The functionality of a lawn maintenance machine heavily relies on its various essential components. Each section plays a critical role in ensuring optimal performance and efficiency. Grasping how these elements interact can significantly enhance the maintenance process.

In this guide, we will explore the intricate layout of the specific assembly that aids in grass cutting. By breaking down the structure into manageable parts, users can better appreciate their individual functions and the overall operation of the equipment.

Utilizing a visual representation of these elements can serve as the ultimate tool for both novice and experienced operators. It enables a deeper understanding of potential repairs and replacements, ensuring your machine remains in peak condition.

Understanding the John Deere L120

This section delves into the intricacies of a well-regarded lawn maintenance machine, designed to enhance efficiency and performance in outdoor tasks. It focuses on the critical components that contribute to its reliable operation, allowing users to achieve a beautifully manicured lawn with ease.

Key Features

Equipped with a powerful engine, this model boasts impressive cutting capabilities and maneuverability. Its intuitive design enables users to navigate various terrains effortlessly. Additionally, the robust construction ensures durability, making it a worthwhile investment for homeowners and landscapers alike.

Maintenance Tips

To ensure optimal functionality, regular upkeep is essential. Checking oil levels, cleaning the blades, and inspecting the overall condition can significantly prolong its lifespan. Adopting these practices not only enhances performance but also guarantees a smooth mowing experience. Investing time in maintenance will pay off in the long run.

Importance of Lawn Mower Deck Parts

The various components that make up the mowing mechanism play a crucial role in the overall performance and efficiency of any grass-cutting machine. Each element contributes to the functionality, affecting not just the quality of the cut but also the machine’s longevity and ease of use.

Key Functions of Mowing Mechanism Components

Understanding the roles of these essential components helps users maintain their machines effectively:

- Cutting Quality: Each component ensures a clean and even cut, promoting healthy grass growth.

- Efficiency: Well-functioning elements minimize energy consumption, allowing for longer operation times.

- Durability: Regular maintenance of these parts extends the lifespan of the entire machine.

- Safety: Properly functioning components reduce the risk of accidents during operation.

Maintenance and Care

Regular checks and timely replacements of worn-out components are vital for optimal performance:

- Inspect components regularly for signs of wear.

- Clean all areas to prevent debris buildup.

- Lubricate moving parts to ensure smooth operation.

- Replace damaged components promptly to avoid further issues.

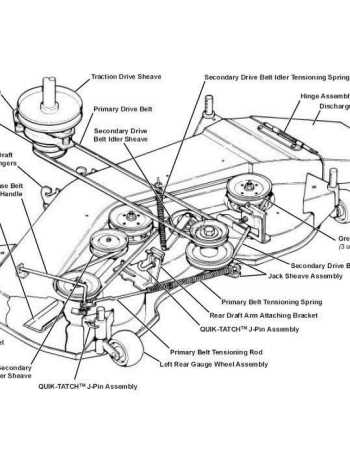

Overview of L120 Deck Components

This section explores the essential elements that contribute to the functionality and efficiency of the mowing apparatus. Understanding these components can enhance maintenance practices and overall performance.

Key Elements

Several crucial parts work together to ensure optimal operation. The cutting mechanism plays a vital role in achieving a clean, even trim, while the support structure provides stability and durability. Regular inspection of these components is necessary to maintain peak performance.

Maintenance Considerations

Regular upkeep is essential for longevity. Inspecting blades, belts, and pulleys can prevent costly repairs and improve cutting efficiency. Awareness of wear and tear will lead to better management of the entire system.

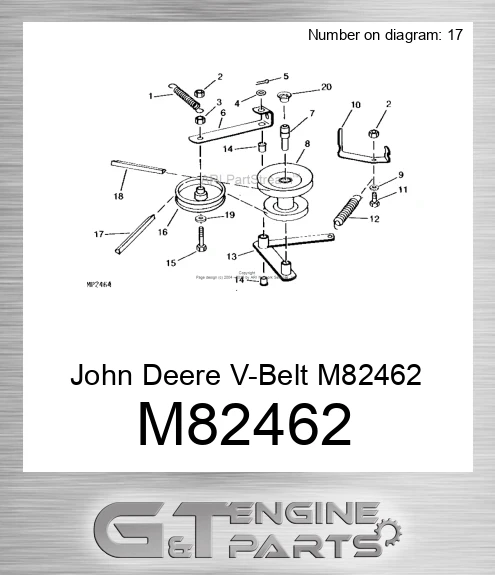

Identifying Key Parts in Diagrams

Understanding essential components within illustrations is crucial for effective maintenance and repair. Recognizing these elements can greatly enhance one’s ability to troubleshoot and ensure optimal functionality of equipment.

Visual representation often provides a clearer understanding of how various components interact. By analyzing the layout, one can pinpoint critical sections that require attention or replacement.

Utilizing labels and symbols effectively allows for quick identification of necessary items. This knowledge streamlines the repair process and helps in sourcing the right replacements.

Familiarity with these visuals fosters confidence, enabling users to delve deeper into their machinery’s mechanics. Mastering this skill can lead to improved efficiency and longevity of the equipment.

Common Issues with Deck Assembly

Proper assembly of lawn equipment is crucial for optimal performance. However, several challenges may arise during the construction process that can hinder functionality and efficiency.

- Misalignment: Components may not fit together correctly, leading to uneven cutting and increased wear.

- Loose Fasteners: Bolts and screws can become loose over time, causing instability and vibration.

- Worn Components: Older parts can degrade, impacting the overall effectiveness and safety of the assembly.

- Improper Lubrication: Lack of adequate lubrication can lead to increased friction and potential damage.

- Corrosion: Exposure to moisture can result in rust, affecting metal components and their longevity.

Addressing these issues promptly can enhance the lifespan and functionality of the equipment.

How to Maintain Your Mower Deck

Regular upkeep of your lawn care equipment is essential for optimal performance and longevity. Proper maintenance ensures efficient operation, prevents costly repairs, and enhances the quality of your mowing experience. Here are some key steps to keep your equipment in excellent condition.

- Clean the Surface: After each use, remove grass clippings and debris. This prevents rust and maintains a clean cutting area.

- Inspect for Damage: Regularly check for any wear and tear. Look for cracks, rust spots, or loose components that may require attention.

- Sharpen the Blades: Dull blades can lead to uneven cuts. Sharpen them at least once a season or more frequently if you mow often.

- Lubricate Moving Parts: Apply lubricant to hinges, wheels, and other moving parts to ensure smooth operation and reduce friction.

- Check Belts and Cables: Inspect belts for cracks or fraying and ensure cables are tight and functioning correctly.

Following these maintenance tips will not only enhance performance but also extend the lifespan of your equipment. Consistent care leads to a well-maintained tool that performs effectively season after season.

Parts Replacement for Optimal Performance

Ensuring the best functionality of your equipment requires timely updates and substitutions of essential components. Regular maintenance not only enhances efficiency but also prolongs the lifespan of machinery, preventing unexpected failures and costly repairs. Understanding which elements to replace and when is crucial for maintaining peak operation.

| Component | Signs of Wear | Recommended Replacement Frequency |

|---|---|---|

| Blades | Dull edges, uneven cuts | Every 20-25 hours of use |

| Belt | Fraying, cracks | Annually or as needed |

| Spindles | Noisy operation, wobbling | Every 2 years |

By addressing these critical elements proactively, you can ensure your machinery runs smoothly, delivering ultimate performance and reliability throughout its service life.

Where to Find Genuine Parts

Finding authentic components for your lawn care machinery is crucial for maintaining optimal performance and longevity. Whether you are looking to replace a worn-out element or upgrade your equipment, sourcing reliable parts ensures your machinery operates efficiently. Here are some effective strategies for locating quality replacements.

Official Retailers

Visiting authorized dealers is one of the best ways to secure genuine components. These retailers offer a wide range of original items that are specifically designed for your equipment. They often have knowledgeable staff who can assist you in identifying the right components based on your model.

Online Marketplaces

Numerous online platforms specialize in selling original components. Make sure to choose reputable websites that guarantee authenticity and provide customer reviews. It’s essential to cross-check part numbers to ensure compatibility with your machinery.

Step-by-Step Deck Repair Guide

Maintaining your mowing apparatus is essential for ensuring its optimal performance and longevity. This guide will provide a systematic approach to restoring the cutting assembly, helping you achieve a smooth and efficient operation. Follow these steps to tackle repairs effectively and confidently.

1. Gather Your Tools and Materials

Before starting, collect all necessary tools such as wrenches, screwdrivers, and replacement components. Having everything on hand will streamline the process and prevent interruptions.

2. Safety First

Ensure that the machine is turned off and disconnected from any power source. Wear appropriate safety gear, including gloves and goggles, to protect yourself during the repair.

3. Remove the Assembly

Carefully detach the cutting unit from the main body of the apparatus. This usually involves unscrewing several bolts and disconnecting any attached cables. Take your time to avoid damaging any components.

4. Inspect and Identify Issues

Examine all parts for signs of wear or damage. Look for cracks, rust, or missing pieces that may need replacement. Keeping a detailed checklist will help in tracking what needs to be fixed or changed.

5. Replace Damaged Components

Once you have identified the faulty parts, proceed to replace them with new, compatible pieces. Ensure that all fittings are secure and properly aligned for optimal performance.

6. Reassemble the Unit

Carefully reattach the cutting mechanism to the main unit. Make sure all screws and bolts are tightened appropriately to prevent any looseness during operation.

7. Test the Equipment

Once everything is reassembled, reconnect the power and perform a test run. Monitor the machine closely to ensure it operates smoothly and without any unusual noises or vibrations.

8. Regular Maintenance

To prolong the lifespan of your equipment, establish a regular maintenance schedule. This includes routine inspections and cleaning, which will help prevent future repairs and keep your machine running efficiently.

DIY vs. Professional Repairs

When faced with equipment maintenance, individuals often grapple with the choice between tackling repairs themselves or seeking expert assistance. Each approach offers unique advantages and challenges that can significantly impact the overall outcome and efficiency of the repair process.

Advantages of DIY Repairs

Engaging in self-repairs can be rewarding, providing a sense of accomplishment and a chance to save on labor costs. With the right tools and guidance, many find that they can effectively address minor issues, gaining valuable skills in the process.

Benefits of Professional Services

On the other hand, enlisting a professional can ensure high-quality workmanship and quicker resolution of complex problems. Experts bring extensive experience and specialized knowledge, minimizing the risk of further damage and providing peace of mind.

Cost Considerations for Deck Parts

When it comes to maintaining outdoor equipment, understanding the financial implications of components is essential. The expenses associated with various elements can significantly affect your overall budget. This section will explore the factors influencing costs, helping you make informed decisions.

Quality vs. Price: Investing in high-quality components may come with a higher upfront cost, but it often leads to better performance and longevity. Cheaper alternatives might seem attractive initially, but they can result in more frequent replacements and repairs, ultimately increasing expenses.

Availability: The source of your components can also impact pricing. Local suppliers may offer convenience but could charge a premium. Online retailers might have competitive prices, but shipping costs can offset savings. Always compare options to find the best deal.

Compatibility: Ensuring that the selected elements are compatible with your equipment is crucial. Mismatched components can lead to inefficiencies or even damage, resulting in additional costs for repairs or replacements. Research and confirm compatibility before purchasing.

Maintenance: Regular upkeep of components can prevent costly breakdowns. Understanding the maintenance requirements associated with each part can help you budget for ongoing care, ultimately saving you money in the long run.

By considering these aspects, you can better manage your expenses related to outdoor equipment components and make choices that align with your financial goals.

Upgrading Your L120 Mower Deck

Enhancing the performance of your mowing equipment can significantly improve efficiency and results. Focusing on specific components can lead to a smoother operation and a better finish on your lawn. By selecting high-quality alternatives and replacements, you can achieve the ultimate performance.

When considering modifications, it’s essential to evaluate the current setup. Assess the wear and tear on existing elements, as well as compatibility with newer technologies. Upgrading to advanced materials and features can elevate your equipment’s durability and functionality.

Incorporating innovative accessories can also streamline your mowing experience. Attachments designed for ease of use and improved maneuverability will not only save time but also enhance the overall mowing process. Be sure to consult reliable resources for recommendations on the best upgrades available.

Resources for Further Research

This section aims to provide a curated list of valuable materials and references to enhance your understanding and knowledge on maintenance and components related to lawn care equipment. Utilizing these resources will allow enthusiasts and professionals alike to gain deeper insights into efficient operations and troubleshooting techniques.

Online Communities

- Forums dedicated to lawn equipment discussions

- Social media groups focused on repair tips

- Dedicated subreddits for troubleshooting advice

Instructional Videos

- YouTube channels specializing in machinery repairs

- Webinars hosted by industry experts

- Video tutorials on maintenance procedures