The intricacies of large power units play a vital role in the performance and longevity of various vehicles and machinery. Knowledge of how different components interconnect and function can significantly enhance maintenance and repair efficiency. This understanding is crucial for both professionals and enthusiasts alike, as it provides insights into troubleshooting and optimizing engine operations.

Within the realm of heavy machinery, a particular focus on specific configurations can unveil critical information about operational efficiency and potential areas of improvement. By exploring the arrangement of essential elements, users can better appreciate the complexities involved in ensuring peak performance. This exploration not only fosters a deeper understanding but also aids in the identification of potential issues before they escalate.

Engaging with component layouts allows for a comprehensive view of mechanical systems, paving the way for informed decisions regarding repairs and upgrades. A clear grasp of these configurations can lead to enhanced reliability and effectiveness, ultimately contributing to the smooth operation of the entire engine. As we delve into these arrangements, the ultimate goal is to empower users with the knowledge necessary to maintain and enhance their mechanical assets.

Overview of Detroit Diesel Series 60

This section provides a comprehensive look at a renowned engine model that has established its reputation in various industries. Known for its robust performance and reliability, this power unit has become a go-to choice for many applications.

Key features include:

- High torque output

- Fuel efficiency

- Durable construction

These attributes make it suitable for:

- Commercial transportation

- Construction equipment

- Marine applications

Understanding the components and functionality is essential for optimal operation and maintenance.

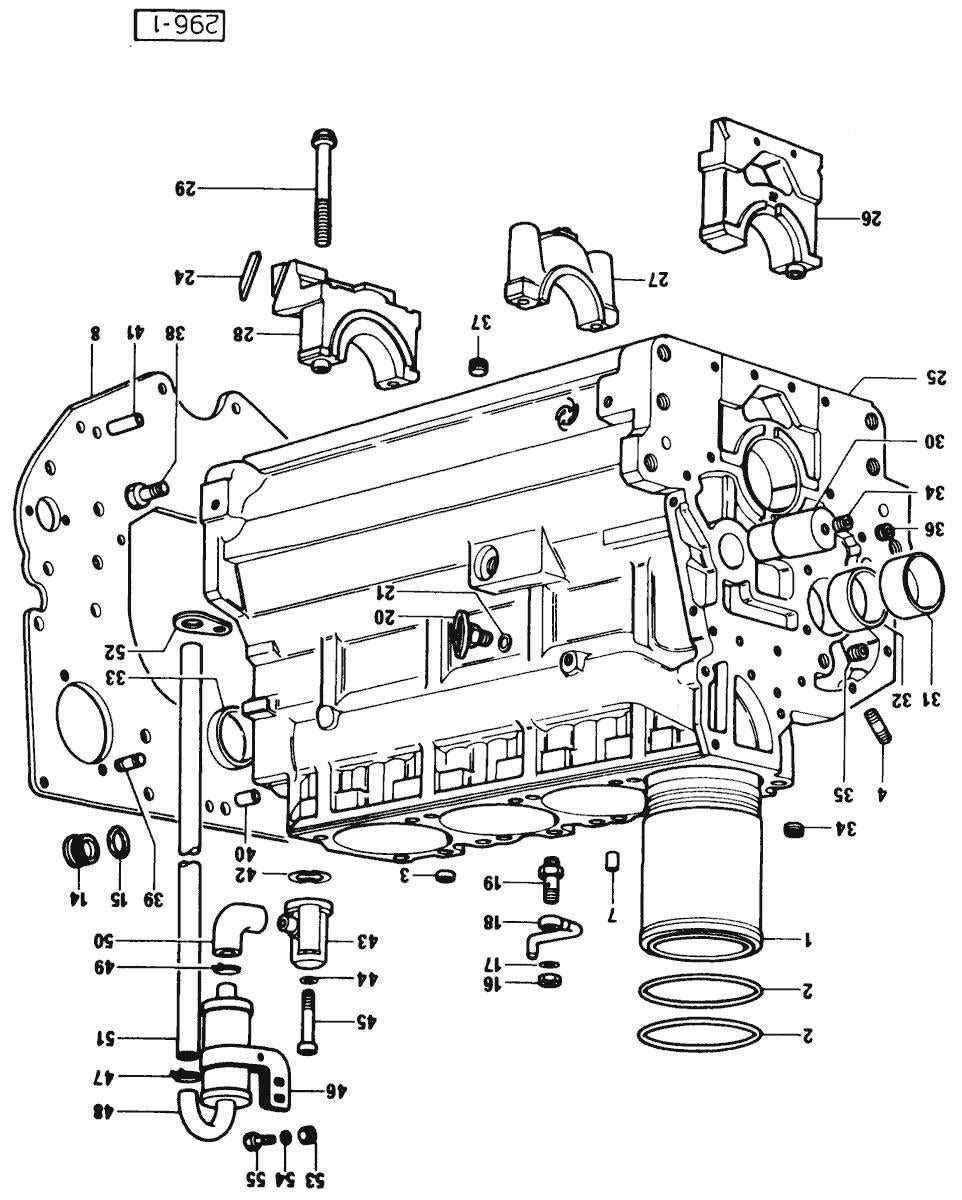

Key Components of Series 60 Engine

This section explores the fundamental elements that make up this renowned power unit, highlighting their roles and significance in ensuring optimal performance and reliability.

- Cylinders: The core of the engine where combustion occurs, contributing to overall power output.

- Pistons: Vital components that convert combustion energy into mechanical work.

- Crankshaft: Transforms the linear motion of the pistons into rotational energy to drive the vehicle.

- Turbocharger: Enhances engine efficiency by forcing additional air into the combustion chamber.

- Fuel Injectors: Precisely deliver fuel into the combustion chamber for effective ignition and performance.

Understanding these components helps in grasping the ultimate functionality of the engine and its overall impact on vehicle operation.

Importance of Parts Diagrams

Understanding the components of a mechanical system is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for technicians, enabling them to identify and locate individual elements efficiently. This clarity enhances workflow and minimizes the risk of errors during service tasks.

Facilitating Repairs

When addressing issues, having access to detailed visuals can significantly improve the repair process. Key benefits include:

- Quick identification of faulty components.

- Streamlined assembly and disassembly procedures.

- Enhanced understanding of complex systems.

Training and Education

Visual aids play a vital role in training new technicians. They help in:

- Providing a clear learning resource.

- Improving retention of information.

- Fostering confidence in handling repairs.

How to Read Engine Diagrams

Understanding technical schematics can significantly enhance your ability to work on machinery. These visuals provide a detailed representation of components and their relationships, allowing you to troubleshoot and repair effectively. Mastering this skill is crucial for anyone involved in engine maintenance.

Identifying Components

Begin by familiarizing yourself with common symbols used in schematics. Each element usually corresponds to a specific part, which can vary based on the engine type. Make a list of symbols and their meanings for quick reference as you delve into the information.

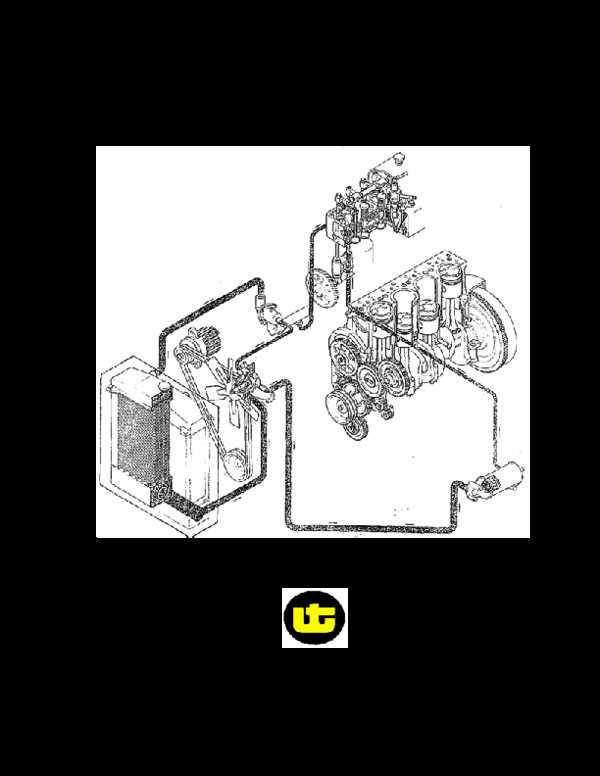

Interpreting Connections

Next, focus on how components are interconnected. Lines often represent various types of links, such as electrical wiring or fluid pathways. Follow these connections to understand the overall function of the system and pinpoint potential issues.

Common Issues and Solutions

Understanding the typical challenges associated with heavy machinery can significantly enhance maintenance and operational efficiency. Various components may encounter difficulties, leading to performance degradation or even complete failure. Identifying these issues early and knowing how to address them can save time and resources.

1. Overheating: One frequent problem is overheating, often caused by inadequate coolant levels or a malfunctioning radiator. Regularly checking and maintaining coolant levels, as well as inspecting the radiator for blockages, can help mitigate this issue.

2. Oil Leaks: Oil leaks can arise from worn gaskets or seals. Regular inspections and timely replacements of these components are essential to prevent potential engine damage and maintain optimal performance.

3. Fuel System Problems: Blocked fuel filters or failing injectors can lead to poor engine performance. Ensuring that filters are replaced at regular intervals and using quality fuel can help reduce the risk of these issues.

4. Electrical Failures: Electrical problems, such as a dead battery or faulty wiring, can disrupt operation. Regularly checking battery health and ensuring connections are secure can help avoid unexpected breakdowns.

5. Exhaust System Issues: Blockages or leaks in the exhaust system can lead to increased emissions and reduced efficiency. Routine inspections of exhaust components and prompt repairs can maintain optimal engine performance.

By being aware of these common issues and implementing preventive measures, operators can ensure the longevity and reliability of their equipment.

Maintenance Tips for Series 60

Ensuring optimal performance of your engine requires regular upkeep and attention. Adopting a proactive maintenance routine can significantly extend the lifespan of your machinery while enhancing efficiency. Here are essential tips to keep in mind for effective care.

Regularly check and change the oil to maintain proper lubrication and prevent wear. Monitor fluid levels consistently, including coolant and transmission fluid, to avoid overheating and mechanical issues. Clean or replace air and fuel filters to ensure smooth operation and optimal fuel efficiency.

Inspect belts and hoses for signs of wear or damage, and replace them as necessary to prevent breakdowns. Pay attention to the exhaust system and ensure it is free from obstructions, which can lead to performance drops. Additionally, conduct routine checks on electrical systems to prevent starting issues.

Lastly, follow the manufacturer’s recommendations for service intervals and use quality components for replacements. This diligence will ultimately yield better reliability and performance from your engine.

Finding Genuine Replacement Parts

Locating authentic components for your machinery is essential for ensuring optimal performance and longevity. The market is filled with various options, making it crucial to identify reliable sources that provide high-quality alternatives. This section will guide you through the best practices for acquiring genuine items for your engine.

Identifying Authentic Sources

When searching for genuine components, consider the following strategies:

- Research Authorized Dealers: Look for certified distributors who specialize in your engine model.

- Check Manufacturer Websites: Official sites often list approved retailers and provide details on specific items.

- Read Customer Reviews: Feedback from other users can help gauge the reliability of a seller.

Benefits of Using Genuine Components

Opting for authentic items brings several advantages:

- Enhanced Reliability: Genuine components are designed to fit perfectly and perform effectively.

- Longer Lifespan: High-quality alternatives often result in reduced wear and tear.

- Better Warranty Protection: Using approved items may keep your warranty intact.

By prioritizing the acquisition of authentic components, you can ensure the reliability and efficiency of your machinery for years to come.

Aftermarket Options for Series 60

Exploring alternatives in the market can significantly enhance performance and reliability. Many enthusiasts and professionals opt for aftermarket solutions to meet their specific needs, providing flexibility and potential cost savings.

When considering alternatives, it’s essential to evaluate various components that can improve functionality:

- Performance Upgrades: Enhanced filters, tuners, and exhaust systems can lead to improved efficiency and power output.

- Replacement Components: High-quality substitutes for original elements can offer durability and extended lifespan.

- Maintenance Solutions: Aftermarket fluids and lubricants designed for optimal operation can prolong service intervals.

Choosing the right alternatives involves careful research and consideration of compatibility with existing systems. Engaging with trusted suppliers and experienced technicians can facilitate informed decisions, ensuring optimal performance and reliability.

Investing in aftermarket solutions can lead to significant enhancements in both functionality and cost-effectiveness. The right choices will depend on individual preferences and specific operational requirements.

Comparing Different Series 60 Models

This section aims to explore the variations within a specific line of high-performance engines, highlighting their unique characteristics and applications. Understanding these distinctions can guide users in selecting the optimal variant for their needs.

Model Variations

Each variant of this engine series presents distinct features, such as horsepower ratings, torque specifications, and efficiency levels. For instance, some models are tailored for heavy-duty applications, while others excel in fuel efficiency and emissions control.

Applications and Performance

The choice of model often depends on the intended use, ranging from commercial transport to specialized machinery. Comparative analysis of performance metrics can help identify the ultimate fit for specific operational demands, ensuring maximum productivity and reliability.

Impact of Parts Quality on Performance

The quality of components in any mechanical system significantly influences its overall efficiency and reliability. When superior materials and craftsmanship are employed, the machinery operates more smoothly, leading to enhanced performance metrics. Conversely, inferior elements can introduce vulnerabilities, resulting in frequent breakdowns and reduced effectiveness.

Resources for Technical Support

When navigating the complexities of engine maintenance and repair, having access to reliable support resources is essential. Whether you are troubleshooting issues or seeking guidance on installation procedures, the right information can make all the difference in ensuring optimal performance and longevity of your machinery.

Online Forums and Communities

Engaging with online forums dedicated to engine enthusiasts and professionals can provide valuable insights. These platforms often feature discussions on common challenges, solutions, and innovative practices shared by users with varying levels of expertise. Participating in these communities allows you to ask questions and share experiences, fostering a collaborative environment.

Official Documentation and Manuals

Utilizing official documentation is crucial for understanding the specifications and requirements of your equipment. Manuals often include detailed instructions, troubleshooting tips, and maintenance schedules. Accessing these resources can help you stay informed about best practices and ensure that all procedures are performed accurately.

By leveraging both community knowledge and official resources, you can enhance your technical understanding and improve your maintenance strategies.

Community Insights and Experiences

This section highlights the collective wisdom and personal stories from users engaged with a specific engine model. Participants share valuable insights gained from their own encounters, fostering a sense of community and support among enthusiasts and professionals alike.

Shared Knowledge

Contributors often discuss maintenance tips and best practices to ensure longevity and optimal performance. Common themes include:

- Routine maintenance schedules that enhance reliability.

- Recommendations for high-quality replacement components.

- Experiences with various service centers and their expertise.

Challenges Faced

Community members frequently recount obstacles they have encountered, providing learning opportunities for others. Typical challenges include:

- Troubleshooting mechanical issues and their solutions.

- Adapting to changes in technology and updates.

- Finding trustworthy suppliers for essential items.

These shared experiences create a supportive environment where individuals can seek advice and share solutions, ultimately enhancing the overall understanding and enjoyment of the engine’s capabilities.