In the realm of outdoor maintenance, a well-functioning tool is essential for achieving a pristine landscape. This section delves into the intricate components that contribute to the overall efficiency of these machines. Recognizing each element’s role enhances not only performance but also prolongs the lifespan of the device.

Knowledge of individual segments is crucial for effective maintenance and repair. By familiarizing oneself with the layout and function of various components, users can troubleshoot issues with confidence and ensure their equipment operates at peak capacity. This understanding empowers gardeners to tackle tasks with greater ease and precision.

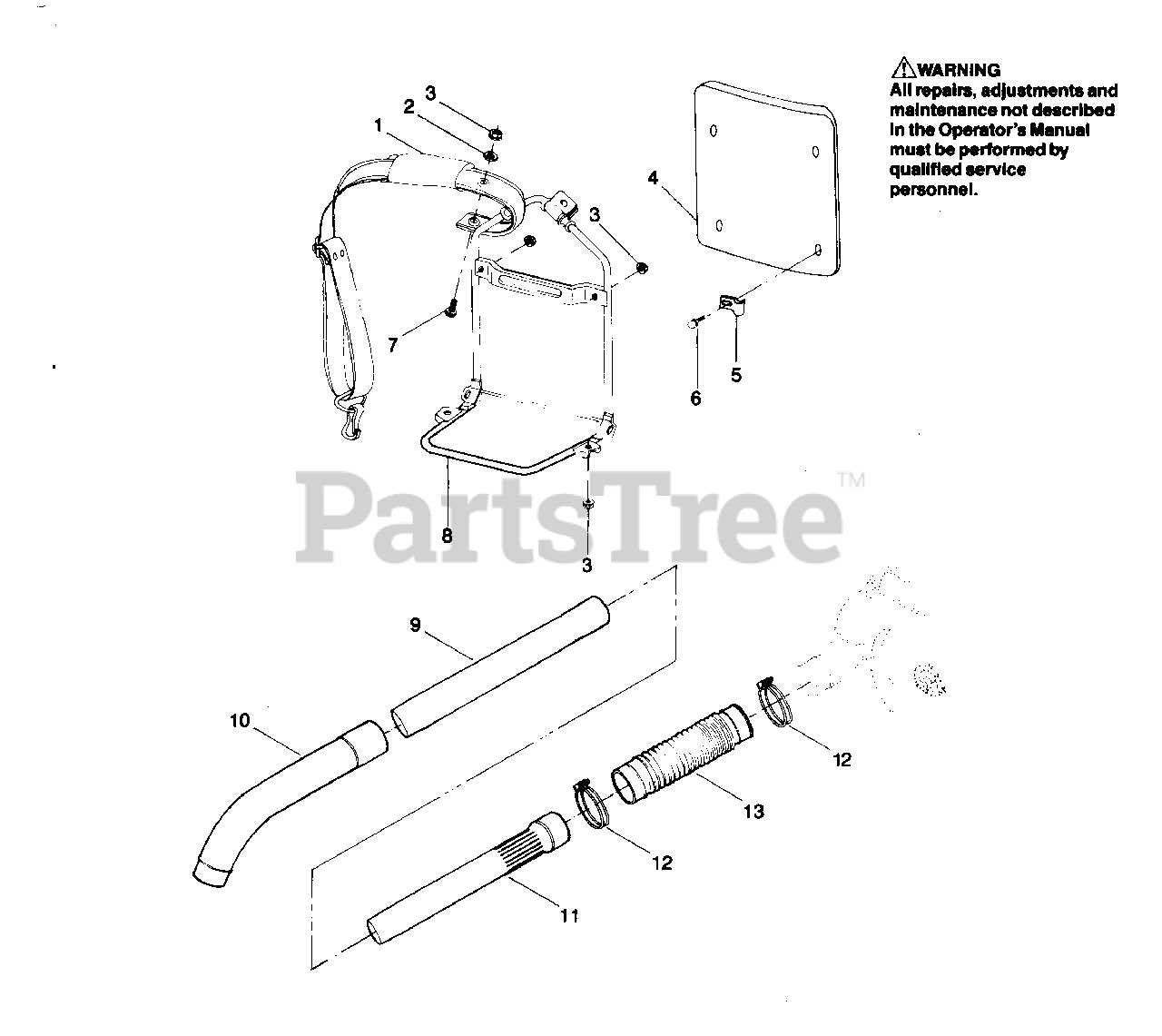

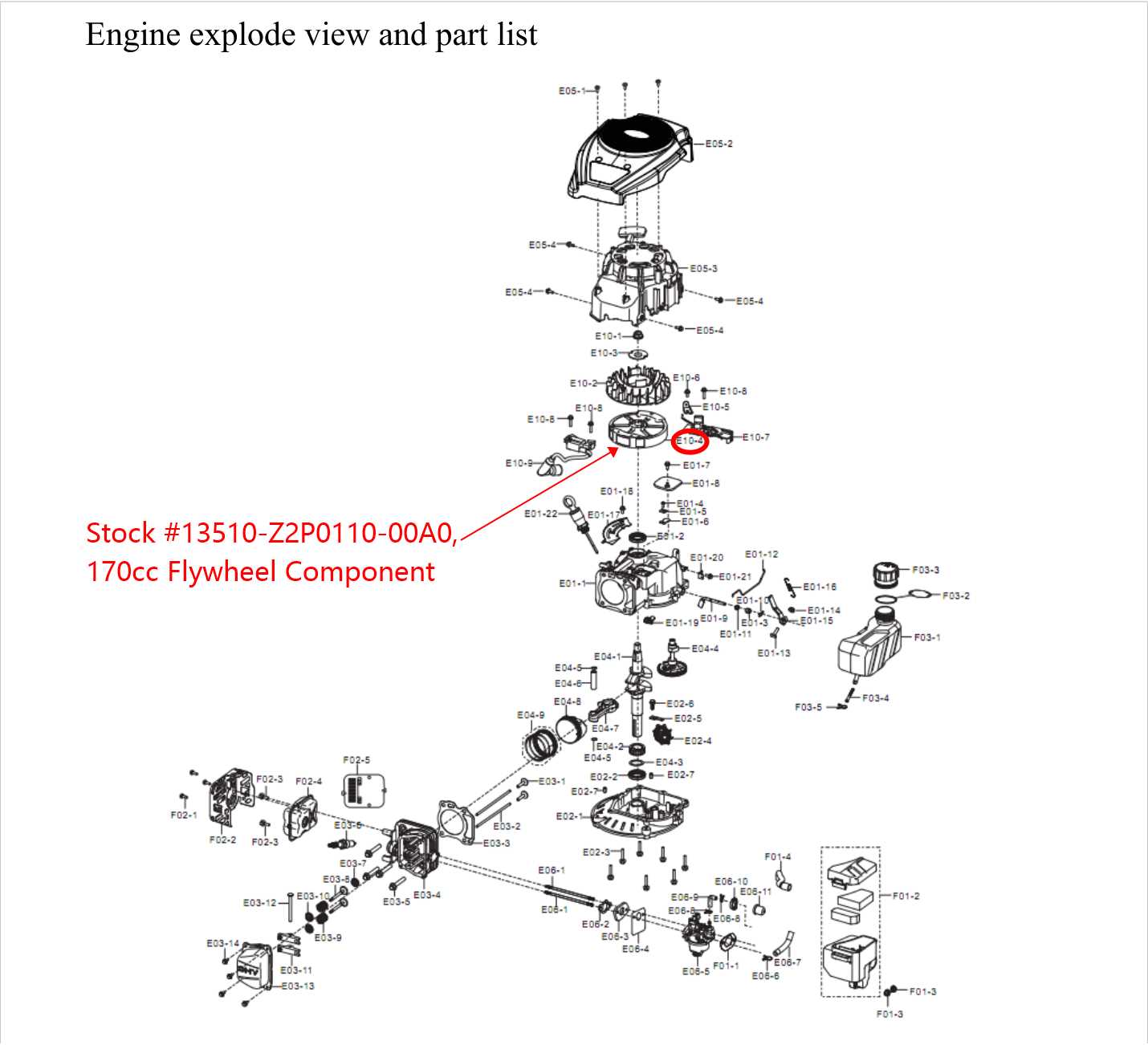

Furthermore, accessing visual representations of these configurations provides clarity and aids in comprehending how each piece interacts within the assembly. Whether one is a novice or an experienced operator, grasping the fundamentals of these mechanisms can lead to more successful outcomes in garden upkeep.

Understanding Weed Eater Blowers

This section explores the essential components and functionalities of handheld gardening tools designed for efficient debris management. Grasping the mechanics and design of these devices enhances user experience and maintenance practices.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation, influencing speed and efficiency. |

| Air Intake | Facilitates airflow, crucial for optimal performance and effective debris dispersal. |

| Fan Blade | Generates airflow by rotating at high speeds, directing air towards the target area. |

| Handle | Ensures user comfort and control during operation, minimizing fatigue. |

Essential Components of Weed Eaters

Understanding the crucial elements of trimming devices is fundamental for their effective operation and maintenance. These tools rely on various components that work together to achieve optimal performance. Each element plays a specific role in ensuring efficiency and reliability during use.

Main Functional Elements

- Engine: The powerhouse of the machine, responsible for generating the necessary energy.

- Cutting Mechanism: Typically consists of blades or line that effectively manage overgrowth.

- Handle: Provides user control and comfort during operation.

- Guard: A protective feature that ensures safety by preventing debris from flying towards the user.

Supporting Components

- Fuel System: Stores and supplies energy to the engine, critical for performance.

- Starter Mechanism: Facilitates the initiation of the engine, ensuring easy operation.

- Throttle Control: Allows users to regulate the speed and power output of the device.

- Air Filter: Maintains engine efficiency by preventing dust and debris from entering.

Common Blower Parts Explained

Understanding the various components of a yard maintenance tool is essential for effective operation and maintenance. Each element plays a critical role in ensuring optimal performance, making it important to familiarize oneself with their functions and interactions.

The engine serves as the powerhouse, converting fuel into mechanical energy to drive the device. Its efficiency directly influences the overall performance, affecting speed and power output. Coupled with the engine is the air intake system, which is crucial for supplying the necessary airflow required for combustion.

The fan assembly is another key component, responsible for generating airflow. Its design determines the volume and speed of the air produced, impacting how effectively the tool can clear debris. Additionally, the housing encases the inner mechanisms, providing protection and structural integrity while aiding in directing the airflow to the desired area.

Control handles are designed for comfort and ease of use, allowing the operator to maintain a secure grip while maneuvering the equipment. Lastly, the exhaust system manages emissions, ensuring that harmful gases are effectively expelled, promoting a safer working environment.

By understanding these fundamental elements, users can ensure better maintenance, troubleshoot issues, and enhance the overall efficiency of their equipment.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any outdoor equipment. By investing time in maintenance, users can significantly extend the lifespan of their tools, reducing the likelihood of costly repairs and replacements. A well-maintained machine not only performs better but also enhances safety during operation.

Benefits of Routine Care

Engaging in consistent care practices leads to numerous advantages. First and foremost, it helps to identify and address potential issues before they escalate into major problems. This proactive approach not only saves money but also minimizes downtime. Additionally, well-maintained equipment operates more efficiently, leading to improved performance and productivity.

Best Practices for Upkeep

To ensure optimal functioning, users should follow specific guidelines. Regularly cleaning components and checking for wear and tear are vital steps. Utilizing high-quality lubricants and following the manufacturer’s recommendations can further enhance performance. Paying attention to details, such as air filters and fuel systems, can make a significant difference in longevity.

Ultimately, investing in maintenance translates to a more reliable and efficient machine, providing peace of mind and a better overall experience.

How to Identify Parts in Diagrams

Understanding the components within technical illustrations is crucial for effective maintenance and repair. By familiarizing yourself with the layout and symbols used, you can streamline the process and enhance your skills.

Key Steps for Recognition

- Examine the overall layout to grasp the arrangement of elements.

- Identify common symbols and their meanings, as these often indicate specific functionalities.

- Pay attention to labels and annotations, which provide vital information about each component.

Tips for Effective Analysis

- Use a reference guide for clarification on less familiar symbols.

- Take notes on the components you recognize for future reference.

- Practice with various illustrations to build confidence and proficiency.

Replacement Parts: When to Upgrade

Understanding the optimal timing for enhancing your equipment can significantly improve performance and longevity. Regular usage can lead to wear and tear, impacting efficiency and effectiveness. Recognizing the signs of decline is crucial for maintaining the best results.

Signs of Wear: Look for decreased power, unusual noises, or inconsistent performance. These indicators suggest that components may need attention or replacement.

Timing Your Upgrades: Ideally, consider upgrades during regular maintenance intervals or at the first sign of performance issues. This proactive approach helps prevent larger problems down the line.

Investing in quality replacements not only ensures optimal functionality but also extends the lifespan of your equipment, allowing you to achieve the ultimate performance.

Tools Needed for DIY Repairs

When tackling home maintenance tasks, having the right equipment is essential for achieving the best results. A well-equipped toolkit can make the difference between a smooth repair process and a frustrating experience.

To start, you will need a set of basic hand tools, including wrenches, screwdrivers, and pliers. These are crucial for loosening and tightening components effectively. Additionally, an adjustable wrench can be a versatile asset, adapting to various sizes.

Consider investing in power tools like drills and saws for more complex jobs. They enhance efficiency and precision, allowing you to delve into deeper repairs. A good-quality multimeter is also recommended for troubleshooting electrical issues, providing the ultimate insight into your device’s performance.

Lastly, don’t forget safety gear such as gloves and goggles to protect yourself during repairs. By assembling these tools, you will be well-prepared to handle any maintenance project that comes your way.

Common Issues and Troubleshooting Tips

When operating outdoor equipment, it’s not uncommon to encounter certain challenges that can affect performance. Identifying these issues and knowing how to resolve them is crucial for maintaining efficiency and prolonging the lifespan of your tools.

Frequent Problems

- Inconsistent power output

- Difficulty starting

- Overheating

- Unusual noises

- Vibration issues

Troubleshooting Strategies

- Inconsistent Power Output: Check the fuel levels and ensure they are fresh. Clogged air filters may also restrict airflow, so inspect and clean them as necessary.

- Difficulty Starting: Examine the spark plug for wear or damage. Replacing it can often resolve starting issues. Also, ensure that the choke and throttle are set correctly.

- Overheating: This may be caused by dirty cooling fins or blocked vents. Regularly clean these areas to maintain optimal airflow.

- Unusual Noises: Listen for any irregular sounds that may indicate loose components or debris within the machinery. Tightening bolts and removing foreign objects can help.

- Vibration Issues: Imbalanced components can cause excessive shaking. Inspect blades and attachments for damage and realign them as needed.

Where to Find Replacement Parts

Finding the necessary components for your outdoor equipment can be a straightforward process if you know where to look. Various resources are available that offer a range of options, ensuring you can restore your tools to optimal condition.

Online Retailers

- Amazon: A wide selection of components and user reviews.

- eBay: Great for both new and used items, often at competitive prices.

- Specialty Websites: Sites dedicated to outdoor tools often have comprehensive inventories.

Local Stores

- Home Improvement Centers: Large chains usually stock essential components.

- Garden Supply Shops: Ideal for specialized equipment needs.

- Repair Shops: Local businesses may have parts or can order them for you.

Using Diagrams for Efficient Repairs

Visual representations play a crucial role in simplifying the repair process. They provide a clear overview of components, helping users understand the assembly and disassembly procedures. By utilizing these illustrations, one can quickly identify the necessary tools and parts required for effective maintenance, ultimately saving time and reducing frustration.

Benefits of Visual Aids

Incorporating illustrations into repair manuals offers several advantages:

| Advantage | Description |

|---|---|

| Clarity | Visuals make it easier to comprehend complex structures. |

| Efficiency | Quickly locate parts without extensive reading. |

| Accuracy | Reduces the likelihood of errors during assembly. |

Maximizing Repair Success

To achieve the best results during repairs, refer to visual guides frequently. They serve as a reliable reference, ensuring each component is handled correctly. By mastering the use of these resources, individuals can enhance their skills and become more confident in their repair capabilities.

Understanding Different Models Available

When exploring the variety of outdoor maintenance tools, it’s essential to recognize the distinctions among available models. Each type caters to specific needs, making it crucial to choose the right option for optimal performance.

Types of Machines

Several categories exist, from lightweight handheld versions to more robust, professional-grade units. The former is ideal for small tasks, while the latter provides the ultimate power for larger areas.

Key Features to Consider

Pay attention to factors such as fuel efficiency, ease of use, and durability. Understanding these characteristics can significantly enhance your experience and ensure that you select a model that meets your expectations.

Safety Tips During Maintenance Tasks

Performing upkeep on outdoor equipment can be essential for optimal performance, but it also requires a focus on safety. Taking precautionary measures can prevent accidents and ensure a smooth maintenance process.

Essential Safety Precautions

- Always wear protective gear, including gloves, goggles, and sturdy footwear.

- Ensure the equipment is powered off and disconnected from any power source before starting work.

- Keep your workspace organized to avoid tripping hazards.

Handling Tools Properly

- Use the right tools for the job to minimize risk.

- Inspect tools for damage before use and replace any defective items.

- Store tools safely when not in use to prevent accidents.

Maximizing Performance with Proper Care

To achieve the ultimate efficiency from your outdoor equipment, regular maintenance is essential. This involves not only cleaning and inspecting components but also ensuring optimal functionality through timely replacements. By understanding the intricacies of each part, users can significantly enhance performance and longevity.

Regular Maintenance: Consistent upkeep prevents wear and tear. Schedule routine checks to identify any issues early on, which can save time and resources in the long run.

Quality Components: Using high-quality replacements when necessary can make a substantial difference. Always opt for reputable brands that offer reliable products, ensuring compatibility and performance.

Environmental Considerations: Proper care also involves being mindful of the surrounding environment. Maintaining equipment reduces emissions and noise, contributing to a more sustainable approach to yard work.

By incorporating these practices, you can delve into the potential of your tools and achieve the best results with every use.