In the world of power equipment, having a clear visual representation of the individual elements that make up a machine is crucial for both maintenance and repair. Such layouts serve as valuable resources for users, helping them to identify each part and understand its function within the overall system. By familiarizing oneself with these schematics, operators can enhance their troubleshooting skills and ensure optimal performance of their tools.

Effective maintenance relies on a comprehensive understanding of how each component interacts with others. These visual guides not only facilitate the identification of specific pieces but also illustrate the relationship between various elements. This knowledge empowers users to conduct repairs more efficiently, potentially saving both time and money in the long run.

Moreover, having access to these layouts can significantly reduce the frustration often associated with disassembling and reassembling equipment. Whether for routine checks or unexpected repairs, a well-structured visual reference can simplify the process, allowing users to approach their tasks with confidence. Embracing these resources can ultimately lead to a more informed and capable operator, equipped to handle any challenge that may arise.

Dewalt Parts Diagram Overview

This section provides a comprehensive look at the visual representations used for understanding the various components of power tools. These illustrations serve as essential guides, making it easier for users to identify and locate individual elements necessary for maintenance or repair. Understanding these visuals enhances the overall experience of managing equipment effectively.

Importance of Visual Guides

Visual aids are invaluable for both beginners and experienced users. They simplify the process of disassembly and reassembly, ensuring that each piece is correctly handled. Additionally, these resources foster a deeper understanding of how tools function, ultimately leading to better care and longer service life.

Components Breakdown

| Component | Description |

|---|---|

| Motor | The core part that powers the tool. |

| Switch | Controls the on/off function. |

| Housing | Protects internal components. |

| Blade/Bit | The part that interacts with the material. |

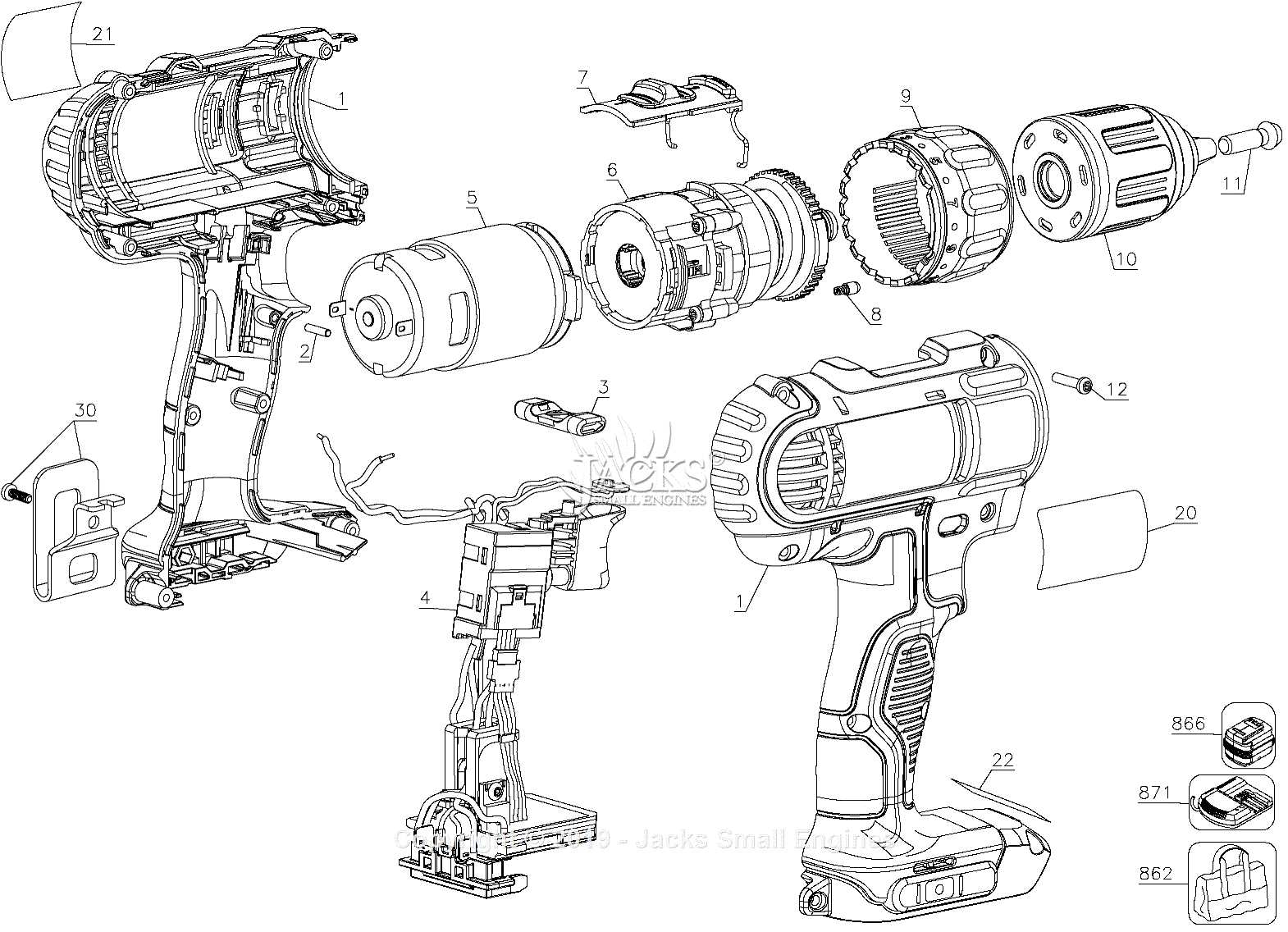

Understanding Dewalt Tool Components

Comprehending the elements that constitute power equipment is essential for effective usage and maintenance. Each component plays a critical role in the overall performance, ensuring that the tools operate efficiently and safely. By gaining insight into these components, users can enhance their skills and prolong the lifespan of their tools.

| Component | Description |

|---|---|

| Motor | The driving force behind the tool, responsible for powering the operation. |

| Switch | Controls the activation and deactivation of the device. |

| Housing | Protects internal components and provides a gripping surface for users. |

| Battery | Supplies the necessary energy for cordless operation. |

| Chuck | Secures the accessory or bit in place during use. |

Benefits of Using Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining equipment. They offer clear insights into the various elements involved, aiding users in navigating complex systems efficiently.

Here are some key advantages of utilizing such visual guides:

- Enhanced Clarity: Detailed illustrations make it easier to identify specific elements, reducing confusion during repairs or assembly.

- Efficient Troubleshooting: Quickly pinpointing faulty components helps in diagnosing issues without extensive trial and error.

- Streamlined Ordering: Knowing exact part numbers and descriptions simplifies the process of acquiring replacements.

- Improved Communication: Clear visuals facilitate better discussions between technicians and suppliers, ensuring everyone is on the same page.

- Time Savings: Understanding the layout of a device reduces the time spent searching for components during maintenance tasks.

Incorporating these visual aids into maintenance routines not only boosts productivity but also enhances overall equipment longevity.

Common Dewalt Tools and Their Diagrams

This section explores various popular tools commonly used in construction and woodworking, providing insights into their design and functionality. Understanding these tools enhances the user’s ability to operate and maintain them effectively, ensuring optimal performance and longevity.

Power Tools

Power tools are essential for efficient work in various projects. Examples include drills, saws, and sanders, each with distinct features that cater to specific tasks. Familiarity with their components can significantly aid in troubleshooting and repairs.

Hand Tools

Hand tools remain indispensable for precise tasks. Items like wrenches, screwdrivers, and pliers offer reliability and control. Knowing the arrangement of these tools’ elements helps in understanding their mechanics and enhances user experience.

In summary, having a clear comprehension of the components and assembly of both power and hand tools empowers users to make informed decisions during maintenance and usage.

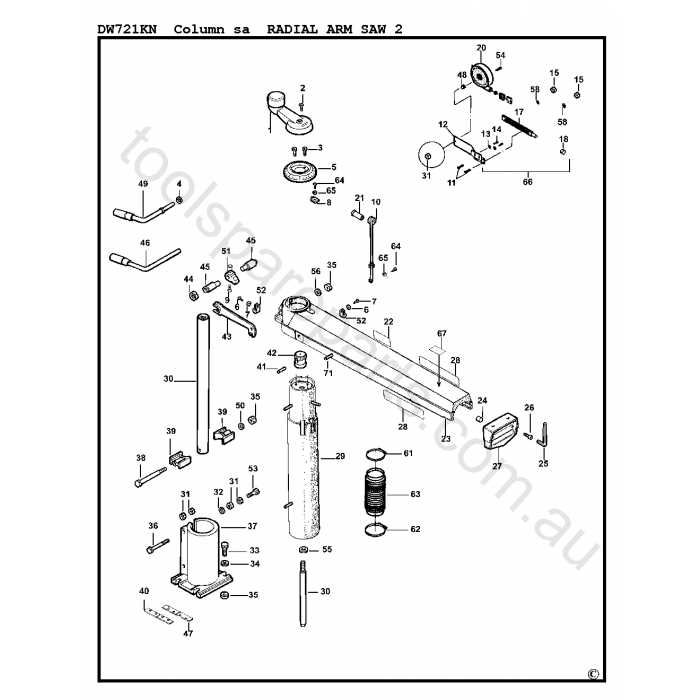

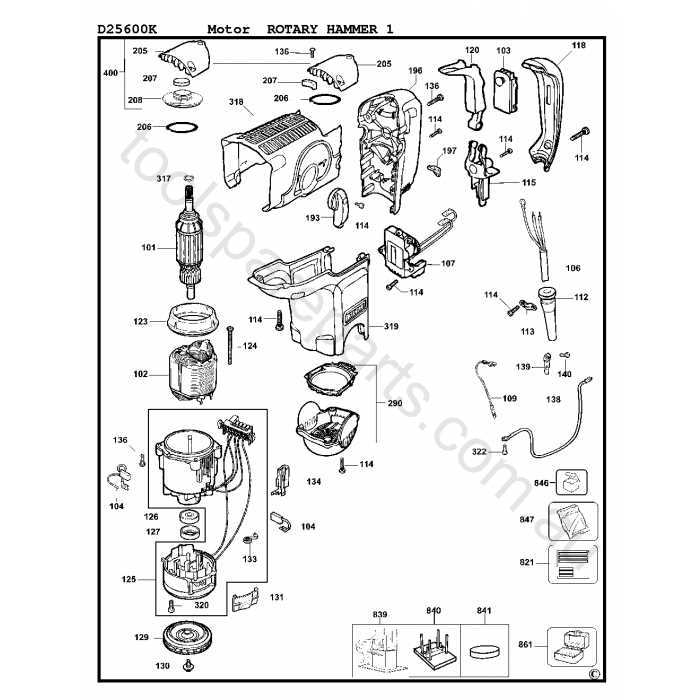

How to Read a Parts Diagram

Understanding technical illustrations is essential when it comes to assembling or repairing machinery. These visual guides provide a clear representation of components and their connections, helping users identify what they need for maintenance or replacements.

Breaking Down the Sections

Most technical illustrations are divided into different sections to make it easier to locate individual items. Each section typically represents a specific area of the equipment or system, with labels or item numbers for easy reference.

- Start by identifying the main areas or categories.

- Check for item numbers and their corresponding descriptions in the provided list.

- Use these references to find and understand how each element fits into the whole assembly.

Tips for Effective Interpretation

Reading technical illustrations efficiently requires practice. Follow these steps to make sure you get the most out of the provided drawings:

- Review the key or legend for any symbols or abbreviations.

- Look for the assembly order if available, especially for complex structures.

- Ensure each component aligns with the listed reference to avoid errors during assembly.

Identifying Replacement Parts Easily

Finding the right components for tool maintenance can be challenging, especially when dealing with intricate systems. It’s important to know how to distinguish various elements, ensuring each piece matches your device perfectly. Understanding the structure and functionality of these components is key to making efficient repairs.

When searching for specific replacements, focus on examining details such as model numbers, specifications, and unique features that set one part apart from another. This methodical approach helps in avoiding confusion and ensures the proper element is selected, leading to a smooth repair process.

Organized documentation or visual aids can further assist in identifying the correct pieces swiftly. Paying close attention to assembly layouts and descriptions will make it easier to pinpoint the exact component you need, minimizing downtime and maximizing productivity.

Where to Find Diagrams for Your Tools

To keep your equipment running smoothly, it’s important to access visual guides that showcase the internal structure of your devices. These illustrations can assist in understanding the arrangement of components and how they interact during operation. Finding such resources ensures that you can quickly identify necessary replacements or fixes.

There are numerous sources available online that provide detailed visual breakdowns for various devices. Official websites and trusted third-party platforms often host these resources, offering downloadable or viewable illustrations. Additionally, many repair forums and technical support sites maintain archives with these types of guides, catering to different models and tools.

It’s advisable to consult multiple sources to cross-check the accuracy of the illustrations you find. Be sure to verify that the visual matches the specific model of your equipment to avoid any discrepancies during the maintenance or repair process.

Tips for Ordering Replacement Parts

When it comes to getting the right components for repairs, it’s important to approach the process with careful planning. Before making any decisions, ensure that you’re identifying the correct item that matches your tool or equipment model. This will save time and prevent unnecessary frustration.

Start by checking the product’s manual or manufacturer resources to verify the exact specifications of the item you need. Comparing part numbers and descriptions is essential to avoid errors. Additionally, always consider sourcing items from authorized dealers to ensure quality and compatibility.

Once you’ve identified the correct component, don’t forget to factor in shipping times and availability. Ordering early can help avoid delays in your project. Keeping a list of frequently used items can also speed up the process for future replacements.

Maintenance Tips Using Diagrams

Understanding the internal structure of your tools is key to ensuring their longevity. By referring to visual representations of components, users can quickly identify areas that require attention during routine upkeep. This approach simplifies the process of detecting wear and tear, ensuring that repairs are done efficiently.

Identify Wear Early

Visual guides allow you to spot potential issues before they lead to larger problems. Examining key areas where strain is most common helps in preemptive replacement of certain elements, thus extending the lifespan of your equipment.

Follow Clear Steps

Using visual references makes following maintenance instructions straightforward. With clear, step-by-step instructions, you can perform tasks like cleaning, lubrication, or component replacement confidently, ensuring that your tool functions smoothly over time.

DIY Repairs with Dewalt Diagrams

Understanding the structure of your tool is essential for effective maintenance and fixing. Visual breakdowns offer a clear way to see how each component fits together, helping you pinpoint the source of issues. These guides are especially helpful when it comes to replacing worn-out elements or making small adjustments yourself. By following detailed illustrations, even complex systems become easier to navigate, making the repair process smoother and more efficient.

How Visual Guides Simplify the Process

Whether you’re dealing with a mechanical breakdown or simply need to change a part, these visual tools make it easier to identify the exact location of each piece. This allows for targeted repairs, saving time and reducing frustration. With everything laid out clearly, even intricate repairs are within reach for those with basic technical skills.

Common Issues and Solutions

Several common malfunctions can be addressed using these detailed images. By comparing what you see in the guide with the actual state of your equipment, you can quickly diagnose problems like wear and tear or missing components.

| Issue | Solution |

|---|---|

| Worn out blade | Locate

Enhancing Longevity of Dewalt Tools

Maximizing the lifespan of power equipment requires proper maintenance and careful usage. Following a few simple practices can help ensure your gear performs efficiently for a longer period, minimizing wear and tear. Regular Cleaning and InspectionOne of the key factors in maintaining your equipment’s functionality is keeping it clean. Dust and debris can accumulate, leading to performance issues. Regularly inspect for any signs of damage or irregularities.

Proper StorageStoring your tools correctly also plays a significant role in extending their lifespan. Exposure to moisture, extreme temperatures, or direct sunlight can damage sensitive mechanisms.

|