Exploring the intricacies of machinery reveals a wealth of information about how individual elements interact within a larger system. This knowledge is crucial for enthusiasts and professionals alike, allowing them to effectively maintain and repair various tools and equipment.

By examining detailed visual representations, one can gain insight into the specific roles of each component, fostering a deeper appreciation for engineering design. This exploration not only aids in troubleshooting but also enhances the user’s ability to make informed decisions regarding maintenance and upgrades.

In this section, we will delve into the essential features of a comprehensive assembly chart, focusing on the ultimate goal of optimizing functionality and longevity of your equipment. Understanding these layouts is key to unlocking the full potential of your tools.

Understanding Craftsman 944.36 Design

This section explores the intricate structure and thoughtful engineering behind a specific model in the tools domain. By examining its components and overall functionality, we can appreciate the design philosophy that prioritizes efficiency and usability. Each element is meticulously crafted to enhance performance and user experience.

Key Features: The innovative aspects of this creation include ergonomic design and durable materials, which contribute to its reliability. Analyzing these features helps us understand how they interact to facilitate seamless operation.

Importance of Design: A well-considered layout not only influences performance but also affects maintenance and repair. Understanding these elements is crucial for users aiming to maximize longevity and functionality in their toolkit.

Key Components of Craftsman 944.36

Understanding the fundamental elements of any machinery is essential for optimal performance and longevity. This section explores the crucial parts that contribute to the overall functionality of the equipment, providing insights into their roles and significance in ensuring efficient operation.

Essential Elements

Each component plays a vital role in the seamless interaction of the entire system. Below is a table highlighting some of the primary elements along with their functions:

| Component | Function |

|---|---|

| Motor | Provides the necessary power for operation. |

| Gearbox | Transmits torque and adjusts speed for efficiency. |

| Blade | Facilitates cutting and shaping materials effectively. |

| Chassis | Supports and houses various components securely. |

Maintenance Considerations

Regular inspection and upkeep of these key components are critical to maintaining high performance. By ensuring each part remains in optimal condition, users can achieve the ultimate efficiency and reliability from the machinery.

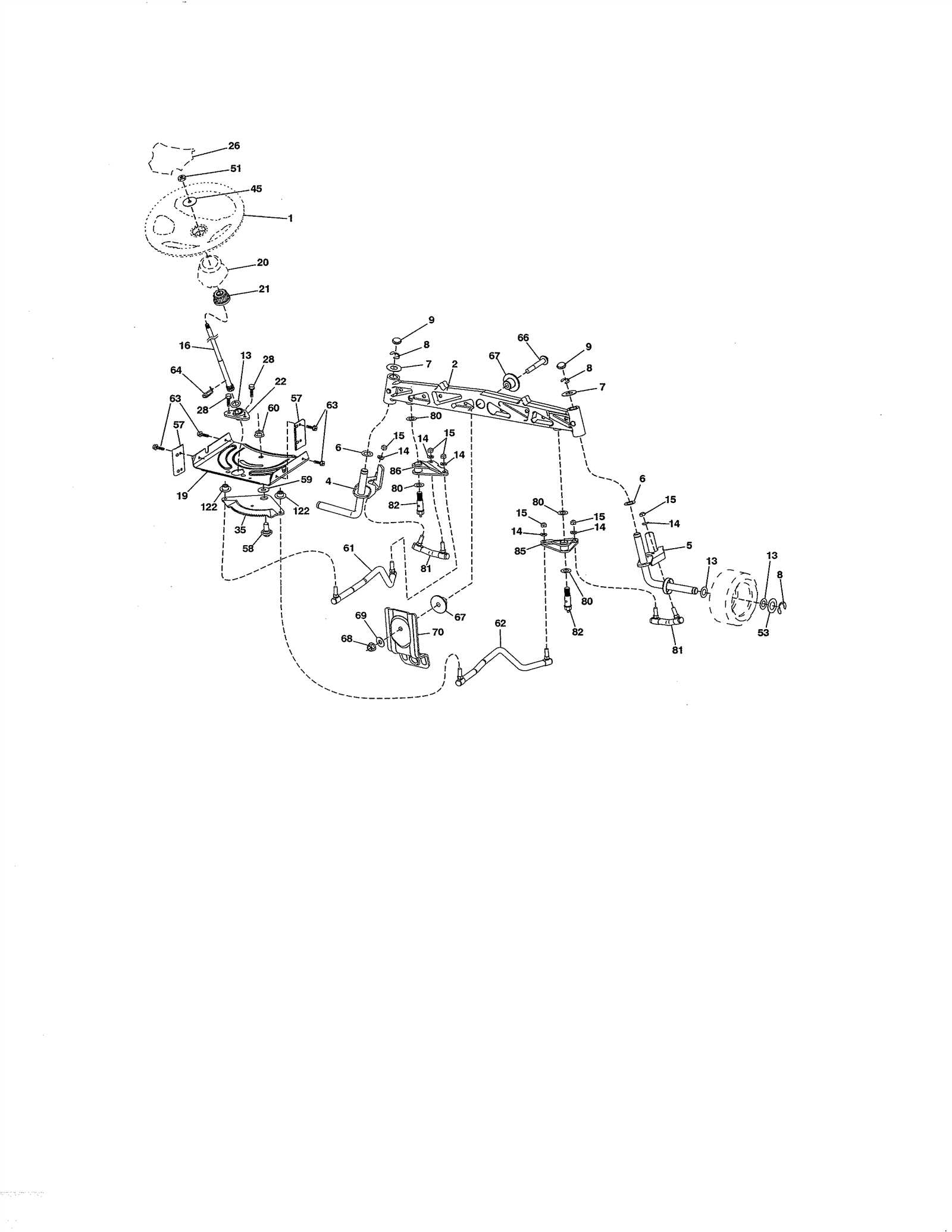

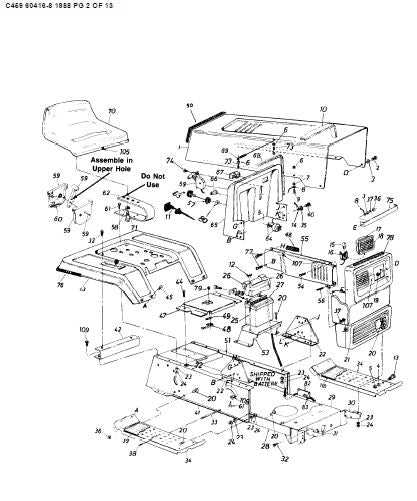

Importance of Parts Diagrams

Understanding the components of any machinery is essential for effective maintenance and repair. Visual representations serve as crucial tools, helping users identify and manage each element systematically. These illustrations not only enhance comprehension but also streamline the process of troubleshooting and restoring functionality.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear view of each element’s placement and function. |

| Efficiency | Speeds up repair processes by offering quick reference points. |

| Accuracy | Reduces errors during assembly and disassembly. |

| Planning | Assists in organizing necessary tools and replacement items. |

Common Issues with Craftsman Equipment

Users often encounter several recurring challenges when operating power tools and machinery. Understanding these common issues can help in troubleshooting and maintaining optimal performance.

1. Overheating is a prevalent concern, especially during extended use. This can lead to reduced efficiency and, in some cases, permanent damage if not addressed promptly. Regular maintenance and ensuring proper ventilation are essential to prevent this issue.

2. Difficulty starting is another frequent problem that can stem from various sources, including fuel issues or battery failure. Users should regularly check fuel levels and battery condition to avoid frustration during use.

3. Poor performance can manifest in various ways, such as reduced power or inconsistent operation. Often, this can be traced back to clogged filters or worn-out components. Routine inspections and replacements can help restore functionality.

4. Excessive vibration may indicate underlying mechanical issues or imbalance. This not only affects precision but can also lead to operator fatigue. Ensuring all parts are secure and balanced can alleviate this problem.

5. Leaks are another issue that can arise, particularly in gas-powered models. Regular checks for signs of leakage and maintaining seals can prevent more significant repairs in the future.

By being aware of these potential issues, users can enhance their experience and prolong the lifespan of their equipment.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for efficient repair and maintenance. These visual representations provide a detailed view of components, their arrangement, and how they interact. Familiarity with these visuals can greatly enhance your troubleshooting skills and make the process more straightforward.

Key Elements to Identify

- Labels: Often, each part will have a corresponding identifier that helps in locating it within the overall system.

- Connections: Pay attention to lines indicating how parts connect or relate to one another.

- Legend: Some illustrations include a legend to explain symbols and terminology used.

Steps to Analyze

- Start by locating the main component you are interested in.

- Follow the lines to see how it connects to adjacent elements.

- Use the labels to cross-reference with a list for further details.

Maintenance Tips for Longevity

Ensuring the durability of your tools requires regular attention and care. Implementing effective maintenance practices can significantly extend their lifespan and enhance performance.

- Regular Cleaning: Remove dust and debris after each use to prevent buildup.

- Proper Lubrication: Apply suitable lubricants to moving parts to minimize friction.

- Inspect Components: Frequently check for wear and tear, replacing parts as necessary.

- Storage Conditions: Store in a dry, cool place to avoid rust and corrosion.

By following these simple yet crucial steps, you can delve into the art of maintaining your equipment for ultimate longevity.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its efficiency and longevity. Several resources offer a variety of options, making it easier for you to restore functionality and ensure optimal performance.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often provide comprehensive catalogs and direct purchasing options for original components. |

| Authorized Dealers | Local retailers or online sellers affiliated with the brand can offer genuine products and expert advice. |

| Online Marketplaces | Platforms like eBay or Amazon may have a wide selection of new and used items at various price points. |

| Local Repair Shops | These establishments might stock essential pieces and can also assist with installation and maintenance. |

Tools Needed for Repairs

When it comes to undertaking repairs, having the right instruments is essential for achieving successful outcomes. The appropriate equipment not only facilitates the process but also ensures that tasks are completed efficiently and safely. Understanding which tools to gather beforehand can save time and prevent frustration during the repair process.

Basic Hand Tools: A sturdy set of hand tools is fundamental. This includes items like wrenches, screwdrivers, and pliers, which are versatile enough to tackle a variety of tasks. Ensure that these tools are well-maintained to provide optimal performance.

Power Tools: For larger or more complex jobs, power tools can significantly increase efficiency. Drills, saws, and sanders are examples of electric equipment that can help streamline the repair process, allowing for quicker results.

Measuring Instruments: Accurate measurements are crucial for any repair. Having reliable measuring tapes, levels, and calipers will help ensure that components fit correctly, minimizing the likelihood of errors.

Safety Gear: Protecting oneself during repairs is non-negotiable. Safety goggles, gloves, and ear protection should always be part of the toolkit, as they safeguard against potential hazards encountered during work.

Specialized Tools: Depending on the specific repair needs, additional specialized tools may be necessary. These can range from particular types of saws to unique fasteners that are tailored for specific applications.

Having these tools on hand not only prepares one for immediate repair tasks but also contributes to a more organized and efficient workspace, ultimately leading to better results.

Identifying Faulty Parts Quickly

Recognizing defective components in machinery is essential for maintaining optimal performance and prolonging lifespan. Swift identification can save time and resources, allowing for prompt repairs and minimal downtime.

Common Signs of Malfunction

- Unusual Noises: Listen for any grinding, squeaking, or rattling sounds that indicate potential issues.

- Inconsistent Performance: Notice if the equipment operates erratically or fails to perform tasks effectively.

- Visible Wear: Inspect for any signs of physical damage, such as cracks, rust, or corrosion.

- Overheating: Monitor temperature; excessive heat can signal an underlying problem.

Steps for Quick Diagnosis

- Conduct a thorough visual inspection of all accessible areas.

- Utilize diagnostic tools to check for electrical or mechanical faults.

- Refer to manuals or guides to understand normal operation parameters.

- Replace any suspected defective items with known good components for testing.

DIY Repair Techniques Explained

Understanding how to effectively address minor issues in tools or machinery can save both time and money. Mastering repair techniques empowers individuals to confidently tackle a range of challenges, enhancing the longevity and performance of their equipment. This section delves into practical methods that anyone can implement to ensure optimal functionality.

Begin by assessing the problem thoroughly; identifying the root cause is crucial. Utilizing basic hand tools, one can often disassemble components for inspection. Replacing worn-out parts or tightening loose fittings can resolve many common issues. When working with mechanical systems, lubrication can significantly improve performance and reduce wear.

For electrical devices, testing circuits with a multimeter can help locate faults. Always prioritize safety by disconnecting power before making repairs. Additionally, following online tutorials or consulting repair manuals can provide valuable guidance and tips tailored to specific challenges.

Safety Precautions During Repairs

When undertaking any repair work, prioritizing safety is essential to prevent accidents and injuries. Proper preparation and adherence to guidelines can significantly mitigate risks associated with handling tools and machinery. Awareness of potential hazards and implementing safety measures can ensure a secure and efficient working environment.

Always Wear Protective Gear: It is crucial to don appropriate personal protective equipment, such as gloves, goggles, and masks. These items serve as barriers against dust, debris, and harmful substances that may arise during the repair process.

Maintain a Clean Workspace: Keeping the area tidy minimizes the chances of tripping or dropping tools. Clear away any unnecessary items that could obstruct movement or distract from the task at hand.

Use Tools Properly: Familiarize yourself with the correct usage of each tool. Misusing equipment can lead to accidents, so always refer to manufacturer instructions and guidelines when available.

Disconnect Power Sources: Before starting any maintenance, ensure that power sources are disconnected. This includes unplugging electrical devices or removing batteries to prevent accidental activation while working.

Be Mindful of Your Surroundings: Stay aware of your environment, especially when working in tight spaces or near others. Communication with nearby individuals can help avoid unexpected interruptions and enhance overall safety.

Take Breaks: Working for extended periods can lead to fatigue, increasing the risk of errors and accidents. Schedule regular breaks to maintain focus and ensure a clear mind throughout the repair process.

By following these essential safety precautions, you can create a secure environment that fosters effective and safe repair practices.

Resources for Craftsman Enthusiasts

For those passionate about their tools and machines, having access to reliable resources is essential for maintenance, upgrades, and community support. Whether you’re seeking manuals, forums, or instructional videos, a wealth of information is available to enhance your experience and knowledge.

Online Communities

Joining online forums and social media groups can connect you with fellow enthusiasts who share insights and tips. These platforms are invaluable for exchanging experiences and troubleshooting challenges.

Instructional Materials

Comprehensive guides and tutorial videos are readily available on various websites, providing step-by-step instructions for repairs and modifications. These resources empower you to delve deeper into the intricacies of your equipment and achieve optimal performance.