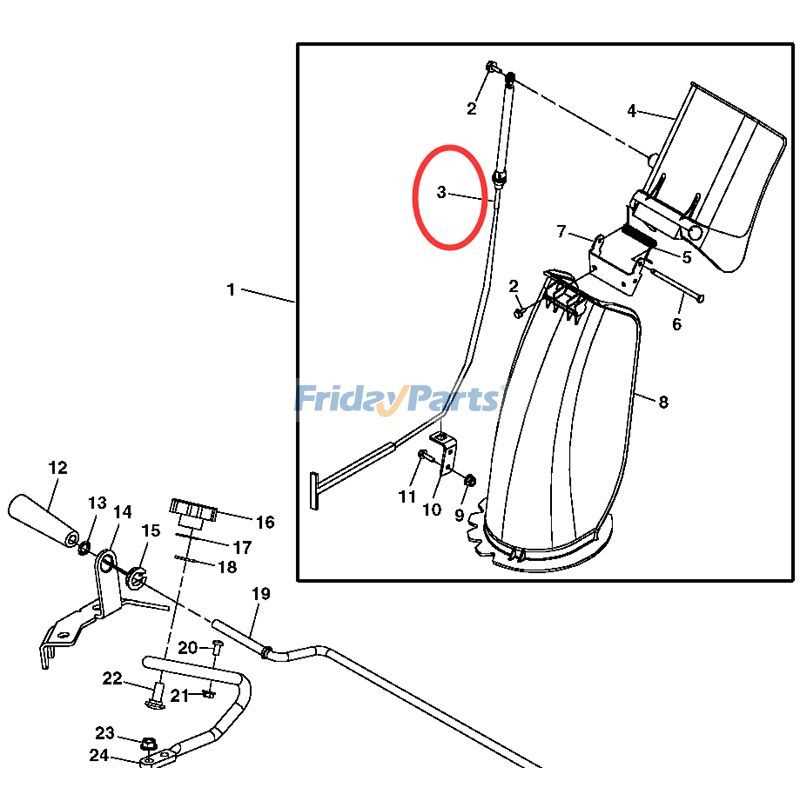

When it comes to maintaining a small agricultural machine, understanding how its mechanical systems work together is key to keeping it running smoothly. The intricate network of elements that work under the hood can sometimes seem overwhelming, but with a little guidance, you can easily navigate the layout of these essential parts

Comprehensive Overview of Lawn Tractor Engines

Lawn tractors are an essential tool for maintaining large outdoor spaces. At the heart of these machines is a powerful system that provides the necessary force to drive the tractor’s functions. Understanding the key components involved can help in maximizing performance and ensuring long-term durability. This guide breaks down the fundamental elements of lawn tractor power units, offering insights into their mechanics and maintenance tips for keeping them in top condition.

Key Components and Their Roles

The inner workings of these machines involve multiple interconnected systems. Each one plays a vital role in ensuring smooth operation and efficient power distribution. Some of the most important components include the combustion unit, cooling mechanism,

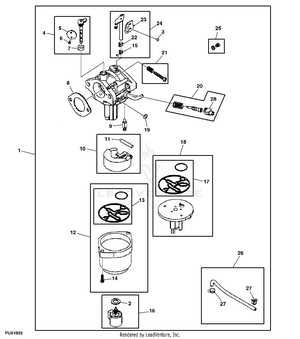

Key Components of Small Gasoline Engines

Understanding the fundamental elements of compact combustion systems is essential for anyone looking to maintain or repair such machinery. These systems are composed of several interconnected mechanisms that work together to convert fuel into energy, driving mechanical motion. Let’s explore the critical parts that ensure smooth operation and efficiency.

Combustion System

The combustion chamber is where fuel mixes with air and ignites, creating the force that powers the system. This process relies on precise timing and the proper ratio of fuel to air, managed by various control devices. Elements like the spark plug initiate ignition, while the valves regulate airflow and exhaust.

Understanding the Internal Combustion Process

At the heart of many mechanical systems lies a fundamental process that powers vehicles and machinery alike. This method involves the transformation of fuel into energy through controlled ignitions, generating the necessary force to move or operate equipment. By converting chemical energy into kinetic force, this process enables motion and functionality in numerous applications.

The Role of Fuel and Air

For this process to occur, a precise balance between fuel and air is essential. When these elements combine under the right conditions, an explosion occurs inside the enclosed system. This creates a force that pushes components into motion. Proper management of this balance ensures efficient operation, preventing issues such as overheating or loss of power.

Stages of the Process

Examining the Functionality of Engine Cylinders

The role of these components is crucial in the operation of any mechanical system. Understanding how they work provides insight into the overall performance and efficiency of the machinery. Their primary purpose involves housing key processes that directly impact the system’s output.

These elements are responsible for facilitating controlled reactions, turning raw energy into usable power. The arrangement, condition, and coordination of these components ensure smooth functionality, playing a pivotal role in the machinery’s overall health and performance.

| Component | Function | Importance | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cylinder Walls

Maintenance Tips for Belt and Pulley SystemsEnsuring the proper care of belts and pulleys is key to maintaining a smooth and efficient performance in mechanical assemblies. Regular inspections, adjustments, and replacements of these components can prevent unnecessary wear, increase longevity, and improve overall reliability. Below are some practical suggestions to help you maintain the health of these systems. Regular Inspection and Tension AdjustmentIt is important to periodically check for signs of wear, such as cracks or fraying. Additionally, make sure the belt maintains optimal tension, as a belt Critical Role of Carburetors in Engine PerformanceThe functionality of fuel delivery systems is vital for optimizing the output and efficiency of any machinery. A crucial component in this system is responsible for mixing air and fuel in the appropriate proportions, ensuring that combustion occurs smoothly and efficiently. This process directly impacts the overall performance and reliability of the machine. Essential Functions of Carburetors

Impact on Performance and Efficiency

In conclusion, the significance of this component cannot be overstated, as it plays a pivotal role in ensuring that machinery operates effectively and efficiently. Regular maintenance and timely adjustments are essential to harness its full potential. Identifying Common Issues in Air Intake SystemsThe air intake system plays a crucial role in ensuring optimal performance and efficiency of machinery. Proper airflow is essential for combustion, and any disruption can lead to significant operational challenges. Understanding the common problems that may arise within this system can help in diagnosing issues early and maintaining performance levels. Blocked Air Filters

One of the most frequent issues encountered is the blockage of air filters. Dust, debris, and other contaminants can accumulate, restricting airflow. This restriction can cause the engine to run rich, leading to poor fuel efficiency and increased emissions. Regular inspection and timely replacement of filters can prevent these complications. Vacuum Leaks

Vacuum leaks are another concern that can adversely affect the intake system. These leaks can occur due to cracked hoses or loose fittings, allowing excess air to enter the system. This condition can disrupt the air-fuel mixture, resulting in erratic performance and increased wear on components. Identifying and sealing any leaks promptly is essential for maintaining system integrity. Exploring the Importance of Proper LubricationMaintaining adequate lubrication is essential for ensuring the optimal performance and longevity of mechanical systems. Effective fluid application reduces friction and wear between moving components, preventing overheating and potential damage. Regular checks and timely replacement of lubricants can lead to smoother operation and enhanced efficiency. In any mechanical setup, the role of lubrication cannot be overstated. It facilitates the seamless interaction of parts, minimizes wear, and helps maintain operational integrity. When lubricants are properly applied, they not only support performance but also contribute to overall reliability and safety.

Adopting a proactive approach to lubrication can prevent costly repairs and downtime. Regular maintenance practices, including monitoring lubricant levels and condition, are crucial in sustaining the effectiveness of all moving elements. How Ignition Systems Influence Engine EfficiencyThe performance of a power unit heavily relies on the effectiveness of its ignition mechanism. A well-designed spark generation system not only initiates combustion but also optimizes fuel usage, leading to enhanced operational efficiency. Understanding the intricacies of these systems can significantly impact the overall functionality and longevity of the machinery. Key Components of Ignition MechanismsSeveral crucial elements contribute to the effectiveness of ignition setups. Each component plays a vital role in ensuring a reliable spark that ignites the fuel-air mixture. The following table summarizes these parts and their functions:

Impact on Performance and Fuel EfficiencyEfficient ignition systems contribute significantly to the performance and fuel economy of a power unit. Proper timing and reliable spark generation minimize unburned fuel, reduce emissions, and enhance power output. Consequently, investing in high-quality ignition components and ensuring their regular maintenance can lead to improved operational reliability and cost-effectiveness over time. Essential Cooling Mechanisms in Small EnginesEfficient temperature regulation is crucial for the longevity and performance of compact power units. As these systems generate heat during operation, effective cooling strategies are essential to maintain optimal functioning and prevent overheating. Various techniques can be employed to ensure that thermal levels remain within a safe range. The primary cooling methods utilized in smaller mechanical systems include:

Each of these cooling strategies plays a significant role in maintaining performance and preventing damage. Understanding the importance of these mechanisms can aid in better maintenance and longevity of power units. Checking and Replacing Spark PlugsRegular maintenance of ignition components is essential for optimal performance. One critical aspect is the assessment and replacement of the small electrodes responsible for igniting the fuel-air mixture. These components can wear out over time, affecting the efficiency and reliability of the machinery. To begin, it is important to inspect the condition of the electrodes. Look for signs of wear, such as excessive carbon buildup or erosion. A clear indication that replacement is necessary includes difficulty starting the machine or irregular engine behavior. When replacing these components, ensure you use the correct type specified for your machinery. Once the new components are obtained, carefully remove the old ones using the appropriate tools. Take note of the installation sequence to ensure proper alignment during reassembly. After installation, perform a test run to verify that the ignition system is functioning smoothly. Regular checks will help maintain peak performance and extend the lifespan of the machinery. Evaluating the Role of Exhaust SystemsExhaust systems play a crucial role in the overall performance and efficiency of machinery. They are designed to channel combustion gases away from the power unit, ensuring that the internal processes operate smoothly and efficiently. Properly functioning exhaust mechanisms not only enhance power output but also contribute to fuel efficiency and emissions control. The significance of these systems extends beyond mere functionality; they also influence noise levels and the longevity of various components. Analyzing the design and condition of exhaust systems can provide insights into potential issues and areas for improvement.

In conclusion, understanding the various components and their roles within the exhaust framework is essential for maintaining optimal performance and efficiency. Regular inspection and maintenance of these systems can lead to significant improvements in the overall operation of the machinery. |