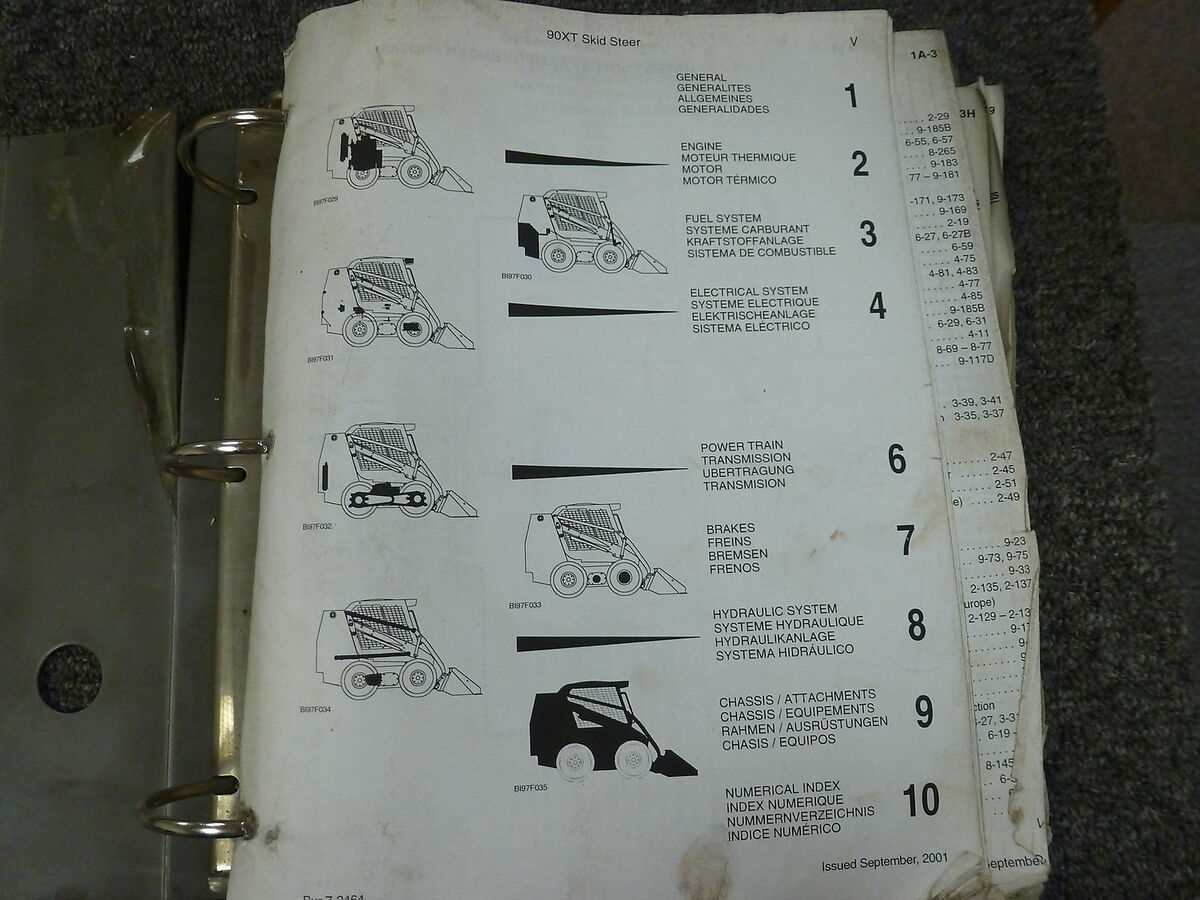

The intricate machinery utilized in agricultural and industrial settings requires a comprehensive understanding of its various elements. Each component plays a crucial role in ensuring the overall efficiency and functionality of the equipment. Understanding these elements is essential for maintenance, repairs, and optimal performance.

In this section, we will delve into the visual representations of the equipment’s inner workings. These illustrations provide a clear overview of how different parts interact, facilitating a better grasp of their individual functions and the assembly as a whole. A thorough examination of these visuals will aid in troubleshooting and enhance operational knowledge.

By familiarizing yourself with these intricate details, you can ensure that your machinery operates smoothly. Knowledge of the specific components and their arrangements will empower you to perform necessary upkeep effectively. Let’s embark on this journey to uncover the vital aspects that keep these machines running at their best.

Understanding the essential components of heavy machinery is crucial for efficient operation and maintenance. Recognizing these elements can enhance troubleshooting and repair processes, ensuring that the equipment functions optimally.

Common Components

Familiarity with various machine elements allows operators and technicians to diagnose issues effectively. Here are some of the primary components to be aware of:

- Engine: The power source that drives the entire machine.

- Hydraulic System: Responsible for the movement and operation of various attachments.

- Transmission: Controls the speed and torque delivered to the wheels.

- Frame: The structural foundation that supports all other parts.

- Electrical System: Powers the controls and other electronic components.

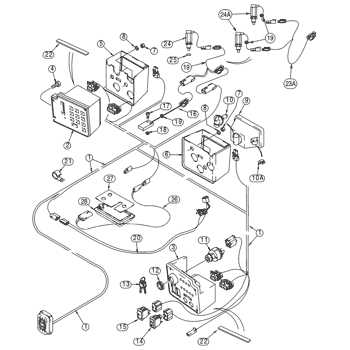

Visual References

Utilizing visual references can significantly aid in recognizing these components. Illustrated guides can provide clarity on the location and function of each part:

- Locate the engine and its corresponding accessories.

- Identify the hydraulic lines and their connections.

- Understand the arrangement of the transmission system.

- Examine the structural elements of the frame.

- Review the layout of the electrical components.

By familiarizing yourself with these critical elements, you can improve your ability to operate and maintain machinery effectively.

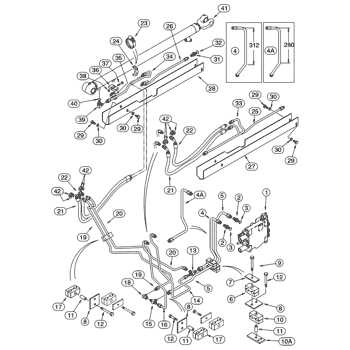

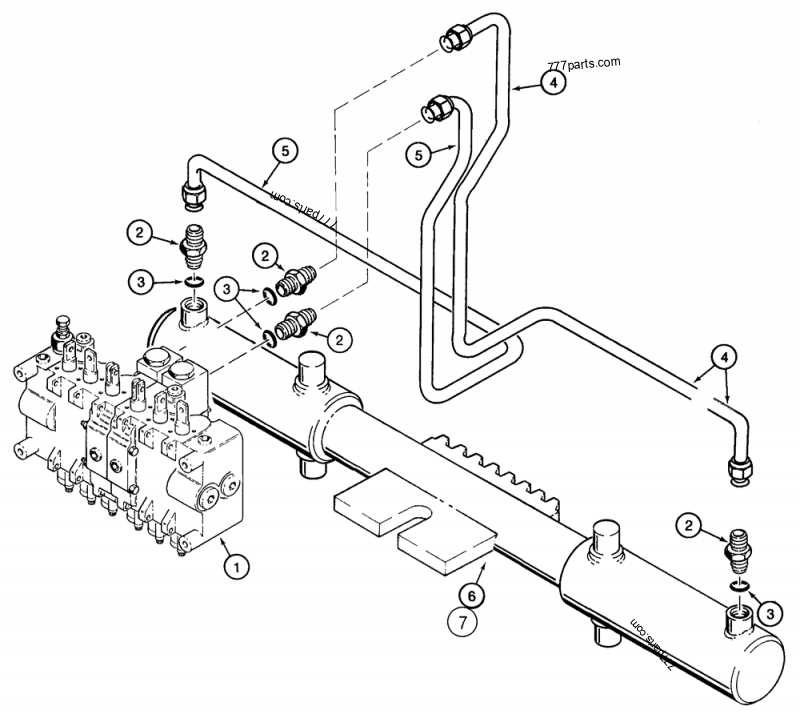

Exploring the Hydraulic System Layout

The hydraulic system plays a crucial role in the functionality of machinery, enabling efficient movement and operation of various components. Understanding its configuration is essential for maintenance and troubleshooting. This section delves into the arrangement of hydraulic elements, showcasing how they interact to facilitate fluid transfer and power transmission.

The system typically consists of a network of hoses, valves, pumps, and cylinders that work together seamlessly. Each element is strategically positioned to ensure optimal performance, with fluid flow directed through specific pathways. Proper identification of these components aids in diagnosing issues and performing effective repairs.

By familiarizing oneself with the overall design and connection points, operators can enhance their understanding of machine operation and improve their ability to conduct timely maintenance. This knowledge not only prolongs equipment life but also boosts productivity in various applications.

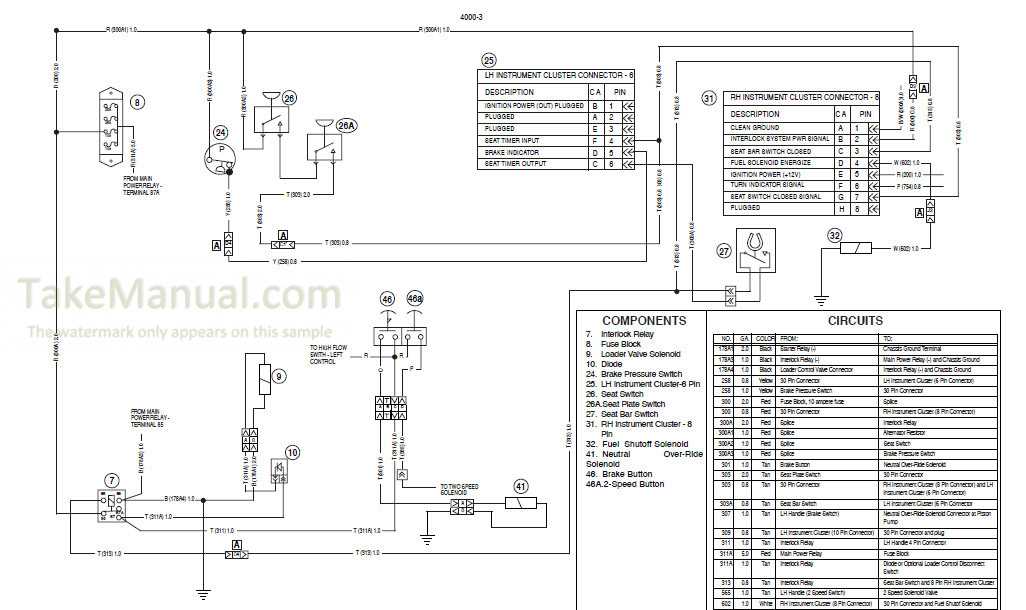

Electrical System Wiring Diagram

The electrical network of a machinery unit plays a crucial role in its overall functionality. Understanding the layout of this network is essential for effective maintenance and troubleshooting. This section explores the intricacies of the electrical wiring layout, outlining its key components and their interconnections.

Key elements of the electrical configuration include:

- Power distribution systems

- Control circuits

- Signal pathways

- Grounding mechanisms

By familiarizing oneself with these components, operators and technicians can enhance their understanding of the machine’s electrical framework. This knowledge facilitates more efficient repairs and modifications, ensuring optimal performance.

Moreover, a well-structured wiring arrangement allows for easier identification of potential issues, such as:

- Short circuits

- Loose connections

- Faulty components

Ultimately, mastering the electrical wiring layout not only improves troubleshooting efficiency but also contributes to the longevity and reliability of the equipment.

Understanding Engine Assembly Parts

The engine assembly is a complex system comprised of various components that work together to ensure optimal performance. Each element plays a crucial role in the overall function of the engine, contributing to its efficiency and reliability. A thorough comprehension of these components is essential for effective maintenance and troubleshooting.

Key elements of the engine assembly include the cylinder block, which houses the cylinders and supports other components, and the crankshaft, which converts linear motion into rotational energy. Additionally, the pistons are vital as they move within the cylinders to generate power. Understanding how these parts interact helps in diagnosing issues and performing necessary repairs.

Furthermore, components such as the timing belt and valve train are critical for synchronizing engine operations. The timing belt ensures that the crankshaft and camshaft work in harmony, while the valve train controls the intake and exhaust of gases. Familiarity with these parts allows for a more comprehensive approach to engine maintenance and enhances overall performance.

Transmission Components Explained

The functioning of any heavy machinery relies heavily on its transmission system. This system plays a crucial role in transferring power from the engine to the wheels, enabling smooth operation and efficient performance. Understanding the various components involved can help in maintaining and optimizing the overall functionality of the equipment.

Main Transmission Elements

Within the transmission assembly, several key components work in harmony to ensure effective power delivery. These parts include gears, clutches, and shafts, each serving distinct purposes. The interaction between these elements allows for the control of speed and torque, which is essential for the machine’s operation.

Each component has a specific role that contributes to the efficiency of the transmission system:

| Component | Function |

|---|---|

| Gears | Alter the speed and torque output by changing the gear ratios. |

| Clutches | Engage and disengage power transmission to allow for smooth shifting. |

| Shafts | Transfer rotational energy from the engine to other components. |

Understanding these components and their functions is vital for anyone involved in maintenance and repair tasks. Regular checks and timely replacements of worn parts can significantly extend the lifespan of the machinery.

Maintenance Parts and Accessories

Ensuring optimal performance of your equipment relies heavily on the availability of essential components and supplementary tools. Regular upkeep not only extends the lifespan of machinery but also enhances operational efficiency. This section outlines the vital elements that contribute to maintaining functionality and reliability.

Essential Components

Critical elements such as filters, belts, and lubricants play a significant role in the upkeep process. Filters, for instance, help to remove impurities from fluids, ensuring that systems operate smoothly. Meanwhile, high-quality belts are necessary for effective power transmission, minimizing wear and tear. Regularly inspecting and replacing these components is essential for preventing potential breakdowns.

Supplementary Tools

In addition to core components, various accessories can aid in routine maintenance. Items like wrenches, screwdrivers, and diagnostic tools are invaluable for performing inspections and adjustments. Investing in reliable tools facilitates quick repairs and routine checks, ultimately saving time and resources while maintaining the equipment’s performance.

Common Replacement Parts Needed

When maintaining heavy machinery, certain components tend to wear out more frequently than others. Understanding which elements are essential for regular upkeep can significantly enhance the longevity and efficiency of your equipment.

Essential Components for Maintenance

- Filters: Regularly changing oil and air filters ensures optimal performance and engine health.

- Batteries: Reliable power sources are crucial for starting machinery and powering electrical systems.

- Belts and Hoses: These components can deteriorate over time, leading to performance issues if not replaced promptly.

- Seals and Gaskets: Preventing leaks and maintaining pressure requires frequent inspection and replacement of these items.

Frequently Used Wear Items

- Hydraulic Fluids: Keeping the hydraulic system topped off with the correct fluid is vital for smooth operation.

- Brake Pads: Worn brake pads can compromise safety, making timely replacement crucial.

- Tires: Inspecting and replacing tires is essential for maintaining traction and stability on various terrains.

Parts Ordering and Availability

Acquiring components for machinery can be a crucial process that impacts operational efficiency. Understanding the ordering procedure and ensuring the accessibility of necessary items are essential for maintaining performance and minimizing downtime.

When seeking specific components, it is important to identify reliable suppliers that can provide the required items promptly. Many vendors offer online platforms where you can browse inventories and place orders easily. Here are some key factors to consider when ordering:

| Factor | Description |

|---|---|

| Supplier Reliability | Choose vendors with a proven track record for timely deliveries and quality products. |

| Inventory Levels | Check stock availability to avoid delays in receiving essential components. |

| Lead Time | Understand the time frame from placing an order to receiving the item. |

| Return Policy | Be aware of the conditions for returning or exchanging items that do not meet specifications. |

Additionally, consider establishing a routine to monitor inventory levels regularly. This proactive approach can help anticipate shortages and ensure a continuous supply of critical components. Collaborating with local suppliers can also enhance the speed of obtaining items, particularly in urgent situations.

Using the Parts Diagram Effectively

Understanding the visual representation of components can significantly enhance your ability to manage and maintain machinery. A well-organized illustration serves as a valuable tool for identifying individual elements and their relationships within the system. By leveraging this resource, users can streamline their troubleshooting and repair processes.

Here are some strategies for maximizing the effectiveness of the visual representation:

- Familiarize Yourself with the Layout: Before diving into repairs, take time to study the arrangement of components. Knowing where each piece is located can save time during disassembly and reassembly.

- Cross-Reference with the Manual: Utilize the accompanying documentation to gain insights into the specifications and functions of each component. This combination enhances your understanding of the overall system.

- Highlight Key Areas: Mark crucial parts that require regular attention or are prone to wear. This will help you focus on maintenance needs and anticipate potential issues.

By incorporating these techniques, users can effectively utilize the visual representation, leading to improved performance and longevity of the machinery.

Tips for Assembly and Repair

Proper assembly and maintenance are crucial for ensuring the longevity and efficiency of your machinery. Adhering to specific guidelines can significantly improve the overall functionality and reduce the risk of future issues. Here are some essential tips to consider during the process.

| Tip | Description |

|---|---|

| Use the Right Tools | Employing the correct tools can prevent damage and ensure proper fit during assembly. Invest in quality equipment for optimal results. |

| Follow Manufacturer Guidelines | Refer to the provided instructions to ensure all components are installed correctly. This minimizes errors and ensures compatibility. |

| Inspect Components | Before beginning assembly, examine all parts for wear or damage. Replacing worn components can prevent future breakdowns. |

| Keep a Clean Workspace | A tidy environment reduces the risk of losing parts and helps maintain focus during the assembly process. |

| Take Your Time | Rushing can lead to mistakes. Allow ample time for each step to ensure accuracy and thoroughness. |