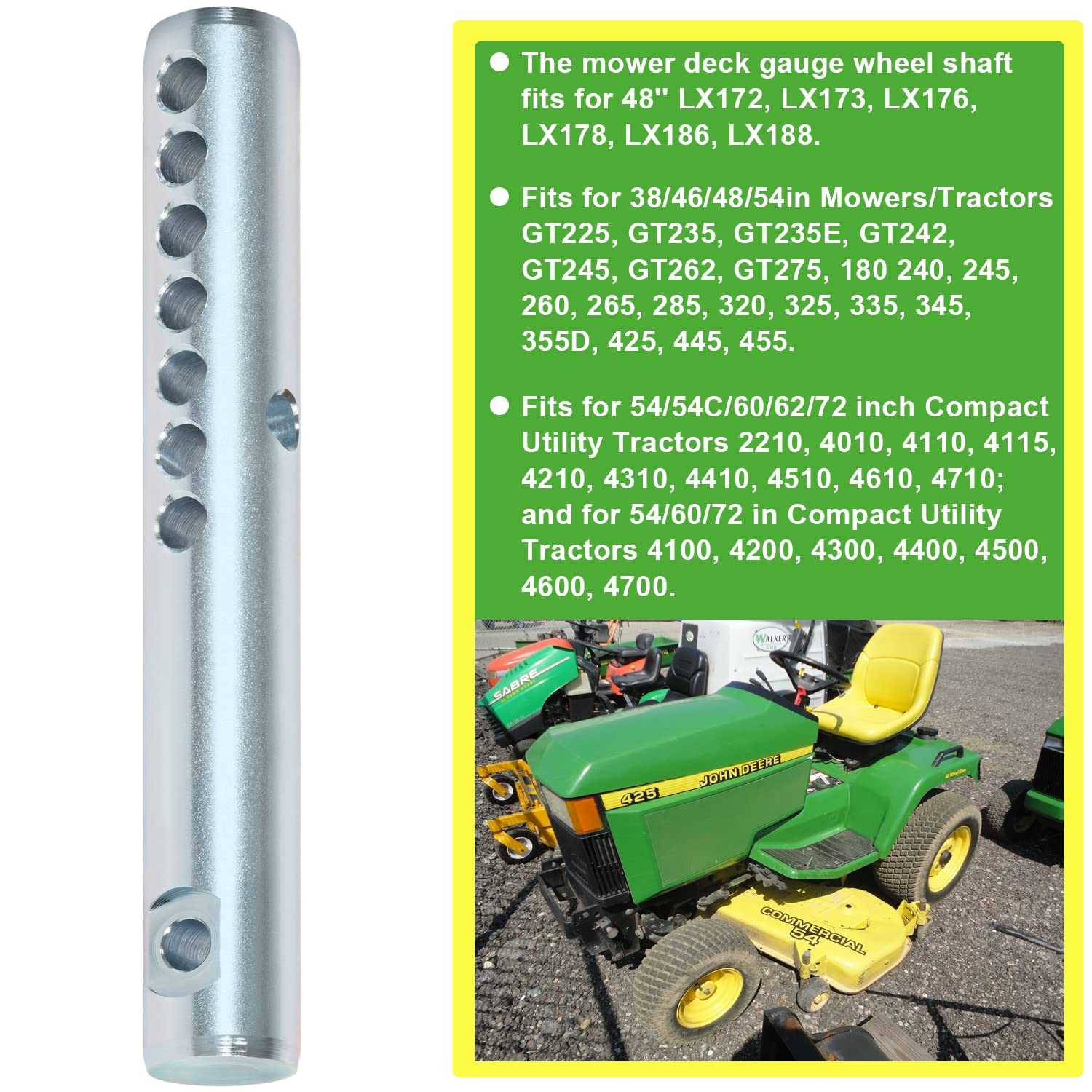

Replacement Parts for John Deere 445

Maintaining your outdoor equipment requires a thorough understanding of essential components. This section explores various options for sourcing necessary replacements that ensure optimal performance and longevity. Whether it’s for routine maintenance or unforeseen repairs, having access to quality alternatives is crucial.

Common Components: Key elements often require attention, including blades, belts, and filters. Upgrading these can significantly enhance efficiency.

Quality Considerations: When selecting replacements, consider factors such as durability and compatibility. Investing in superior products can prevent future issues and ensure smooth operation.

Where to Buy: Numerous suppliers provide reliable options, both online and in local stores. Researching reviews and specifications is vital to make informed choices.

Maintenance Tips for Mower Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your landscaping equipment. Regular attention not only enhances performance but also extends the lifespan of crucial components, allowing for a more enjoyable and effective experience.

1. Regular Cleaning: Keep the exterior and interior clean to prevent buildup of grass clippings and debris. This reduces wear and tear and promotes optimal functionality.

2. Oil Changes: Frequent oil changes are vital. Use high-quality lubricants to ensure smooth operation and protect engine components from damage.

3. Blade Maintenance: Sharpen blades regularly to ensure a clean cut. Dull blades can stress the engine and lead to uneven cutting.

4. Tire Care: Check tire pressure and tread regularly. Proper inflation enhances maneuverability and reduces strain on the machine.

5. Seasonal Storage: Prepare your equipment for off-season storage by cleaning it thoroughly and removing fuel to prevent gumming in the fuel system.

6. Inspect Belts and Cables: Regularly check for wear and tear. Replacing worn belts and frayed cables promptly can prevent larger issues down the line.

Implementing these practices will not only enhance performance but also significantly increase the longevity of your equipment.

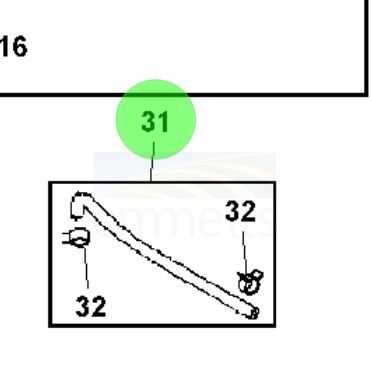

How to Identify Parts by Diagram

Understanding a schematic can greatly enhance your ability to recognize and locate various components within your equipment. This approach not only simplifies repairs but also aids in the selection of appropriate replacements. Familiarizing yourself with the visual representation allows for efficient identification and problem-solving.

Steps to Identify Components

- Examine the Overview: Start by looking at the entire schematic to get a general idea of how the elements are organized.

- Locate Labels: Identify any labels or numbers associated with specific items. These often correspond to reference lists.

- Trace Connections: Follow the lines that show how parts connect. This can reveal the function of each component.

Common Symbols and Notations

- Circles: Typically represent fasteners or joints.

- Rectangles: Often indicate solid components such as frames or covers.

- Arrows: Show the direction of movement or flow.

By becoming familiar with these visual cues, you can effectively navigate any schematic and identify components with confidence.

Tools Needed for Mower Repair

Proper maintenance of outdoor equipment requires a variety of essential instruments. Having the right tools not only streamlines the repair process but also ensures that tasks are completed safely and efficiently. Whether you are performing routine checks or significant repairs, being equipped with the appropriate gear is crucial.

Essential Tools

- Wrenches and Sockets

- Screwdrivers (flat and Phillips)

- Pliers (needle-nose and regular)

- Jack Stands or Lifts

- Torque Wrench

Additional Equipment

- Safety Gear (gloves, goggles)

- Cleaning Supplies (brushes, cloths)

- Oil and Fuel Filters

- Replacement Belts and Blades

Having these tools on hand will facilitate a smoother experience when tackling maintenance and repairs, ultimately prolonging the lifespan of your equipment.

Where to Purchase Replacement Parts

Finding the right components for your outdoor equipment is essential for maintaining performance and longevity. Various sources offer these items, catering to both DIY enthusiasts and professionals seeking quality solutions.

Authorized Dealers

Visiting certified retailers ensures access to genuine components designed specifically for your equipment. These dealers often provide expert advice and additional services to help you with installation.

Online Marketplaces

Numerous e-commerce platforms specialize in outdoor machinery components, allowing for easy comparison of prices and availability. User reviews can help in making informed decisions about your purchases.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine parts, expert advice | Potentially higher prices |

| Online Marketplaces | Convenience, price comparisons | Variable quality, shipping times |

Benefits of Upgrading Mower Components

Enhancing the various elements of your cutting machine can significantly improve its performance and efficiency. By investing in superior components, users can experience a more effective operation, leading to a more enjoyable maintenance experience.

Improved Performance: Upgrading to high-quality elements often results in better cutting efficiency and a smoother operation. Enhanced materials and designs can reduce wear and tear, prolonging the lifespan of the machine.

Enhanced Reliability: Newer components typically offer greater reliability, minimizing breakdowns and costly repairs. This ensures that your equipment operates at its best, reducing downtime.

Increased Comfort: Advanced features can lead to a more comfortable experience, allowing users to operate with less fatigue. Ergonomic designs and improved controls can make the task more enjoyable.

Cost-Effectiveness: Investing in quality upgrades can save money in the long run by increasing efficiency and reducing maintenance costs. Better components often lead to lower fuel consumption and fewer repairs.

Overall, the decision to upgrade various components can lead to significant improvements, enhancing both the performance and longevity of your equipment.

Expert Recommendations for Mower Care

Caring for your cutting equipment is essential to ensure longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Here are some key practices to keep your equipment in top shape.

1. Regular Cleaning: After each use, it’s important to clean the machine thoroughly. Remove grass clippings and debris to prevent rust and corrosion.

2. Sharp Blades: Keep the cutting blades sharp. Dull blades can tear grass instead of cutting it cleanly, leading to unhealthy lawns.

3. Oil Changes: Follow a consistent schedule for oil changes. Fresh oil helps lubricate internal components and prevents wear.

4. Fuel Quality: Use high-quality fuel and store it properly. Stale or contaminated fuel can lead to performance issues.

5. Inspection: Conduct regular inspections of belts, filters, and cables. Replacing worn parts promptly can avert breakdowns and maintain efficiency.

By implementing these recommendations, you can ensure that your equipment remains reliable and effective for years to come.