Understanding the structure and assembly of a power tool is essential for both maintenance and repair tasks. Knowing how each piece fits together and operates within the machine can greatly enhance its lifespan and functionality. In this section, we delve into the key elements that make up a specific type of equipment, focusing on its mechanical setup and the role of various components.

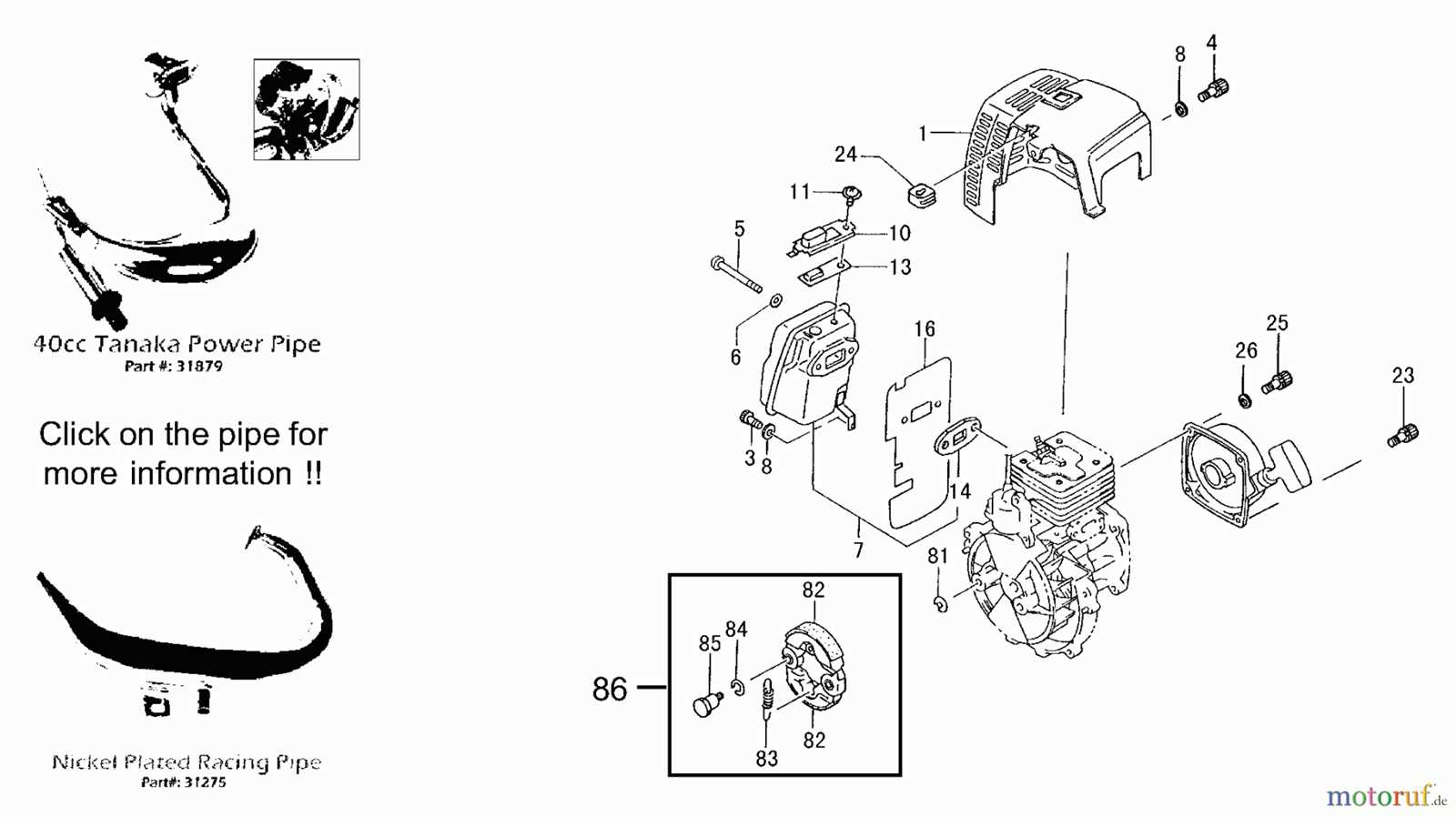

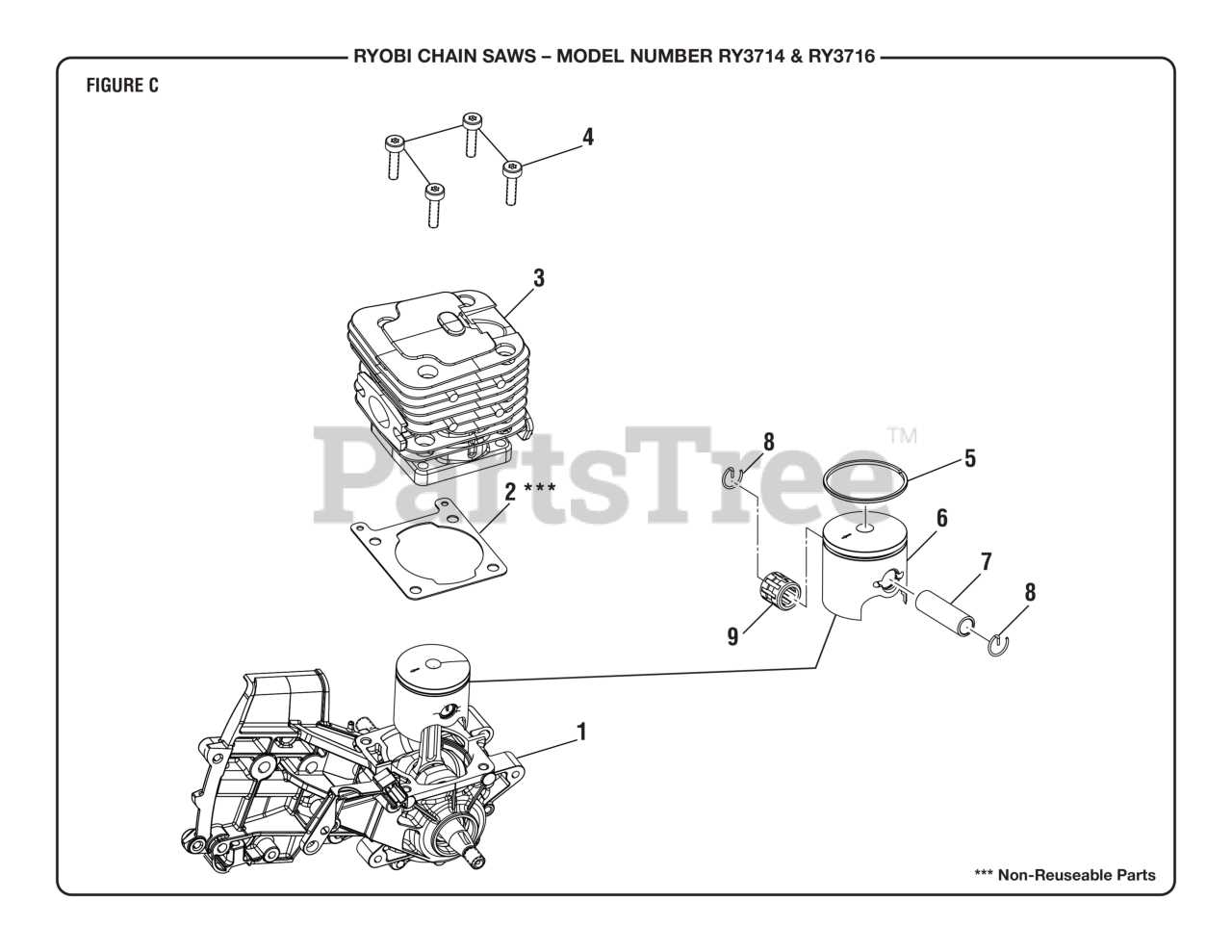

Detailed schematics serve as a visual representation, providing a clear overview of how each part interacts with the others. Whether it’s for troubleshooting or routine maintenance, having access to a comprehensive guide can help identify where issues may arise and how to address them effectively.

Efficient disassembly and reassembly of a tool require a solid understanding of its layout. By referring to detailed illustrations, users can confidently tackle problems, ensuring that repairs are both precise and safe. This kind of knowledge helps in prolonging the tool’s operational efficiency, allowing it to continue performing at its best.

Understanding the Ryobi Ry3714 Components

When dealing with power tools, knowing the individual elements that make up the machine is essential for proper operation and maintenance. These tools consist of various components that work in unison to achieve optimal performance. Each piece plays a crucial role in ensuring the tool runs smoothly, and understanding their function helps users troubleshoot and maintain the equipment more effectively.

Main Assembly Parts

The core of any device is its assembly structure. It typically consists of the motor, housing, and key mechanisms responsible for movement. These components interact to convert energy and perform the intended task. Maintenance often requires checking for wear or damage in these areas to prolong the life of the machine.

| Component | Description |

|---|---|

| Motor | Converts electrical energy into mechanical energy, powering the tool. |

| Housing | Protects internal components and provides a safe enclosure for users. |

| Trigger | Acts as the control mechanism for starting and stopping the tool. |

Additional Mechanisms

Other essential elements include safety features, adjustment settings, and connectors. These parts allow the user to fine-tune the tool’s performance, while also ensuring safe usage during operation. Regular checks on these mechanisms are important for avoiding malfunctions and ensuring that the equipment operates within safety guidelines.

| Component | Description |

|---|---|

| Safety Lock | Prevents accidental activation of the tool for user safety. |

| Adjustment Mechanism | Allows fine-tuning of the tool’s functionality for specific tasks. |

| Connectors | Ensure secure attachment of various components to each other. |

Key Features of Ryobi Ry3714 Model

The model under discussion is a well-crafted tool designed for versatility and efficiency in various tasks. It incorporates several practical features that make it an excellent choice for both DIY enthusiasts and professionals. The design prioritizes user comfort, while offering robust performance for various applications.

- Durable and lightweight construction for easy handling during extended usage.

- Powerful motor, ensuring consistent performance across different tasks.

- Adjustable components for flexibility and ease of use in different working conditions.

- Safety mechanisms built in to protect the user during operation.

- Compact design for portability and easy storage when not in use.

This model emphasizes practicality without compromising on reliability, offering high efficiency for both small and large projects alike. Whether for personal use or professional applications, its features make it a versatile addition to any toolbox.

Exploring the Internal Mechanism of Ry3714

The inner workings of this tool are crafted to deliver exceptional performance, combining robust engineering and precise functionality. Understanding the components that drive its efficiency reveals the complexity behind the seamless operation. From its power source to the intricate gear assemblies, every element has a specific role in ensuring smooth operation and longevity. This section delves into the structure that makes the tool a reliable choice for various tasks.

Power and Drive Mechanism

At the heart of the tool lies the power system, which converts electrical energy into mechanical motion. This conversion is achieved through a series of interconnected components that work in harmony to generate sufficient torque. The motor plays a central role in initiating the motion, which is then transmitted through the drive shaft to the operational parts. Key to maintaining efficiency is the gear mechanism, which modulates the speed and power distribution to ensure consistent results.

Operational Assembly and Components

Several critical assemblies contribute to the tool’s functionality, each working together to perform its specific task. The intricate arrangement of gears, levers, and support structures allows the tool to handle various challenges effectively. The interaction between these elements ensures a seamless user experience, enabling easy adjustments and reliable performance throughout its lifespan.

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical power |

| Gear Mechanism | Modulates speed and power distribution |

| Drive Shaft | Transfers motion from the motor to operational components |

| Levers | Enable manual control and adjustments |

Detailed Breakdown of Ryobi Ry3714 Parts

Understanding the various components of a power tool is essential for ensuring its optimal functioning and efficient maintenance. By dissecting each element, users can better comprehend how the tool operates, identify potential issues, and perform necessary repairs. This breakdown will focus on the critical pieces that contribute to the overall performance of the machine, providing a clearer insight into its internal structure and assembly.

Main Functional Elements

The core functionality of this device relies on several key components working in harmony. These include the motor, the housing that encases the internal mechanisms, and the various moving parts that facilitate its operation. Each of these plays an important role in delivering power and efficiency. Below is a detailed view of some of the most crucial pieces.

| Component | Description |

|---|---|

| Motor Assembly | Responsible for generating the force needed to operate the tool. It converts electrical energy into mechanical motion. |

| Housing | Protects the internal parts and provides structural integrity. Often made from durable plastic or metal for added protection. |

| Handle | Provides grip and control, ensuring stability during operation. Designed for comfort and ease of use. |

| Switch Mechanism | Enables the user to turn the device on and off. Includes safety features to prevent accidental activation. |

| Cutting Mechanism | The part responsible for the actual cutting, whether it be a blade, chain, or other specialized tool. |

Maintenance Considerations

Regular upkeep of these components is critical to prolong the life of the tool and maintain its functionality. Over time, wear and tear can occur, especially in moving parts like the cutting mechanism and motor. Regular inspection, cleaning, and lubrication of these elements will help ensure the equipment remains in peak condition.

How to Identify Ry3714 Replacement Parts

Recognizing which components need to be replaced in a machine can significantly extend its lifespan and ensure smooth operation. The process of determining suitable replacements requires a keen eye for detail and understanding how various elements fit and work together. By examining the equipment thoroughly and cross-referencing it with available resources, you can easily identify the necessary components for maintenance.

Start by inspecting the tool to find any worn or damaged areas. Pay attention to moving parts, connectors, and other elements that frequently undergo stress. If certain areas show signs of wear, they may require replacement. It’s also useful to consult the manual or trusted resources for reference on which specific elements correspond to your equipment.

Matching components with your tool is a critical step. Ensure that the replacement is designed for your specific model to avoid compatibility issues. Always verify the specifications such as size and material to confirm a perfect fit. Using exact matches ensures optimal performance and extends the life of your equipment.

When choosing new elements, consider quality and durability. Opt for original or well-reviewed alternatives that guarantee reliability and precision. This will minimize the risk of malfunction and ensure your machine continues to operate effectively for years to come.

Common Issues with Ryobi Ry3714 Tools

Like many mechanical devices, chainsaws can experience various issues over time due to regular use and wear. Identifying common problems and knowing how to address them can help prolong the life of your tool and ensure it operates efficiently. Below are several frequently encountered issues along with potential solutions.

| Issue | Potential Cause | Solution | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Won’t Start | Fuel problems, clogged air filter, or faulty spark plug | Check fuel level and quality, clean or replace air filter, inspect and replace spark plug if necessary | ||||||||||||||||||||

| Poor Cutting Performance | Dull or improperly tensioned chain | Sharpen or replace the chain, adjust chain tension | ||||||||||||||||||||

| Overheating | Blocked air vents or lack of lubrication | Clear air vents, check oil levels, and ensure proper lubrication | ||||||||||||||||||||

| Excessive Vibration | Loose components or worn-out anti-vibration mounts | Tighten loose parts, replace damaged mounts |

| Component Name | Description | Location | |||||

|---|---|---|---|---|---|---|---|

| Engine Block | The heart of the machine, responsible for driving the cutting mechanism. | Central section | |||||

| Fuel Tank | Stores fuel for the engine, ensuring continuous operation. | Rear section | |||||

| Guide Bar | The metal bar that guides the cutting chain during operation. | Front section | |||||

| Chain Tensioner |

Maintenance Tips for Extended Part LifeEnsuring longevity and optimal performance of your equipment requires consistent care and regular upkeep. Proper maintenance not only prevents unexpected breakdowns but also maximizes efficiency over time. Implementing a few simple strategies can significantly enhance the durability of various components, reducing the need for frequent replacements.

|