In the realm of construction and woodworking, the efficient operation of fastening equipment is crucial for ensuring quality and durability. A comprehensive understanding of the individual elements that make up these tools can significantly enhance their functionality and longevity. Knowing how each component interacts not only aids in effective maintenance but also empowers users to troubleshoot issues that may arise during use.

Familiarity with the various sections of fastening devices helps users grasp their mechanisms and improve their skills. Recognizing the specific functions of each element allows for better decision-making when selecting the right tool for a project. Whether it’s for home renovations or professional construction, a well-informed user can maximize productivity and ensure optimal results.

In this exploration, we will delve into the intricate assembly of fastening machinery, highlighting the roles of various components. By dissecting the structure and function of these elements, individuals can cultivate a deeper appreciation for the technology that drives their projects forward. This knowledge serves as a foundation for effective tool usage and maintenance, ultimately leading to a more successful and satisfying experience in any fastening endeavor.

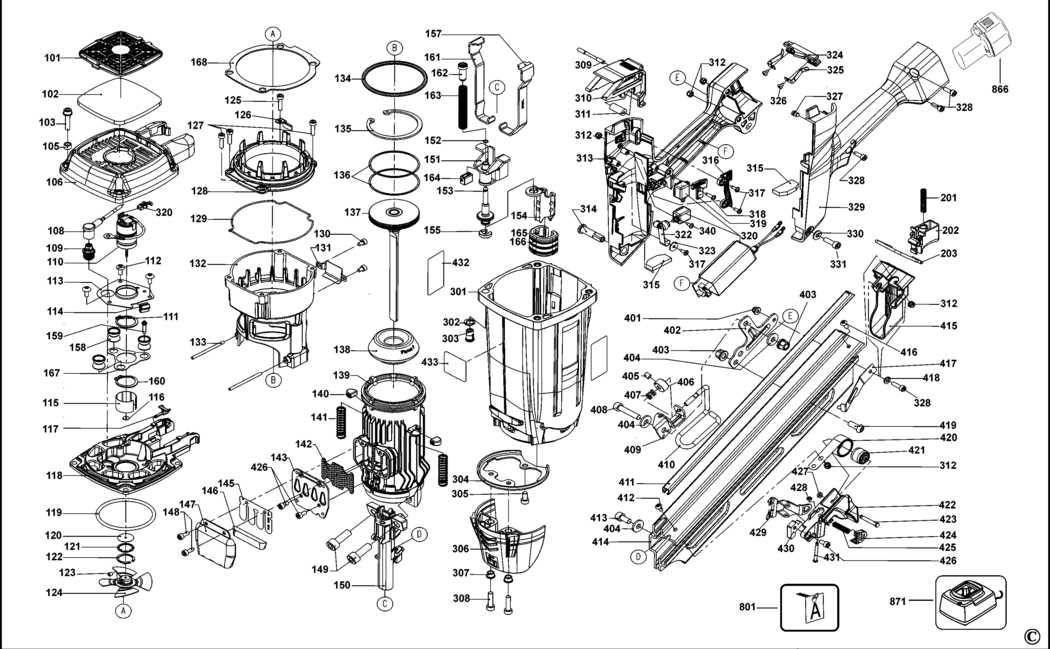

Dewalt Nail Gun Parts Overview

This section provides a comprehensive look at the various components that make up a popular fastening tool. Understanding these elements is essential for effective maintenance and optimal performance.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal mechanisms. |

| Trigger | Activates the tool and controls operation. |

| Magazine | Holds and feeds fasteners into the firing chamber. |

| Motor | Powers the tool’s operation, driving the fasteners. |

| Firing Mechanism | Engages the fastener, ensuring proper placement. |

| Exhaust Port | Releases air and minimizes pressure buildup. |

Essential Components of Dewalt Nail Guns

Understanding the key elements of fastening tools is crucial for both effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality and reliability of the tool. Familiarity with these parts enhances not only the user experience but also ensures safety and efficiency during tasks.

Main Functional Elements

- Motor System: Powers the mechanism, providing the necessary force for driving fasteners.

- Trigger Mechanism: Controls the activation of the tool, allowing for precise usage.

- Drive Assembly: Responsible for delivering fasteners with the required speed and depth.

- Magazine: Holds a supply of fasteners, enabling quick reloading during projects.

- Exhaust Port: Channels away air and debris, ensuring optimal performance and comfort during use.

Safety and Maintenance Features

- Safety Lock: Prevents accidental activation, safeguarding the user.

- Depth Adjustment: Allows customization of fastener depth for various materials.

- Clearing Mechanism: Facilitates easy removal of jams, minimizing downtime.

- Grip and Handle: Designed for comfort and control, reducing user fatigue during prolonged use.

Understanding Nail Gun Functionality

In the world of construction and woodworking, a powerful tool facilitates efficient fastening processes. These devices are engineered to drive fasteners into various materials, significantly enhancing productivity and precision in projects.

Core Mechanisms play a pivotal role in the operation of these tools. The interaction between components ensures that each fastener is deployed with the right force and accuracy, making it essential to grasp their function for effective usage.

Safety Features are also integral to the design, preventing accidental discharge and ensuring user protection during operation. Understanding these elements is crucial for anyone looking to utilize this equipment effectively.

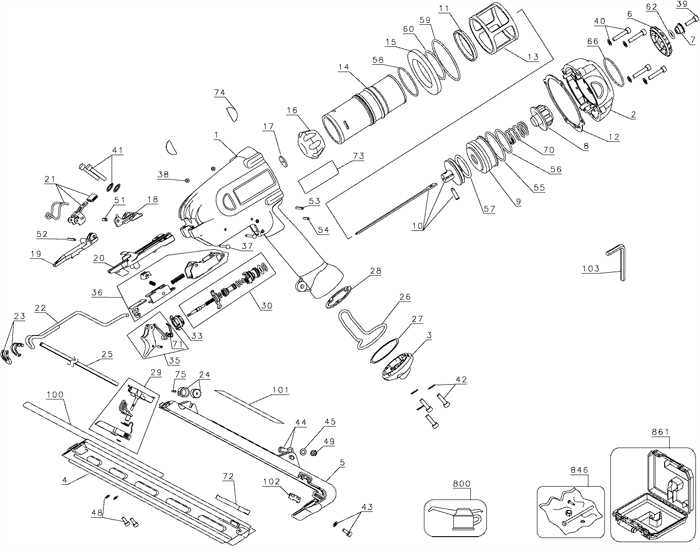

Common Replacement Parts for Maintenance

Regular upkeep of your tool is essential to ensure optimal performance and longevity. Certain components may wear out over time, and being familiar with these can aid in timely replacements and effective maintenance. Here are some common elements that often require attention:

- O-rings: These are crucial for maintaining air pressure and preventing leaks.

- Driver blades: Essential for pushing fasteners into materials, these can dull and require regular replacement.

- Feed mechanism components: These parts help in the smooth feeding of fasteners; they can become jammed or damaged.

- Seals: Vital for preventing air leaks, worn seals can lead to decreased efficiency.

- Trigger assembly: A malfunctioning trigger can affect the tool’s responsiveness and safety.

Identifying and replacing these key components can significantly improve the performance of your equipment. Regular inspection is advisable to catch any wear and tear early on.

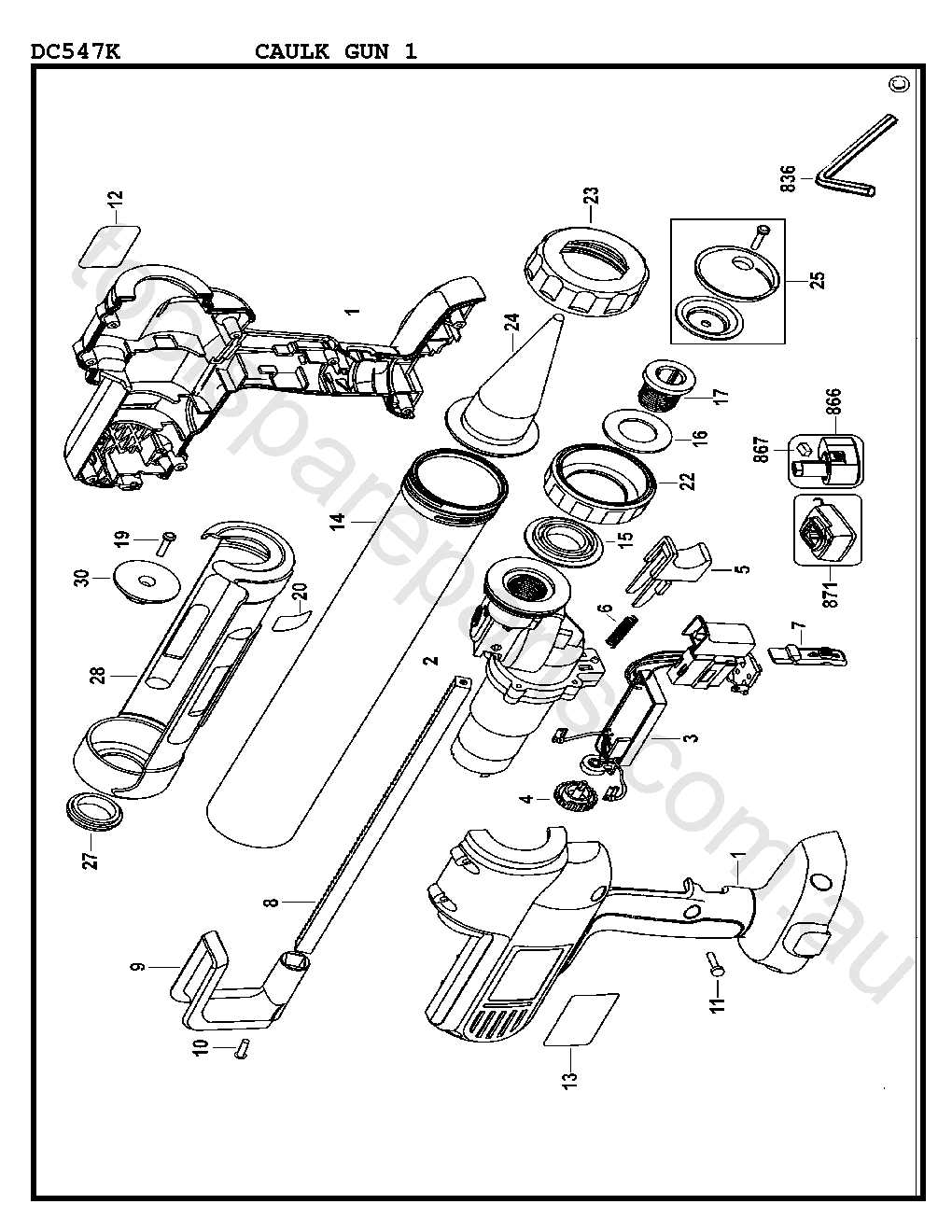

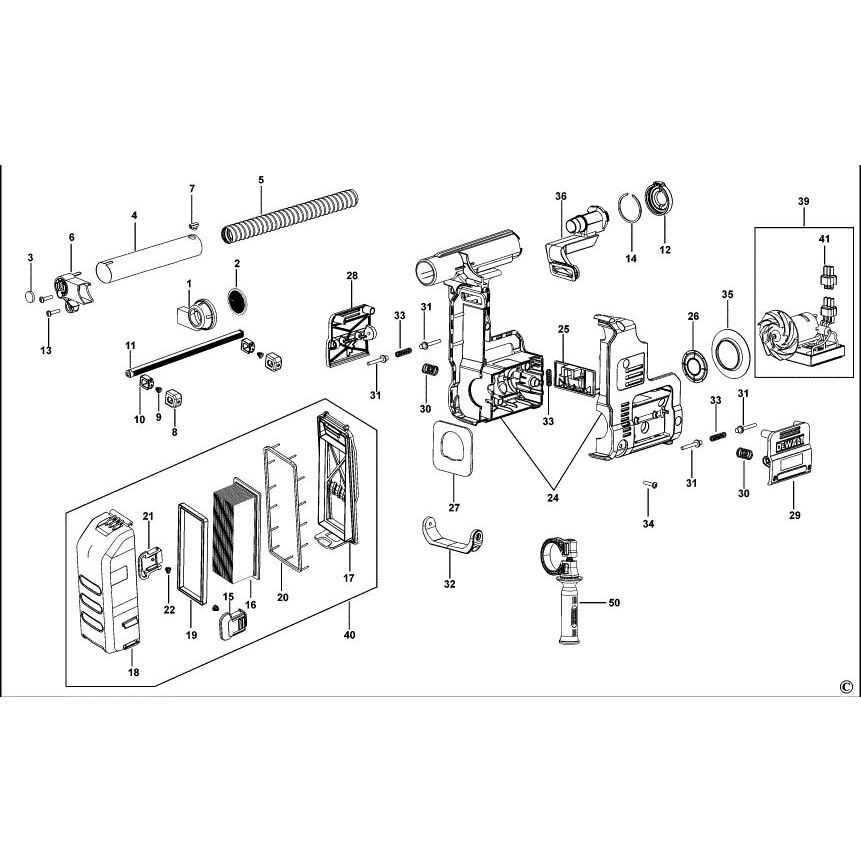

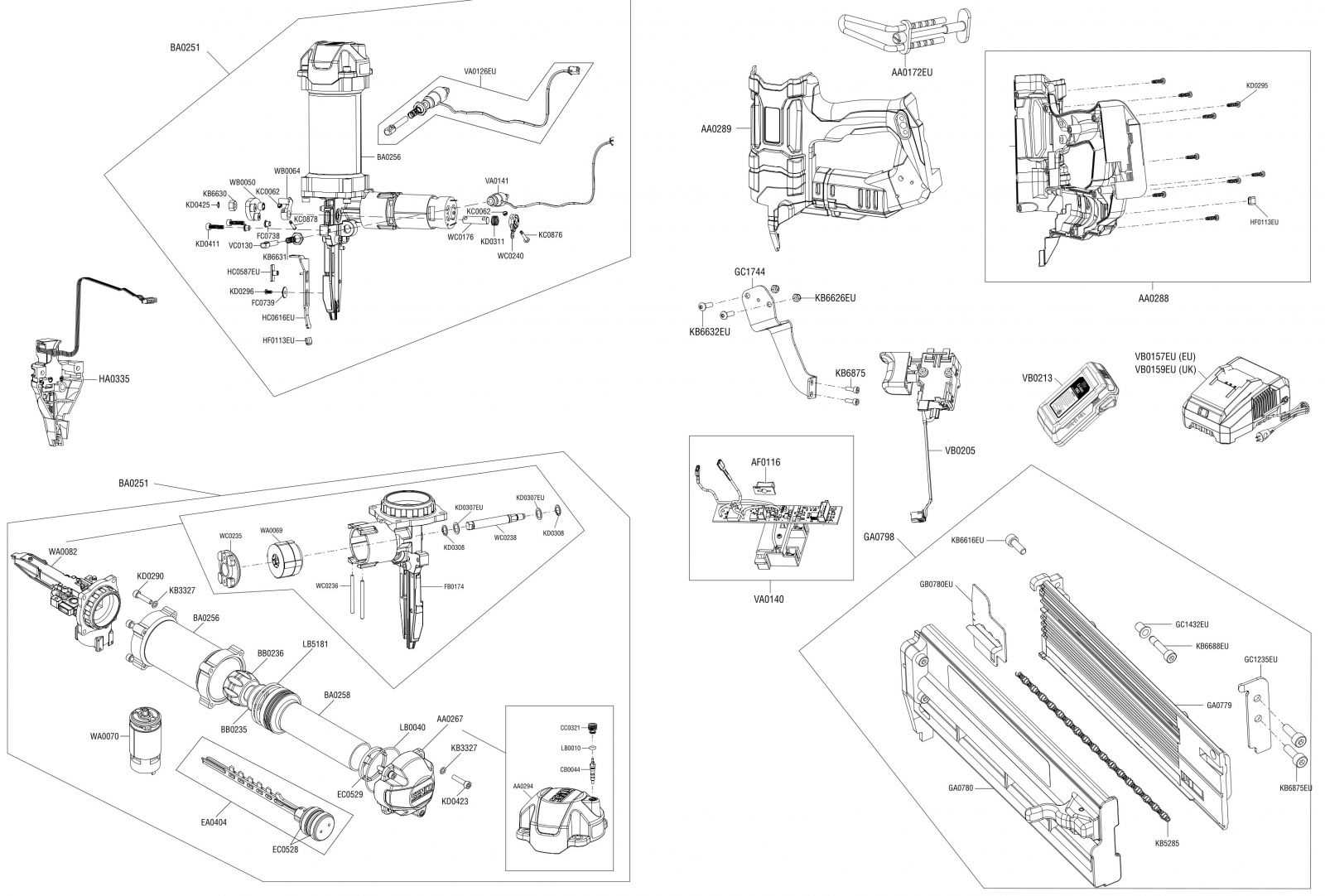

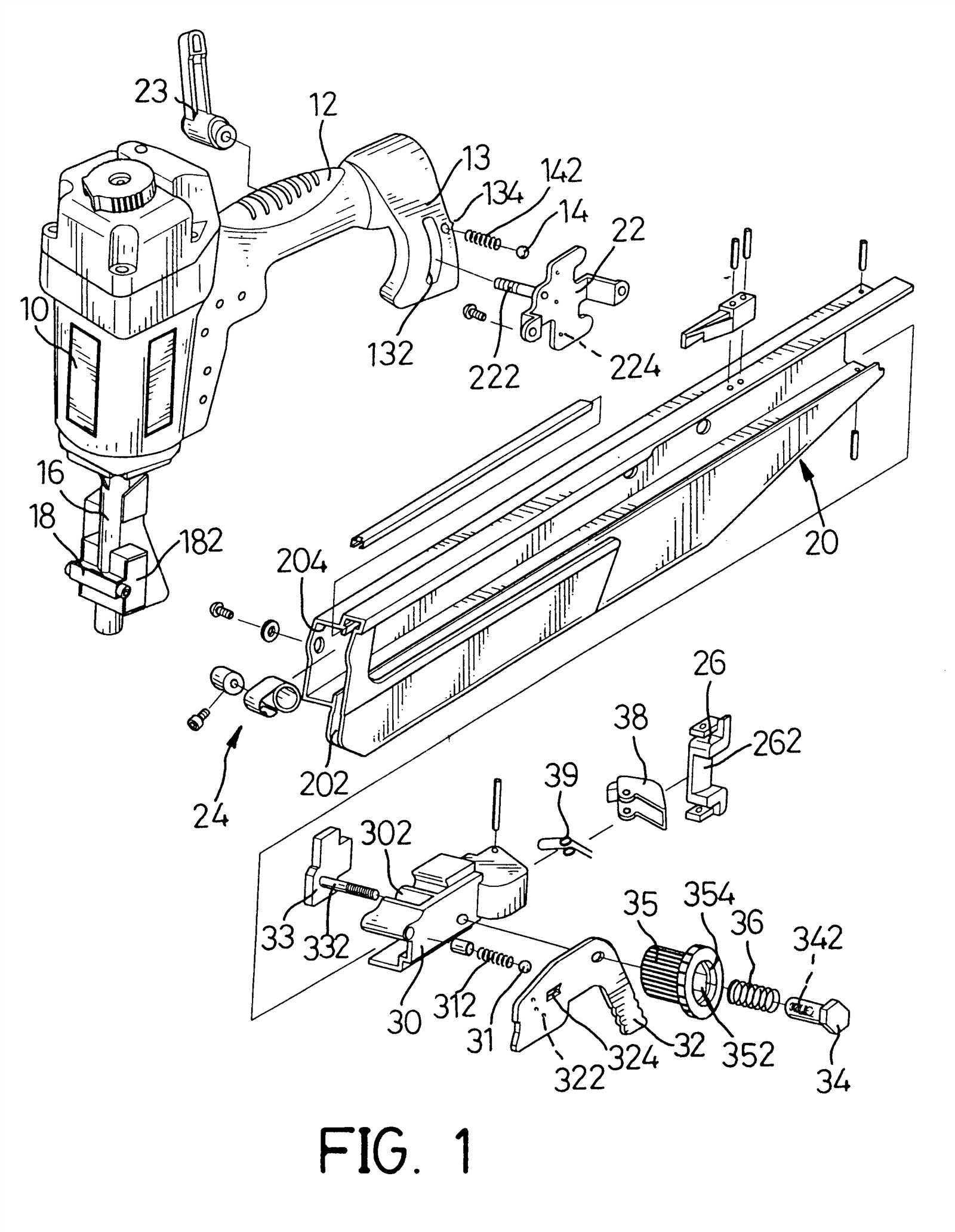

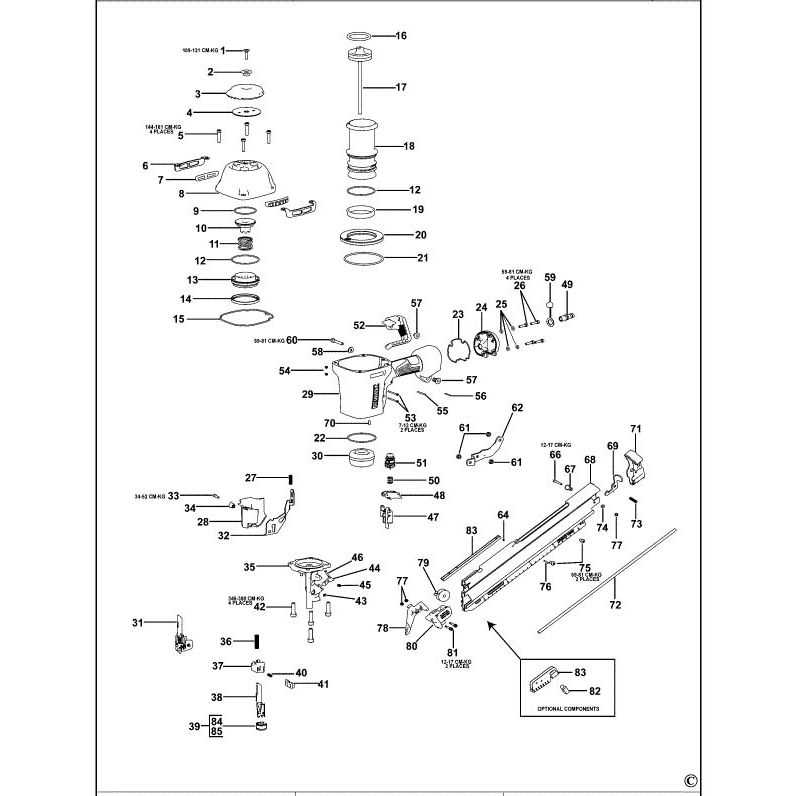

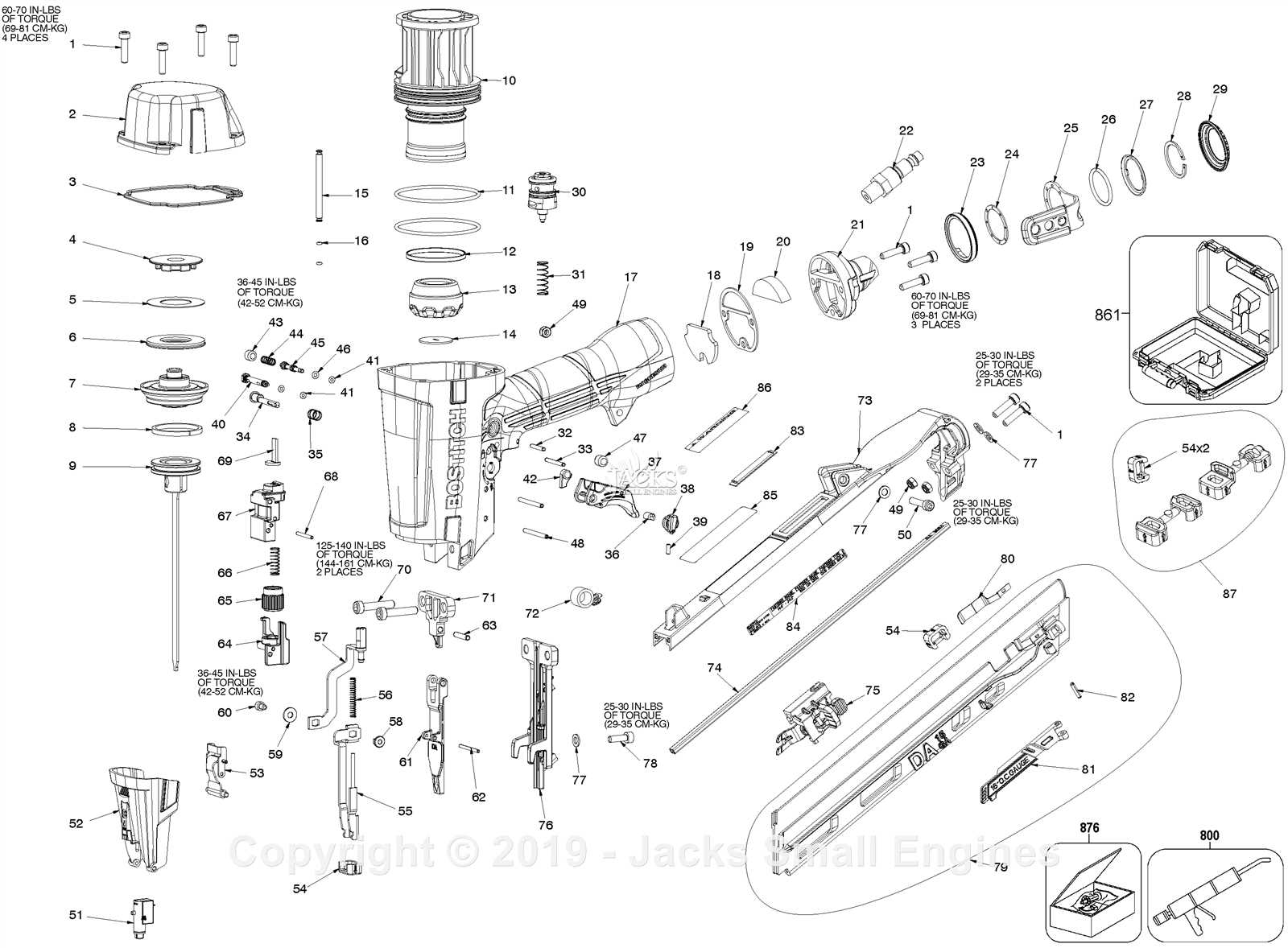

How to Identify Specific Parts

Recognizing the various components of a tool is essential for maintenance and effective operation. Understanding the layout and function of each element ensures proper usage and troubleshooting, making it easier to replace or repair as needed.

Visual Inspection

Start with a thorough visual examination of the tool. Look for identifying markings or labels that indicate specific functionalities. Familiarize yourself with the general structure and layout to aid in locating each item efficiently. Pay attention to shapes, sizes, and connections.

Consulting Manuals and Resources

Utilize user manuals or online resources for detailed descriptions of each component. These documents often include diagrams that can guide you in identifying parts. Cross-reference the visuals with your inspection to ensure accuracy in identification. If uncertain, consider reaching out to community forums or professionals for assistance.

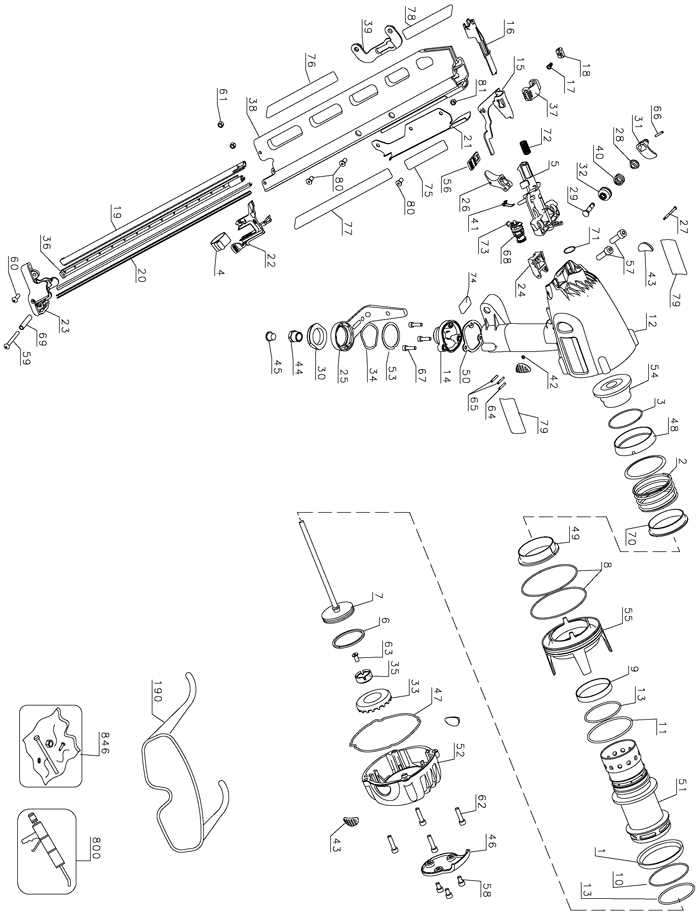

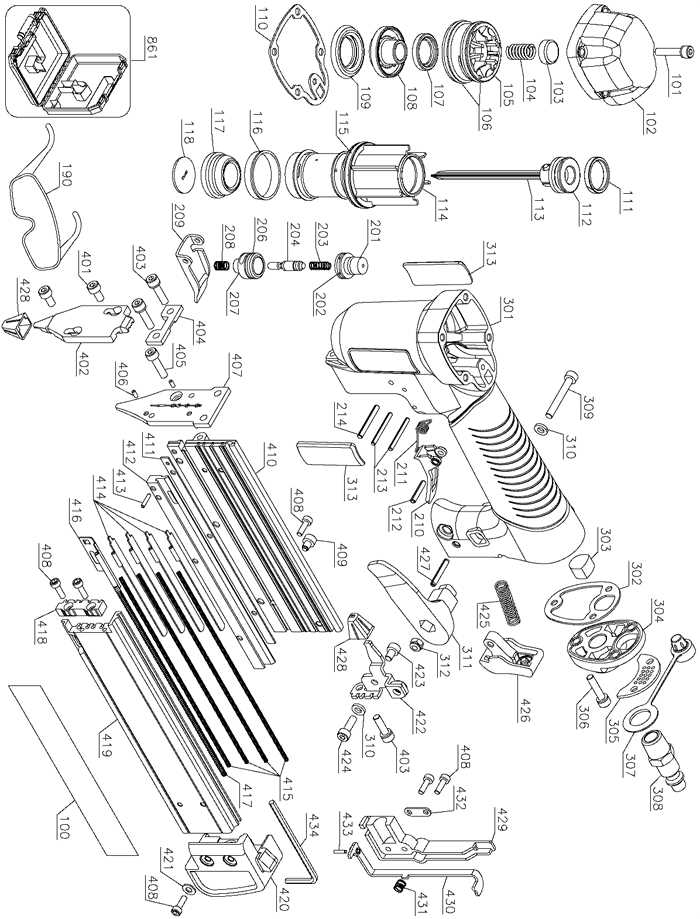

Visual Guide to Parts Diagram

This section offers an informative overview designed to enhance understanding of tool components and their functions. By utilizing a clear visual reference, users can better navigate the assembly and maintenance processes, ensuring optimal performance and longevity.

Identifying Components: Each segment of the tool plays a crucial role in its operation. Familiarizing yourself with these elements allows for more effective troubleshooting and repairs.

Maintenance Tips: Regular inspection and understanding of each section will aid in preventing common issues. Staying aware of wear and tear can significantly extend the lifespan of your equipment.

Safety Features in Nail Gun Design

Modern fastening tools are equipped with a variety of safety mechanisms designed to protect users from potential hazards. These features not only enhance user confidence but also significantly reduce the risk of accidents during operation. Understanding these safety elements is crucial for anyone using these powerful devices.

Key Safety Mechanisms

- Sequential Triggering: This system requires the user to press the trigger and the tool against the material simultaneously, ensuring that fasteners are only deployed when intended.

- Contact Safety Mechanism: This feature prevents accidental discharge by requiring constant pressure on the tool’s tip before a fastener can be released.

- Depth Adjustment: Allows users to control the penetration depth, minimizing the risk of over-driving and potential injury.

- Automatic Reset: Tools equipped with this feature reset after a jam, reducing the need for manual intervention and potential mishaps.

Additional Safety Considerations

- Always wear appropriate personal protective equipment, including eye protection and hearing protection.

- Regularly inspect and maintain the tool to ensure all safety features are functioning correctly.

- Follow manufacturer guidelines and safety instructions to maximize safe usage.

Tools Needed for Repair and Maintenance

Effective upkeep and troubleshooting of your equipment require a selection of essential instruments. Having the right tools at hand ensures smooth operations and prolongs the life of your devices.

- Wrenches: For tightening and loosening various components.

- Screwdrivers: A variety of sizes and types are crucial for different screws.

- Replacement parts: Stock up on necessary components for quick fixes.

- Lubricants: Essential for maintaining smooth functionality and reducing wear.

- Cleaning supplies: Brushes and cloths help keep your tools in optimal condition.

By ensuring you have these tools available, you can easily tackle maintenance tasks and perform repairs as needed.

Common Issues and Troubleshooting Tips

In the realm of power tools, encountering difficulties is not uncommon. Understanding typical challenges and their solutions can significantly enhance performance and prolong the life of your equipment. This section outlines frequent problems along with practical advice to help you resolve them effectively.

Frequent Problems

- Inconsistent fastener placement

- Jamming of materials

- Failure to power on

- Leakage of compressed air

- Excessive noise during operation

Troubleshooting Steps

- Check Power Source: Ensure that the device is properly connected or charged. Inspect the outlet for any issues.

- Clear Jams: If materials are stuck, carefully remove them following the manufacturer’s instructions to prevent damage.

- Inspect for Wear: Examine components for signs of wear or damage. Replace any faulty parts to restore functionality.

- Adjust Settings: Review and adjust settings according to the specifications for different materials.

- Regular Maintenance: Schedule routine inspections and cleanings to keep the tool in optimal condition.

By familiarizing yourself with these common issues and their respective solutions, you can ensure efficient operation and minimize downtime.

How to Access Internal Components

Gaining entry to the inner workings of your tool requires careful attention and the right approach. Understanding the assembly and mechanisms involved is crucial for maintenance and troubleshooting. Proper disassembly not only ensures safety but also allows for effective inspection and replacement of components.

Begin by disconnecting the power source to avoid any accidental activation. Use the appropriate tools to remove outer casings, which typically involve screws and clips. Keep track of all fasteners to facilitate reassembly. Once the exterior is off, identify the internal elements you wish to inspect, taking note of their positioning and connections. This methodical approach will streamline the process and help prevent damage to sensitive parts.

After completing your checks or replacements, reverse the disassembly steps to restore your equipment. Ensure everything is secure and reconnected before reconnecting the power source. Following this guide will help maintain optimal performance and longevity of your device.

Benefits of Genuine Dewalt Parts

Using authentic components for your tools offers numerous advantages that significantly enhance performance and longevity. By opting for original materials, you ensure reliability and efficiency in your projects, which ultimately leads to better results and a smoother working experience.

Quality Assurance

One of the primary benefits of selecting original components is the guarantee of quality. Authentic items undergo rigorous testing to meet high standards, ensuring that they perform optimally in various conditions. This quality assurance translates to:

- Enhanced durability

- Consistent performance

- Reduced likelihood of failures

Perfect Compatibility

Genuine components are designed specifically for your equipment, ensuring perfect compatibility. This compatibility results in:

- Smoother operation

- Better fit and function

- Minimized wear on other components

By investing in original materials, you protect your tools and enhance their efficiency, ultimately saving time and money in the long run.

Where to Find Replacement Parts

Locating components for your tools can enhance their longevity and performance. There are various avenues to explore when seeking the right items for your equipment, ensuring that you can maintain its functionality effectively.

Online Resources

- Official Manufacturer Websites

- Specialized Retailers

- E-commerce Platforms

Local Options

- Home Improvement Stores

- Tool Repair Shops

- Surplus Stores