When working with specialized equipment, it’s essential to have a clear understanding of how various elements come together to ensure smooth operation. A well-organized visual guide can significantly aid in recognizing the proper layout of mechanical and electronic units. This knowledge is crucial for both assembly and troubleshooting tasks, allowing for efficient and effective maintenance.

Identifying the structure of these components can help technicians quickly pinpoint areas that need attention. With a detailed breakdown, users can visualize how individual segments interact with each other, ensuring seamless functionality and reducing the chance of errors during setup or repairs.

Moreover, clear documentation offers invaluable support to those looking to extend the lifespan of their machinery. Understanding the arrangement of essential pieces leads to improved performance and minimizes downtime, contributing to a more reliable and efficient workflow.

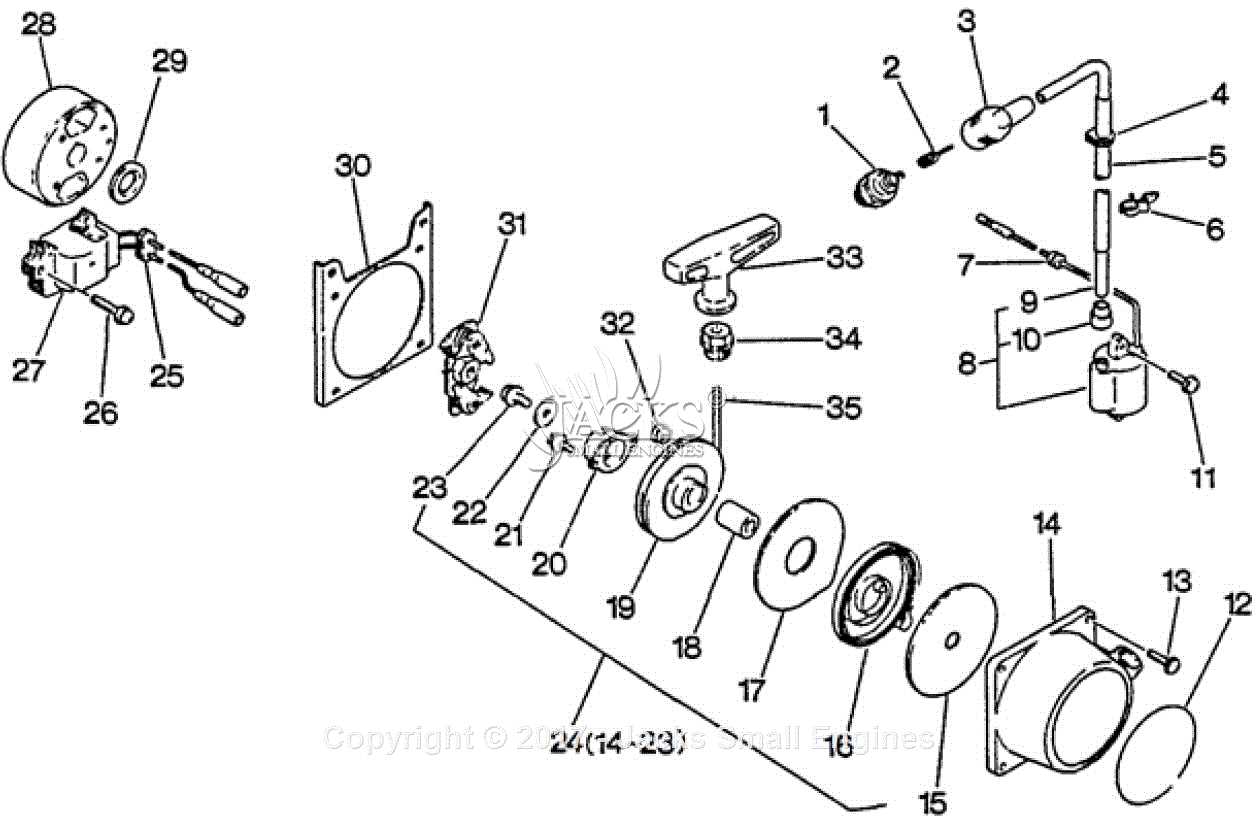

Happijac 4500 Parts Overview

In this section, we will explore the key components that make up this essential mechanism, designed to provide reliable and efficient performance in its field. Understanding the individual elements and their function is crucial to maintaining and repairing the system effectively. Each component plays a specific role in ensuring smooth operation and durability over time.

Main Components

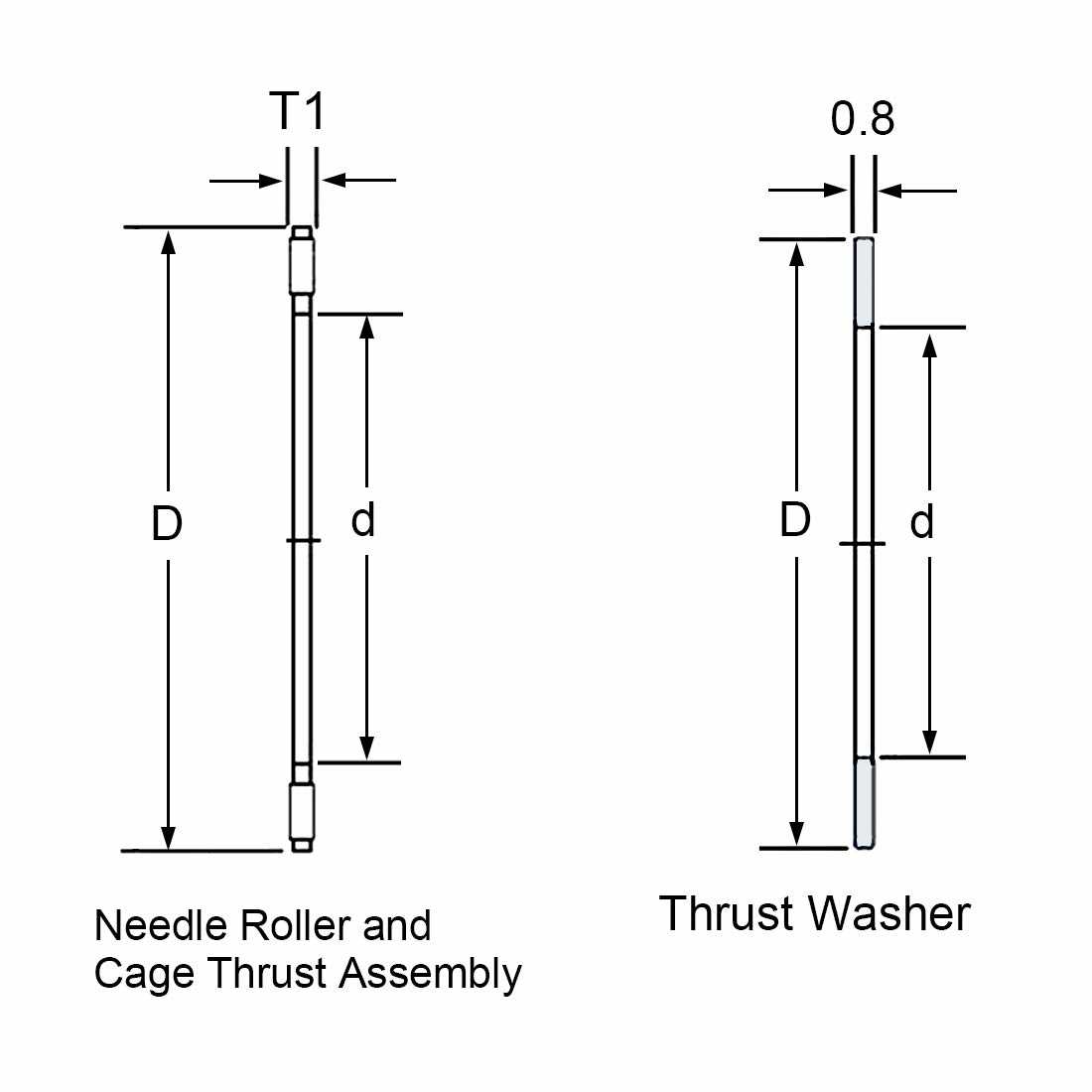

The unit is comprised of several major elements, each contributing to its overall functionality. The motor is responsible for powering the mechanism, while the gearbox ensures proper torque and control. Additionally, connectors and mounting brackets hold everything in place, ensuring stability and ease of use.

Additional Features

Other important elements include safety mechanisms, such as limit switches, that prevent overextension or damage. Fasteners and screws ensure the structural integrity, while seals and gaskets help protect the inner workings from external elements, ensuring long-lasting performance.

Understanding the Main Components

The primary elements of the system work together to ensure smooth operation and reliability. These components are designed to handle various tasks that contribute to the overall functionality. Each part plays a crucial role, and understanding how they interact is key to maintaining and troubleshooting the system effectively.

| Component | Function | |

|---|---|---|

| Motor Assembly | Powers the lifting and lowering mechanism, ensuring controlled movement. | |

| Drive Mechanism | Transfers motor power into mechanical motion, enabling the system to perform its tasks. | |

| Support Brackets | Provide stability and secure mounting for the entire system, ensuring safe operation. | |

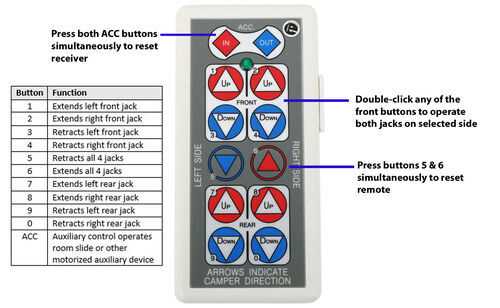

| Control Switch | Allows the user to activate and regulate the system’s actions, providing manual control over operations. |

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for any signs of wear. |

| Deep Cleaning | Quarterly | Use a vacuum or compressed air. |

| Component Testing | Annually | Ensure all parts are functioning correctly. |

Compatibility with Other Truck Camper Jacks

When selecting a lifting mechanism for your vehicle, it’s crucial to understand how different models can interact with one another. Ensuring that various jacks can work together provides flexibility in use and enhances overall efficiency. This section explores the interoperability of different truck camper support systems, emphasizing essential factors to consider.

Mounting Systems: The compatibility of mounting systems plays a vital role in achieving seamless integration. Many jacks utilize standardized mounting brackets, allowing for straightforward attachment to a variety of truck configurations.

Weight Capacity: It’s important to consider the weight limits of each lifting device. Ensuring that all jacks involved can support the combined load is necessary for safe operation. Review the specifications to avoid potential hazards.

Operation Mechanism: Different jacks may employ various operational mechanisms, such as hydraulic or manual systems. Understanding these differences can help in choosing a compatible option that meets your specific needs and preferences.

Adaptability: Many modern jacks are designed with adaptability in mind, allowing for compatibility with an array of camper types. This flexibility can make it easier to switch between different units as needed, depending on the situation.

By taking these factors into account, users can make informed decisions when selecting lifting solutions that work well together, ensuring a safer and more efficient camping experience.

Upgrading Your Happijac 4500 Efficiently

Enhancing the functionality and performance of your equipment can significantly improve your overall experience. Whether you’re looking to increase efficiency or simply refresh the look, understanding the components involved is crucial. A well-planned approach will ensure that the upgrades not only meet your needs but also maintain the integrity of the entire system.

Begin by assessing the current state of your apparatus. Identify any areas that could benefit from improvements, such as mechanical parts, aesthetic elements, or technological features. Once you have a clear picture, research compatible upgrades that will enhance performance without compromising safety.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Mechanical System | High-Performance Actuator | Increased speed and reliability |

| Aesthetic Features | Custom Covering | Improved appearance and protection |

| Control System | Smart Controller | Enhanced user interface and control |

Incorporating these enhancements will not only revitalize your apparatus but also provide a smoother and more efficient operation. With the right upgrades, you can enjoy improved functionality and a renewed sense of satisfaction.

Step-by-Step Assembly Instructions

In this section, we will guide you through the detailed process of assembling your unit efficiently. Following these instructions will ensure that every component fits perfectly, resulting in optimal functionality and safety.

Step 1: Begin by gathering all necessary components and tools. Ensure you have a clean workspace to facilitate an organized assembly process. Familiarize yourself with each piece and its intended location.

Step 2: Start with the base structure. Connect the primary sections as indicated in the provided layout. Use the appropriate fasteners to secure each joint firmly, ensuring stability.

Step 3: Once the base is secure, proceed to attach the side panels. Align them correctly with the pre-drilled holes, and tighten the screws until snug, but avoid overtightening, which could damage the material.

Step 4: Install any internal components next. Refer to your reference guide to ensure each part is positioned accurately. This step is crucial for the overall function of the assembly.

Step 5: Finally, complete the assembly by attaching the top cover. Ensure all previous connections are tight and stable before proceeding. Perform a final inspection to confirm that all elements are securely in place.

By following these steps carefully, you will successfully assemble your unit, ready for use.

Preventative Care for Longer Lifespan

Maintaining the longevity of your equipment requires a proactive approach that emphasizes regular maintenance and care. Implementing effective preventative measures can significantly enhance the performance and durability of your devices, ensuring they remain in optimal condition for extended periods.

To achieve a longer lifespan for your equipment, consider the following strategies:

- Regular Inspections: Schedule routine check-ups to identify and address potential issues before they escalate.

- Proper Cleaning: Keep your devices clean to prevent the buildup of dirt and debris that can hinder functionality.

- Routine Lubrication: Apply lubricants as needed to reduce friction and wear on moving parts.

- Environmental Considerations: Store your equipment in a suitable environment to protect it from extreme temperatures and humidity.

- Quality Repairs: If any components require replacement or repair, ensure that high-quality parts are used to maintain integrity.

By following these guidelines, you can significantly increase the lifespan of your equipment and enhance its overall efficiency.

Common Issues and Troubleshooting Tips

When dealing with various mechanisms, users often encounter a range of challenges that can affect performance and functionality. Identifying common problems and implementing effective solutions is crucial for maintaining optimal operation. This section highlights frequent issues and provides helpful tips for resolution.

One prevalent issue involves failure to operate correctly. This may stem from improper installation, worn-out components, or electrical malfunctions. It is essential to ensure all parts are securely fitted and check for any visible damage. Regular maintenance can also prevent these issues from arising.

Common Problems

| Issue | Description | Solution |

|---|---|---|

| Power Failure | The mechanism does not respond when activated. | Check the power supply and connections for any disruptions. |

| Noisy Operation | Unusual sounds during operation indicate potential mechanical failure. | Inspect moving parts for debris or misalignment and lubricate as necessary. |

| Inconsistent Performance | Variable operation can result from fluctuating power or component wear. | Test electrical connections and replace any damaged parts to ensure steady function. |

By addressing these common challenges with systematic troubleshooting, users can enhance the reliability and longevity of their equipment. Regular checks and prompt repairs will significantly reduce the risk of more serious complications in the future.