In the realm of winter maintenance, effective machinery is essential for efficiently managing snowfall. Familiarity with the various elements that contribute to the functionality of such equipment is crucial for both operation and maintenance. This section aims to enhance your understanding of the critical components that ensure optimal performance in challenging weather conditions.

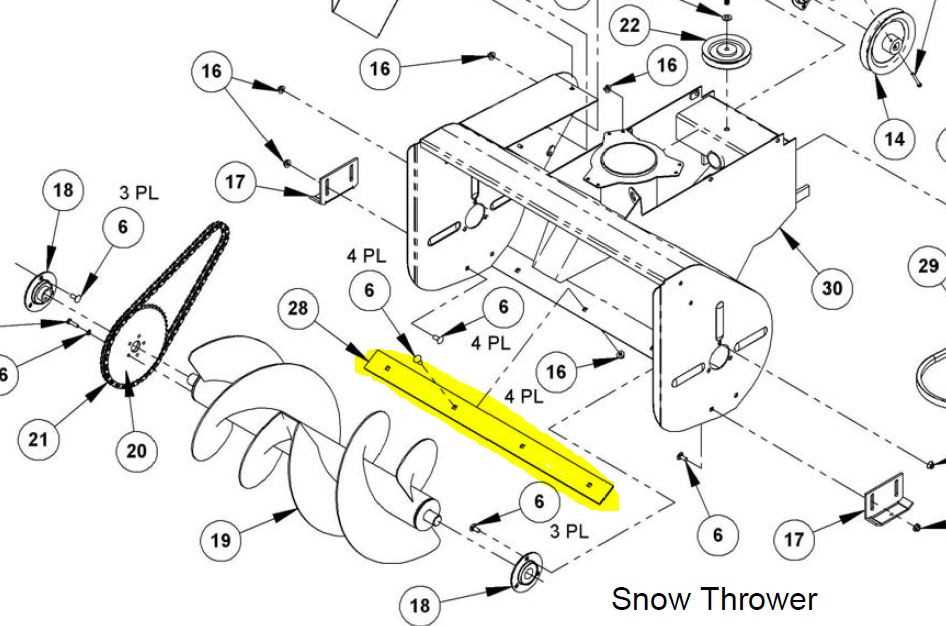

Visualizing the structure of this snow-clearing apparatus allows users to pinpoint specific functionalities and address potential issues. A comprehensive overview of its assembly enables operators to navigate the intricacies of their equipment with confidence, ensuring that they can swiftly address any concerns that arise during use.

By familiarizing yourself with the individual components, you empower yourself to make informed decisions about repairs and upgrades. This knowledge not only enhances operational efficiency but also extends the lifespan of your machinery, ultimately leading to better performance in the long run.

44 Inch John Deere Snowblower Parts

The efficient operation of a snow-clearing machine relies heavily on its individual components. Understanding these elements is essential for maintaining functionality and ensuring optimal performance during winter months. This section will delve into the key components that contribute to the overall efficiency of the equipment.

Key Components:

- Auger: Responsible for gathering and breaking up snow, this component plays a crucial role in the initial clearing process.

- Impeller: This part works to discharge the snow effectively, ensuring that it is expelled away from the area being cleared.

- Skids: Located on the bottom, these elements help control the height at which the equipment operates, allowing for effective maneuverability over different surfaces.

- Gearbox: This mechanism transfers power from the engine to the working components, facilitating smooth operation.

- Chassis: The frame provides structural support and houses all other components, ensuring stability during use.

Familiarity with these essential elements allows for effective maintenance and troubleshooting, ultimately prolonging the lifespan of the machine and enhancing performance during snowy conditions.

Understanding the Snowblower Mechanism

Understanding the operation of a winter clearing device is crucial for effective maintenance and optimal performance. This apparatus consists of various components that work together to facilitate the efficient removal of snow. Each element has a specific role that contributes to the overall functionality, making it essential for users to familiarize themselves with how these parts interact.

Key Components

Several critical components play significant roles in the mechanism of this equipment:

- AUGER: This rotating blade is responsible for gathering the snow and pushing it toward the discharge chute.

- IMPELLER: Once the snow reaches the chute, the impeller expels it away from the machine.

- DRIVE SYSTEM: This system powers the auger and impeller, ensuring smooth operation during use.

- DISCHARGE CHUTE: The chute directs the ejected snow to the desired location, allowing for controlled clearing.

How It Works Together

The effective operation of a winter clearing device relies on the synergy between its various components. When the machine is engaged, the auger rotates, collecting snow and transporting it towards the impeller. The impeller then uses centrifugal force to throw the snow through the discharge chute, where it can be directed away from pathways or driveways. This process repeats as long as the device is in operation, allowing for efficient snow removal.

Familiarizing oneself with the mechanism’s components and their functions can enhance the user’s ability to maintain and troubleshoot the equipment, ensuring reliable performance throughout the winter season.

Key Components of the 44 Unit Model

In this section, we explore the essential elements that define the structure and functionality of the 44 unit. Understanding these core components is crucial for grasping its operational principles and maintenance requirements.

How to Identify Replacement Components

In this section, we will guide you through the process of identifying and selecting the correct replacement components for your equipment. Proper identification ensures that the parts you order fit seamlessly into your machinery, maintaining optimal performance and longevity.

- Start by locating the model number of your equipment. This identifier serves as a crucial reference point in finding compatible replacements.

- Examine the part requiring replacement carefully, noting its unique characteristics and dimensions.

- Refer to the manufacturer’s manual or documentation for specifications and part numbers.

- Compare the identified part with available diagrams or illustrations to confirm its match.

- Consult with authorized dealers or online resources that specialize in your equipment’s replacement parts.

By following these steps, you can confidently acquire the correct replacement components, ensuring your equipment operates at peak efficiency.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Regular maintenance practices can significantly extend its lifespan and enhance its efficiency. Below are essential tips to keep your machinery in excellent condition.

- Regular Inspections: Periodically check all components for signs of wear or damage. Early detection of issues can prevent more extensive repairs.

- Cleaning: Keep the exterior and interior free from debris and dirt. This helps in maintaining airflow and prevents overheating.

- Lubrication: Apply appropriate lubricants to moving parts as recommended in the user manual. This reduces friction and wear.

- Check Belts and Cables: Inspect all belts and cables for signs of fraying or stretching. Replace them if necessary to avoid malfunction.

- Fluid Levels: Regularly check and maintain optimal fluid levels, including fuel and oil. This ensures proper functioning and reduces the risk of damage.

- Storage: When not in use, store the equipment in a dry and protected area to prevent corrosion and damage from the elements.

By following these maintenance tips, you can enhance the reliability and longevity of your machinery, ensuring it operates smoothly for many seasons to come.

Exploring Auger and Impeller Details

Understanding the components that contribute to efficient snow clearing is essential for optimal performance. This section delves into the crucial elements that aid in the effective movement and expulsion of accumulated snow, ensuring seamless operation in various conditions.

The mechanism consists of two primary components that work in unison: the auger, which collects and channels the snow, and the impeller, responsible for propelling it away from the machine. Each of these elements plays a vital role in the overall functionality, and their design impacts efficiency and performance.

| Component | Function | Material |

|---|---|---|

| Auger | Collects and directs snow towards the center | Steel or high-strength composite |

| Impeller | Propels collected snow out of the chute | Durable plastic or metal |

Maintaining these components in top condition is crucial for achieving peak performance. Regular inspections and timely replacements can significantly enhance the effectiveness of the overall system, ensuring a smooth and efficient operation during winter challenges.

Chute Control Assembly Breakdown

This section delves into the components of the chute control mechanism, essential for directing the flow of material during operation. Understanding each part’s function and interrelation is crucial for effective maintenance and troubleshooting.

The chute control assembly consists of several key elements:

- Control Lever: This is the primary interface used by the operator to adjust the chute angle.

- Cable System: A network of cables that transmits the movement from the control lever to the chute.

- Chute Assembly: The structure that directs the expelled material, which can be tilted or rotated based on user input.

- Mounting Bracket: Secures the chute assembly to the main frame, ensuring stability during operation.

- Adjustment Mechanism: Allows for fine-tuning of the chute angle and position to achieve optimal performance.

Regular inspection of these components can prevent operational issues and extend the lifespan of the assembly. Identifying any signs of wear or damage early can facilitate timely repairs.

Belt and Pulley System Guide

The belt and pulley system plays a crucial role in the operation of various machinery, providing the necessary transfer of power between components. Understanding the mechanics of this system can enhance performance and ensure longevity. This guide will explore the essential elements, their functions, and how to maintain them effectively.

At the core of this system are belts, which transmit motion between pulleys. These belts come in various types and sizes, designed to handle different loads and speeds. Pulleys, on the other hand, serve as the connection points, redirecting the force generated by the engine to drive the equipment. The correct alignment and tension of these components are vital for optimal functionality.

Regular inspection is key to preventing wear and tear. Look for signs of fraying or cracking on the belts and ensure that pulleys are free from debris. Proper adjustment of tension is essential; too loose or too tight can lead to premature failure. By adhering to these maintenance practices, you can ensure the reliability of the system and improve overall efficiency.

Proper Installation of Shear Pins

Ensuring the correct installation of shear pins is essential for the smooth operation of your equipment. These components play a vital role in protecting the machinery by breaking under excessive stress, preventing damage to the overall system. Proper handling and installation can significantly enhance the longevity and efficiency of the unit.

Steps for Installing Shear Pins

- Begin by gathering all necessary tools and replacement shear pins.

- Ensure that the equipment is turned off and disconnected from any power source to prevent accidents.

- Remove any existing shear pins carefully, noting their position and orientation.

- Insert the new shear pins into their designated holes, ensuring they fit snugly without excessive force.

- Check for proper alignment and secure the pins in place, confirming they are flush with the surface.

Maintenance Tips

- Regularly inspect shear pins for signs of wear or damage.

- Replace shear pins immediately if they show any signs of breakage or bending.

- Maintain a stock of spare shear pins to avoid downtime during operations.

Common Issues and Troubleshooting Tips

This section addresses frequent problems encountered with the equipment and offers practical solutions to enhance its performance. Understanding these challenges and knowing how to resolve them can save time and improve the efficiency of your machinery.

1. Equipment Fails to Start

If the machinery does not power on, check the fuel level and ensure there are no blockages in the fuel line. Additionally, inspect the ignition system for any issues, such as faulty spark plugs or loose connections. Regular maintenance of these components is essential to prevent starting problems.

2. Ineffective Clearing Performance

In cases where the equipment struggles to clear effectively, examine the condition of the blades and the chute for any obstructions. Ensure that the settings are adjusted correctly for the type of snow being handled. Adjusting the angle of the chute can also significantly impact clearing efficiency. Regularly cleaning and maintaining these areas can enhance overall functionality.

How to Adjust the Skid Shoes

Properly adjusting the skid shoes is crucial for optimal performance and effective operation of your equipment. These components play a significant role in controlling the height of the working edge, ensuring that the machine operates efficiently on various surfaces.

Follow these steps to adjust the skid shoes effectively:

- Gather the necessary tools, including a wrench and measuring device.

- Park the equipment on a flat and stable surface to ensure accurate adjustments.

- Locate the skid shoes on either side of the machine. They are typically secured with bolts.

- Using the wrench, loosen the bolts that hold the skid shoes in place.

- Adjust the skid shoes to the desired height by either raising or lowering them. Make sure both sides are adjusted evenly to maintain balance.

- Once the desired height is achieved, retighten the bolts securely.

- Test the adjustment by running the equipment on the intended surface to ensure proper clearance and functionality.

Regular checks and adjustments of the skid shoes will enhance the longevity of your equipment and improve its overall effectiveness.

Lubrication Points and Grease Fittings

Proper maintenance of outdoor equipment is essential for optimal performance and longevity. One critical aspect of this maintenance is ensuring that all lubrication points and grease fittings are adequately serviced. Regular lubrication minimizes wear and tear on moving components, preventing premature failure and enhancing the efficiency of the machine.

| Location | Type of Lubricant | Frequency of Lubrication |

|---|---|---|

| Pivot points | Grease | Every 50 hours of operation |

| Drive shaft bearings | Grease | Every 100 hours of operation |

| Chain links | Oil | Every 25 hours of operation |

| Wheels and axles | Grease | At the beginning of each season |

Identifying these lubrication points and adhering to the recommended maintenance schedule will significantly contribute to the reliability and effectiveness of your equipment.

Where to Find Compatible Parts

Locating the right components for your equipment can significantly enhance its functionality and longevity. Whether you’re looking for replacements or upgrades, several avenues exist to help you find the necessary items without hassle.

Online Retailers

Numerous online retailers specialize in machinery components, offering a vast selection for various models. Websites such as Amazon and eBay provide user reviews and ratings that can assist in making informed decisions. Additionally, specialized websites dedicated to outdoor equipment often feature extensive inventories and detailed descriptions.

Local Dealers and Repair Shops

Your local dealers and repair shops can be invaluable resources. They not only stock a range of components but also possess the expertise to recommend suitable options for your specific model. Establishing a relationship with these professionals can lead to reliable advice and potential discounts on future purchases.