When diving into the mechanics of a vehicle’s drive train, it’s essential to focus on the mechanisms that ensure smooth power distribution. These elements are crucial for handling torque and controlling movement, playing a vital role in the overall performance of the automobile. Whether you’re working on maintenance or learning about the assembly, understanding these components will help ensure efficiency and longevity.

Many drivers might not realize how interconnected these mechanical systems are, but their seamless operation is what guarantees stability on different terrains. Proper upkeep of these systems can prevent common issues and improve the handling and reliability of your vehicle. By familiarizing yourself with their structure and functionality, you’ll be better equipped to manage any necessary repairs or adjustments.

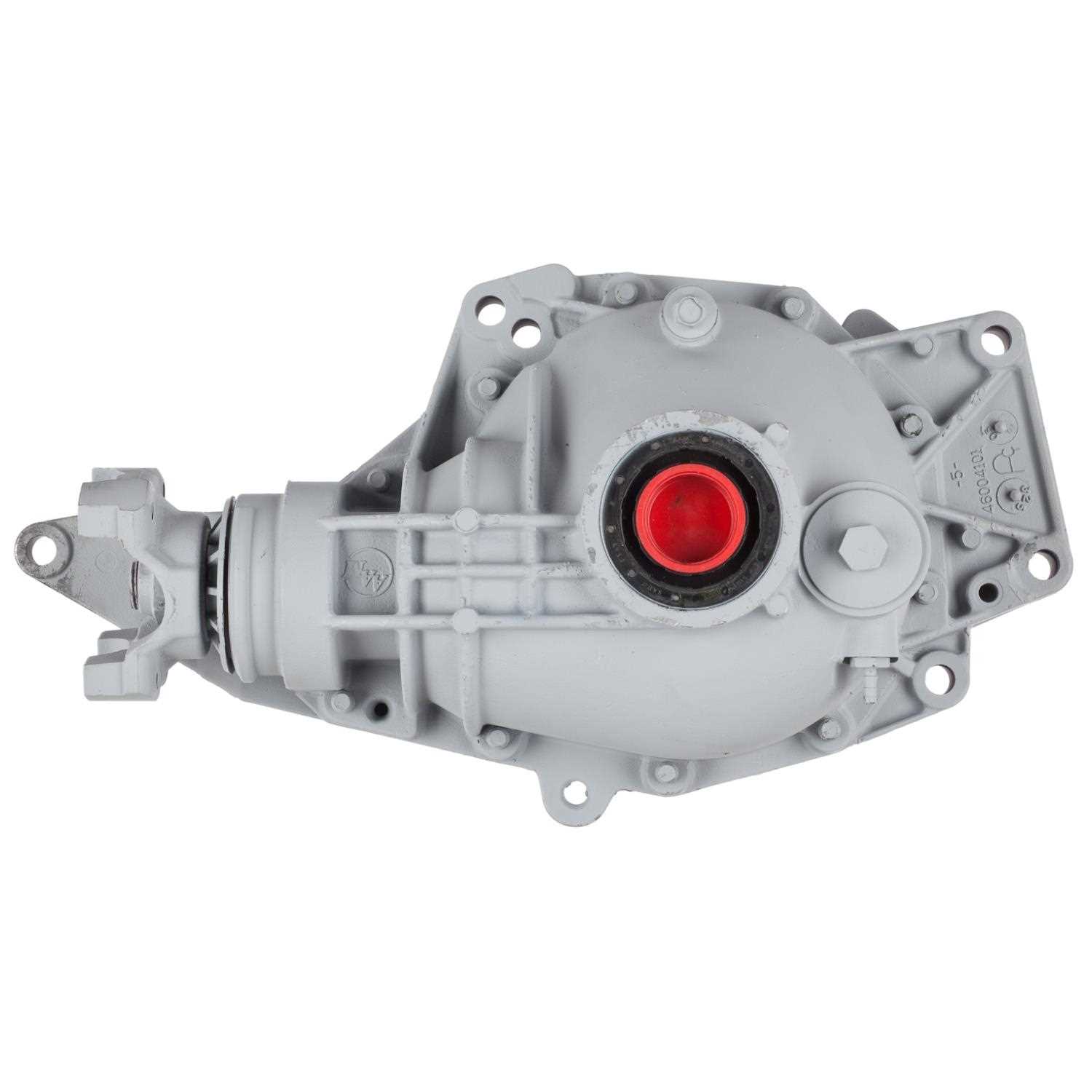

Understanding the Chevy Front Differential

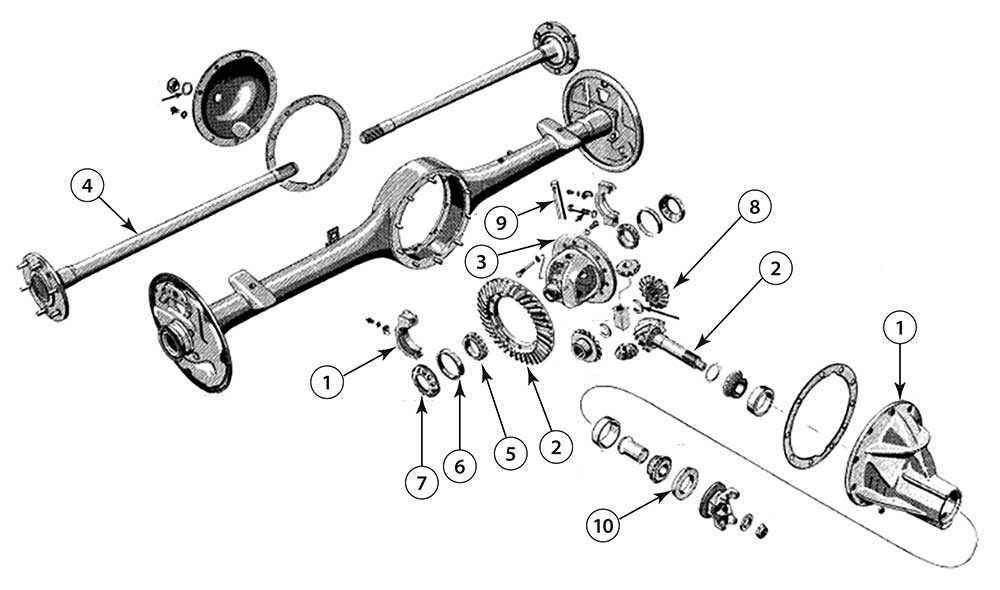

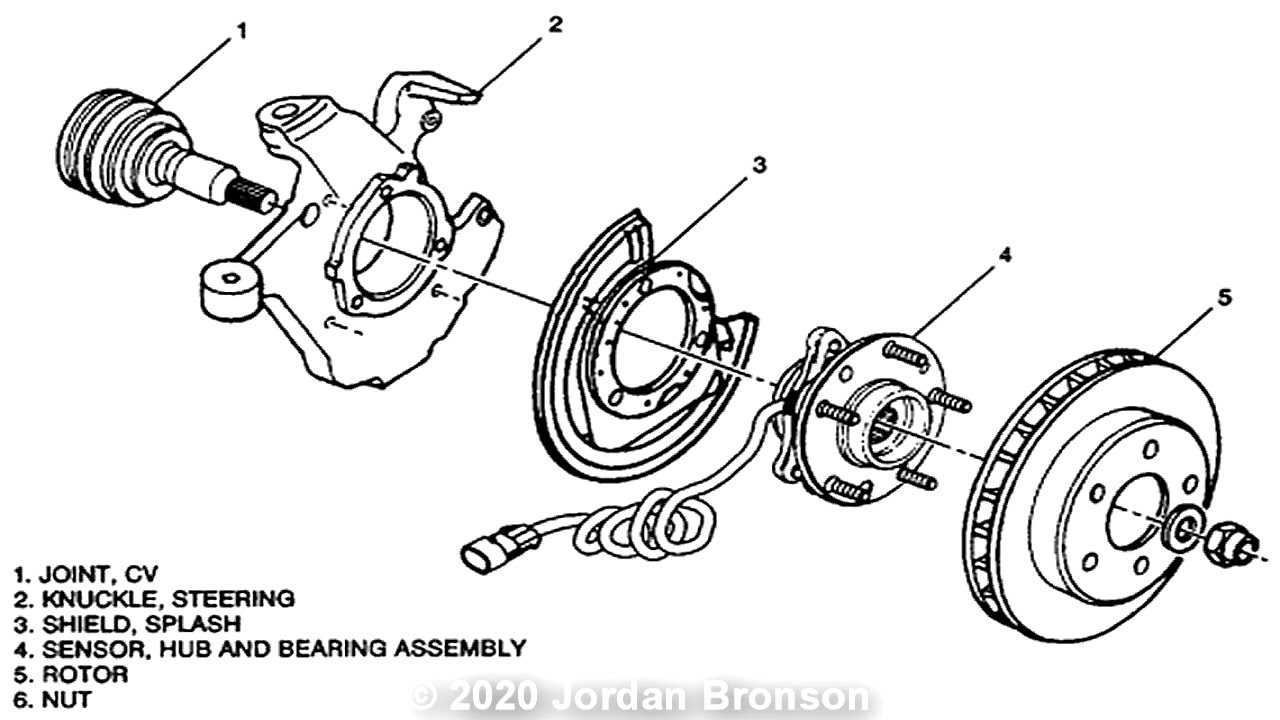

When examining the vehicle’s drive system, it’s important to focus on the complex component responsible for managing power distribution between wheels. This mechanism plays a crucial role in ensuring smooth handling and stability, especially during turns and uneven terrain. By controlling the rotation speed of individual wheels, it helps maintain grip and prevents slippage, particularly in off-road or challenging driving conditions.

The inner workings of this element include gears, shafts, and other moving parts, all designed to function together in harmony. Proper maintenance and timely inspections are key to avoiding potential damage. Ensuring the system is well-lubricated and free from wear is essential for long-term performance and safety on the road.

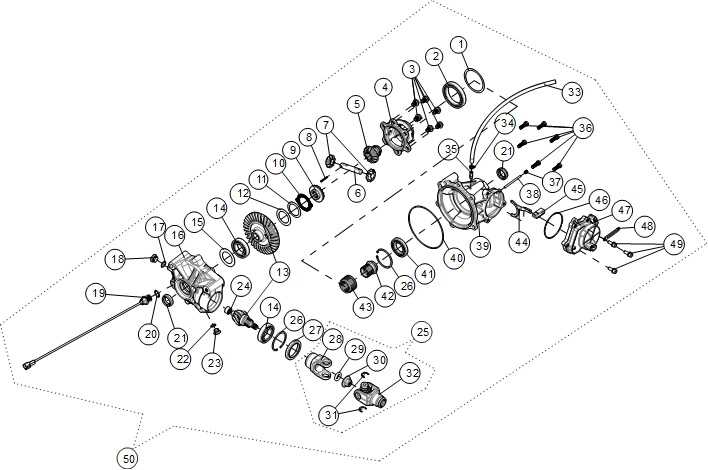

Components of the Chevy Differential System

The assembly that distributes power from the engine to the wheels plays a critical role in a vehicle’s overall performance. It ensures smooth handling and stability during turns by allowing the wheels to rotate at different speeds. This sophisticated network of gears, shafts, and bearings works in harmony to transfer energy efficiently while maintaining balance.

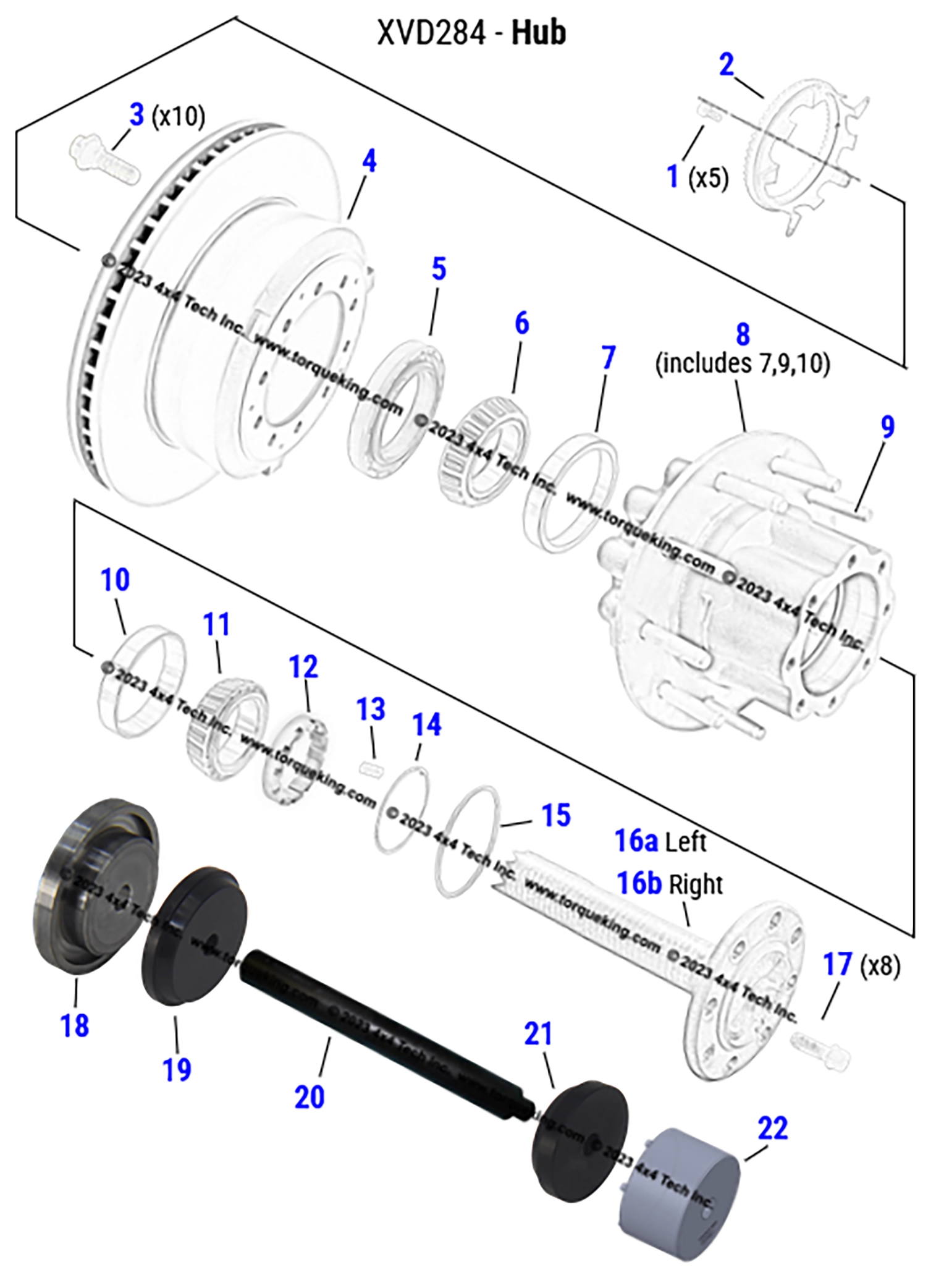

Core mechanisms include several key elements that operate together to provide controlled movement. At the center of this system is a set of gears that regulate speed and torque distribution. These gears are supported by axles, which transfer the motion to the wheels. The assembly also relies on bearings to reduce friction and ensure that the rotating parts work smoothly under load.

Another important part of the structure involves the casing, which holds all these components securely in place, protecting them from external elements and damage. This protective shell

How the Front Axle Works

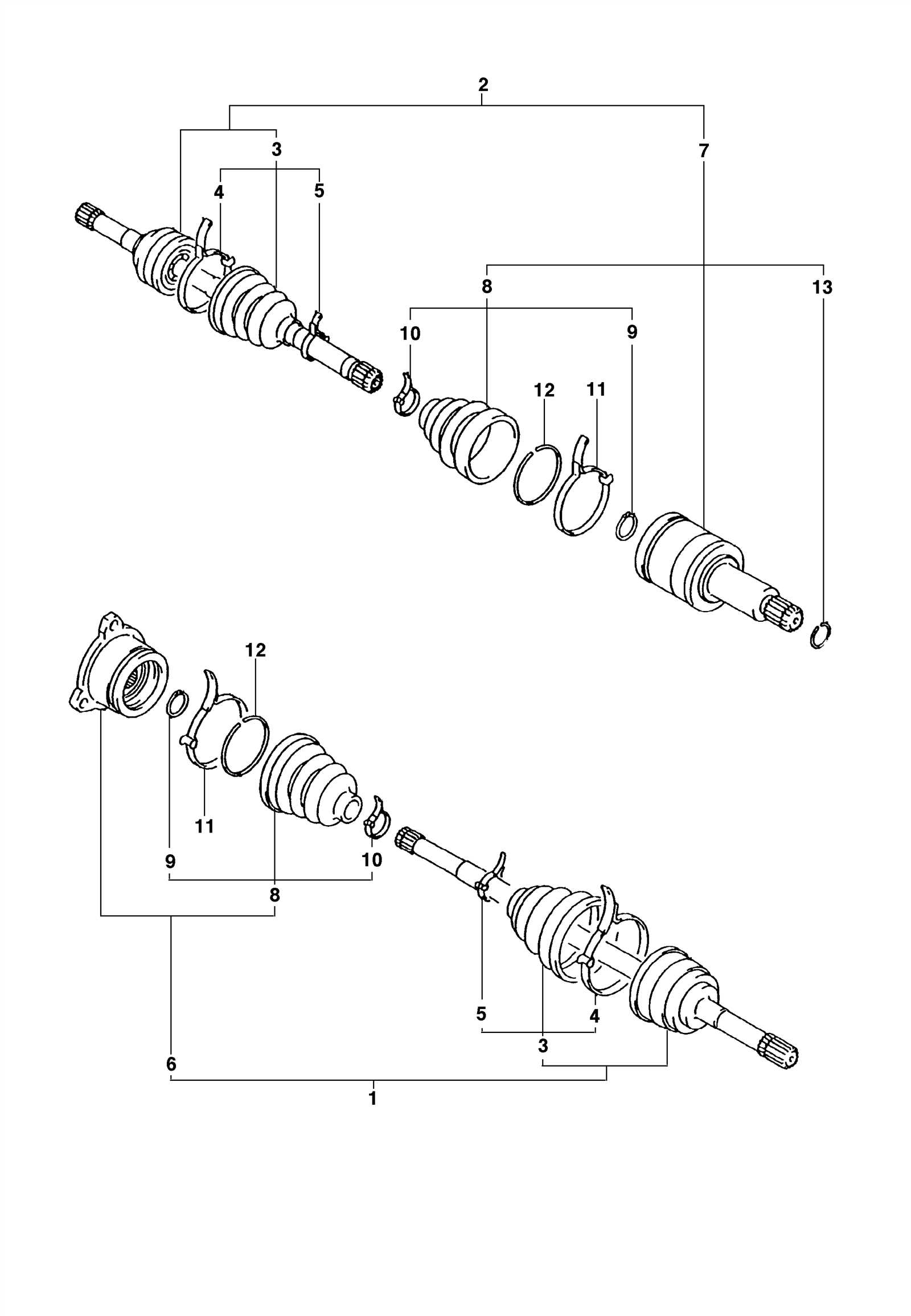

The primary function of the axle system is to transfer torque from the engine to the wheels, enabling movement while maintaining stability and control. It plays a crucial role in navigating uneven terrains, ensuring that power is distributed efficiently for smooth driving performance.

The axle assembly is designed to connect the wheels to the powertrain, managing the load of the vehicle and allowing the wheels to rotate independently during turns. This ensures that both tires can adapt to different road conditions without causing strain on the vehicle’s suspension.

- The axle supports the vehicle’s weight and distributes it evenly between the wheels.

- It works in conjunction with various components to manage steering and handling, especially in challenging driving situations.

- By adjusting to the terrain, the axle system provides improved traction and control, enhancing the driving experience.

In summary, the axle is integral to the vehicle’s movement and performance, allowing efficient power transfer while supporting the overall structure and ensuring reliable operation during turns

Importance of the Differential Gear Setup

Proper assembly of the gear mechanism plays a crucial role in ensuring smooth and efficient power transmission to the wheels. The alignment of the gears within this system is essential for optimal performance, enabling a vehicle to handle different driving conditions without excessive strain or wear.

Key Elements of Gear Arrangement

When configuring the gear system, attention to spacing and interaction between components is vital. Incorrect setup can lead to noise, reduced efficiency, and even premature failure. By maintaining correct gear contact patterns, the power distribution remains balanced, which minimizes the risk of damage and improves longevity.

Advantages of a Well-Adjusted Mechanism

An accurately tuned gear assembly ensures better traction, improved control, and greater overall stability. This precision allows for enhanced maneuverability, particularly in situations where one wheel requires more torque than the other. Proper maintenance of the system also

Examining the Differential Bearing Functions

The smooth operation of a vehicle’s mechanical system depends largely on the performance of key internal components, one of which plays a critical role in managing rotational forces and ensuring stability during movement. These components are designed to minimize friction, allowing the system to handle varying loads efficiently while maintaining durability.

To further explore the functions and interaction of these elements, the following table outlines essential points regarding their operation and maintenance considerations:

| Function | Description | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load Support | Helps in distributing the weight of the rotational parts, preventing excessive strain on individual elements. | ||||||||||||||||||||||

| Friction Reduction | Reduces resistance between moving surfaces, allowing smoother rotation and extended component lifespan

Role of the Differential Pinion AssemblyThe pinion assembly plays a crucial role in the functionality of a vehicle’s drivetrain. It serves as a vital component that aids in the smooth transmission of power from the engine to the wheels. This mechanism allows for the necessary adjustments in torque and speed, ensuring optimal performance during various driving conditions. Understanding the assembly’s function involves recognizing its contribution to maintaining balance within the drivetrain. By allowing for differences in wheel speed during turns, it minimizes tire wear and enhances maneuverability. The design of the pinion assembly facilitates effective torque distribution, which is essential for maintaining stability and traction. Regular maintenance of this assembly is important to prevent excessive wear and tear. Neglecting its upkeep can lead to performance issues, such as unusual noises or difficulty in handling. By ensuring that the pinion assembly operates smoothly, vehicle owners can enhance the overall longevity and reliability of their automotive systems. Exploring the Purpose of the Axle Shaft

The axle shaft plays a crucial role in the overall functionality of a vehicle’s drivetrain. It serves as a vital link between the power generated by the engine and the wheels, enabling motion and stability. Understanding its significance can shed light on how vehicles operate smoothly and efficiently. Key Functions of the Axle Shaft

Common Issues Associated with Axle Shafts

Common Issues with Chevy DifferentialsUnderstanding the typical problems that can arise with these crucial components is essential for maintaining optimal vehicle performance. These assemblies are vital for ensuring smooth power transfer to the wheels, and when they experience issues, it can lead to a range of complications that affect drivability and safety. Noise and VibrationUnusual sounds and vibrations are often the first indicators of trouble. Drivers may notice grinding, whining, or clunking noises while turning or accelerating. Such symptoms can indicate worn bearings, damaged gears, or insufficient lubrication, all of which require immediate attention to prevent further damage. Fluid LeaksLeaks are another common problem, often caused by worn seals or gaskets. These leaks can lead to a loss of lubricant, resulting in overheating and potential failure of the entire assembly. Regular inspections are crucial to catch any leaks early and maintain adequate fluid levels.

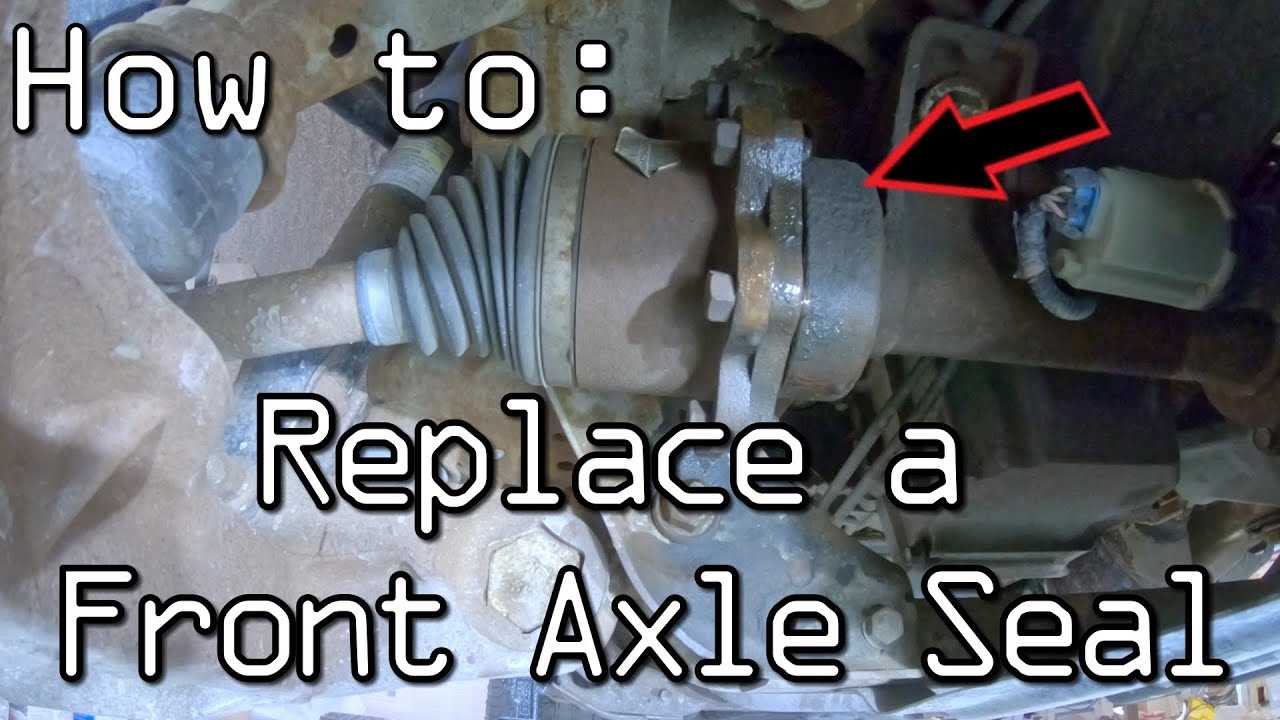

Chevy Differential Seal Maintenance

Proper upkeep of seals is essential for ensuring the longevity and efficiency of your vehicle’s drive system. These components serve as vital barriers that prevent fluid leaks and protect internal mechanisms from dirt and debris. Regular attention to their condition can help avoid costly repairs and enhance overall performance. Regular inspection of seals should be part of your routine maintenance. Look for signs of wear, such as cracks or deformation, and replace any damaged seals promptly. Additionally, ensure that the sealing surfaces are clean and free from contaminants before installing new components. This attention to detail will help maintain a secure fit and optimal function. During replacement, it’s crucial to use high-quality materials that are compatible with your vehicle’s specifications. Proper installation techniques are also important; avoid over-tightening, which can lead to premature failure. Following these best practices will enhance the durability of seals and contribute to the smooth operation of your vehicle. Signs of Differential Wear and Damage

Understanding the indicators of deterioration and harm in a vehicle’s drive system is essential for maintaining optimal performance. Over time, components can experience wear due to various factors, leading to noticeable symptoms that can affect the overall functionality. Recognizing these signs early can prevent further damage and ensure safe operation. Common IndicatorsDrivers may notice several telltale signs that suggest a problem within the system. Unusual noises, such as grinding or clunking, often signal that parts are failing or misaligned. Additionally, difficulties in handling and decreased responsiveness can also indicate underlying issues. Visual Inspection and Monitoring

Regular visual checks can reveal issues like fluid leaks or signs of corrosion, which are detrimental to the longevity of the components. It’s vital to monitor fluid levels and condition, as dark or gritty fluid can suggest contamination and wear.

Tips for Replacing Front Differential PartsWhen it comes to the replacement of essential components in your vehicle’s drivetrain, proper techniques and precautions are crucial for a successful outcome. Understanding the intricacies involved can lead to improved performance and longevity of your vehicle. Here are some valuable insights to help you navigate this process effectively. Preparation is KeyBefore beginning the replacement process, gather all necessary tools and components. Ensure you have a clean workspace to facilitate the repair. Double-check the compatibility of the new components with your vehicle model to avoid any mismatches. Taking the time to organize your workspace can save you headaches later on. Follow a Systematic ApproachIt is essential to work methodically when disassembling and reassembling components. Start by documenting the original setup with photographs to serve as a reference during reinstallation. Labeling each component and its respective location can significantly streamline the process. Finally, ensure all connections are secure and that you conduct a thorough inspection before taking your vehicle for a test drive. |