The maintenance of outdoor machinery is essential for optimal performance and longevity. A thorough comprehension of the individual elements that comprise these devices allows users to ensure their equipment operates smoothly and efficiently. This knowledge not only enhances functionality but also extends the lifespan of the machinery.

In this section, we will explore the various components of a specific cutting apparatus, emphasizing the relationships between each element. Understanding how these pieces work together is crucial for troubleshooting and performing routine upkeep.

Whether you are a seasoned operator or a newcomer, having access to a comprehensive reference guide is invaluable. With the right information, you can easily identify necessary replacements or upgrades to enhance your equipment’s capabilities.

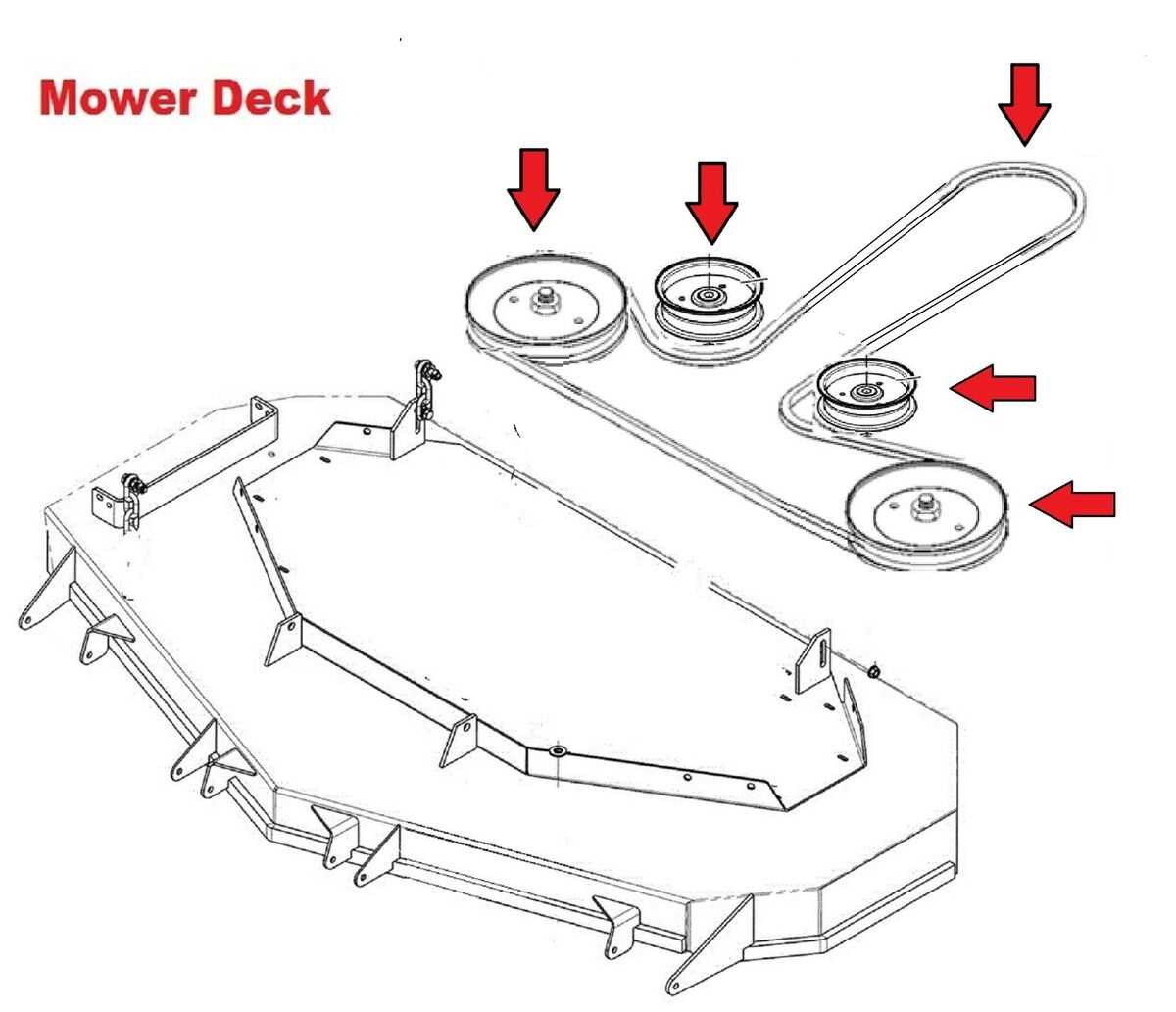

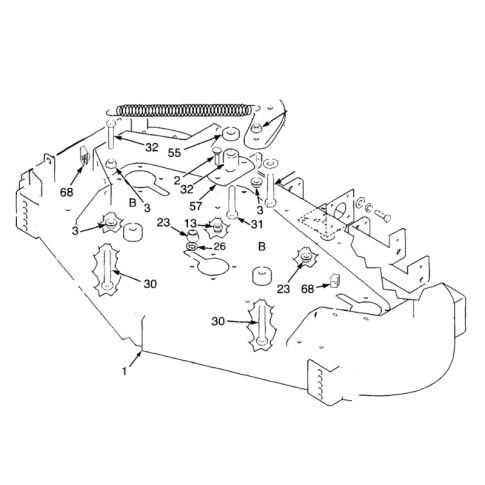

Understanding Husqvarna Mower Deck Components

In the realm of lawn care machinery, a clear comprehension of the essential elements involved in the cutting mechanism is vital for optimal performance. Each component plays a significant role in ensuring efficiency and longevity, contributing to a smooth and effective grass trimming experience.

Key Elements of the Cutting Mechanism

The primary elements include the blade assembly, which is crucial for achieving a clean cut, and the spindle housing, providing necessary support and rotation. Additionally, the belt system transmits power from the engine, enhancing overall functionality. Regular maintenance of these components ensures the reliability and durability of your equipment.

Maintenance and Troubleshooting

To maximize the lifespan of your equipment, routine inspections and timely replacements of worn components are essential. Identifying signs of wear early can prevent more extensive issues later. Understanding these critical parts not only aids in effective maintenance but also empowers users to tackle common challenges with confidence.

Essential Parts of a 46-Inch Deck

When it comes to maintaining a quality cutting experience, understanding the fundamental components that contribute to performance is crucial. Each element plays a significant role in ensuring efficiency and durability, helping to achieve an ultimate mowing result.

Blades: The cutting elements are vital for achieving a clean and even finish. Regular sharpening and replacement are necessary for optimal performance.

Spindles: These support the blades and allow them to rotate effectively. Keeping them well-lubricated ensures longevity and smooth operation.

Belts: The drive mechanisms rely on these to transfer power from the engine to the cutting components. Regular inspection for wear is essential.

Chassis: This sturdy framework houses all elements, providing structural integrity. Ensuring it’s free of rust and damage is important for overall performance.

Wheels: These support mobility and stability, allowing for smooth navigation across various terrains. Checking for wear and proper inflation enhances usability.

By delving into each of these essential components, users can better appreciate how they contribute to achieving the ultimate in lawn care efficiency.

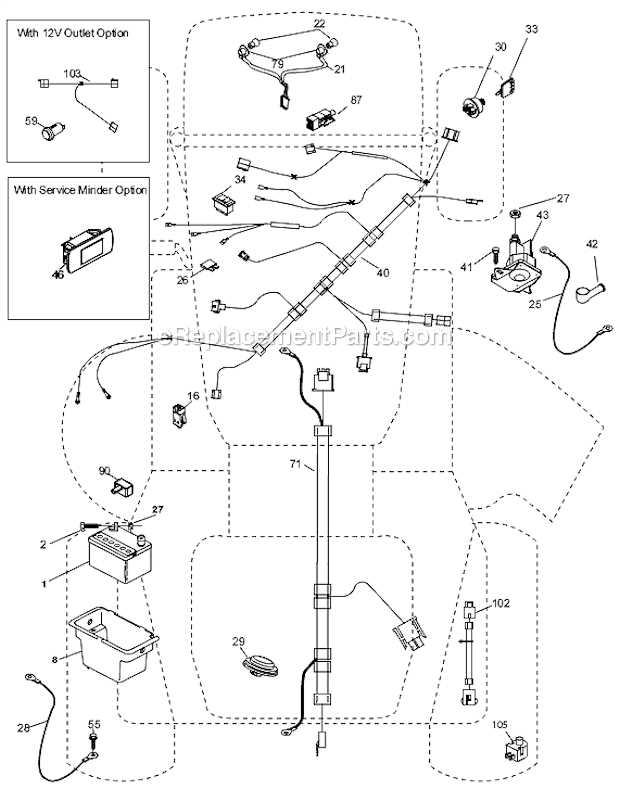

How to Interpret the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These illustrations serve as a guide, showcasing the relationship between various elements, making it easier to identify each part’s function and placement.

Identifying Components

Start by familiarizing yourself with the labeled sections of the illustration. Each part is usually marked with numbers or letters that correspond to a list, helping you recognize what you’re looking at. Pay attention to symbols and connections, as they indicate how parts interact with one another.

Understanding Relationships

Look for lines and arrows that represent movement or flow. These connections provide insight into how components work together, enabling you to diagnose issues or plan for upgrades. Analyzing these relationships can ultimately enhance your overall comprehension of the system.

Common Issues with Mower Decks

When maintaining your lawn equipment, several typical challenges may arise that can impact performance and efficiency. Understanding these issues is crucial for effective troubleshooting and ensuring longevity.

Uneven Cutting can be a frustrating problem, often resulting from imbalanced blades or improper height adjustments. Regular inspections can help maintain an even cut.

Clogging occurs when grass clippings and debris accumulate, leading to poor functionality. Regular cleaning and maintenance are essential to prevent this issue.

Noise and Vibration may indicate wear or damage to components. Addressing these sounds promptly can prevent more serious problems down the line.

Blade Dullness affects cutting efficiency and can lead to a ragged finish. Regular sharpening is necessary to keep blades in optimal condition.

By being aware of these common challenges, users can delve deeper into effective maintenance practices for their equipment, ensuring the ultimate performance and durability.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the long-lasting performance of your outdoor equipment. Regular care not only enhances efficiency but also prolongs the lifespan of the machinery. Here are some key practices to consider.

Regular Cleaning

- Remove debris after each use to prevent buildup.

- Clean components with a soft brush or cloth.

- Inspect for rust and treat affected areas promptly.

Routine Inspections

- Check belts and cables for wear and tear.

- Examine blades for sharpness and replace when necessary.

- Monitor fluid levels and top off as required.

Implementing these practices will help maintain optimal functionality and extend the life of your equipment.

Identifying Replacement Parts Quickly

Understanding how to efficiently locate components for your equipment can save time and ensure proper maintenance. Knowing the essential features and layout of the system helps streamline the replacement process.

Visual Reference

A clear visual guide can significantly enhance your ability to identify required elements. Observing diagrams aids in recognizing specific components and their functions.

Key Tips

To expedite your search, consider these strategies:

| Strategy | Description |

|---|---|

| Consult Manuals | Refer to the user manual for detailed illustrations and part numbers. |

| Online Resources | Utilize reputable websites for visual guides and replacement lists. |

| Local Dealers | Engage with local suppliers for expert advice and part availability. |

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for effective repairs and ensuring longevity. This section outlines the essential tools to facilitate a smooth and efficient repair process.

Essential Instruments

- Wrench Set

- Screwdriver Set

- Pliers

- Socket Set

- Measuring Tape

Safety Equipment

- Gloves

- Safety Goggles

- Hearing Protection

With these tools and safety gear, you will be well-prepared to delve into any repair project, achieving the ultimate results efficiently and safely.

Step-by-Step Repair Guide

This section provides a comprehensive approach to tackling common maintenance and repair tasks for your equipment. By following a systematic method, you can ensure efficient operation and prolong its lifespan.

Assessing the Condition

Begin by inspecting the machinery thoroughly. Look for signs of wear, damage, or irregular performance. Identifying issues early on is crucial for effective resolution.

Gathering Necessary Tools

Compile all required tools and replacement components before starting the repair. Having everything on hand will streamline the process and minimize downtime.

Importance of Regular Inspections

Routine evaluations are essential for maintaining optimal performance and longevity of outdoor equipment. Regular checks help identify potential issues before they escalate, ensuring smooth operation and preventing unexpected failures.

| Benefits | Description |

|---|---|

| Increased Safety | Frequent assessments minimize the risk of accidents by addressing wear and tear promptly. |

| Enhanced Performance | Regular maintenance keeps machinery operating at peak efficiency, reducing downtime. |

| Cost Savings | Early detection of issues can prevent costly repairs and extend the life of equipment. |

| Environmental Impact | Well-maintained equipment operates more cleanly and efficiently, reducing emissions and waste. |

Where to Buy Replacement Parts

Finding quality components for your outdoor equipment can significantly enhance its performance and longevity. Various sources offer a range of options, ensuring you can select the best fit for your needs.

Online Retailers

Online platforms provide convenience and a vast selection. Many websites specialize in equipment supplies, making it easy to compare prices and find specific items.

Local Dealers

Visiting nearby stores can also be beneficial. Local dealers often have knowledgeable staff who can assist you in identifying the correct components.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, competitive prices |

| Local Dealers | Expert assistance, immediate availability |

| Manufacturer Websites | Genuine parts, warranty support |

Comparing OEM vs. Aftermarket Parts

When maintaining outdoor equipment, the choice between original components and third-party alternatives is crucial. Each option offers distinct advantages and potential drawbacks that can influence performance and longevity.

Original components, often referred to as OEM, are designed specifically for compatibility and quality. They typically provide:

- Guaranteed fit and function

- Manufacturer-backed warranty

- High-quality materials

On the other hand, third-party alternatives can be appealing due to their cost-effectiveness and availability. Their benefits include:

- Lower prices

- Wider selection

- Potential for improved performance in some cases

Ultimately, the decision hinges on personal priorities, such as budget constraints and desired reliability. Each type presents a unique set of characteristics that can significantly impact the maintenance experience.

Understanding Deck Leveling Techniques

Achieving a balanced cutting surface is essential for maintaining a lush and healthy lawn. Proper alignment ensures that the blades operate effectively, promoting even grass growth and reducing the risk of scalping or uneven patches. Familiarizing yourself with various adjustment methods can significantly enhance the performance of your equipment.

There are several techniques to consider when leveling your cutting apparatus. Each method has its own benefits and can be applied depending on the specific design and usage of your machine. Below is a comparison of common approaches.

| Technique | Description | Advantages |

|---|---|---|

| Manual Adjustment | Involves physically raising or lowering individual corners to achieve a level position. | Simple and requires minimal tools. |

| Using a Level | Employs a spirit level to check alignment, ensuring an even cut across the width. | Provides precise measurements for optimal results. |

| Measurement Method | Involves measuring the height of the blades from the ground and adjusting accordingly. | Effective for achieving uniform blade height across the entire cutting area. |

| Consulting a Manual | Refers to the manufacturer’s guidelines for specific adjustment procedures. | Offers tailored solutions based on design specifications. |

By employing these techniques, operators can ensure their equipment functions optimally, leading to a well-maintained outdoor space. Regular checks and adjustments can prevent common issues, extending the lifespan of your machinery while enhancing its performance.

Best Practices for Seasonal Storage

Proper seasonal storage is essential to prolonging the lifespan and efficiency of your outdoor equipment. By following key practices, you can ensure that your machinery remains in optimal condition and is ready for use when needed. This involves careful preparation and maintenance to prevent deterioration during off-seasons.

Preparation Steps

Before storing, clean your equipment thoroughly to remove dirt, grass, and debris. Check fluid levels, replace any worn parts, and lubricate moving components. This not only protects against rust but also ensures smooth operation when you bring it out again.

Storage Environment

Choose a dry, cool place for storage to minimize the risk of moisture and extreme temperatures. Cover your machinery with a breathable tarp to protect it from dust and potential pests while allowing air circulation.

| Action | Purpose |

|---|---|

| Clean Thoroughly | Prevents rust and buildup |

| Check Fluids | Ensures functionality |

| Lubricate Moving Parts | Reduces wear |

| Store in a Dry Place | Minimizes moisture damage |