The intricate network of elements within machinery plays a crucial role in its functionality and longevity. Recognizing how each piece interconnects can enhance maintenance practices and ensure optimal performance. A comprehensive overview of these components not only aids in troubleshooting but also empowers operators with the knowledge needed for efficient care.

In this section, we will explore the essential elements that comprise your machinery. By examining the various components, users can gain insights into their specific functions and importance. Understanding these details can significantly improve the overall operation and lifespan of the equipment.

Whether you are a seasoned professional or a newcomer, having access to clear illustrations and explanations is invaluable. This exploration will allow you to delve deeper into the mechanics at play, providing the ultimate advantage in maintaining and enhancing your machinery’s capabilities.

Understanding John Deere S160

This section delves into the intricacies of a popular lawn care machine, focusing on its components and functionality. Gaining insight into its design and operation can enhance maintenance and performance.

Key features of this equipment include:

- Powerful engine for efficient mowing

- Ergonomic controls for user comfort

- Durable chassis for long-lasting use

- Versatile cutting options for various terrains

Regular maintenance is crucial for optimal performance. Understanding the main elements involved can assist in keeping the machine in peak condition. Consider the following aspects:

- Engine care: Regular oil changes and filter replacements

- Blade maintenance: Sharpening and replacing as needed

- Tire inspection: Ensuring proper inflation and tread

- Battery health: Checking connections and charge levels

Familiarity with the machine’s specifications and upkeep will contribute to its longevity and efficiency. Utilizing a comprehensive resource for all components can facilitate troubleshooting and repairs.

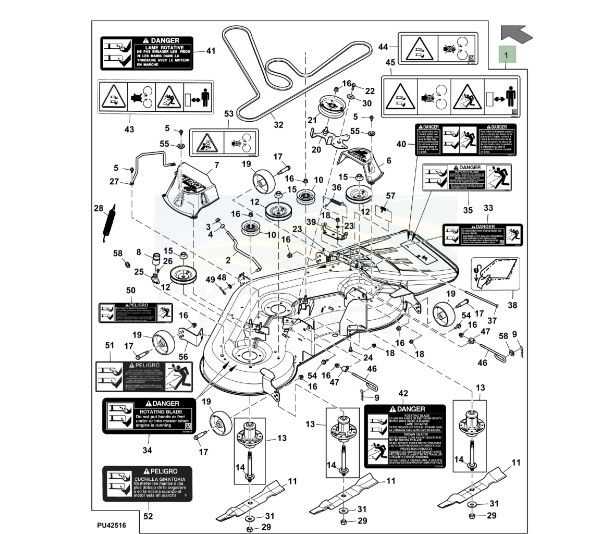

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate design and functionality of machinery. They serve as invaluable tools for both professionals and enthusiasts, simplifying the process of assembly, maintenance, and repair. By providing a clear overview of individual elements and their relationships, these illustrations enhance comprehension and efficiency.

Benefits of Visual Representations

- Clarity: These illustrations eliminate ambiguity by clearly showing how parts fit together.

- Efficiency: They streamline the process of locating and identifying components, saving time during repairs.

- Education: Users can learn about the machinery’s structure and function more effectively through visual aids.

- Accuracy: Detailed visuals minimize the risk of errors during assembly or maintenance tasks.

Applications in Maintenance and Repair

- Servicing equipment becomes more straightforward, as technicians can quickly reference the layout.

- Identification of faulty components is expedited, reducing downtime.

- Enhanced communication among team members improves collaboration during complex tasks.

- Training new employees is more efficient, as they can visualize processes rather than relying solely on verbal instructions.

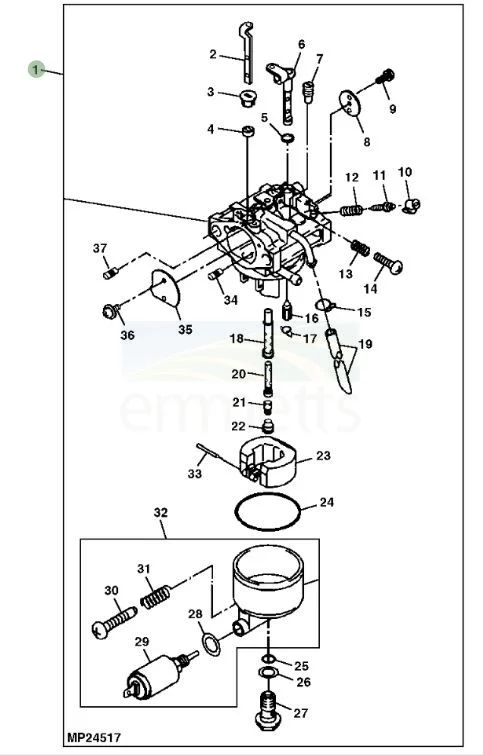

Key Components of the S160

The efficient operation of any lawn maintenance machine relies on its core elements. Understanding these fundamental parts is essential for proper upkeep and performance. Each component plays a crucial role in ensuring that the equipment runs smoothly and effectively, enhancing the overall user experience.

- Engine: The heart of the machine, responsible for providing the necessary power to perform various tasks.

- Transmission: This component transmits power from the engine to the wheels, enabling movement and control.

- Deck: The cutting deck houses the blades, determining the quality of the cut and the width of the swath.

- Blades: Sharp and durable, these are designed to provide a clean and even cut, essential for a well-manicured lawn.

- Wheels: Offering stability and maneuverability, they facilitate movement across various terrains.

- Battery: Powers the electrical systems, ensuring the machine starts reliably and runs efficiently.

- Controls: These allow the operator to manage speed, direction, and various functions, enhancing usability.

Each of these components contributes to the overall functionality and performance of the machine. Regular maintenance and understanding of these elements can lead to prolonged life and efficiency.

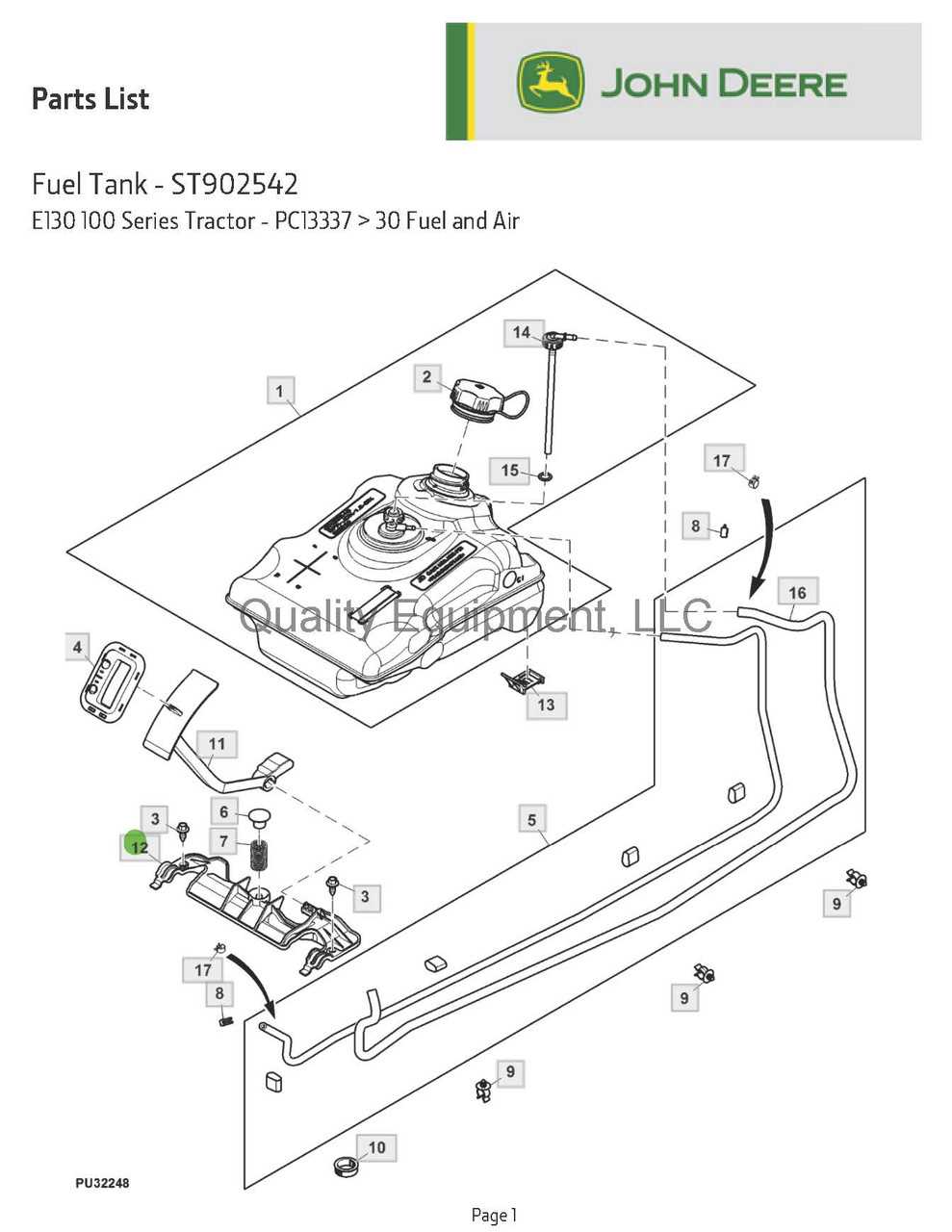

How to Use the Diagram

Utilizing a visual representation of components can greatly enhance your understanding of machinery assembly and maintenance. This guide will help you navigate the intricacies of these illustrations, ensuring efficient identification and replacement of elements.

First, familiarize yourself with the layout. Each section is typically organized to reflect the physical arrangement of components within the equipment. Take note of labels and numbers that correspond to individual pieces.

| Step | Description |

|---|---|

| 1 | Identify the area of focus based on the issue or maintenance task at hand. |

| 2 | Locate the relevant components in the illustration. |

| 3 | Cross-reference with your manual to ensure accuracy. |

| 4 | Proceed with the disassembly or replacement as outlined. |

By mastering this approach, you will ultimately streamline your repair and maintenance processes.

Common Repairs for S160 Models

Regular maintenance and prompt repairs are essential for keeping lawn and garden machinery in optimal condition. Various issues may arise over time, necessitating attention to ensure reliable performance. Here, we will explore some frequent repairs encountered with this particular model.

- Engine Troubles:

- Starting difficulties

- Overheating issues

- Excessive noise during operation

- Transmission Problems:

- Slipping gears

- Difficulty in shifting

- Fluid leaks

- Electrical System Failures:

- Battery drainage

- Faulty wiring connections

- Malfunctioning ignition system

- Cutting Deck Issues:

- Uneven cutting height

- Blades not rotating

- Clogs and debris buildup

Addressing these common issues promptly can enhance the longevity and efficiency of the equipment. Regular check-ups and proactive measures can significantly reduce the likelihood of major repairs.

Finding Genuine John Deere Parts

When maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Counterfeit or substandard replacements can lead to inefficiencies and further damage. Here’s how to identify and procure reliable replacements for your machinery.

- Verify Vendor Credentials: Always purchase from authorized dealers or reputable retailers to ensure quality.

- Check Product Codes: Cross-reference part numbers with official documentation to confirm authenticity.

- Examine Packaging: Genuine components usually feature distinctive packaging and branding elements.

- Consult Online Resources: Utilize manufacturer websites and forums for guidance on identifying legitimate products.

- Seek Recommendations: Join community groups or forums to gather insights from other users about trusted suppliers.

By following these guidelines, you can ensure that you are investing in high-quality components that will support the performance of your machinery over time.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention to detail. By adopting a systematic maintenance approach, you can enhance performance and extend the lifespan of your machinery. Below are essential tips to consider for effective care.

- Regular Inspections: Frequently examine the machinery for signs of wear and tear. Early detection of issues can prevent costly repairs.

- Cleanliness: Keep the equipment clean. Dirt and debris can lead to malfunctions. Use appropriate cleaning tools and solutions.

- Lubrication: Regularly lubricate moving parts to minimize friction and wear. Follow the manufacturer’s guidelines for the best results.

- Fluid Levels: Monitor and maintain proper levels of oil, coolant, and other fluids. Low levels can lead to overheating and other serious problems.

- Replace Filters: Change air, oil, and fuel filters as per the recommended schedule. This helps maintain efficiency and engine health.

By incorporating these maintenance practices, you can ensure that your equipment operates smoothly and reliably for years to come.

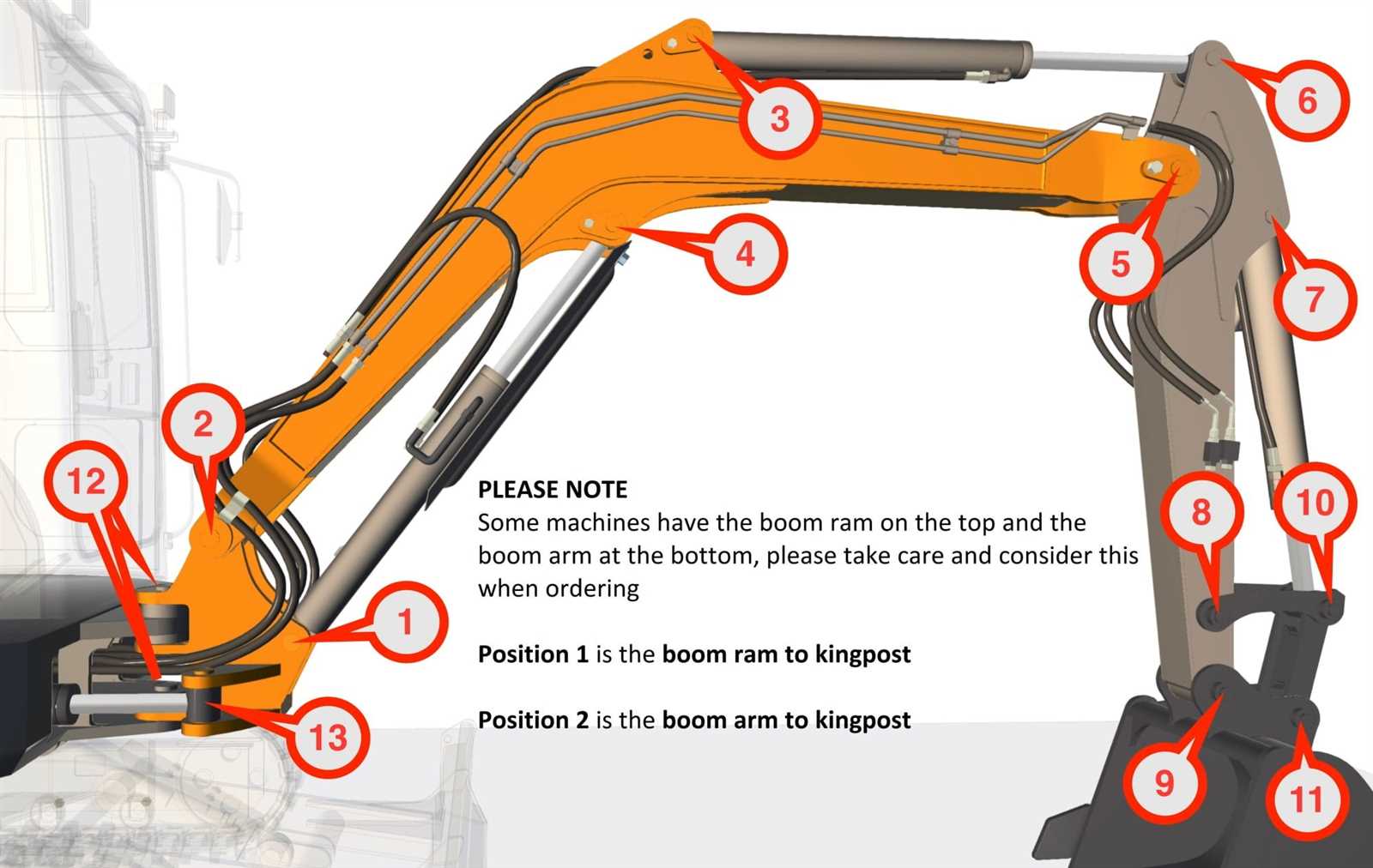

Assembly and Disassembly Guide

This section provides a comprehensive overview of the processes involved in assembling and disassembling your equipment. Understanding these procedures is crucial for maintenance and ensuring longevity.

Preparation Steps

- Gather necessary tools and safety gear.

- Ensure a clean and organized workspace.

- Review the user manual for specific instructions.

Assembly Process

- Begin by aligning all components as indicated in the manual.

- Secure parts with bolts and screws, ensuring they are tightened properly.

- Check all connections for stability and proper fit.

- Conduct a final inspection before operating the machinery.

Disassembly Process

- Disconnect power sources to ensure safety.

- Remove components in reverse order of assembly.

- Keep track of all fasteners and small parts for reassembly.

- Inspect parts for wear or damage during disassembly.

Troubleshooting Common Issues

When operating machinery, encountering difficulties is not uncommon. Identifying and resolving these problems promptly can enhance performance and extend the life of your equipment. This section will guide you through some prevalent challenges and their potential solutions.

Engine Performance Problems

Engine issues can manifest in various ways, such as poor starting, reduced power, or unusual noises. Here are some common causes:

- Insufficient fuel supply

- Clogged air filters

- Worn spark plugs

To troubleshoot, check the fuel levels, replace filters as needed, and inspect the ignition system for wear.

Electrical System Failures

Electrical problems can hinder operation and may include dead batteries or faulty connections. Consider the following:

- Check battery charge and connections.

- Inspect fuses for continuity.

- Look for any frayed wires or loose terminals.

Addressing these issues promptly can prevent further complications and ensure smooth functioning.

Aftermarket vs. OEM Parts

When it comes to equipment maintenance, choosing between original and alternative components can significantly impact performance and longevity. Both options offer distinct advantages and potential drawbacks, influencing not only functionality but also cost efficiency.

OEM components are produced by the original manufacturer, ensuring compatibility and quality. They typically come with warranties, providing peace of mind regarding durability. However, this assurance often comes at a higher price.

On the other hand, aftermarket alternatives can be more budget-friendly and may even surpass original specifications in some cases. These parts, made by third-party manufacturers, can enhance performance but may vary in quality. It’s essential to research and choose wisely to ensure optimal functionality.

In conclusion, the ultimate decision between these two types hinges on individual needs, budget constraints, and performance expectations. Careful consideration will lead to the best choice for maintaining your equipment.

Upgrading Your S160 Performance

Enhancing the efficiency and functionality of your equipment can significantly improve its overall performance. By focusing on key components and considering various upgrades, you can achieve a more powerful and reliable machine that meets your specific needs.

First, consider the engine. Upgrading to a more robust power unit can provide increased torque and better fuel efficiency. Additionally, improving the air intake system can enhance combustion and performance.

Next, examine the transmission. A smoother, more responsive transmission allows for better power transfer and improved handling. Installing a high-performance clutch can further enhance this aspect.

Lastly, don’t overlook the importance of the cutting system. Upgrading blades and enhancing the deck can result in a cleaner cut and faster operation, maximizing productivity. Regular maintenance and choosing the right attachments can also contribute to superior performance.

Safety Precautions During Repairs

Ensuring a safe environment during maintenance activities is crucial for both the individual performing the work and the equipment itself. Adhering to safety protocols minimizes risks and enhances overall efficiency.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect power sources before starting any repairs to prevent accidental activation.

- Keep the workspace organized and free of hazards to avoid slips and falls.

- Utilize proper tools designed for specific tasks to ensure effective and safe operation.

By following these guidelines, one can delve into repair tasks with confidence and achieve the ultimate safety and effectiveness during the process.

Where to Access Diagrams Online

Finding detailed schematics and illustrations for machinery is essential for maintenance and repairs. Numerous resources exist online that provide these visual aids, allowing users to efficiently locate the information they need to ensure their equipment operates smoothly.

| Resource | Description |

|---|---|

| Manufacturer’s Website | Official sites often have a dedicated section for manuals and schematics specific to their products. |

| Online Forums | Community-driven platforms where enthusiasts share resources and diagrams related to various machinery. |

| Third-Party Websites | Several independent sites specialize in offering diagrams and repair guides for a range of equipment. |

| Social Media Groups | Facebook and other platforms host groups where users frequently post and exchange helpful visuals. |