When it comes to maintaining your outdoor machinery, having a clear visual representation of its intricate elements is vital. These illustrations serve as a roadmap, guiding users through the various sections and ensuring that every part functions harmoniously. Mastery of these components not only enhances efficiency but also prolongs the lifespan of your equipment.

In this section, we will explore the ultimate resources available to help you navigate through the essential elements of your gardening tools. By delving into these visual aids, you will gain a deeper understanding of how each component interrelates and contributes to optimal performance. The knowledge acquired here empowers you to make informed decisions regarding repairs and upgrades.

Whether you are a seasoned professional or a weekend enthusiast, having access to these visual resources is crucial. They provide clarity and confidence in addressing any issues that may arise, ensuring that your gardening experience remains enjoyable and productive.

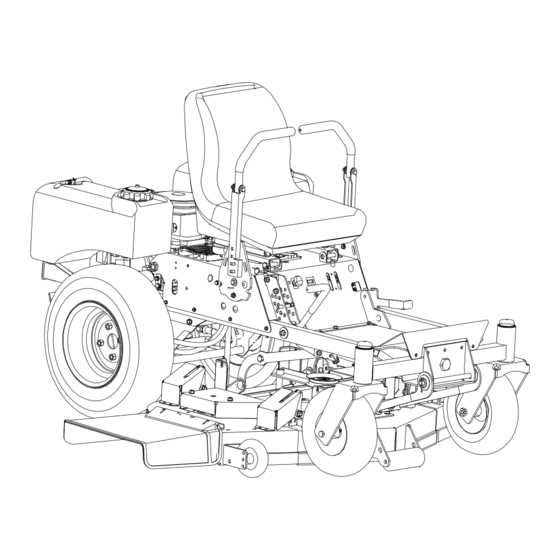

Cub Cadet Mower Overview

This section provides a comprehensive insight into the renowned outdoor equipment brand, focusing on its various models and their capabilities. Known for their reliability and innovative designs, these machines cater to both residential and commercial needs, making them a popular choice among users.

Key Features

The equipment is equipped with advanced technology that enhances performance and ease of use. From powerful engines to efficient cutting systems, each model offers unique specifications that appeal to diverse users, ensuring an ultimate mowing experience.

Maintenance and Support

Proper upkeep is essential for longevity. Users can access detailed resources that assist in understanding the workings of their machines, allowing for effective troubleshooting and maintenance. This guidance ensures optimal performance over time.

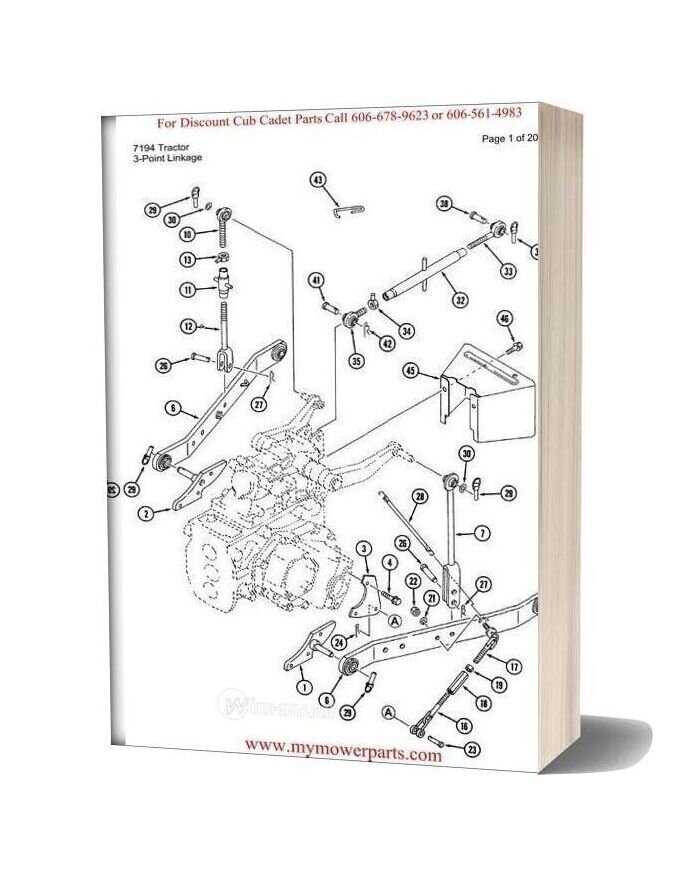

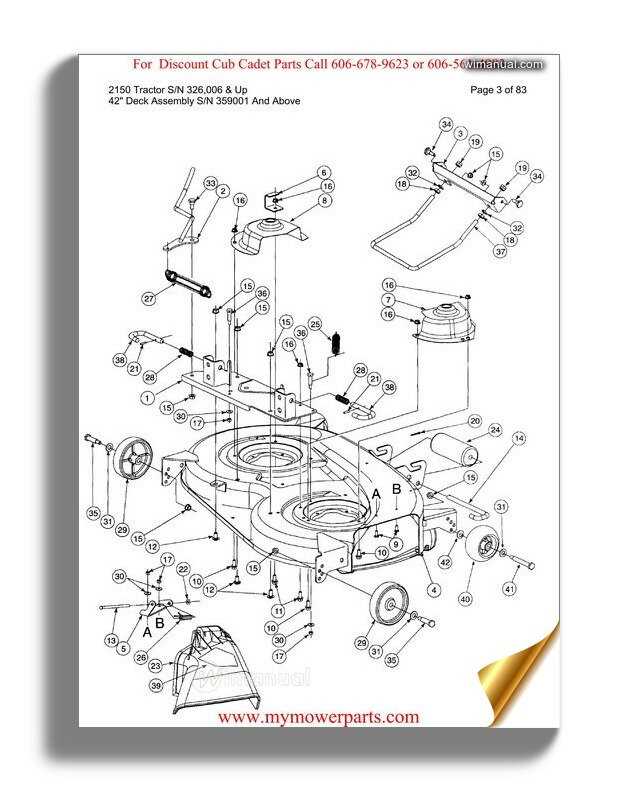

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools, guiding users through the complexities of assembly and disassembly. They enable a clearer comprehension of individual elements, ensuring that each part is handled with care and precision.

Benefits of Visual Guides

- Enhanced clarity in identifying components

- Streamlined maintenance processes

- Reduction in errors during repairs

- Improved troubleshooting efficiency

Applications in Repair and Maintenance

- Facilitates accurate ordering of replacements

- Assists in understanding compatibility between elements

- Supports training for new technicians

Common Issues with Mower Components

Understanding the typical challenges associated with different machine components is essential for effective maintenance and optimal performance. Identifying these issues early can prevent costly repairs and prolong the lifespan of the equipment.

- Fuel System:

- Clogged filters affecting flow.

- Leaks causing inefficient operation.

- Electrical Components:

- Faulty wiring leading to ignition problems.

- Weak batteries hindering performance.

- Cutting Mechanism:

- Dull blades resulting in uneven cuts.

- Debris buildup causing blockages.

- Wheels and Tires:

- Worn tires affecting traction.

- Misaligned wheels leading to uneven wear.

Regular checks and maintenance can significantly reduce these common issues, ensuring better performance and longevity.

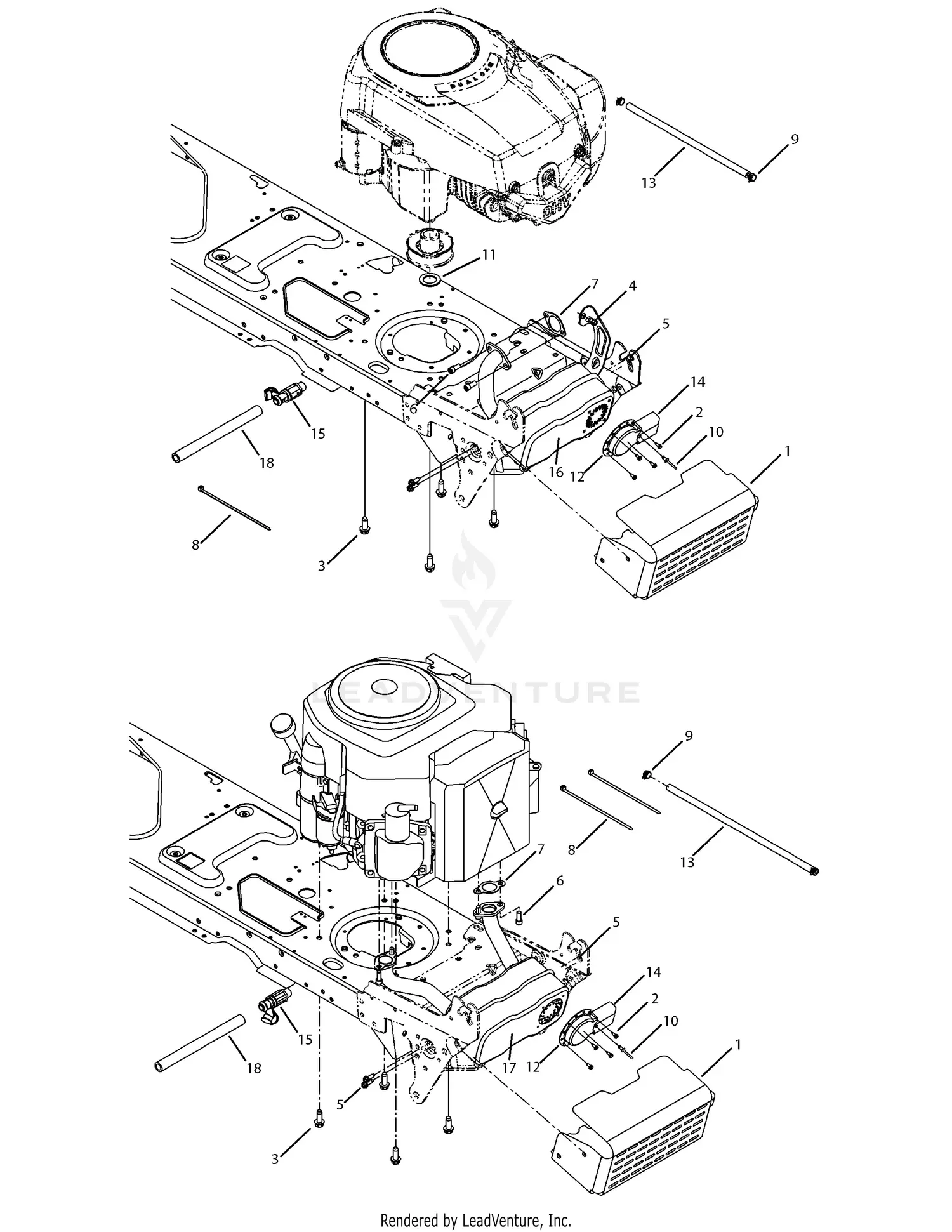

Understanding Engine Parts Layout

Grasping the arrangement of components within an engine is essential for effective maintenance and operation. Each section plays a critical role, and recognizing their positions enhances troubleshooting and repair efficiency. This knowledge empowers users to identify issues quickly and ensures optimal performance.

Key Components and Their Functions

Among the primary elements are the cylinder, piston, and crankshaft. The cylinder serves as the chamber where combustion occurs, while the piston moves up and down, converting energy into mechanical motion. The crankshaft transforms this linear motion into rotational energy, powering the machine.

Importance of Layout Understanding

A clear comprehension of the layout not only aids in repairs but also in routine checks. Identifying each component’s location can prevent misdiagnosis and facilitate the discovery of performance issues before they escalate. This ultimate understanding fosters a proactive approach to engine care.

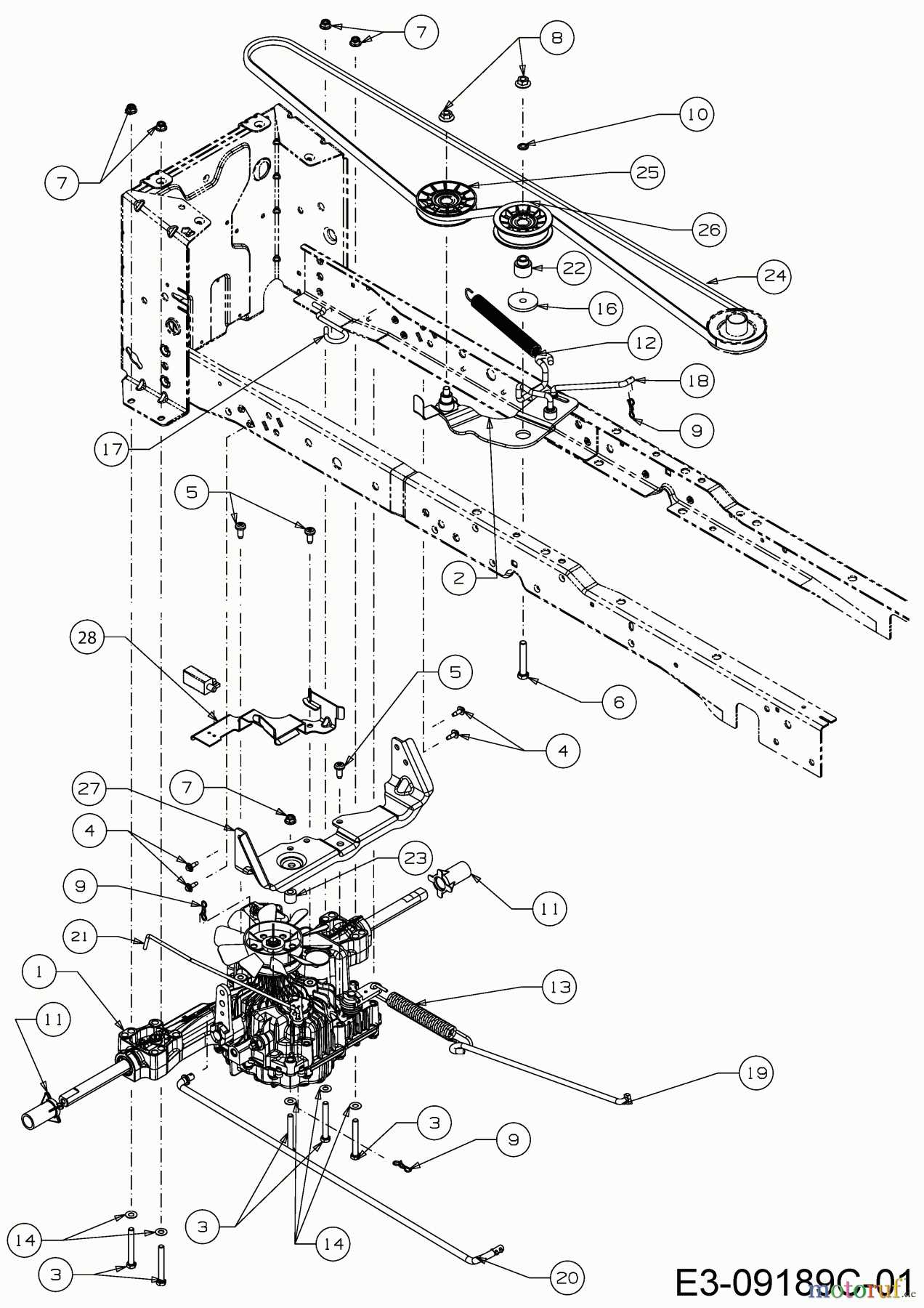

Transmission System Diagram Insights

Understanding the intricacies of the power transfer system is essential for optimal machine performance. This section explores key components, their functions, and how they interconnect to facilitate smooth operation.

- Components Overview:

- Gears

- Belts

- Clutches

- Functionality:

- Energy transfer from the engine to the wheels.

- Speed regulation through various gear ratios.

- Ensuring smooth engagement and disengagement of motion.

- Maintenance Tips:

- Regularly check for wear and tear.

- Lubricate moving parts to prevent friction.

- Inspect belts for signs of damage.

By delving into these aspects, users can enhance the longevity and functionality of their machines.

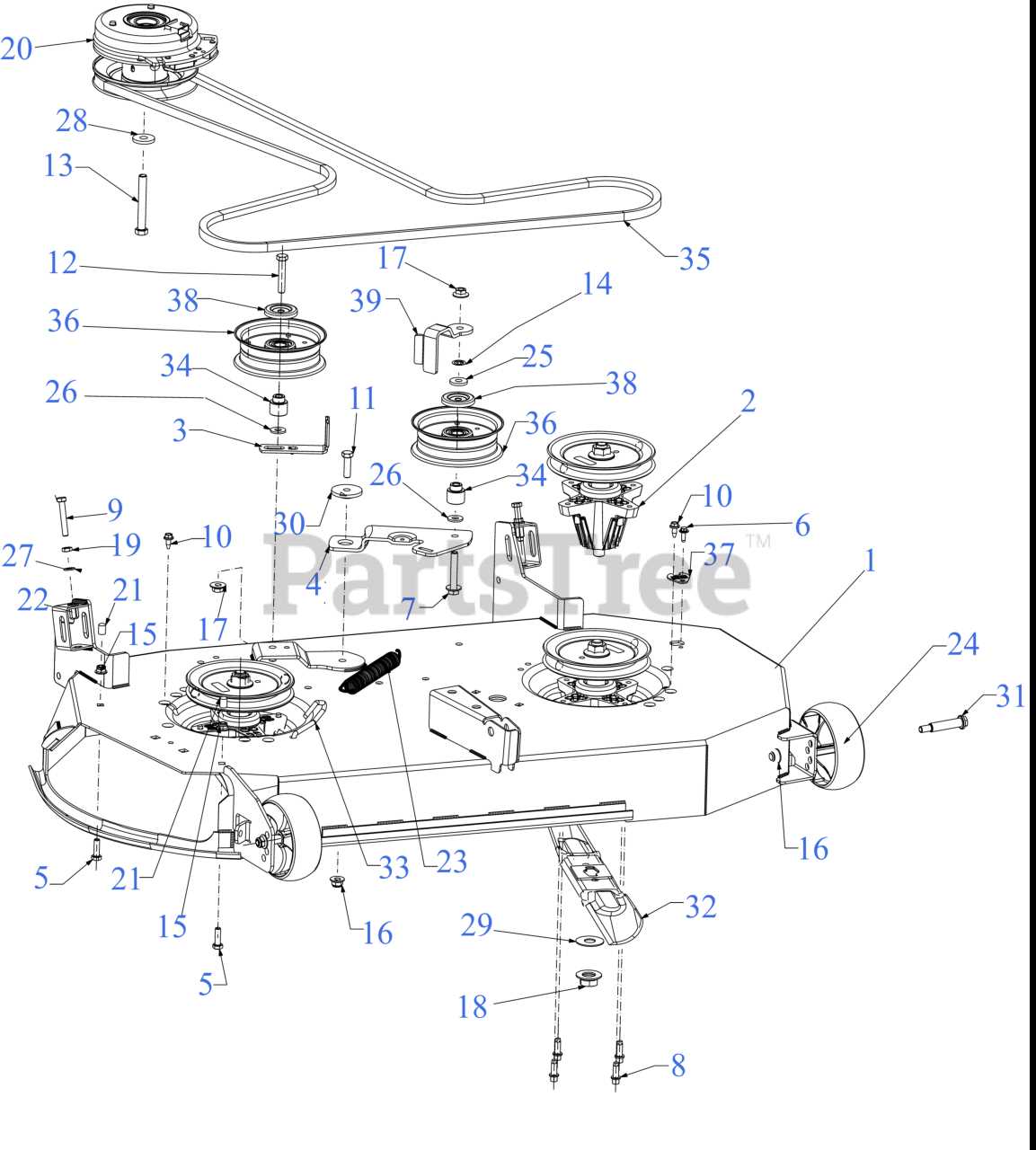

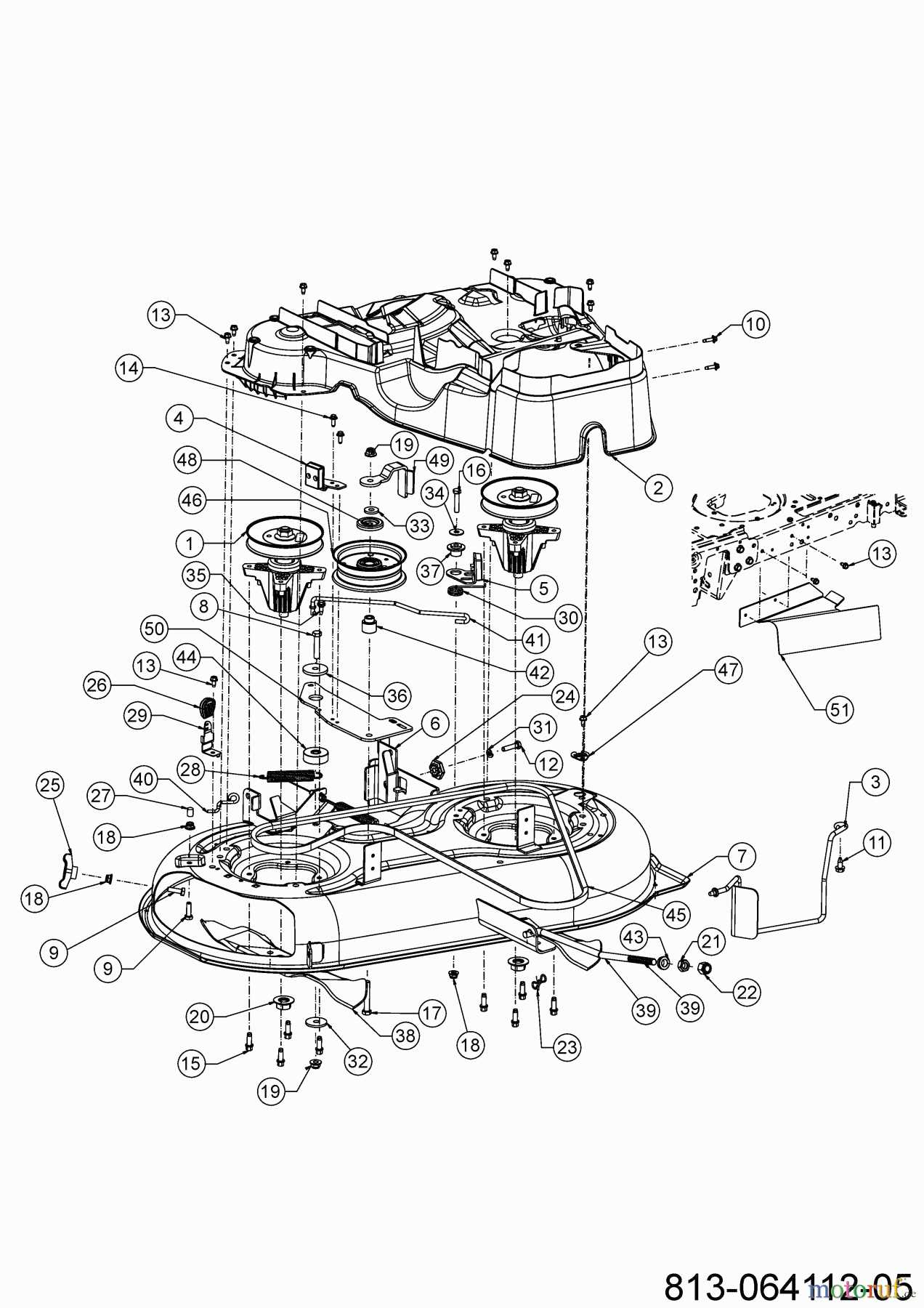

Blade Assembly and Replacement Guide

This section provides essential information on assembling and replacing the cutting components of your machine, ensuring optimal performance and efficiency. Proper maintenance of these elements is crucial for achieving a pristine finish on your grass and enhancing the longevity of your equipment.

Understanding Blade Components

The cutting mechanism consists of several key components that work together to deliver a clean cut. Familiarizing yourself with these parts, including the blades, nuts, and washers, will help streamline the replacement process and ensure that everything functions harmoniously.

Steps for Replacement

To replace the cutting assembly, begin by disconnecting the power source to avoid accidents. Next, lift the machine to access the underside, remove any securing fasteners, and carefully detach the old components. Install the new cutting parts by following the reverse order, ensuring all connections are secure. Finally, reconnect the power and perform a safety check before operating.

Electrical System Component Overview

The electrical system in outdoor power equipment plays a vital role in ensuring smooth operation and reliability. Understanding its components is essential for effective maintenance and troubleshooting. This section outlines the key elements that contribute to the functionality of the electrical network.

- Battery: Supplies the necessary power to start the engine and operate electrical accessories.

- Starter Motor: Engages the engine’s flywheel to initiate the combustion process.

- Ignition Coil: Generates the high voltage required for spark plug ignition, facilitating engine startup.

- Wiring Harness: Connects all electrical components, allowing for efficient power distribution and communication.

- Switches: Control the flow of electricity to various parts, enabling operators to manage functionality effectively.

Each of these components interacts to create a cohesive system that powers and operates equipment effectively. Regular inspection and maintenance of these elements can enhance performance and extend the lifespan of the machinery.

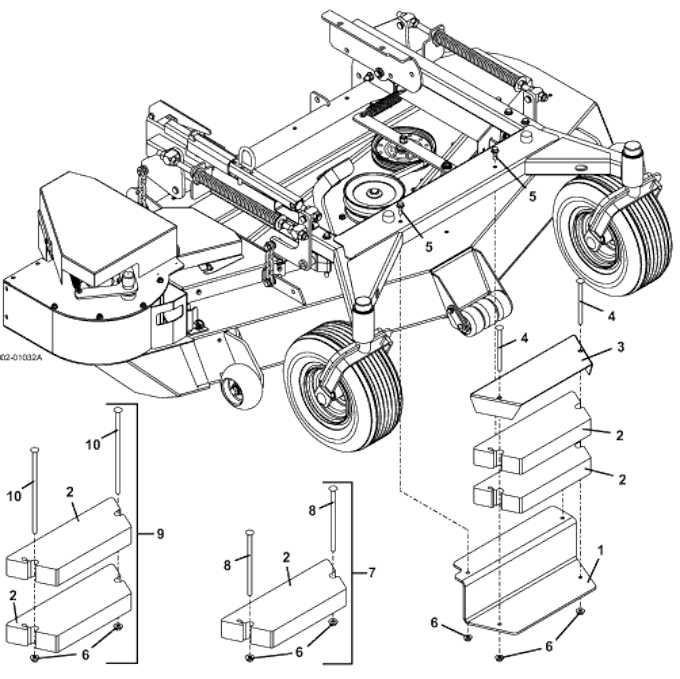

Wheel and Tire Assembly Breakdown

This section explores the intricate components that form the assembly responsible for movement and stability in outdoor machinery. Understanding each element is crucial for effective maintenance and optimal performance.

Components Overview

The assembly comprises various elements, including the rim, tire, hub, and bearings. Each part plays a vital role in ensuring smooth operation and safety during use. Regular inspection of these components can prevent issues and enhance longevity.

Maintenance Tips

To keep the assembly in top condition, it’s essential to regularly check for wear and tear. Inflation levels should be monitored to avoid uneven wear, while bearings should be lubricated to ensure efficient rotation. Taking these steps can lead to a smoother experience and improved reliability.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. By following a structured maintenance routine, you can significantly extend the lifespan of your machinery while also enhancing its performance. Below are some practical tips to help you achieve optimal results.

Routine Inspections

Conducting regular checks is crucial for identifying potential issues before they escalate. Focus on the following:

- Examine belts and cables for signs of wear.

- Check the oil level and quality, changing it as necessary.

- Inspect air filters for clogs and replace them periodically.

- Look for leaks or corrosion in the fuel system.

Cleaning and Care

Maintaining cleanliness is vital for the smooth operation of your equipment. Implement these practices:

- Clean the exterior regularly to prevent dirt buildup.

- Remove grass clippings and debris from undercarriages after each use.

- Wipe down components with appropriate cleaners to avoid rust.

- Store the equipment in a dry place to prevent moisture damage.

Finding Replacement Parts Easily

Locating components for your equipment can be a straightforward process when you know where to look. Understanding how to navigate resources effectively ensures you can maintain optimal functionality without unnecessary delays. By utilizing the right tools and platforms, you can simplify the search and obtain what you need quickly.

Utilizing Online Resources

Many websites offer extensive catalogs of necessary components, allowing you to search by model or type. These platforms often feature user-friendly interfaces, enabling you to view specifications and availability. Take advantage of online communities and forums as well; they can provide invaluable insights and recommendations from fellow users.

Consulting Manufacturer Guides

Always refer to the manufacturer’s guides for specific recommendations on suitable replacements. These resources typically include comprehensive lists of compatible items, ensuring you select the right option. Additionally, don’t hesitate to reach out to customer support for assistance; they can help clarify any uncertainties.

Utilizing Online Resources Effectively

In today’s digital age, leveraging web-based tools for maintenance and repair can significantly enhance efficiency and accuracy. Users can tap into a wealth of information, ensuring they have access to the latest specifications and guidance. Navigating these resources requires a strategic approach to maximize their benefits.

| Resource Type | Description | Best Practices |

|---|---|---|

| Forums | Community-driven platforms where users share experiences and solutions. | Engage actively, ask questions, and contribute knowledge. |

| Instructional Videos | Visual guides that demonstrate processes step-by-step. | Follow along with your own equipment for practical learning. |

| Official Websites | Manufacturer sites providing detailed manuals and updates. | Check regularly for the latest information and product recalls. |

| Online Retailers | Sites offering parts and accessories with user reviews. | Read reviews and compare options before purchasing. |

By harnessing these tools effectively, users can ensure they are well-prepared for any maintenance challenge, ultimately improving the longevity of their equipment.

Safety Precautions During Repairs

When undertaking any maintenance or repair tasks, ensuring safety should always be the top priority. Proper precautions not only protect the individual performing the repairs but also help prevent potential damage to the equipment being serviced. Adhering to recommended guidelines can lead to a more efficient and hazard-free experience.

Before starting any work, it is essential to disconnect the power source. This simple step can prevent accidental activation of machinery, reducing the risk of injury. Additionally, wearing appropriate personal protective equipment, such as gloves and safety goggles, is crucial to safeguarding against harmful debris or sharp components.

Keeping the work area clean and organized is another vital aspect of maintaining safety. A cluttered workspace can lead to slips, trips, and falls, which can be particularly dangerous in a setting involving heavy equipment. Ensuring that tools are stored correctly and that there is adequate lighting will help minimize hazards.

Furthermore, familiarizing oneself with the equipment’s manual and understanding the specific parts being worked on can prevent mistakes and enhance safety. If uncertainty arises about any aspect of the repair, seeking assistance or professional advice is always a wise choice. Remember, taking the time to prioritize safety can make all the difference in a successful and secure maintenance session.

Frequently Asked Questions about Diagrams

This section aims to address common inquiries related to visual representations used for assembly and repair processes. Understanding these illustrations can greatly enhance your ability to maintain and troubleshoot machinery effectively.

What is the purpose of these visual guides?

These illustrations provide clear and detailed information about the various components and their arrangement, helping users identify parts and understand assembly sequences easily.

How can I access these illustrations?

Typically, these resources are available through manufacturer websites, user manuals, or specialized online forums where enthusiasts share insights and documentation.