In the realm of marine engineering, having a comprehensive grasp of engine components is essential for effective maintenance and repair. This understanding facilitates smoother operations and extends the lifespan of critical machinery. Exploring visual representations of various elements can significantly enhance the ability to diagnose issues and identify necessary replacements.

Every engine consists of numerous intricate parts, each playing a pivotal role in its overall performance. By studying these layouts, enthusiasts and professionals alike can gain insights into the assembly and functionality of each segment. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades and repairs.

Utilizing detailed schematics allows for a more systematic approach to engine upkeep. These illustrations serve as invaluable resources, illustrating the relationships between different components and their respective functions. Engaging with such materials encourages a deeper appreciation for the technology at play, ultimately leading to more effective maintenance strategies.

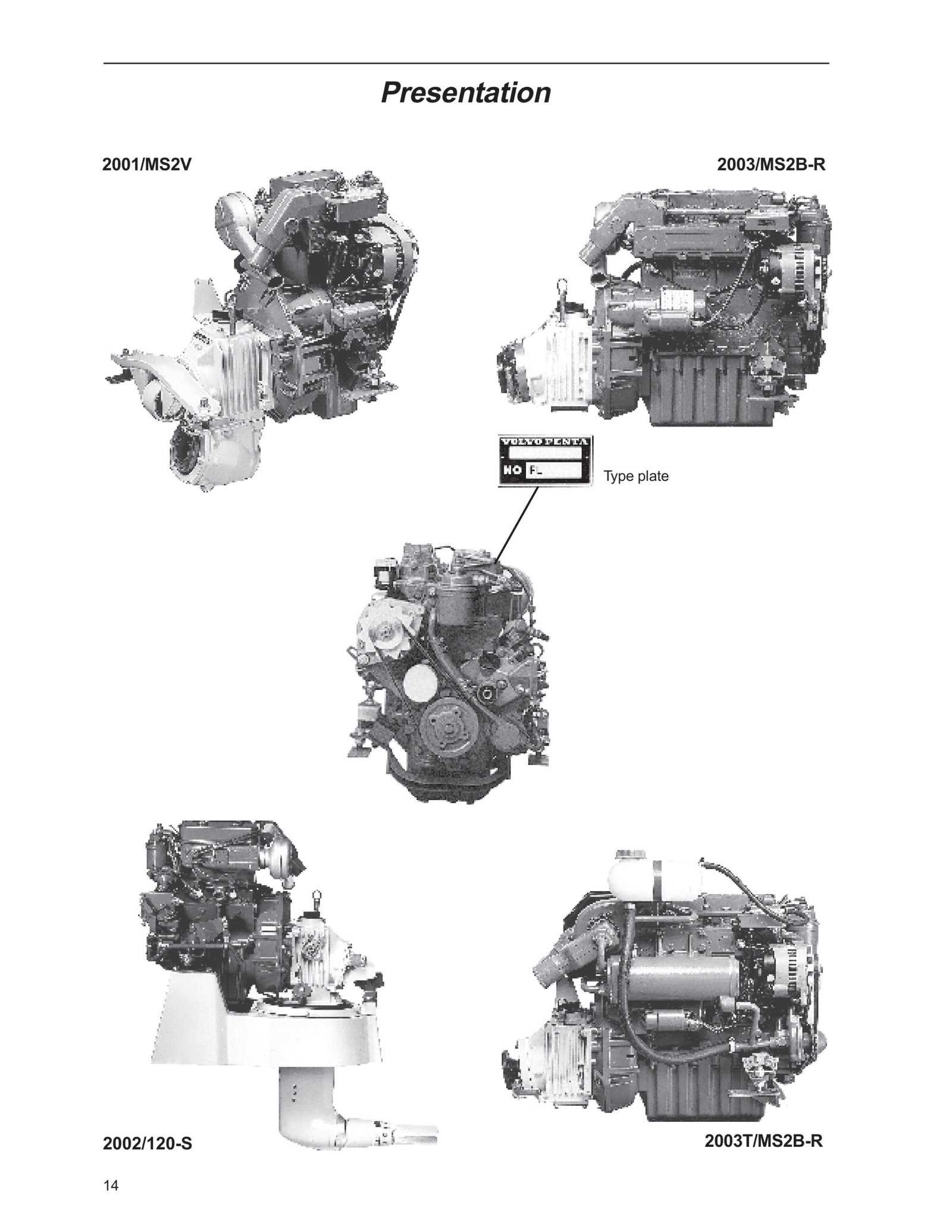

Understanding Volvo Penta 2002 Components

This section aims to explore the intricate elements that contribute to the functionality of marine engines. By examining each component’s role, one can appreciate the harmonious operation that allows these systems to perform optimally in various conditions.

Key Elements of the Engine System

Central to the machinery are the core components that facilitate power generation and distribution. These include the engine block, which houses critical moving parts, and the fuel delivery system, ensuring efficient operation. Understanding their interconnections is essential for anyone involved in maintenance or repair.

Auxiliary Systems and Their Functions

In addition to the primary engine components, auxiliary systems play a vital role. Cooling mechanisms, electrical systems, and exhaust management all contribute to enhanced performance and longevity. Recognizing the importance of each auxiliary part allows for a more comprehensive approach to engine care.

Key Features of Volvo Penta 2002

This section explores the distinctive characteristics of a renowned marine engine model, highlighting its performance and reliability in various aquatic conditions.

Performance Highlights

- Efficient fuel consumption, ensuring cost-effectiveness for prolonged use.

- Robust power output, providing excellent thrust for various watercraft.

- Durable construction, designed to withstand harsh marine environments.

User-Friendly Design

- Compact dimensions, facilitating easy installation in tight spaces.

- Intuitive controls, enhancing operational ease for users.

- Comprehensive support documentation, aiding in maintenance and repairs.

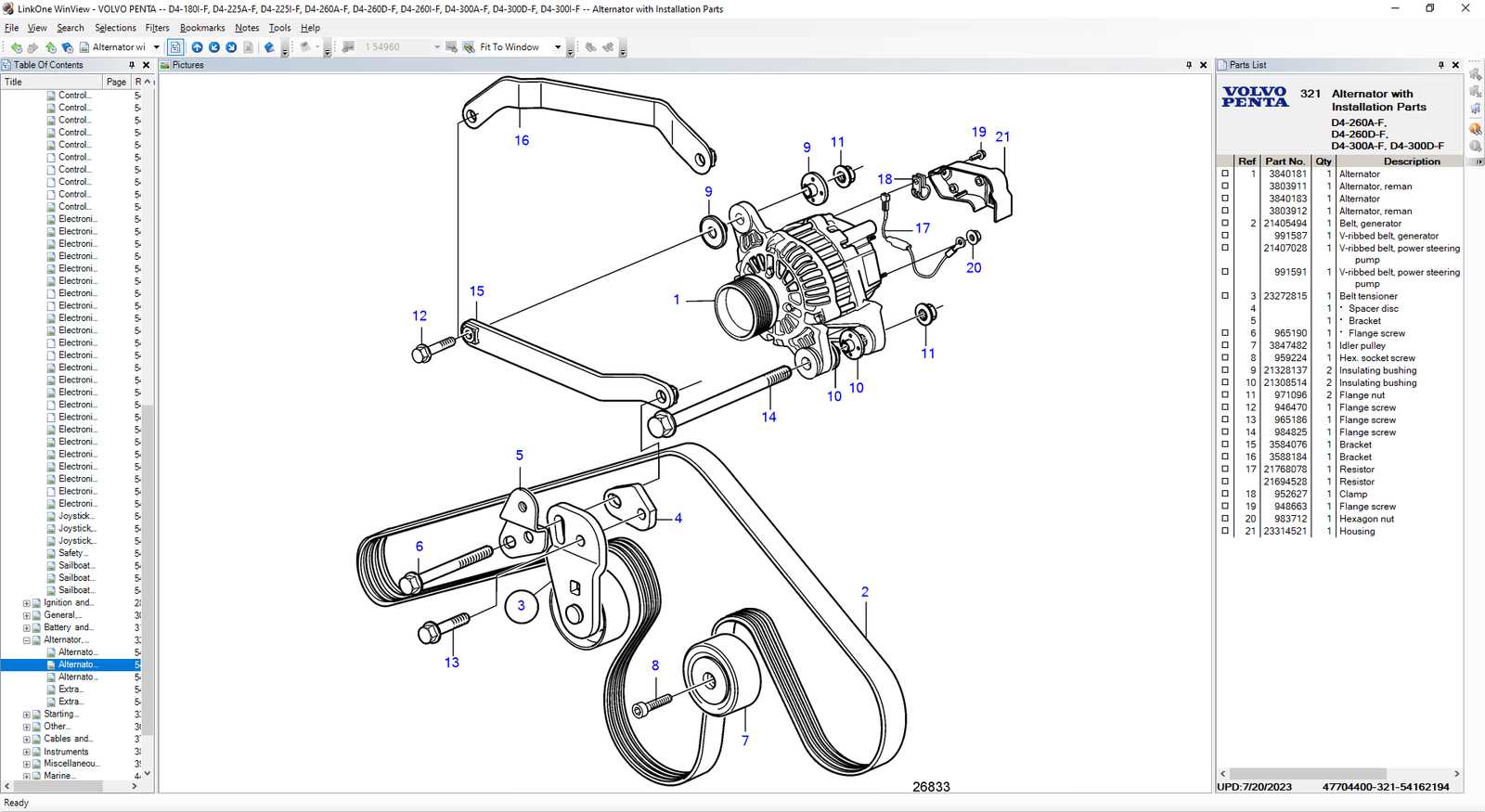

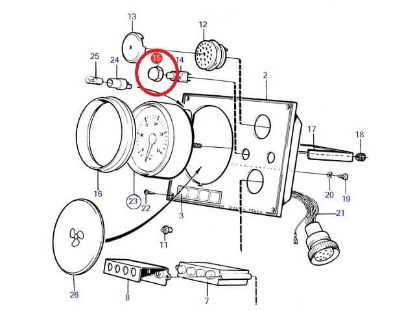

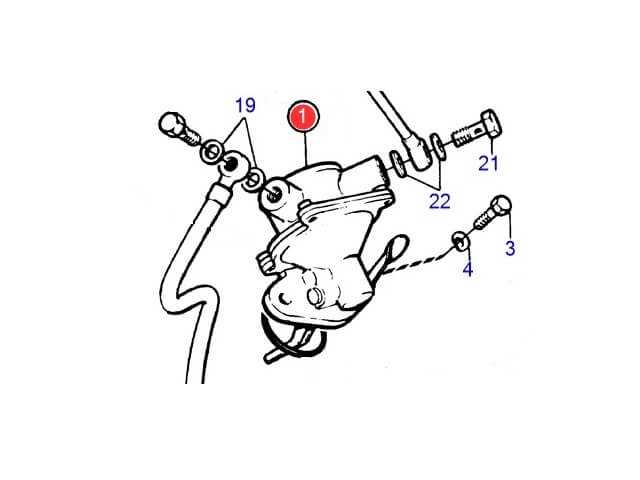

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functioning of machinery. They serve as essential tools for technicians and engineers, allowing for clear identification of each element and its relation to the whole system. This clarity is vital for effective maintenance and repair, ensuring that every piece is accurately recognized and addressed.

Having a detailed visual guide enhances efficiency by streamlining the troubleshooting process. When issues arise, these illustrations enable quick diagnostics by providing a reference point for potential problems. Users can swiftly locate the necessary components, minimizing downtime and facilitating timely solutions.

Moreover, such visual aids contribute to better communication among team members. When everyone can refer to the same graphical information, it reduces misunderstandings and errors during discussions about repairs or upgrades. This shared understanding fosters collaboration and enhances overall productivity in technical environments.

In addition, visual guides are invaluable for training purposes. New technicians can use them to familiarize themselves with the equipment, accelerating the learning curve and promoting confidence in their abilities. As a result, organizations benefit from a more skilled workforce capable of maintaining high operational standards.

Common Issues with Volvo Penta 2002

Engines in this category often encounter several recurring challenges that can affect performance and reliability. Understanding these common issues can help in timely maintenance and repairs, ensuring longevity and efficiency.

Frequent Problems

- Overheating due to coolant leaks or blockages.

- Fuel system malfunctions, leading to poor combustion.

- Electrical faults, including battery drainage and starter issues.

- Oil leaks, which can stem from seals or gaskets wearing out.

Prevention and Maintenance

- Regularly inspect and replace worn components.

- Monitor fluid levels and condition frequently.

- Conduct routine electrical system checks.

- Perform scheduled maintenance as recommended by the manufacturer.

Where to Find Parts Diagrams

Locating technical illustrations for machinery components can greatly enhance maintenance and repair efforts. Understanding where to source these visuals ensures you have the right information at your fingertips.

- Manufacturer’s Website: Start with the official site, which often provides detailed resources.

- Online Forums: Engage with community discussions where enthusiasts share valuable insights and documents.

- Authorized Dealers: Reach out to certified distributors for access to original materials.

- Service Manuals: Look for comprehensive manuals that include illustrations alongside repair instructions.

- DIY Repair Websites: Explore platforms dedicated to home mechanics that might offer user-generated diagrams.

Each of these sources can be a gateway to detailed visuals, enabling a deeper understanding of your machinery’s structure.

Identifying Replacement Parts Easily

Locating the right components for your marine engine can seem daunting. However, understanding the structure and function of each element can streamline the process significantly. By familiarizing yourself with the various parts and their roles, you can quickly identify what needs to be replaced and how to find suitable alternatives.

Here are some tips to aid in identifying components:

| Step | Description |

|---|---|

| 1 | Consult the user manual to understand the layout and functions of each section. |

| 2 | Take clear photographs of the components for easy reference during replacement. |

| 3 | Use online resources and forums to gather information from other users’ experiences. |

| 4 | Visit local suppliers or trusted online shops to compare available options. |

By following these guidelines, you can ensure a smoother experience in sourcing the necessary replacements.

Maintenance Tips for Longevity

Ensuring the extended life of your marine engine requires consistent care and attention. By following a few essential practices, you can optimize performance and reduce the likelihood of unexpected repairs, ultimately enhancing reliability on the water.

Regular Inspections

Frequent checks for wear and tear can help catch potential issues before they escalate. Look for signs of corrosion, leaks, and overall functionality of components.

Fluid Maintenance

Regularly changing oils and coolants is crucial for maintaining peak operational efficiency. Clean fluids help in minimizing friction and preventing overheating.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours | Use manufacturer-recommended oil. |

| Filter Replacement | Every 200 hours | Check for clogs regularly. |

| Cooling System Check | Annually | Inspect for blockages. |

Tools Required for Repairs

Having the right equipment is essential for effective maintenance and repair tasks. Whether you are a seasoned professional or a DIY enthusiast, understanding the necessary tools can streamline your efforts and enhance the quality of your work.

Basic Hand Tools: A reliable set of hand tools, including wrenches, screwdrivers, and pliers, forms the backbone of any repair project. These instruments allow for precise adjustments and disassembly of components.

Power Tools: Depending on the complexity of the task, power tools such as drills and impact wrenches can significantly reduce the time and effort required. They are particularly useful for tasks that involve heavy-duty fastening or cutting.

Specialized Equipment: Some repairs may necessitate specialized instruments, such as torque wrenches or gauges. These tools ensure that components are fitted and tightened to the correct specifications, preventing future issues.

Safety Gear: Don’t overlook the importance of safety equipment, including gloves, goggles, and ear protection. Proper safety measures protect you from potential hazards during the repair process.

By ensuring you have these essential tools at your disposal, you can approach any repair task with confidence and efficiency, ultimately leading to better results.

Understanding Engine Specifications

Grasping the details of an engine’s characteristics is crucial for effective maintenance and optimal performance. These specifications provide insights into how the engine operates, its capabilities, and what components are essential for its functionality.

Key aspects to consider include:

- Power Output: This defines the engine’s performance, typically measured in horsepower or kilowatts.

- Torque: A vital specification that indicates the engine’s twisting force, impacting acceleration and towing capacity.

- Displacement: This measurement represents the total volume of all cylinders, influencing both power and fuel efficiency.

- Fuel Type: Understanding the type of fuel required is essential for optimal operation and longevity.

- Engine Configuration: The layout of the engine (e.g., inline, V-shaped) affects its balance and smoothness of operation.

When examining these characteristics, it’s important to also consider how they interact with various components, influencing overall performance. Each specification plays a role in defining the engine’s suitability for specific applications, from recreational to commercial use.

In conclusion, a thorough understanding of engine specifications aids in making informed decisions regarding maintenance, upgrades, and compatibility with various systems, ultimately ensuring reliable and efficient performance.

Benefits of Using Genuine Parts

Choosing authentic components for your machinery ensures reliability and optimal performance. These original items are specifically designed to fit and function seamlessly, enhancing the overall efficiency of the system. Investing in genuine options ultimately leads to reduced maintenance costs and increased longevity of the equipment.

Quality Assurance

Authentic components undergo rigorous testing and quality checks, guaranteeing that they meet high industry standards. This commitment to quality minimizes the risk of premature failure, ensuring your equipment operates smoothly over time.

Enhanced Performance

Utilizing original components can significantly improve the performance of your machinery. They are engineered to work in harmony with existing systems, leading to better fuel efficiency, lower emissions, and a more enjoyable user experience.

DIY vs. Professional Repairs

When it comes to maintaining machinery, individuals often face the choice between tackling repairs themselves or hiring experts. Each option carries its own set of advantages and challenges. Understanding these can help determine the best approach based on experience, budget, and the complexity of the issue at hand.

Benefits of DIY Repairs

Taking on repairs independently can be a rewarding experience. It allows for a deeper understanding of the equipment and can save money on labor costs. Moreover, accomplishing a repair can boost confidence and enhance skills. For those with a penchant for hands-on tasks, the DIY route often offers flexibility in terms of scheduling and pacing.

Advantages of Professional Assistance

Conversely, enlisting the help of trained professionals brings peace of mind. Experts possess the knowledge and tools necessary to handle intricate problems efficiently. Additionally, relying on experienced technicians can reduce the risk of mistakes that may lead to further issues down the line. This choice is particularly wise for complex repairs that require specialized skills or equipment.

Cost Considerations for Replacement Parts

When it comes to maintaining marine engines, understanding the financial implications of substituting components is essential. Several factors can influence the overall expense, making it vital to evaluate options carefully. From sourcing original equipment to exploring aftermarket alternatives, each choice can impact both performance and budget.

Factors Influencing Cost

- Brand Reputation: Established manufacturers may charge a premium, but their products often come with warranties and proven reliability.

- Material Quality: Higher quality materials tend to last longer, potentially reducing future replacement needs.

- Supplier Location: Proximity to suppliers can affect shipping costs and delivery times.

- Market Demand: Seasonal fluctuations and scarcity can drive prices up for certain items.

Evaluating Options

- Research various suppliers and compare prices.

- Consider the long-term benefits of investing in high-quality components.

- Look for bundles or kits that might offer cost savings over individual purchases.

- Stay informed about warranties and return policies to safeguard your investment.

By carefully analyzing these elements, you can make informed decisions that balance quality and cost-effectiveness, ultimately ensuring the longevity and reliability of your vessel’s engine.

Upgrades and Modifications for Performance

Enhancing the efficiency and power of your marine engine can significantly improve your overall boating experience. By focusing on various components and systems, you can achieve better performance, fuel efficiency, and reliability. This section outlines some key modifications that can help you maximize your vessel’s potential.

Engine Modifications

- High-Performance Air Filters: Upgrading to a high-flow air filter can improve airflow, resulting in better combustion and increased power output.

- Exhaust Systems: Installing a performance exhaust system can reduce backpressure, enhancing engine efficiency and sound.

- Tuning Chips: Utilizing tuning chips or ECU remapping can optimize fuel delivery and ignition timing for improved horsepower.

Propeller and Drive Enhancements

- Propeller Selection: Choosing the right propeller can enhance acceleration and top speed, tailoring the performance to your specific needs.

- Transom Modifications: Adjusting the transom height can improve the angle of attack for better performance in various water conditions.

- Performance Drives: Upgrading to a more advanced drive system can enhance handling and maneuverability, providing a smoother ride.

Implementing these modifications not only boosts performance but also contributes to a more enjoyable and efficient boating experience. Consider each option carefully to achieve the best results for your specific setup.