For enthusiasts and owners of garden machinery, comprehending the intricate layout of a lawn tractor is essential for maintenance and repair. Each element plays a critical role in ensuring the equipment operates smoothly and efficiently. By familiarizing yourself with these components, you can enhance the longevity of your machine and tackle any issues that may arise.

This guide aims to provide clarity on the various sections of your lawn tractor, highlighting the functionality and interconnections of different parts. Understanding these components is not only beneficial for troubleshooting but also for making informed decisions during upgrades or replacements.

Diving into the specifics of your tractor’s assembly allows you to visualize how each part interacts within the whole system. Whether you are a novice or a seasoned operator, this exploration can significantly enhance your overall experience with your equipment.

Overview of the Lawn Tractor

This versatile lawn tractor is designed to meet the needs of homeowners who value efficiency and durability in their gardening tasks. With a robust build and advanced features, it ensures optimal performance across various terrains, making it an essential tool for maintaining a pristine lawn.

Key Features

The machine boasts a powerful engine that provides reliable performance, allowing users to tackle larger areas without compromising on quality. Additionally, its cutting system is engineered for precision, ensuring an even finish that enhances the overall appearance of the yard. The comfortable seating and ergonomic controls further enhance the user experience, making prolonged use enjoyable.

Maintenance and Support

Regular upkeep is crucial for longevity, and this model is designed with accessibility in mind. Clear instructions and readily available resources help owners manage maintenance effectively. Whether it’s routine checks or necessary repairs, support is always within reach, ensuring the machine remains in top condition throughout its lifespan.

Key Features of SLTX 1050

This model stands out due to its remarkable blend of performance, efficiency, and user-friendly design. It is engineered to provide exceptional mowing experiences, catering to both residential and commercial needs. Below are some of its notable characteristics that enhance its functionality and appeal.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that ensures optimal performance across various terrains. |

| Cutting Deck | The wide cutting deck allows for efficient grass handling and a clean finish. |

| Ergonomic Design | Designed with user comfort in mind, making it easy to maneuver and operate. |

| Versatility | Compatible with various attachments, enhancing its usability for different tasks. |

| Durability | Built with high-quality materials to withstand the rigors of regular use. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of the various elements allow users to quickly identify and access the necessary components, ensuring that any issues can be resolved efficiently. Such illustrations serve not only as a reference but also as a guide for those who may not be familiar with the specific machinery.

Benefits of Visual Reference

A schematic overview provides numerous advantages, including enhanced clarity, improved troubleshooting efficiency, and a reduction in the likelihood of errors during repairs. When individuals can visualize how different elements interact, they are better equipped to manage repairs or replacements without unnecessary confusion.

Key Elements in Schematic Representations

| Element | Description |

|---|---|

| Labels | Clear indications of each component’s name and function. |

| Connections | Illustrations of how different elements are linked, aiding in understanding their interactions. |

| Exploded Views | Visuals that show components separated, highlighting the assembly and order of parts. |

| Scale | Dimensions that provide an accurate perspective on size and fit. |

Understanding Engine Components

Engines are intricate systems comprising various elements that work in unison to produce power. Each component plays a critical role in ensuring optimal performance and efficiency, contributing to the overall functionality of the machine.

Main Components

Several key parts can be identified, each fulfilling specific tasks. Recognizing these elements aids in grasping how engines operate and can simplify maintenance and troubleshooting processes.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts combustion energy into mechanical work. |

| Crankshaft | Transforms linear motion from the piston into rotational motion. |

| Camshaft | Controls the opening and closing of valves. |

Importance of Understanding

A solid grasp of engine components is essential for effective maintenance and performance enhancement. Delving into each part’s role can lead to better decision-making and a deeper appreciation for the machinery’s complexity.

Transmission Parts Explained

The components that facilitate power transfer within a vehicle’s drive system play a crucial role in its overall functionality. Understanding these elements is essential for maintaining optimal performance and ensuring a smooth operation. Each segment works in harmony to convert engine output into usable motion, making it vital for users to familiarize themselves with their individual purposes and interactions.

Deck Assembly and Maintenance

This section focuses on the crucial aspects of assembling and maintaining the cutting platform of your mower. Proper care and understanding of its components can significantly enhance performance and longevity.

To ensure efficient operation, follow these guidelines:

- Regularly inspect all components for wear and tear.

- Clean the deck after each use to prevent grass buildup.

- Lubricate moving parts as recommended by the manufacturer.

- Check blade sharpness and replace dull blades promptly.

During assembly, ensure all fasteners are secure to prevent operational issues:

- Align the deck properly with the frame.

- Use the correct tools for tightening screws and bolts.

- Follow the assembly sequence as outlined in the user manual.

Adhering to these maintenance practices will lead to optimal functionality and a prolonged lifespan of your equipment.

Electrical System Breakdown

The electrical framework of a machine plays a crucial role in its overall functionality and efficiency. Understanding the various components that comprise this system is essential for maintenance and troubleshooting. Each element, from the battery to the ignition switch, works in harmony to ensure optimal performance.

Key Components include the battery, which provides the necessary power; the starter motor, responsible for initiating the engine; and the wiring harness, which connects all parts and facilitates electrical flow. Additionally, fuses protect the system from overloads, while the regulator maintains consistent voltage levels.

Regular inspection and understanding of these elements can lead to enhanced reliability and prolonged lifespan of the equipment. Addressing any issues promptly ensures that the machine operates smoothly, minimizing downtime.

Common Wear and Tear Parts

Every machine experiences components that degrade over time due to regular use. Understanding these frequently replaced elements is crucial for maintaining optimal performance and longevity.

- Belts: Subject to tension and friction, these often need replacement to ensure smooth operation.

- Blades: Dull or damaged cutting edges can affect efficiency and require regular sharpening or replacement.

- Batteries: Power sources diminish over time, impacting overall functionality.

- Filters: Air and fuel filters can become clogged, leading to reduced performance and should be checked regularly.

Regular inspection of these components can prevent more significant issues, ensuring your equipment runs at its ultimate best.

Finding Replacement Components

When it comes to maintaining and restoring outdoor machinery, locating suitable replacement pieces is crucial for optimal performance. Understanding how to source these components can significantly extend the lifespan of your equipment. This process involves identifying the necessary elements, their specifications, and potential suppliers.

Begin by consulting the user manual or manufacturer’s resources to get a clear understanding of the required specifications for each component. This documentation often contains crucial information regarding compatibility and installation guidelines, making it an invaluable reference point.

Once you have identified the specific parts needed, explore various sources such as authorized dealers, online marketplaces, and local hardware stores. Many online platforms provide detailed descriptions, reviews, and diagrams that can help ensure you choose the correct replacements. Additionally, consider reaching out to community forums or support groups where enthusiasts share insights and recommendations on where to find reliable components.

Finally, always verify the return policies and warranties when purchasing replacements. This precaution allows you to make informed decisions, ensuring that you receive high-quality items that meet your machinery’s needs.

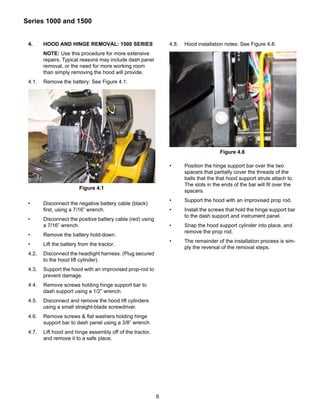

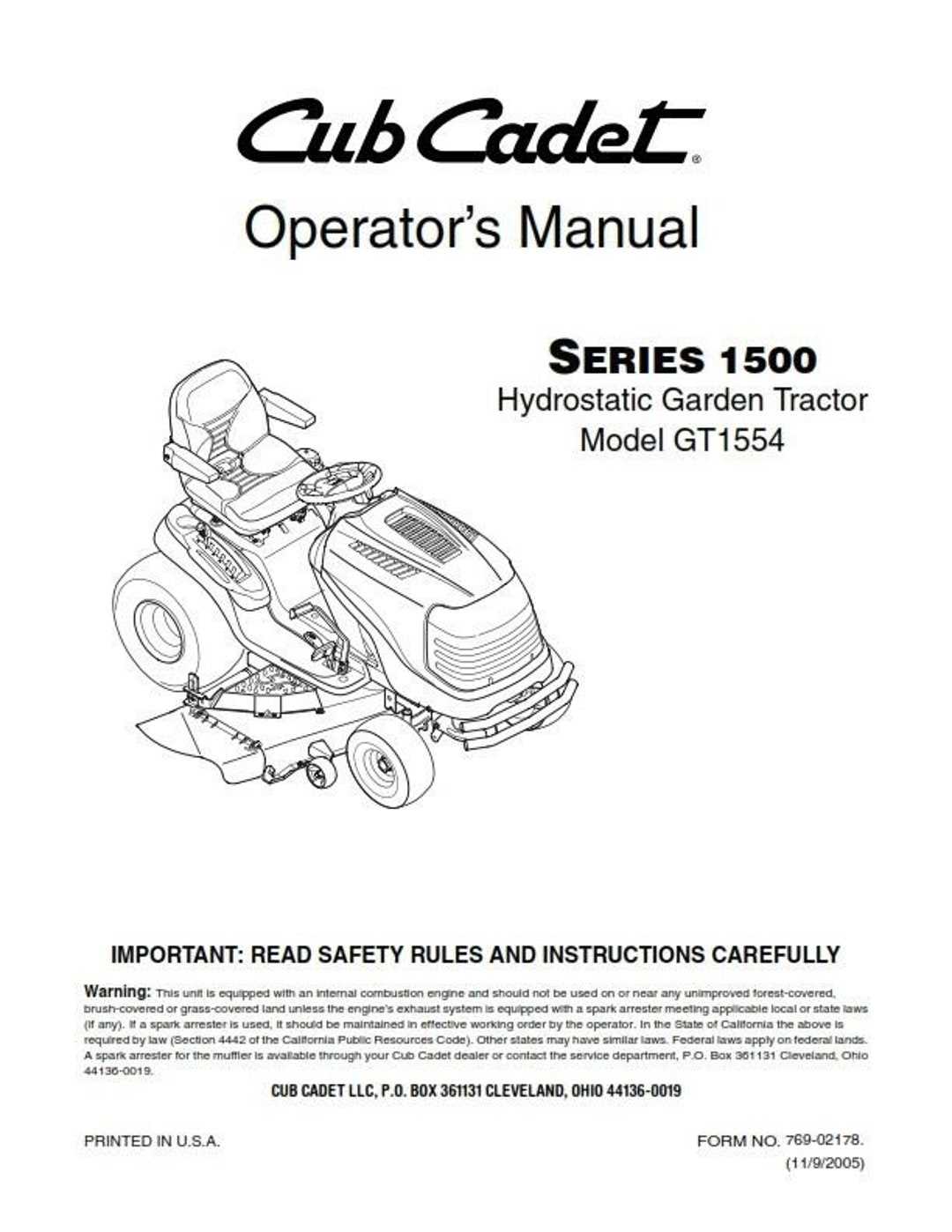

Step-by-Step Repair Guide

This guide is designed to assist you in navigating the repair process of your lawn maintenance equipment. By following these detailed steps, you can effectively address common issues and ensure your machine operates smoothly. A systematic approach will not only save time but also enhance your understanding of the machinery.

Identifying the Problem

Begin by diagnosing the issue at hand. Listen for unusual sounds, check for leaks, or observe performance inconsistencies. Make a list of the symptoms to clarify what needs to be addressed. This initial assessment is crucial for effective repairs.

Gathering Tools and Components

Once the problem is identified, collect the necessary tools and replacement components. Refer to your equipment’s user manual for specifications on required items. Having everything ready beforehand streamlines the repair process and minimizes downtime.

Important: Always prioritize safety. Wear appropriate protective gear and ensure the equipment is powered down before commencing any work.

Following these steps will facilitate a smoother repair experience, allowing you to maintain your machinery’s functionality and extend its lifespan.

Upgrading Your SLTX 1050

Enhancing the performance and functionality of your outdoor equipment can significantly improve your overall experience. Upgrades can range from simple modifications to more complex installations, aimed at increasing efficiency and longevity. Exploring various options allows you to tailor your machine to better meet your specific needs.

Consider investing in high-quality attachments and accessories that boost productivity. Improved blades, efficient engines, and advanced steering systems can make a remarkable difference. Additionally, incorporating features that enhance comfort, such as ergonomic seating and user-friendly controls, ensures a more enjoyable operation.

Regular maintenance and timely replacements are equally vital. Upgrading worn-out components not only optimizes performance but also prevents potential breakdowns. Keeping an eye on the latest advancements in technology can lead to further enhancements, ensuring your equipment remains top-notch.

Ultimately, staying informed about available upgrades allows you to maximize your investment and enjoy a superior experience in your outdoor tasks. Take the time to research and select the enhancements that will work best for you.

Tips for Long-lasting Performance

Maintaining optimal efficiency in machinery is crucial for ensuring longevity and reliability. By implementing a few strategic practices, users can significantly enhance the operational lifespan and reduce the likelihood of unexpected failures.

Regular Maintenance: Establish a routine schedule for inspections and maintenance. This includes checking fluid levels, tightening loose components, and replacing worn parts promptly.

Proper Storage: When not in use, store equipment in a dry and sheltered area to protect it from environmental factors that can cause wear and tear.

Quality Fuel: Using high-quality fuel and lubricants can greatly affect performance. Contaminated or substandard fluids may lead to engine issues and reduced efficiency.

Follow Manufacturer Guidelines: Adhering to the recommended operational practices provided by the manufacturer ensures that the equipment runs within its designed parameters, promoting durability.

Training and Education: Invest time in understanding the machinery and its specific needs. Proper handling and operation can prevent unnecessary strain and damage.