Maintaining a well-functioning cutting apparatus is crucial for achieving a pristine lawn. This section delves into the essential elements that contribute to the overall performance of your equipment. A clear understanding of these components can enhance efficiency and prolong the lifespan of your machine.

In the following details, we will explore various sections of the cutting assembly, highlighting their specific roles and interconnections. Whether you are looking to replace a worn-out element or simply wish to gain insight into the machinery, this overview provides valuable information for both novice and experienced users.

By familiarizing yourself with the intricacies of the unit, you can ensure optimal functionality. A well-informed approach not only streamlines repairs but also enhances your overall experience with the equipment, making yard maintenance more manageable and enjoyable.

Overview of John Deere X300 Mower

This section provides an insight into a well-regarded lawn care machine designed for efficiency and ease of use. Featuring robust construction and innovative technology, this model caters to both residential and professional landscaping needs. With various configurations available, it allows users to tackle diverse mowing tasks effectively.

Key Features

Equipped with a powerful engine and advanced cutting mechanisms, this model ensures a clean and precise finish. The ergonomic design promotes comfort during operation, making it suitable for extended use. Additionally, its user-friendly controls facilitate a smooth experience for both novice and experienced operators.

Maintenance and Care

Regular upkeep is essential for optimal performance and longevity. Routine inspections and prompt replacements of worn components contribute to the machine’s reliability. Following recommended maintenance schedules ensures that the equipment remains in peak condition, allowing users to maximize their investment.

Key Features of the Mower Deck

The design and functionality of this cutting attachment play a crucial role in ensuring a superior performance while maintaining a pristine lawn. Various aspects contribute to its efficiency and ease of use, making it an essential component for any landscaping task.

Durability: Constructed from high-quality materials, this assembly is built to withstand the rigors of regular use, providing longevity and reliability.

Cutting Precision: The configuration of the blades ensures a uniform cut, allowing for an even finish that enhances the overall appearance of the turf.

Height Adjustment: Equipped with an intuitive height modification system, users can easily customize the cutting height to suit different types of grass and desired outcomes.

Maintenance Accessibility: Thoughtfully designed for easy access, routine upkeep can be performed with minimal effort, ensuring optimal performance and extending the life of the unit.

Compatibility: This attachment seamlessly integrates with various models, providing versatility for users with different machines.

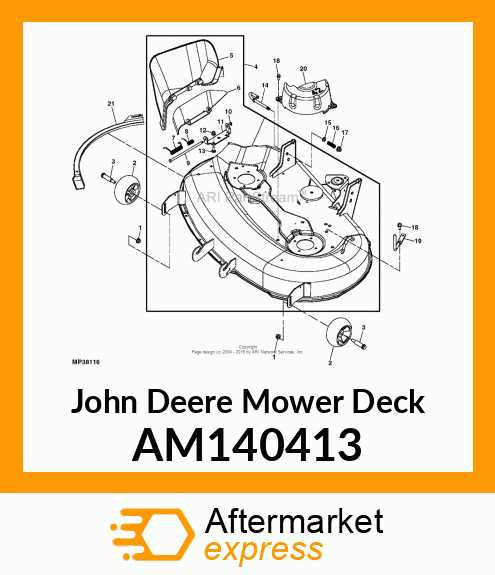

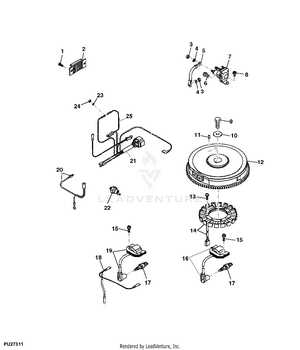

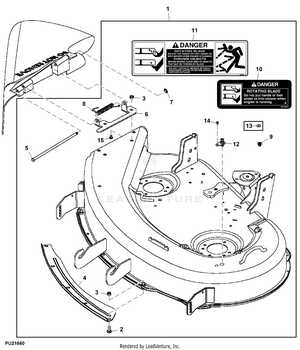

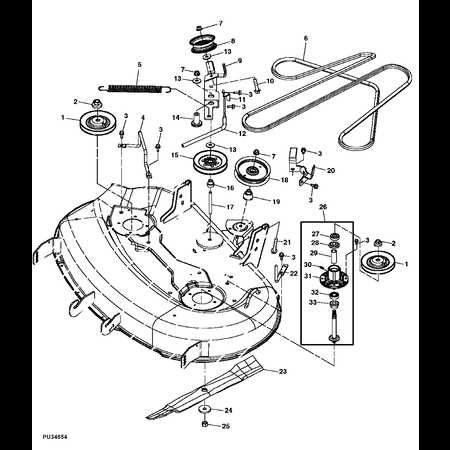

Understanding the Parts Diagram

This section aims to clarify the components that contribute to the overall functionality of the cutting mechanism. By examining the visual representation, one can appreciate how each element interacts to ensure optimal performance during operation.

Key Components and Their Functions

Each element plays a vital role, from the driving mechanisms to the cutting surfaces. Recognizing these parts allows for better maintenance and troubleshooting. Understanding how these components work together can enhance the efficiency and longevity of the equipment.

Importance of Accurate Identification

Accurate recognition of individual elements is essential for effective repairs and replacements. Familiarity with the layout facilitates quicker resolutions to issues that may arise, leading to a more streamlined experience. Being knowledgeable about these components fosters confidence in managing any challenges that may occur during usage.

Identifying Major Components

This section focuses on recognizing the primary elements essential for the efficient operation of the equipment in question. Understanding these components is crucial for maintenance and troubleshooting.

- Cutting Blades: Vital for achieving a clean cut, these elements are strategically positioned to ensure optimal performance.

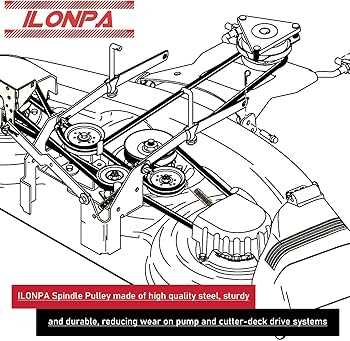

- Spindle Assemblies: These units support the blades, allowing for smooth rotation and effective cutting action.

- Chassis: The framework that holds all components together, providing structural integrity and stability during use.

- Belts: These are essential for transferring power from the engine to the cutting mechanism, facilitating movement and function.

- Wheels: Offering mobility, these components are designed to navigate various terrains effortlessly.

Familiarity with these crucial parts enhances one’s ability to perform effective repairs and optimizations, ultimately improving the overall functionality of the machinery.

Maintenance Tips for the Deck

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a consistent maintenance routine not only enhances efficiency but also minimizes the risk of unforeseen breakdowns. By focusing on key areas, you can keep your machinery in peak condition.

Start by inspecting the cutting mechanism frequently. Ensure that all components are clean and free from debris, as this can affect performance. Sharpening the blades regularly will guarantee a clean cut, promoting healthy growth of the grass.

Additionally, check the alignment of the components to prevent uneven wear. Tighten any loose bolts and fasteners to avoid vibrations that could lead to further damage. Lubricate moving parts as recommended to reduce friction and wear over time.

Lastly, store the equipment in a dry, protected area when not in use. This helps prevent rust and corrosion, prolonging the life of the entire assembly. Following these simple yet effective strategies will ensure your machinery remains reliable and efficient for years to come.

Common Issues with Mower Decks

Maintaining cutting equipment can be challenging due to various complications that may arise during operation. Understanding these common problems is essential for efficient upkeep and optimal performance. Regular inspection and timely intervention can prevent minor issues from escalating into significant repairs.

Uneven Cutting: One prevalent issue is uneven cutting, which can lead to an unsightly lawn. This often occurs due to dull blades, incorrect height adjustments, or worn-out components. Ensuring blades are sharp and properly aligned can mitigate this problem.

Clumping Grass: Clumping can happen when grass clippings accumulate instead of dispersing evenly. This situation can be caused by wet grass, insufficient blade speed, or clogged discharge areas. Regular cleaning and adjusting the cutting height can help alleviate this issue.

Excessive Vibration: Excessive vibrations during operation can indicate loose or damaged components. Checking all fasteners and inspecting the condition of bearings can help identify the source of the problem. Prompt repairs can prevent further damage and ensure a smoother cutting experience.

Difficulty in Maneuverability: If the equipment feels hard to maneuver, it could be due to worn wheels or improper tire pressure. Regular maintenance checks on wheels and tires can enhance handling and ease of use.

How to Replace Mower Parts

Maintaining your cutting equipment is essential for optimal performance and longevity. Understanding how to swap out various components ensures that your machine operates smoothly and efficiently. This guide outlines the necessary steps to effectively replace critical elements of your tool.

Before starting the replacement process, ensure you have all the required tools on hand, including wrenches, screwdrivers, and safety gear. Begin by turning off the machine and disconnecting any power sources to prevent accidents. Once the equipment is secure, carefully remove the existing components according to the manufacturer’s instructions.

After the old parts are detached, inspect the surrounding area for any signs of wear or damage. It’s important to clean the area before installing new components to ensure a proper fit. Align the new parts as specified, securing them firmly to avoid future issues. Double-check all connections before reassembling your machine.

Finally, conduct a test run to confirm that everything is functioning correctly. Regular maintenance and timely replacements will enhance the durability of your equipment, ensuring it remains in peak condition for years to come.

Choosing Quality Replacement Parts

When it comes to maintaining outdoor equipment, selecting high-quality components is crucial for optimal performance and longevity. Quality replacements not only enhance functionality but also ensure safety during operation. By focusing on durability and compatibility, users can prevent frequent breakdowns and costly repairs.

Consider the materials used in manufacturing. Premium-grade materials tend to withstand wear and tear better than cheaper alternatives. Additionally, it’s essential to verify that the replacement aligns with the specifications of the original equipment to avoid any fitment issues. Researching reputable brands and reading customer reviews can provide insights into reliability and performance.

Finally, investing in top-notch components often translates to improved efficiency and a smoother experience. While initial costs may be higher, the long-term benefits make it a wise choice for anyone looking to prolong the lifespan of their machinery.

Tools Needed for Deck Maintenance

Proper upkeep of your cutting apparatus requires specific instruments to ensure efficiency and longevity. Having the right tools on hand not only simplifies the process but also enhances safety while working. Below is a selection of essential equipment for maintaining your setup.

Essential Equipment

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Socket Set | Useful for accessing hard-to-reach fasteners. |

| Blades Sharpener | To keep the cutting edges sharp for optimal performance. |

| Safety Gloves | Protects hands from sharp edges and other hazards. |

| Protective Eyewear | To shield eyes from debris during maintenance. |

Additional Tools

In addition to the basic tools, consider having a torque wrench for precise tightening and a cleaning brush to remove grass and debris. A manual or reference guide can also be invaluable for troubleshooting and ensuring all components are correctly assembled.

Assembly Instructions for Mower Deck

Proper assembly of the cutting apparatus is crucial for optimal performance and longevity. Following these steps will ensure that all components fit securely and function efficiently, contributing to a seamless mowing experience.

Preparation Steps

Before beginning, gather all necessary tools and components. Review the instruction manual to familiarize yourself with each item and its placement. Organizing your workspace will streamline the process and minimize the risk of losing any small pieces.

Assembly Process

Start by securing the main frame to the designated mounting points. Ensure that each connection is tight and stable. Next, attach the cutting blades, aligning them as specified in the guidelines. It is essential to check the orientation of each blade for proper rotation. Finally, connect the drive belt and verify that it moves freely without obstruction.

Tip: Regular maintenance checks will prolong the life of your equipment and enhance its efficiency. Always refer back to your manual for specific instructions on upkeep.

Safety Precautions During Maintenance

Proper safety measures are essential when performing upkeep on any outdoor machinery. Ensuring a secure environment not only protects the individual conducting the maintenance but also enhances the longevity and performance of the equipment. Adhering to guidelines helps prevent accidents and injuries that can arise from improper handling or unforeseen circumstances.

Before starting any maintenance task, always disconnect the power source. This action eliminates the risk of accidental activation, which can lead to serious injuries. Additionally, it is advisable to wear appropriate personal protective equipment, such as gloves, safety goggles, and sturdy footwear, to safeguard against potential hazards.

Ensure that the working area is clean and free of obstructions. A tidy space minimizes the chance of slips, trips, and falls. It is also wise to keep tools organized and within reach, reducing the likelihood of unnecessary movement that could result in accidents.

Follow the manufacturer’s guidelines for maintenance procedures. Understanding the specific requirements for your equipment is crucial in performing tasks effectively and safely. If uncertain, consult the user manual or seek assistance from a professional.

Finally, never underestimate the importance of awareness. Stay alert to your surroundings and any potential risks. By prioritizing safety during maintenance, you not only protect yourself but also ensure that your equipment operates optimally for years to come.

Benefits of Regular Maintenance

Consistent upkeep of your equipment is essential for optimal performance and longevity. By prioritizing maintenance, users can enhance efficiency, reduce the risk of unexpected failures, and ensure safe operation throughout the season.

One of the primary advantages of regular care is the prevention of major issues. Timely inspections and minor repairs can avert costly breakdowns and extend the lifespan of the machinery.

| Benefit | Description |

|---|---|

| Improved Performance | Regular checks help maintain peak efficiency, leading to better results during operation. |

| Cost Savings | Investing in maintenance can reduce long-term repair costs by preventing significant damage. |

| Safety Assurance | Routine servicing identifies potential hazards, ensuring safe use for operators. |

| Increased Resale Value | Well-maintained equipment often commands a higher market value when it’s time to sell. |

Ultimately, adopting a regular maintenance schedule can lead to substantial benefits, safeguarding your investment and enhancing your overall experience.

FAQs About Mower Deck Parts

This section addresses common inquiries regarding the components of a cutting apparatus, offering insights into their functionality and maintenance. Understanding these elements can enhance performance and longevity.

Common Questions

- What are the key components of a cutting apparatus?

- How often should I inspect the components for wear?

- What signs indicate that a component needs replacement?

Maintenance Tips

- Regularly clean the assembly to prevent debris buildup.

- Check for loose connections or signs of corrosion.

- Lubricate moving parts to ensure smooth operation.