In the world of lawn maintenance, having a thorough comprehension of machinery elements is essential for optimal performance and longevity. Each component plays a crucial role in the overall functionality, ensuring that the equipment operates smoothly and efficiently. Familiarity with these elements not only aids in effective usage but also simplifies the maintenance process.

When examining the various features, one can identify the distinct sections that contribute to the machinery’s overall design. Recognizing how each segment interacts with others enhances the ability to troubleshoot issues and perform necessary repairs. This knowledge empowers users, enabling them to make informed decisions when seeking replacements or upgrades.

By delving into the intricate details of these mechanical entities, enthusiasts and operators alike can cultivate a deeper appreciation for the craftsmanship involved. Understanding the arrangement of these components fosters a connection between the user and the machinery, ultimately leading to better care and utilization over time.

The effectiveness of a mowing machine is heavily reliant on its essential elements, each contributing to its overall functionality and performance. Understanding these crucial components enables users to maintain, troubleshoot, and optimize their equipment for the best results.

Main Functional Elements

Several primary parts work together to ensure efficient operation:

- Engine: Powers the machine, providing the necessary force for cutting.

- Cutting Deck: Houses the blades and determines the cutting width.

- Blades: Sharp elements responsible for trimming grass and vegetation.

- Transmission: Transfers power from the engine to the wheels, enabling movement.

- Wheels: Provide mobility and stability on various terrains.

Additional Notable Features

In addition to the core components, other features enhance usability:

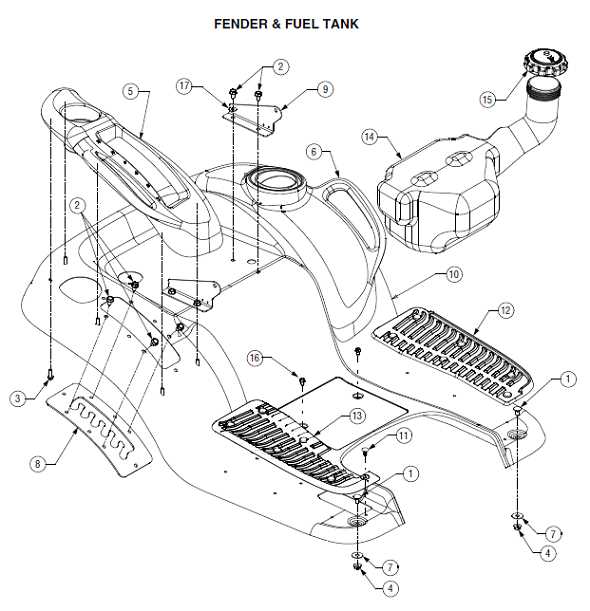

- Fuel System: Supplies the engine with the required fuel for operation.

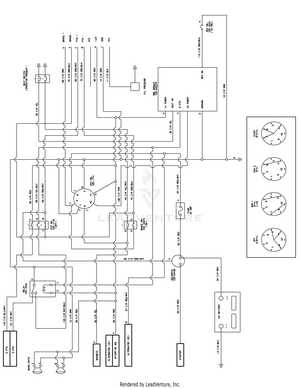

- Electrical System: Powers lights and starter mechanisms.

- Chassis: The frame that supports all other components.

- Height Adjustment Mechanism: Allows users to modify the cutting height.

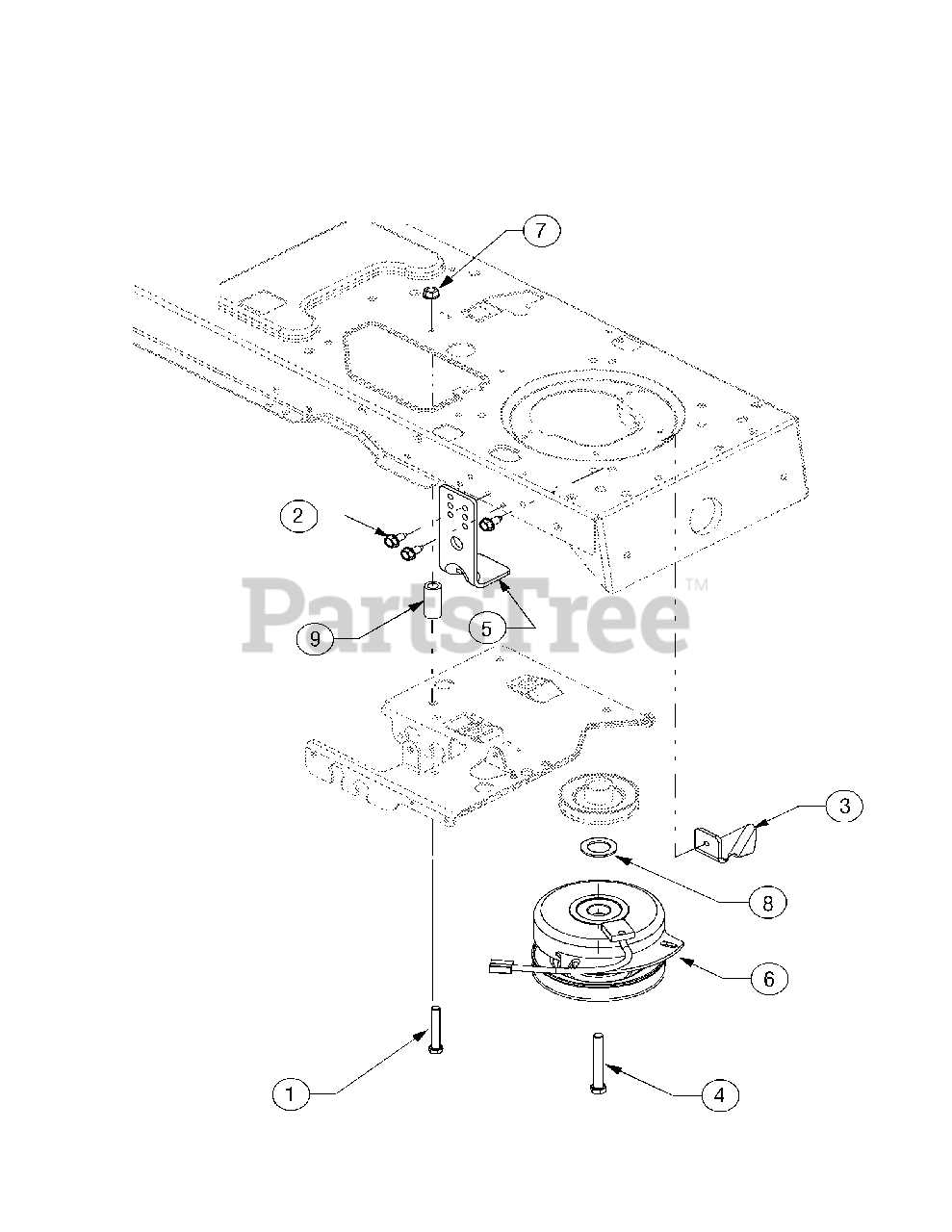

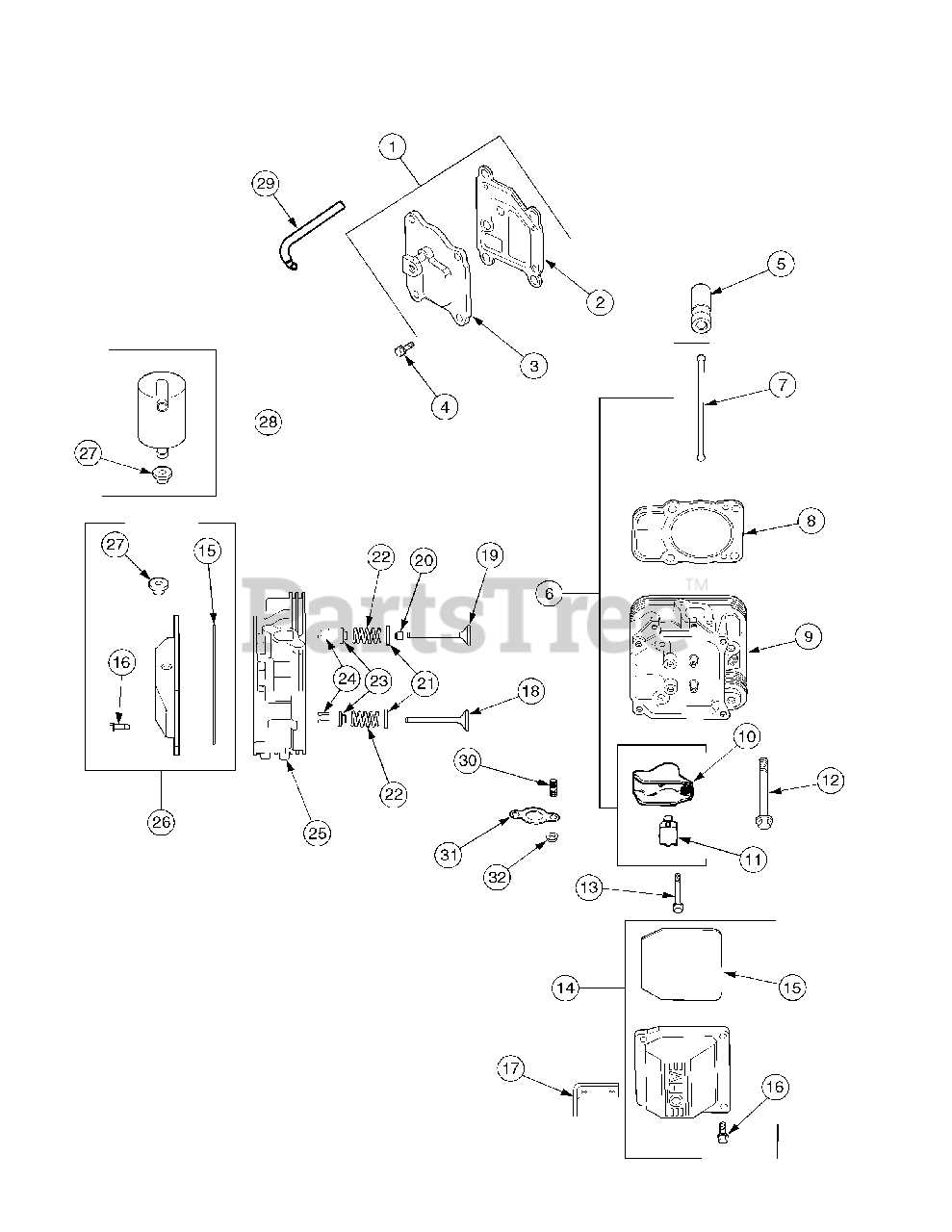

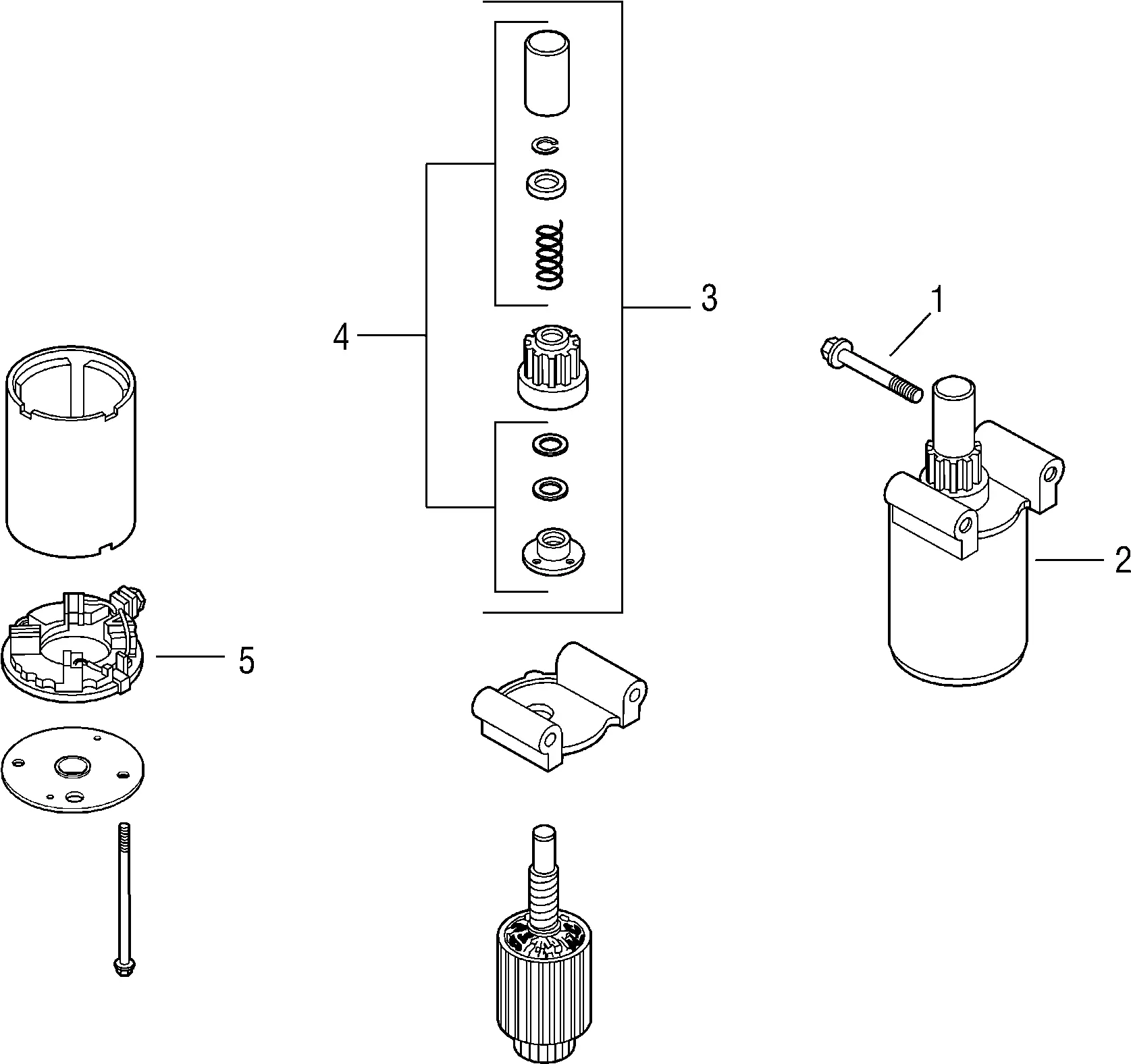

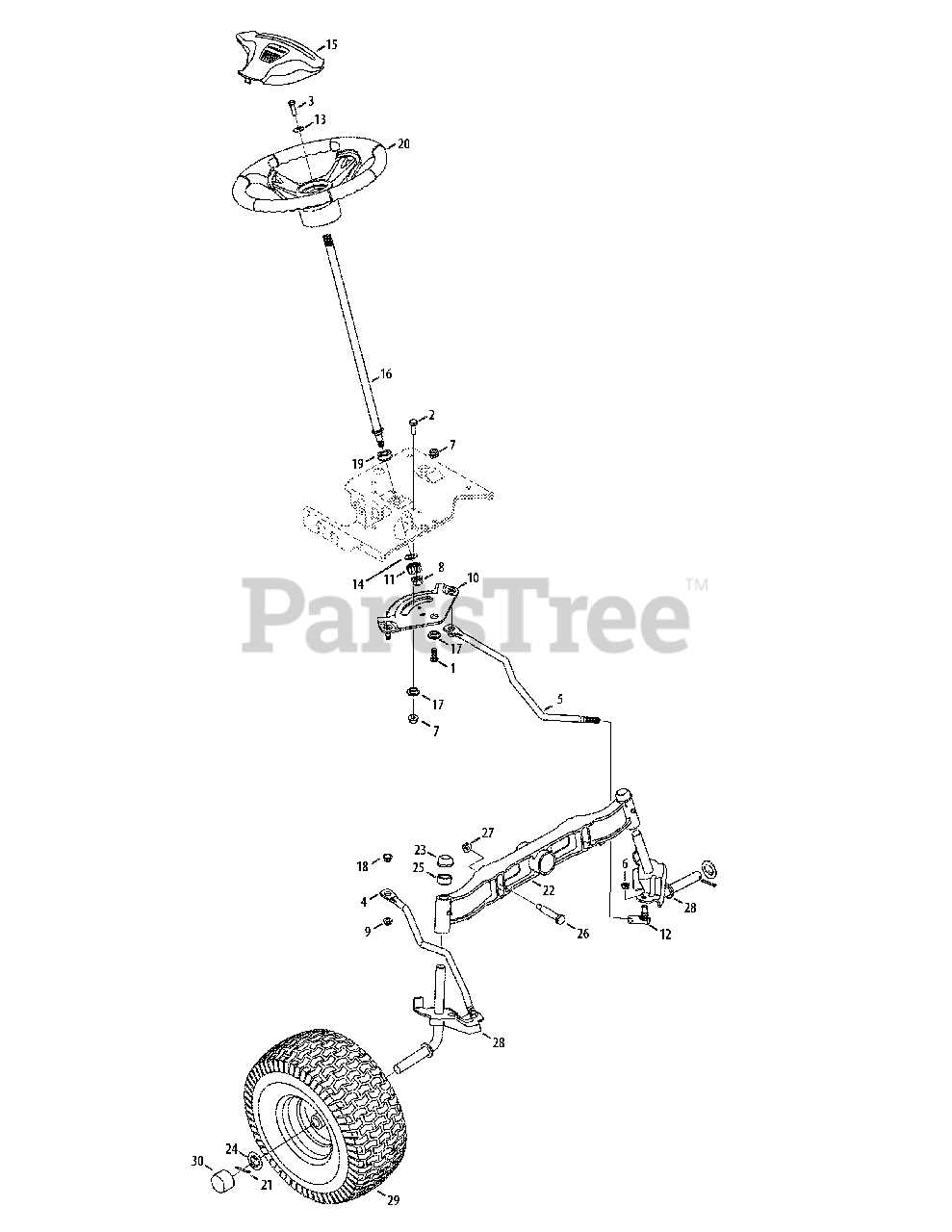

Understanding the Parts Layout

Having a clear overview of the assembly configuration is crucial for effective maintenance and repair. An organized presentation of components allows users to identify and access each element easily, ensuring optimal performance and longevity of the equipment. This section delves into the intricate arrangement of individual elements and their interconnections.

When examining the configuration, it’s important to note the following aspects:

- Component Identification: Each element is labeled for easy recognition, facilitating quick reference during maintenance.

- Interconnections: Understanding how different components interact is essential for diagnosing issues and planning repairs.

- Functionality: Each part serves a specific role, contributing to the overall efficiency of the machine.

By familiarizing yourself with the layout, you can enhance your troubleshooting skills and streamline repair processes. Below are the key categories of elements commonly found in this assembly:

- Engine and drivetrain components

- Chassis and structural elements

- Control systems and interfaces

Thorough knowledge of these configurations will empower users to perform maintenance tasks effectively and ensure the equipment operates smoothly.

Maintenance Tips for Longevity

Ensuring the extended life of your machinery requires regular attention and care. By implementing systematic maintenance practices, you can enhance performance and prevent unexpected failures. This section outlines essential recommendations to keep your equipment in optimal condition.

Regular Inspection

Frequent assessments of your equipment are crucial. Look for signs of wear, leaks, and other issues that could escalate if not addressed promptly. Pay special attention to components that experience high levels of stress during operation.

Proper Lubrication

Maintaining adequate lubrication is vital for reducing friction and wear on moving parts. Use high-quality lubricants as specified by the manufacturer, and ensure that all necessary areas are serviced regularly. This simple step can significantly enhance the operational efficiency of your machinery.

Common Issues and Solutions

In any mechanical system, encountering challenges is a normal part of maintenance and operation. Understanding the typical problems that arise can facilitate effective troubleshooting and prolong the lifespan of the equipment. This section highlights some frequent issues along with practical solutions to address them.

Engine Performance Problems

Engine misfiring can be attributed to various factors, including fuel supply issues or ignition system failures. To rectify this, check the fuel lines for blockages and ensure the spark plugs are functioning correctly. Regular maintenance of these components can prevent most performance-related complications.

Electrical System Failures

Electrical malfunctions, such as inconsistent starting or dim lights, often stem from battery problems or faulty wiring. Inspect the battery for corrosion and ensure all connections are secure. If the battery is old or weak, consider replacing it to restore reliable operation.

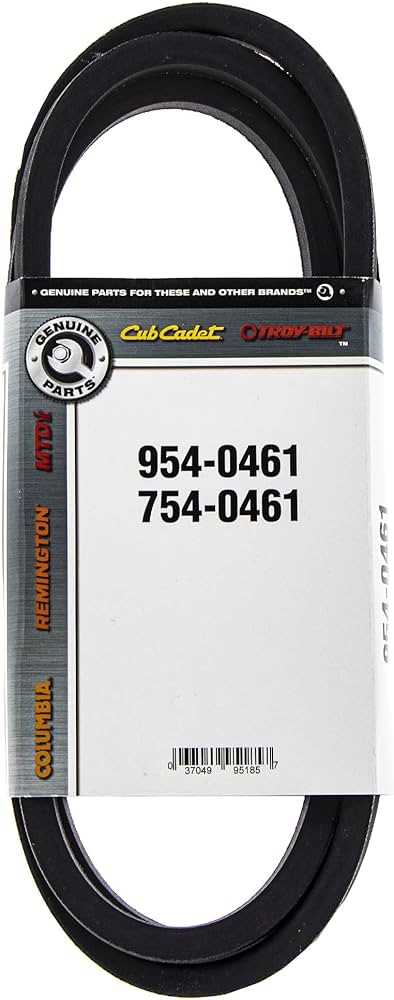

Ordering Replacement Parts

When it comes to maintaining your outdoor equipment, acquiring the right components is crucial for optimal performance. Whether you are repairing a malfunctioning machine or upgrading specific elements, ensuring you obtain high-quality replacements is essential. This section will guide you through the process of effectively sourcing the necessary items to keep your machinery running smoothly.

Identifying Necessary Components

Before placing an order, it is vital to determine which elements need replacement. Carefully assess your equipment to identify any worn or damaged sections. Utilizing a reference guide can assist in pinpointing the exact components you require. Make a list to streamline the ordering process and avoid confusion.

Where to Purchase

Numerous options exist for procuring your needed items. Local suppliers often have a selection of high-quality components, allowing you to inspect them before purchasing. Online retailers provide convenience and often a broader range of options. Be sure to verify the credibility of the seller to ensure you receive genuine merchandise. Reading customer reviews can help you gauge the reliability of the supplier.

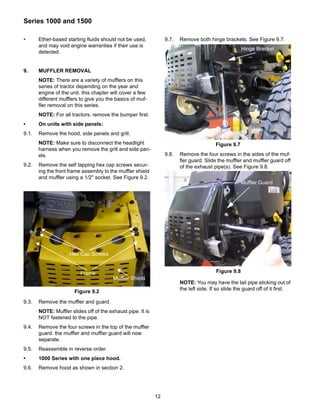

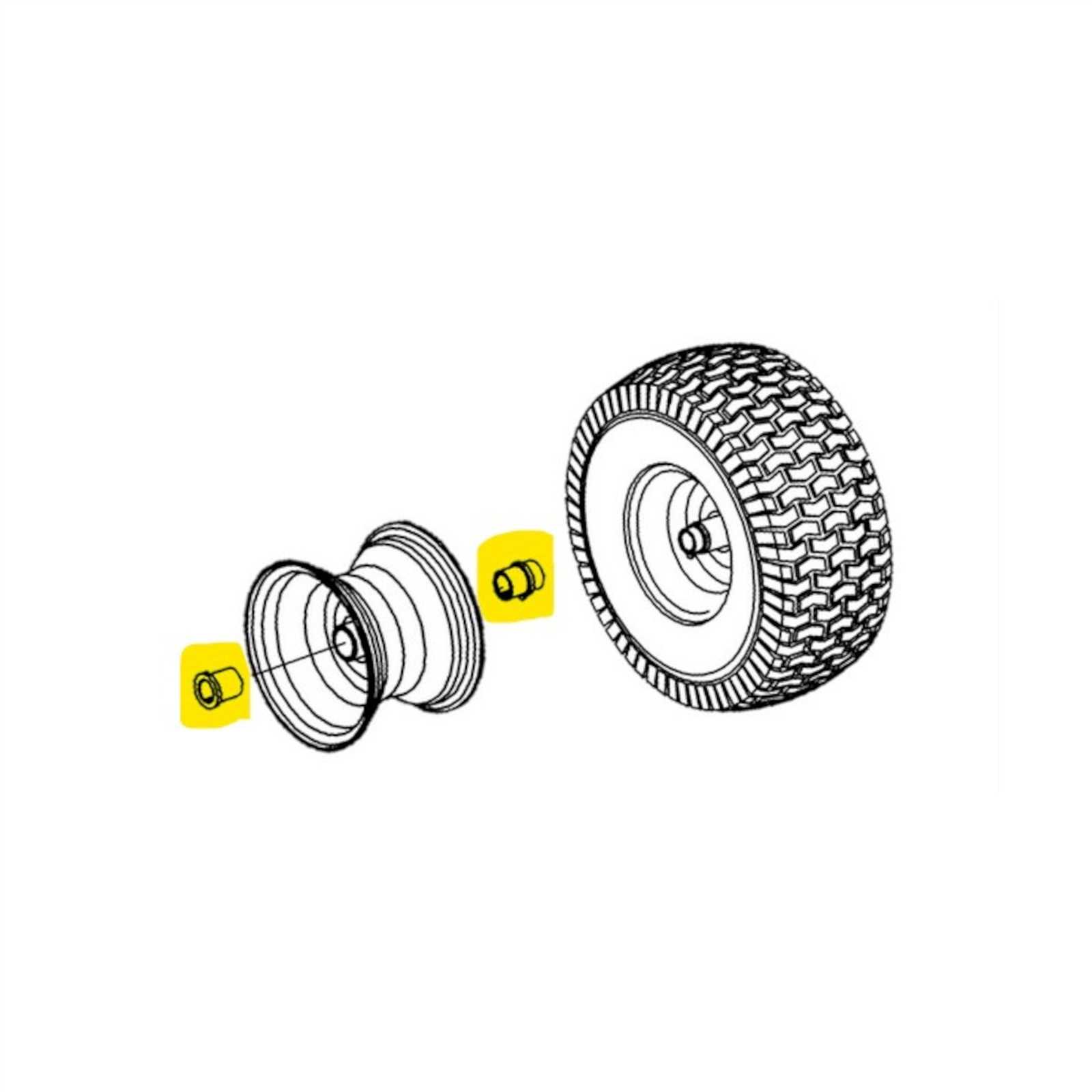

Installation Instructions for Parts

Ensuring proper assembly of components is crucial for the optimal functioning of your machinery. This section provides a clear and concise guide on how to effectively install various elements, guaranteeing a seamless integration and enhanced performance. Following these guidelines will help you maintain the reliability and longevity of your equipment.

Preparation for Installation

Before beginning the installation process, gather all necessary tools and components. Ensure that the workspace is clean and well-lit. Familiarize yourself with each component’s specifications to understand its role within the overall assembly. Proper preparation can significantly reduce installation time and potential errors.

Step-by-Step Assembly

Start with the primary component, following the manufacturer’s recommendations for orientation and placement. Secure each part using the appropriate fasteners, ensuring they are tightened to the specified torque values. Proceed to connect secondary elements, checking for proper alignment and functionality at each step. Regularly consult the manual for any specific instructions related to your model.

Tools Required for Repairs

When undertaking maintenance tasks on machinery, having the right tools is essential for ensuring efficient and effective repairs. A well-equipped workshop can significantly ease the process of fixing any issues that may arise. Below, we outline the various instruments that will assist in the restoration and upkeep of your equipment.

Essential Hand Tools

The following hand tools are fundamental for conducting repairs:

| Tool | Description |

|---|---|

| Wrench Set | Used for tightening or loosening nuts and bolts. |

| Screwdriver Set | Essential for driving screws and performing adjustments. |

| Pliers | Useful for gripping, bending, and cutting wire. |

| Socket Set | Provides various sizes for working with different fasteners. |

Power Tools for Efficiency

In addition to hand tools, power tools can enhance the speed and effectiveness of your repair tasks:

| Tool | Description |

|---|---|

| Drill | Used for making holes and driving screws quickly. |

| Impact Wrench | Offers high torque for loosening stubborn fasteners. |

| Grinder | Used for cutting, grinding, or polishing metal parts. |

| Sander | Essential for smoothing surfaces and preparing for painting. |

Safety Precautions During Maintenance

When conducting upkeep on machinery, it is essential to prioritize safety to prevent accidents and ensure efficient operation. Proper precautions protect not only the equipment but also the individual performing the tasks. Awareness of potential hazards and adherence to guidelines is crucial for a successful maintenance experience.

Before starting any maintenance activity, ensure the machinery is powered off and disconnected from any power sources. Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, to safeguard against injuries. Familiarize yourself with the user manual, which provides valuable insights into safe handling procedures and specific warnings related to the equipment.

Maintain a clean workspace free of clutter to minimize risks and enhance focus. It is also advisable to use tools that are in good condition, as faulty equipment can lead to accidents. Be mindful of your surroundings and avoid distractions while performing maintenance tasks. Lastly, if you are unsure about any procedure, seek guidance from a qualified professional to prevent mishaps.

Frequently Asked Questions

This section addresses common inquiries regarding the components and functionality of a specific model in the machinery lineup. Here, users can find clarity on various aspects, ensuring efficient operation and maintenance.

Common Inquiries

Users often seek information on compatibility, maintenance procedures, and troubleshooting tips. Understanding these factors can enhance the overall experience and longevity of the equipment.

Helpful Resources

| Question | Answer |

|---|---|

| What should I check before operating? | Ensure all components are properly secured and fluids are at recommended levels. |

| How can I improve efficiency? | Regularly maintain the machine and use it as per the manufacturer’s guidelines. |

| Where can I find replacement items? | Authorized dealers or online marketplaces typically stock genuine components. |

| What tools are needed for maintenance? | A basic toolkit, including wrenches, screwdrivers, and pliers, is usually sufficient. |

Resources for Further Information

Accessing reliable resources can significantly enhance your understanding of maintenance and repair for your machinery. Numerous platforms offer comprehensive guides, detailed manuals, and community forums where enthusiasts and experts share valuable insights. Utilizing these materials can help you troubleshoot issues effectively and optimize your equipment’s performance.

Consider exploring manufacturer websites, which often provide technical documents and user manuals. Additionally, online forums and community groups can be excellent places to connect with fellow users, exchange tips, and seek advice. Video tutorials on platforms like YouTube can also serve as practical guides for visual learners, showcasing step-by-step procedures for various tasks.