Understanding the intricacies of modern farming equipment involves delving into the inner workings that drive efficiency and productivity. In this segment, we delve into the vital elements that comprise the foundational aspects of agricultural machinery.

Exploring the anatomy of these mechanical marvels unveils a world of interconnected parts and mechanisms, each playing a pivotal role in the seamless operation of these complex systems.

Unraveling the complexities of component integration highlights how precision engineering fosters reliability and performance, essential for meeting the demanding needs of today’s agricultural practices.

The Importance of Familiarizing with Agricultural Machinery Components

Understanding the intricacies of agricultural equipment is pivotal for efficient operation and maintenance. Familiarity with the various components ensures that farmers and technicians can identify, troubleshoot, and repair machinery swiftly, minimizing downtime and optimizing productivity.

Enhanced Operational Efficiency

Proficiency in recognizing and understanding agricultural machinery components allows operators to perform tasks with greater precision and speed. This knowledge empowers them to make informed decisions during operations, enhancing overall efficiency on the field.

Reduced Maintenance Costs

By being well-versed in the anatomy of agricultural machinery, farmers can conduct preventive maintenance effectively. Early detection of potential issues through regular inspections and understanding component functions helps in preemptively addressing problems, thereby reducing repair costs and extending the lifespan of equipment.

| Component | Description |

|---|---|

| Engine | The powerhouse of the machinery, responsible for generating mechanical energy. |

| Transmission | Facilitates power transfer from the engine to the wheels or implements, enabling movement and operation. |

| Hydraulic System | Controls the flow of hydraulic fluid to enable the operation of various attachments and implements. |

Key Components Highlighted in the Case IH 8330 Diagram

The schematic representation of agricultural machinery offers a valuable insight into the essential elements that ensure optimal functionality and efficiency. By examining these critical components, operators can better understand their roles and importance in the overall operation of the equipment.

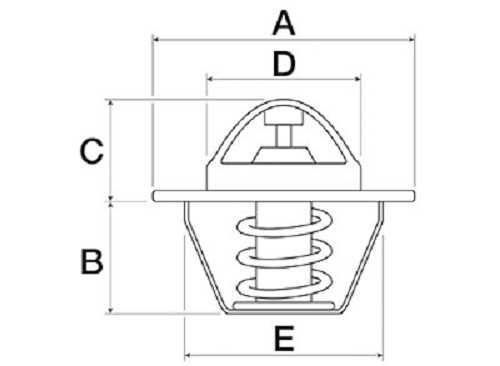

Essential Elements

- Engine Assembly: This is the powerhouse of the machine, providing the necessary energy to perform various tasks.

- Transmission System: A vital mechanism that transfers power from the engine to the wheels, allowing for smooth operation across different terrains.

- Hydraulic System: Responsible for controlling various attachments and implements, this system enhances the versatility of the equipment.

Operational Features

- Fuel System: Ensures efficient delivery of fuel to the engine, optimizing performance.

- Cooling System: Maintains the ideal temperature for the engine, preventing overheating and ensuring longevity.

- Electrical Components: These parts provide the necessary power for starting and operating various features of the machinery.

Understanding these key elements allows operators to perform maintenance effectively, troubleshoot issues, and enhance the overall performance of the agricultural equipment.

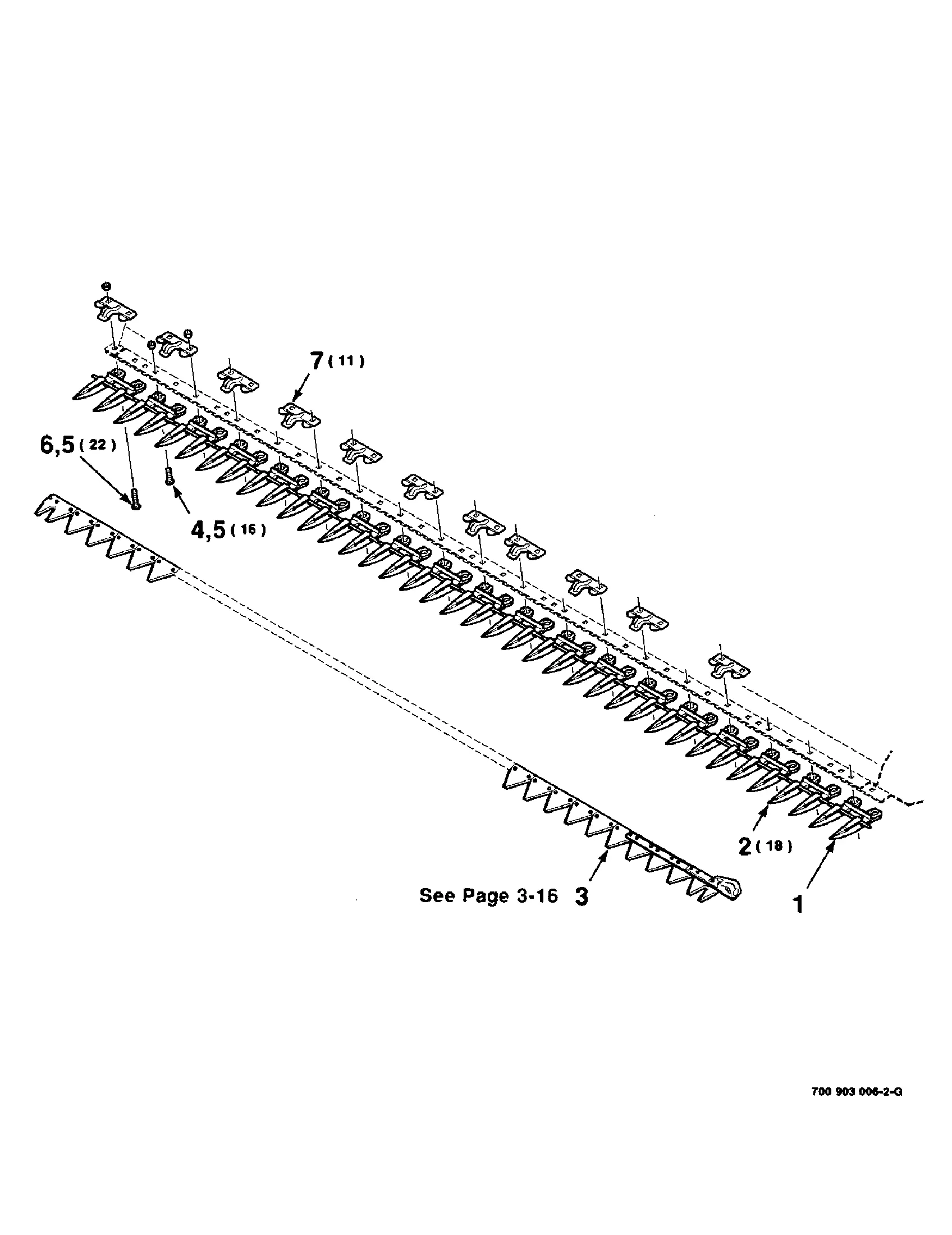

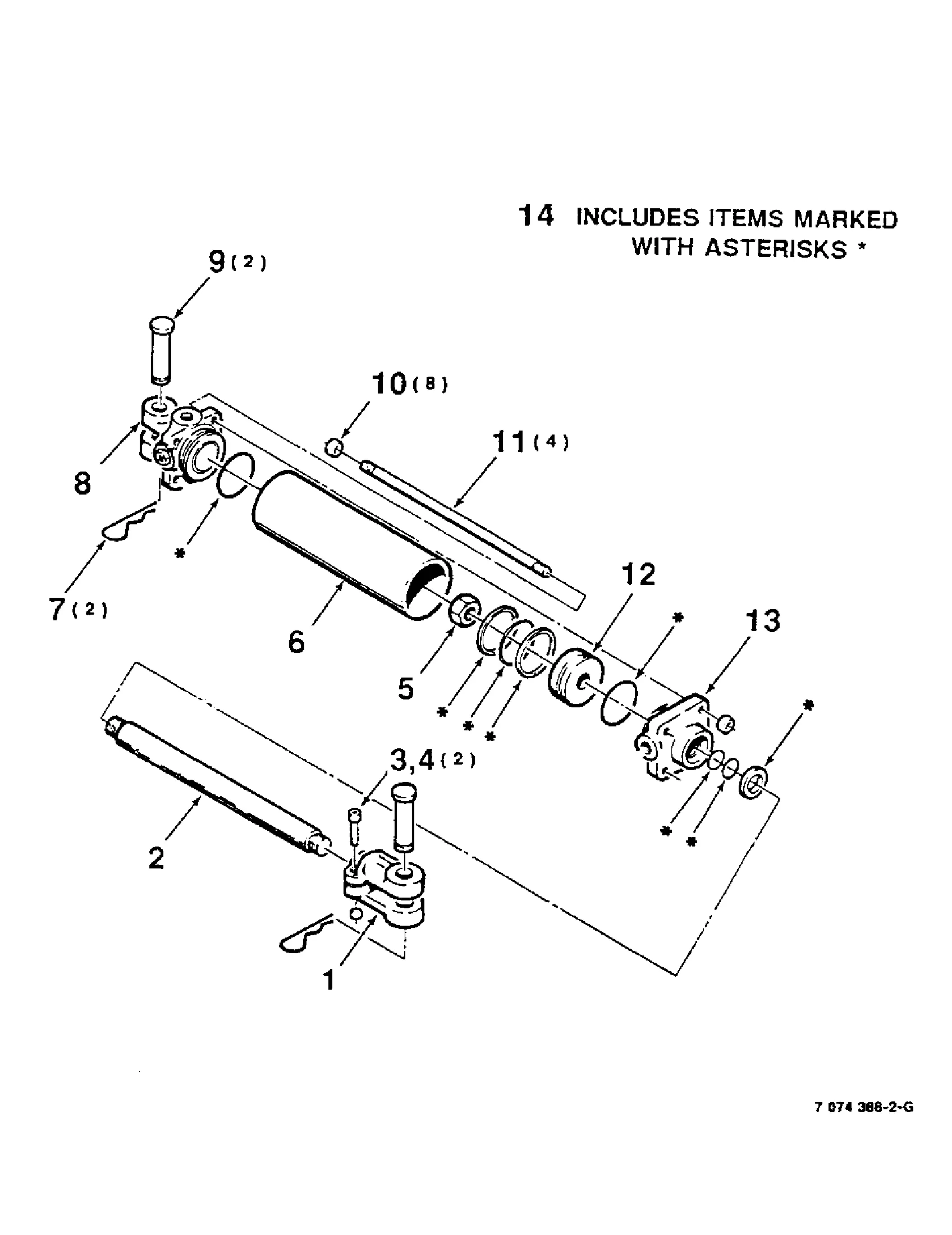

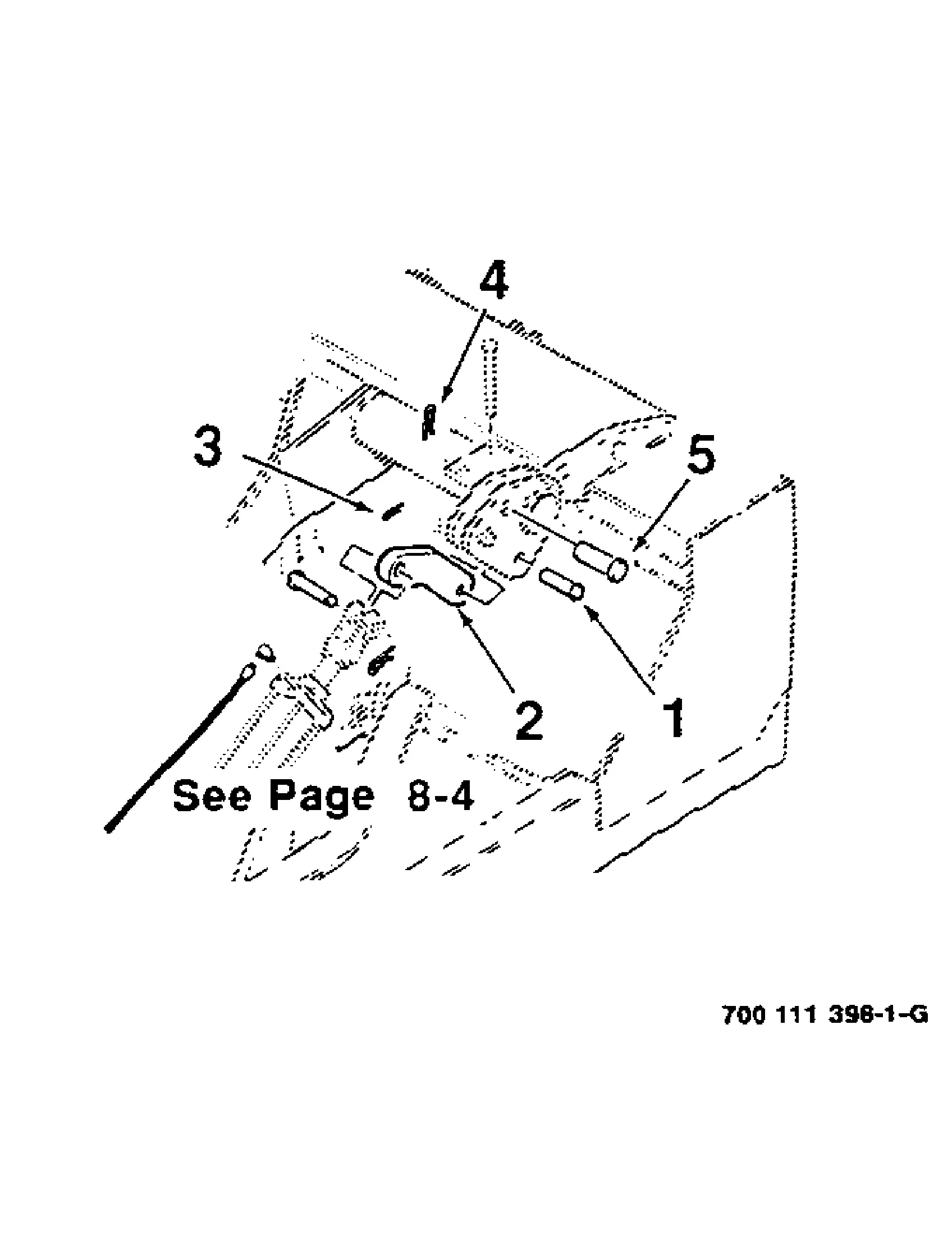

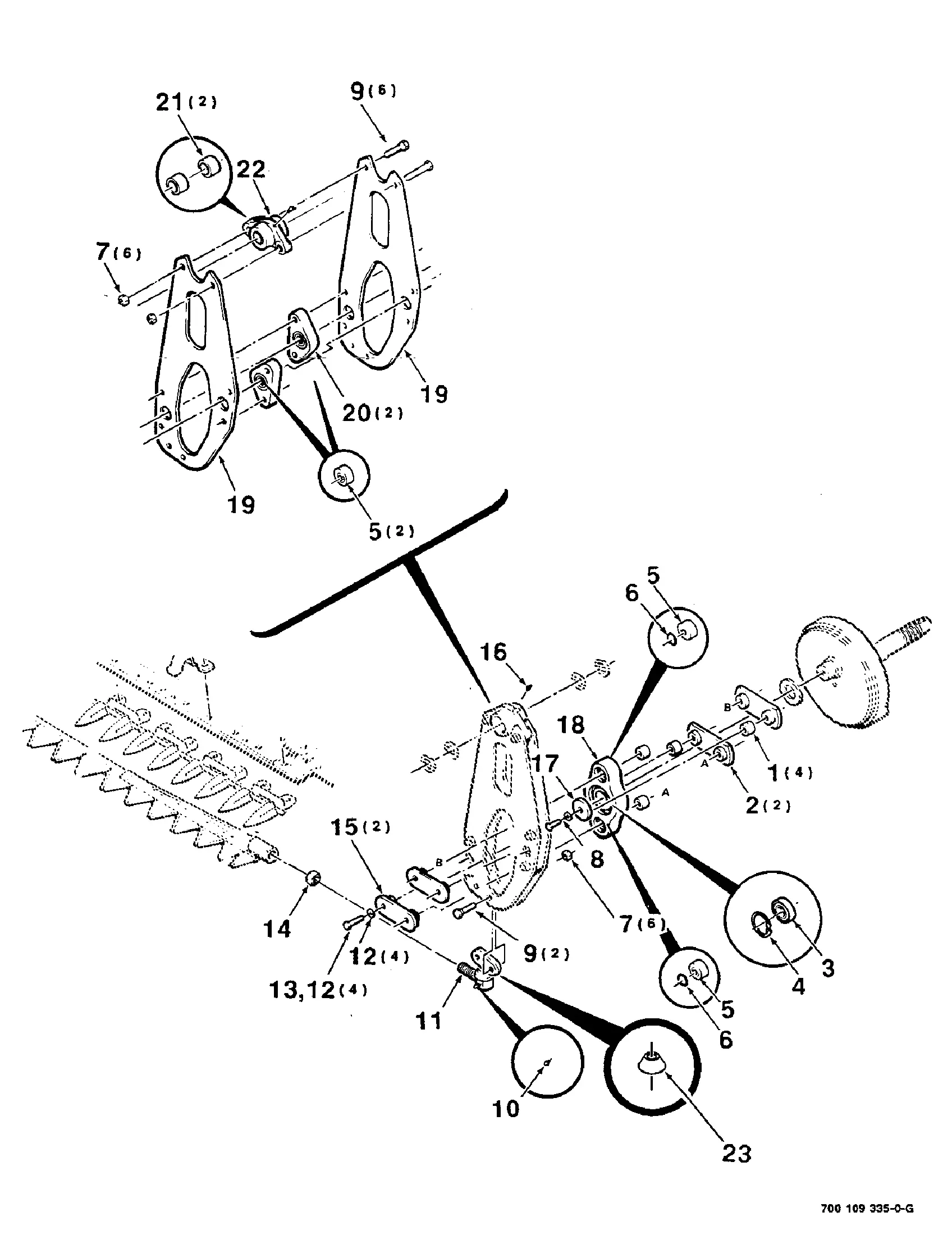

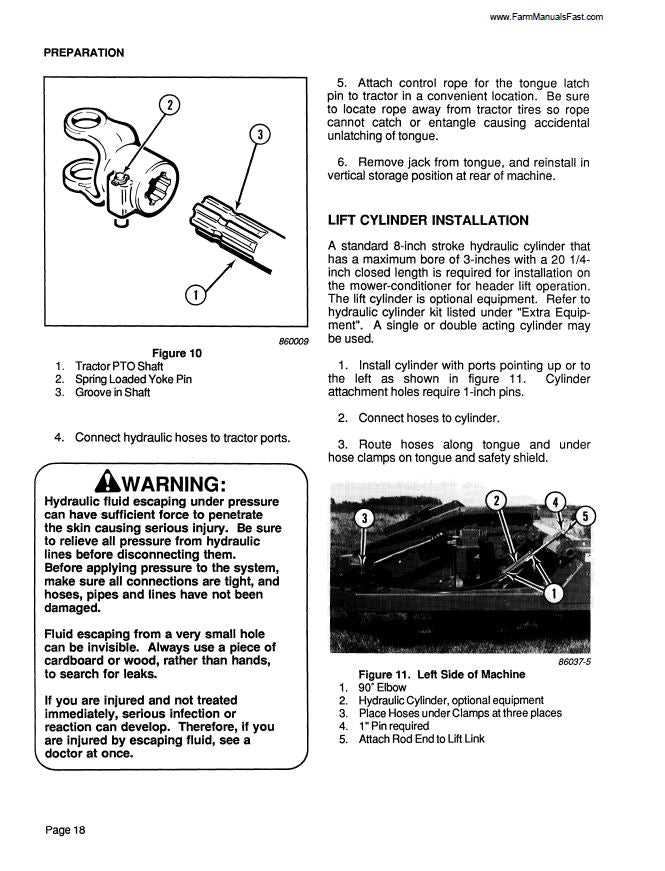

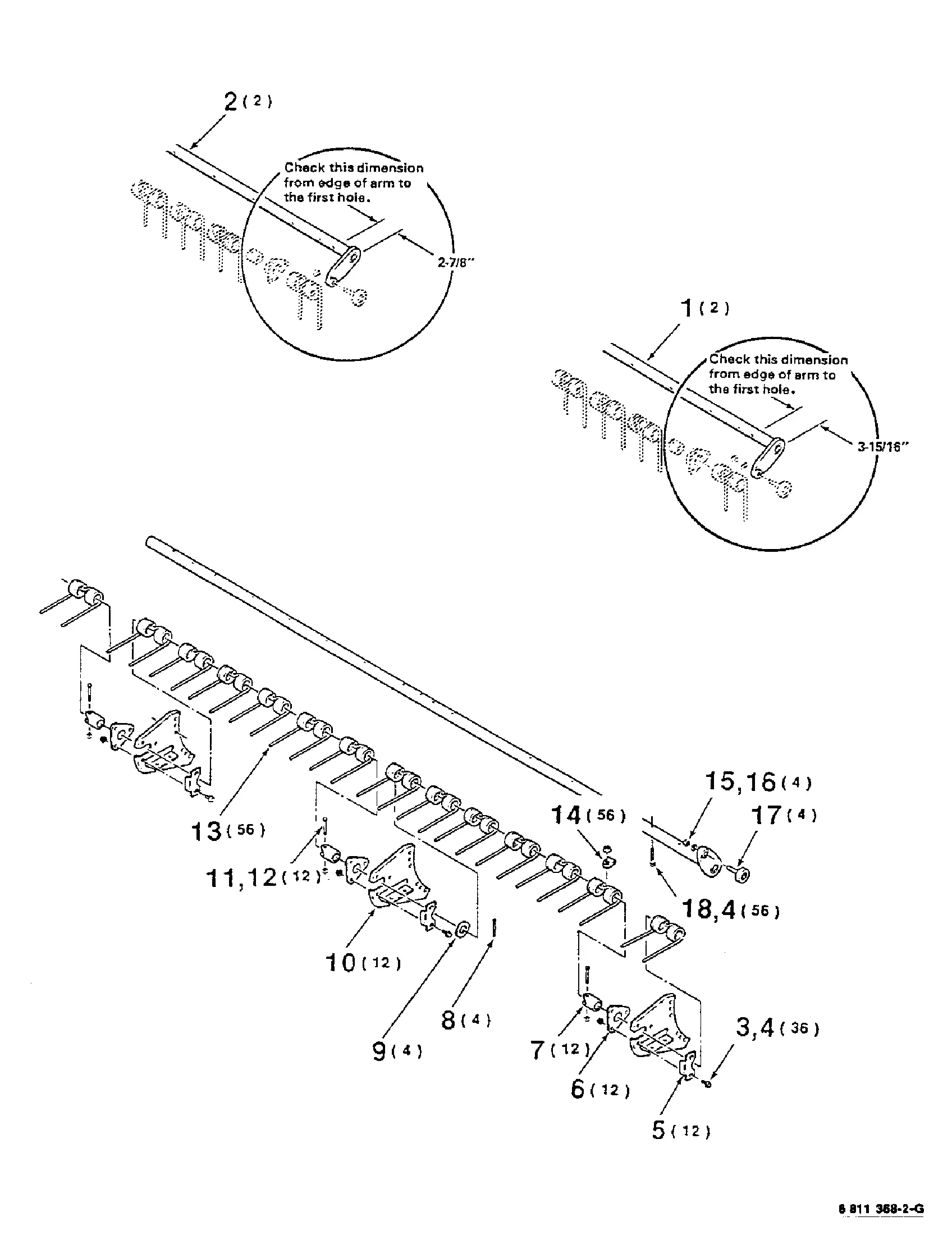

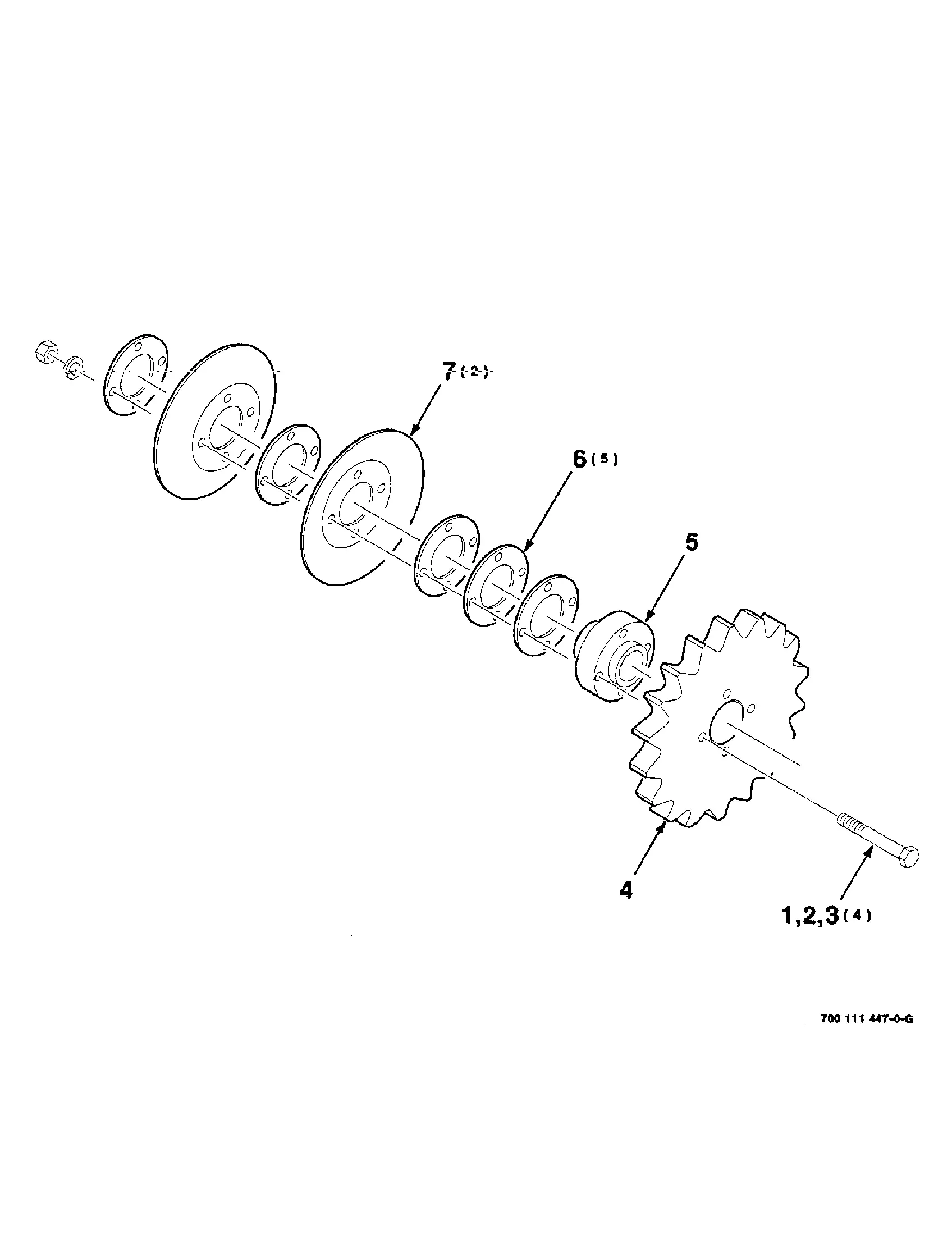

Interpreting Symbols and Annotations in the Diagram

Understanding the various icons and notes within a schematic is crucial for effective navigation and comprehension of the assembly. Each symbol conveys specific information, allowing users to identify components and their interconnections quickly. Familiarity with these representations enhances the ability to troubleshoot and maintain equipment efficiently.

Key elements to consider when analyzing the schematic include:

- Symbols: These represent different parts and functions. Each shape and line style corresponds to a particular element in the assembly.

- Annotations: Notes accompanying symbols provide vital details, such as specifications, ratings, or installation instructions.

- Connections: Lines between symbols indicate how components interact with each other, showing electrical paths or physical links.

To interpret the schematic accurately, it is beneficial to refer to the accompanying legend or key. This guide typically explains the meaning behind each symbol and annotation, serving as a reference point for users.

By familiarizing oneself with these representations, one can enhance understanding and improve the efficiency of maintenance and repair tasks.

Common Maintenance and Repair Insights Derived from the Diagram

Understanding the components and their interrelationships is crucial for effective upkeep and restoration of agricultural machinery. By examining a well-structured visual representation of the assembly, users can glean valuable information about routine care and potential troubleshooting techniques. This insight aids in maintaining optimal performance and longevity of the equipment.

Regular inspections and timely interventions can prevent more significant issues down the line. Familiarity with the key elements involved in machinery operation enables operators to identify wear and tear early, facilitating efficient repairs. Below is a summary of essential maintenance practices derived from a comprehensive breakdown of the equipment’s assembly.

| Maintenance Task | Recommended Frequency | Notes |

|---|---|---|

| Lubrication of moving parts | Every 50 hours of operation | Use appropriate grease for each component. |

| Inspection of belts and hoses | Every 100 hours of operation | Look for signs of wear or damage. |

| Oil change | Every 200 hours of operation | Use manufacturer-recommended oil. |

| Filter replacement | Every 200 hours of operation | Ensure filters are compatible with the system. |

| Battery check | Monthly | Clean terminals and check connections. |

By adhering to these practices and understanding the machinery’s layout, operators can enhance performance, reduce downtime, and ensure that all systems function harmoniously. Proper knowledge and maintenance foster a reliable and efficient operation, extending the life of the equipment significantly.

Exploring Advanced Features Illustrated in the Diagram

Understanding the intricate elements presented in the visual representation can greatly enhance the efficiency and functionality of agricultural machinery. This section delves into the sophisticated components and their roles, highlighting how they contribute to optimal performance and reliability in various operational contexts.

Key Components and Their Functions

The illustration showcases a variety of advanced mechanisms designed to improve productivity. Each element serves a specific purpose, from optimizing power delivery to enhancing user control. Familiarity with these components enables operators to make informed decisions about maintenance and upgrades, ultimately leading to better machinery management.

Integrating Features for Enhanced Performance

Incorporating cutting-edge functionalities allows for greater adaptability in diverse agricultural tasks. The representation provides insights into how these features work together seamlessly to tackle challenging environments. By leveraging this knowledge, users can maximize the capabilities of their equipment, ensuring consistent results across different applications.

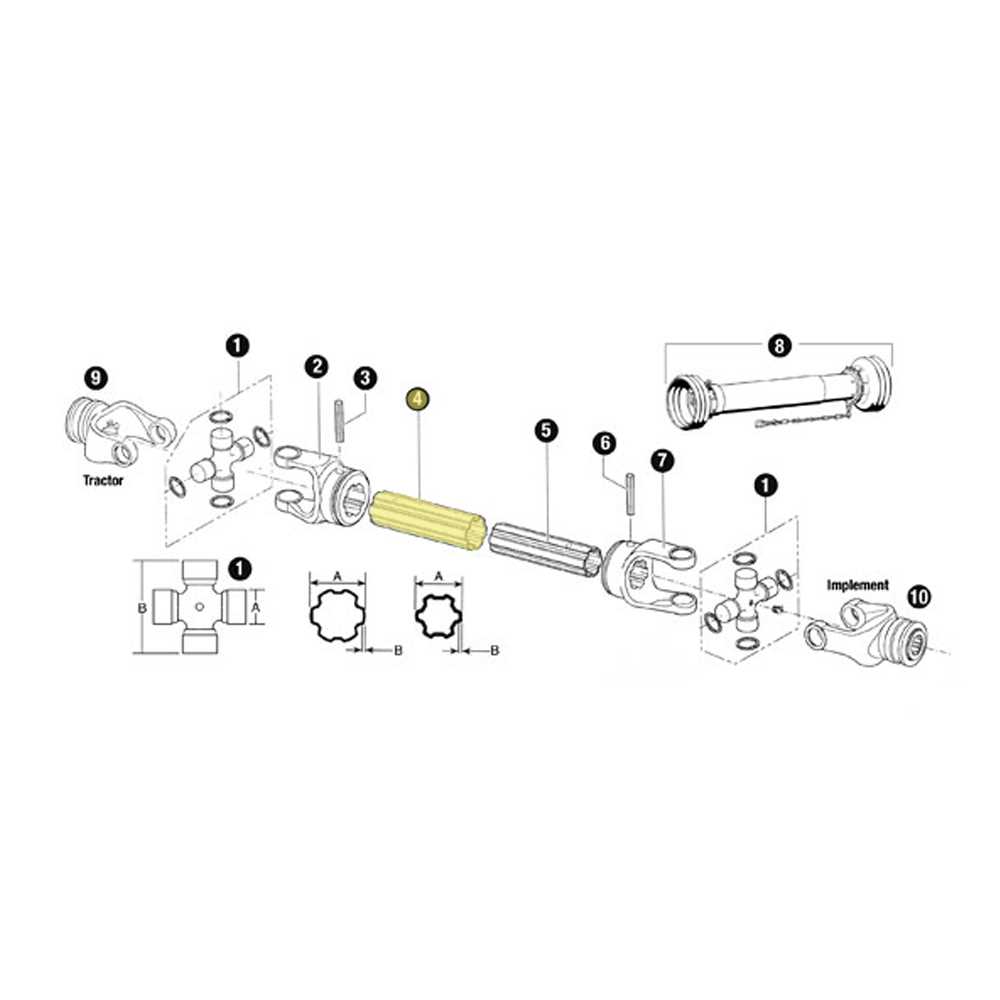

Comparative Analysis with Similar Agricultural Machinery Diagrams

Understanding the intricacies of various agricultural machinery can significantly enhance operational efficiency and maintenance strategies. By comparing the schematics of different models, operators can identify common components, functionality, and design variations that influence performance and durability. This analysis allows for informed decision-making when selecting equipment or sourcing replacement elements, ensuring compatibility and maximizing productivity.

Common Components Across Models

Many agricultural implements share similar features, including drive systems, hydraulic configurations, and control mechanisms. Recognizing these commonalities helps in predicting the compatibility of parts from different manufacturers. For instance, a thorough examination of the hydraulic layout can reveal how similar systems manage fluid dynamics and pressure, leading to improved troubleshooting methods and reduced downtime during repairs.

Design Variations and Their Impact

While certain models may boast similar functionalities, design differences can significantly affect their efficiency and ease of use. Analyzing the layout of components, such as engine placement or transmission types, highlights how these factors influence maintenance accessibility and overall machine handling. Such insights can guide operators in selecting machinery that aligns with their specific agricultural practices.

In summary, engaging in a comparative study of machinery schematics not only broadens the understanding of operational elements but also fosters a more strategic approach to equipment management in the agricultural sector.

Enhancing Efficiency Through Proper Utilization of the Diagram

Utilizing a detailed visual representation of components can significantly streamline operations and maintenance tasks. When individuals have a clear understanding of the various elements within a system, they can enhance their workflow and ensure that each piece is functioning optimally. This understanding is crucial for anyone looking to improve performance and longevity in their machinery.

By leveraging a comprehensive visual guide, users can quickly identify the necessary components for troubleshooting or upgrades. This knowledge reduces downtime and enhances productivity, allowing for more efficient use of resources. Furthermore, a clear overview enables better planning and execution of maintenance schedules, ultimately leading to a more reliable operation.

| Component | Description | Maintenance Tips |

|---|---|---|

| Element A | Provides essential support for system operations. | Regularly inspect for wear and tear. |

| Element B | Critical for ensuring efficient performance. | Keep clean and lubricated to prevent friction. |

| Element C | Helps in maintaining operational stability. | Check connections periodically to ensure reliability. |

Visualizing Integration of Technology in Modern Agricultural Equipment

The evolution of farming implements has significantly transformed the landscape of agriculture. Today, innovative technologies enhance operational efficiency, optimize productivity, and ensure sustainable practices. This integration of advanced tools and systems allows farmers to make informed decisions, resulting in improved crop yields and reduced resource consumption.

Key Technologies Shaping Modern Equipment

- Precision Agriculture: Employing GPS and sensors to monitor and manage field variability.

- Automation: Utilizing robotics and automated systems for tasks such as planting and harvesting.

- Data Analytics: Leveraging big data to analyze soil health, weather patterns, and crop performance.

- Remote Monitoring: Enabling farmers to track equipment performance and field conditions from afar.

Benefits of Technological Integration

- Enhanced Efficiency: Streamlined operations lead to time and cost savings.

- Improved Sustainability: Reduced environmental impact through optimized resource use.

- Better Decision-Making: Access to real-time data enables informed choices.

- Increased Profitability: Higher yields and lower operational costs contribute to financial success.

As the agricultural sector continues to evolve, the integration of technology into farming equipment remains a crucial aspect of modern practices. Embracing these advancements ensures that farmers can meet the challenges of today’s market while fostering a more sustainable future.

Utilizing the Diagram for Diagnostic and Troubleshooting Purposes

Employing visual aids during maintenance and repair tasks can significantly enhance efficiency and accuracy. These illustrations serve as invaluable resources, providing a clear representation of component arrangements and functions. By leveraging such tools, technicians can quickly identify potential issues and streamline the troubleshooting process.

When faced with a malfunction, having a comprehensive reference at hand allows for a methodical approach to diagnostics. By closely examining the visual layout, one can trace connections, locate essential elements, and verify their condition. This practice not only saves time but also reduces the likelihood of oversight, ensuring that no critical aspects are missed during the assessment.

Furthermore, utilizing these illustrations fosters a deeper understanding of the system’s mechanics. Technicians can become familiar with how various components interact, leading to improved problem-solving skills. This knowledge empowers them to diagnose issues more effectively and implement repairs with confidence, ultimately enhancing the longevity and performance of the machinery.

In summary, visual references are indispensable in the realm of equipment maintenance. Their ability to facilitate diagnostics and enhance troubleshooting capabilities makes them essential for anyone involved in the upkeep of complex systems.

Community Insights and User Experiences with the Case IH 8330

The shared knowledge and experiences of users play a crucial role in enhancing understanding and effective use of agricultural machinery. Enthusiasts and operators often exchange valuable insights that help in troubleshooting, maintenance, and optimizing performance. This section highlights key observations and stories from those who regularly work with this specific model, showcasing the benefits and challenges they have encountered.

User Feedback on Performance

Many operators appreciate the reliability and efficiency of this machine in various agricultural tasks. Users have noted its strong engine performance, which contributes to increased productivity during long working hours. Feedback often emphasizes the ease of handling, making it suitable for both seasoned professionals and those new to operating heavy machinery.

Common Maintenance Tips

Regular maintenance is essential for maximizing the lifespan of any piece of equipment. Users recommend adhering to a consistent service schedule, including regular inspections of key components. Sharing tips on routine checks, such as fluid levels and filter replacements, has proven beneficial. Additionally, operators often suggest forming local groups to discuss best practices and share solutions to common issues faced during operation.

Future Trends and Innovations Shaping Agricultural Machinery Diagrams

The landscape of agricultural equipment is rapidly evolving, influenced by technological advancements and shifting industry needs. As manufacturers strive to enhance efficiency and productivity, the visualization of machinery layouts and functions has become increasingly important. Innovations in this area are poised to revolutionize how users interact with their equipment, making operations smoother and more intuitive.

Integration of Smart Technologies

One of the most significant trends in the field is the integration of smart technologies into agricultural machinery layouts. IoT devices and sensors are being employed to collect real-time data, providing users with insights into equipment performance and maintenance needs. This shift towards a more interconnected system enables better decision-making, ultimately leading to increased efficiency and reduced downtime.

Enhanced User Interfaces

The development of user-friendly interfaces is also transforming the way operators engage with their equipment. Modern visualization tools, combined with augmented and virtual reality, allow users to explore machinery designs in a more immersive manner. These advancements not only simplify complex layouts but also facilitate training and troubleshooting, ensuring that operators can maximize their productivity.