In the realm of thermal equipment, having a clear understanding of the inner workings and structure is essential for effective use and maintenance. This section delves into the intricate layout of components that contribute to the functionality of various heating devices. A comprehensive grasp of these elements enhances both operational efficiency and safety.

By examining the arrangement and relationship of different elements, users can identify potential areas for improvement or troubleshooting. A meticulous breakdown of these units provides invaluable insights for both enthusiasts and professionals alike. Familiarity with this configuration not only aids in optimizing performance but also facilitates informed decision-making when it comes to repairs and upgrades.

Whether one is involved in design, maintenance, or simply seeking to enhance their understanding, mastering the layout of these vital components is a crucial step towards achieving expertise in the field of thermal technology.

Understanding the essential elements of this device is crucial for effective utilization and troubleshooting. Each component plays a significant role in ensuring the optimal performance of the system.

The primary elements include:

- Control Mechanism: This unit regulates the operation, allowing for precise management of energy flow.

- Power Module: The heart of the system, responsible for converting and distributing energy efficiently.

- Thermal Management: A critical component that prevents overheating, ensuring longevity and reliability.

- Electrical Connections: These pathways facilitate the transfer of power between various parts, ensuring seamless operation.

- Feedback Sensors: Instruments that monitor performance and provide real-time data to optimize functionality.

Each of these components contributes to the overall effectiveness, enabling the device to perform its intended tasks efficiently and reliably.

Importance of Each Part Explained

Understanding the significance of individual components in any system is crucial for effective functioning. Each element plays a unique role, contributing to the overall performance and reliability of the device. Analyzing these elements helps in troubleshooting, maintenance, and enhancing efficiency.

Functionality and Reliability

The role of each segment cannot be overstated. They work in harmony to ensure the system operates smoothly. For instance, some components are responsible for regulating temperature, while others manage electrical flow. Their reliability directly impacts the longevity and effectiveness of the entire apparatus.

Maintenance and Upgrades

Recognizing the importance of each element facilitates proper upkeep and potential enhancements. When users comprehend how each piece contributes to the overall operation, they can make informed decisions regarding repairs or improvements. This knowledge empowers users to optimize performance and extend the lifespan of the equipment.

Common Applications for the Triac ST

This versatile component plays a crucial role in various electronic systems, enabling precise control over power delivery. Its ability to manage current flow efficiently makes it ideal for applications requiring reliable operation and minimal energy loss.

In industrial settings, this device is frequently utilized for temperature regulation in heating equipment. By adjusting the power supplied to heating elements, it ensures stable temperatures, enhancing process efficiency. Additionally, it finds extensive use in light dimmers, providing users with the capability to modify brightness levels seamlessly, contributing to energy conservation and user comfort.

Moreover, it serves a vital function in motor speed controllers, allowing for smooth and gradual speed adjustments in electric motors. This feature is particularly beneficial in applications such as fans and pumps, where varying speeds can lead to significant energy savings. Overall, its adaptability and effectiveness make it an essential component in numerous modern electronic devices.

Wiring Diagram for the Device

This section provides a comprehensive overview of the electrical connections for the tool, essential for ensuring proper functionality. Understanding the layout of the wiring is crucial for both installation and maintenance, allowing users to visualize how components interact within the system.

Understanding the Connections

The layout consists of various terminals and connectors, each serving a specific purpose. Properly mapping these connections can help avoid operational issues. It’s important to follow the designated paths for the electrical currents to flow efficiently, ensuring optimal performance of the device.

Safety Precautions

When working with the wiring configuration, adhering to safety guidelines is paramount. Always ensure that the power source is disconnected before making any adjustments. Using insulated tools and wearing protective gear can prevent accidents and ensure a safe working environment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of equipment involves regular upkeep and attention to detail. Implementing proactive measures can prevent premature wear and enhance performance. Here are some essential practices to maintain optimal functionality over time.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep surfaces free from dust and debris. Use appropriate cleaning agents to avoid damaging components. |

| Inspect Cables | Check for signs of wear or fraying in wires and connectors. Replace any damaged items promptly. |

| Temperature Control | Avoid exposing the device to extreme temperatures. Store and operate it within the recommended temperature range. |

| Scheduled Maintenance | Perform routine checks and maintenance according to the manufacturer’s guidelines. This includes lubricating moving parts. |

| Safe Storage | When not in use, store the equipment in a dry and clean environment to prevent corrosion and damage. |

Troubleshooting Common Issues

When working with heating tools, users may encounter various challenges that affect performance and efficiency. Identifying and resolving these common problems is crucial to ensure optimal functionality and prolong the lifespan of the equipment. Below are some typical issues and their potential solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Insufficient heating | Faulty heating element, low power supply | Check the power source and replace the heating element if necessary. |

| Overheating | Malfunctioning temperature control, blocked airflow | Inspect the temperature settings and ensure proper airflow around the unit. |

| Inconsistent operation | Loose connections, worn components | Examine all connections for security and replace any worn parts. |

| No power | Tripped circuit breaker, damaged cord | Reset the breaker and inspect the power cord for any damage. |

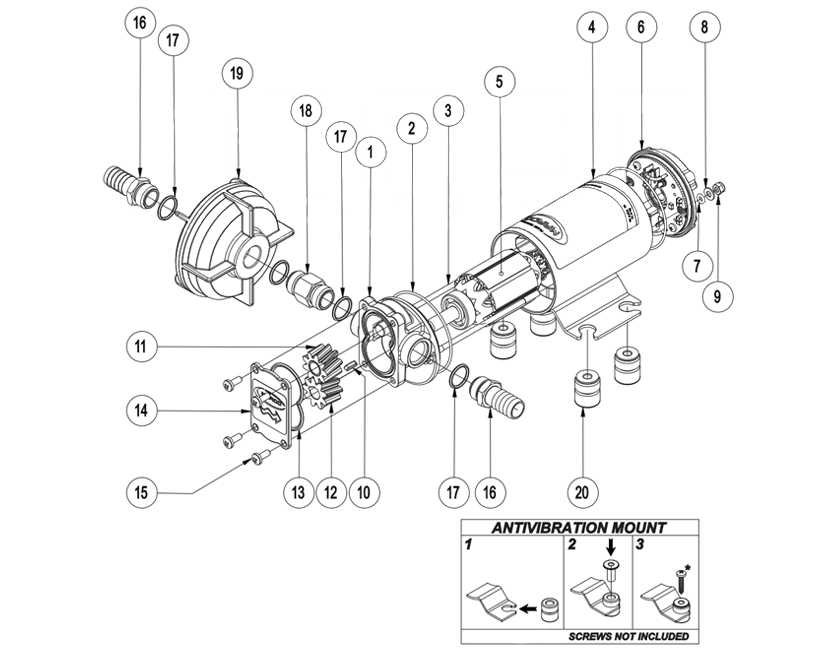

Replacement Parts for the Triac ST

In maintaining your Triac ST, ensuring the availability of suitable replacement components is crucial for continuous operation. This section highlights essential elements required to keep your tool in optimal condition over time.

Heating Elements

One of the critical components in the Triac ST is the element responsible for generating heat during operation. Ensuring the proper functioning of these heating elements is essential for consistent performance.

Control Circuitry

The control circuitry of the Triac ST manages the operational parameters and ensures precise control over temperature and airflow. Components within this circuitry, such as sensors and switches, play a vital role in maintaining operational efficiency.

| Component | Description |

|---|---|

| Heating Element | Generates heat for welding operations. |

| Temperature Sensor | Monitors heat levels to prevent overheating. |

| Switches | Control various functions such as power and airflow. |

Differences Between Triac Models

The variations among different types of solid-state switches play a crucial role in their application across various fields. Each model is designed with unique characteristics and capabilities that cater to specific operational requirements. Understanding these distinctions is essential for selecting the appropriate device for a particular task.

One of the primary factors that differentiate these switches is the current rating. Some models are engineered to handle higher currents, making them suitable for heavy-duty applications, while others are optimized for lower power operations. This variation directly impacts the performance and reliability of the device in diverse environments.

Another significant aspect is the voltage range each model can manage. Devices that can operate at elevated voltages are often used in industrial settings, where robust power supplies are common. Conversely, models designed for lower voltage operations are more prevalent in residential or light commercial applications.

Additionally, the control methods can vary. Some switches are designed for phase control, allowing for more precise regulation of power, while others may offer simpler on/off functionality. This diversity in control options enables users to choose the most efficient solution based on their specific needs.

Finally, the thermal management characteristics differ across models. Some devices incorporate advanced heat dissipation mechanisms, which enhance their durability and operational lifespan. Understanding these thermal properties is vital for ensuring reliable performance under varying load conditions.

Safety Precautions When Operating

When handling specialized equipment designed for heat applications, it’s important to adhere to essential safety measures to ensure a secure working environment. Following the right steps can prevent accidents and equipment damage, promoting longevity and efficiency in use.

| Precaution | Details | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wear Protective Gear | Always wear appropriate safety gear such as heat-resistant gloves, goggles, and protective clothing to avoid

Upgrading Your Triac ST SystemEnhancing the efficiency and performance of your heating tool is crucial for ensuring long-term reliability and improved functionality. By making key adjustments, you can optimize the device for more demanding tasks and extend its service life. Modern upgrades are designed to improve precision, reduce maintenance requirements, and offer better control over various operations. Here are some upgrade options and their benefits:

|