Understanding the essential elements of a machine and how they are interconnected is crucial for efficient maintenance and repairs. A well-structured layout of the various components helps users quickly identify specific elements and address any issues that may arise over time. Whether you’re performing routine upkeep or tackling a more involved repair, having access to accurate schematics can make the process much smoother.

Each mechanical system consists of numerous interconnected pieces that work together to ensure optimal functionality. By familiarizing yourself with the arrangement and function of these elements, you can better anticipate potential wear and tear, as well as diagnose issues more effectively. This guide aims to provide a clear and concise breakdown of how these components are organized.

Efficiency and longevity are closely tied to proper understanding and upkeep of individual elements within the system. This detailed review will aid in visualizing their positioning and relationships, ensuring that each unit continues to operate at its best, even in demanding conditions.

Honda HS55 Snowblower Overview

This powerful outdoor equipment is designed to tackle even the harshest winter conditions with ease. Built for efficiency and durability, it ensures optimal performance when clearing large amounts of snow. Its robust design allows for consistent operation in extreme weather, making it a reliable choice for managing snowfall.

Key Features

Equipped with a variety of practical features, this model provides effective and efficient snow removal. Its engine delivers consistent power, while the adjustable components allow for precise control, enhancing usability for both residential and commercial settings.

| Feature | Description | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Power | Reliable motor with optimal horsepower for smooth operation in cold conditions. | |||||||||||||||||||||||||||||||||||||

| Clearing Width | Wide clearing path, allowing you to remove snow quickly from large areas. | |||||||||||||||||||||||||||||||||||||

| Adjustable Chute | Allows for easy direction control of the discharged snow, improving accuracy and flexibility. | |||||||||||||||||||||||||||||||||||||

| Durability | Constructed with high-quality materials to withstand long-term use in harsh environments. |

| Component | Function |

|---|---|

| Engine | Provides power for both propulsion and snow clearing mechanisms. |

| Drive System | Regulates movement and speed control. |

| Auger | Breaks up snow and feeds it toward the discharge system. |

| Impeller | Throws snow through the chute to clear paths efficiently. |

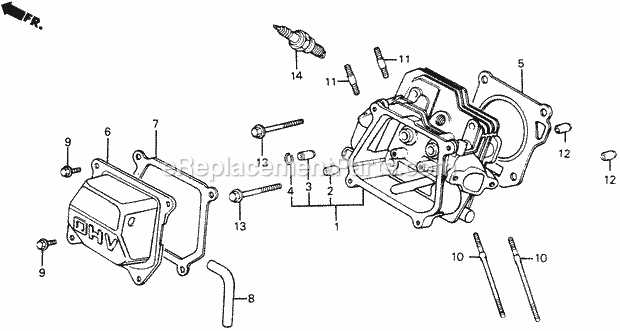

Detailed Breakdown of Engine Parts

The internal mechanisms of any small machinery engine consist of multiple essential components working together to ensure smooth and efficient operation. Understanding these key elements is crucial for maintaining performance and addressing potential issues that may arise over time. In this section, we will explore the fundamental elements of the engine, offering insight into their individual functions and interactions.

Main Components of the Engine

The engine’s core structure is built around the cylinder block, which houses the main moving parts. This block contains pistons, crankshaft, and connecting rods, all of which are vital to converting fuel into motion. Pistons move within the cylinders, driven by the combustion process, while the crankshaft translates this movement into rotational energy.

Supportive Systems

Alongside the primary mechanical components, several auxiliary systems contribute to the overall operation. The fuel delivery system regulates the flow of gasoline or other fuels into the combustion chamber, ensuring an optimal mix with air. Meanwhile, the ignition system provides the necessary spark to ignite the fuel-air mixture, starting the engine’s cycle. Additionally, the cooling system prevents overheating by circulating coolant through various parts of the engine, preserving long-term reliability.

Auger System Parts and Functionality

The auger mechanism plays a critical role in the efficient movement and displacement of snow. By using a rotating blade structure, it channels material into the system, ensuring a continuous flow. This ensures the machine can handle various conditions, from light dusting to more packed and icy accumulations.

The rotating components within the auger assembly are specifically designed for durability and precision. Key elements, such as the spiraled blades, help cut through dense snow, while additional gears work to maintain consistent motion. Each element of the system functions in harmony to deliver optimal performance, reducing the strain on other mechanical components.

The importance of proper alignment and maintenance cannot be overstated. Well-lubricated moving elements and securely fastened components ensure the auger remains efficient, prolonging the equipment’s overall lifespan and enhancing safety during operation.

Chute Control Assembly Explained

The chute control system plays a crucial role in directing the discharge of material to your desired location. Understanding how this mechanism works can help you achieve more precise control and optimize the functionality of the equipment. The system typically consists of several components that work together to rotate and adjust the chute angle.

Main Components of the Chute Control System

- Chute Crank: This part allows the user to rotate the chute horizontally, controlling the direction in which material is expelled.

- Chute Deflector Lever: Adjusts the vertical angle of the chute, enabling finer control over how far the material is thrown.

- Guide Cables or Rods: These connect the control mechanisms to the chute, transmitting the movements from the crank and lever to the chute itself.

How the Chute Control System Works

- The user turns the chute crank to rotate the chute horizontally, aiming material left or right.

- Using the deflector lever, the user adjusts the angle of discharge, controlling how high or low the material will be thrown.

- The connected cables or rods ensure smooth operation, translating the user’s inputs into precise movements of the chute and deflector.

Proper maintenance and regular inspection of the chute control system ensure consistent performance and avoid potential malfunctions that could reduce efficiency.

Transmission and Drive System Overview

The transmission and drive mechanism play a crucial role in the overall functionality and efficiency of outdoor machinery designed for snow clearing. These systems are engineered to convert the engine’s power into controlled movement, enabling the equipment to navigate various terrains effectively.

Typically, the drive system consists of several key components:

- Gearbox: This component facilitates the transfer of power from the engine to the drive wheels, allowing for varied speed and torque.

- Drive Belts: These rubberized straps are essential for transmitting motion from the engine to the gearbox, ensuring smooth operation and minimal slippage.

- Chains and Sprockets: In some models, chains work in conjunction with sprockets to enhance traction and provide a reliable connection between moving parts.

- Control Levers: These are crucial for operator control, allowing for adjustments in speed and direction while ensuring safety and ease of use.

The efficiency of the transmission and drive system significantly impacts the performance of the machine. Proper maintenance and timely replacement of worn components can lead to improved operation and longevity of the equipment. Understanding the intricacies of this system helps users optimize their machinery for maximum effectiveness during operation.

Handlebar and Control Levers Parts

The handlebar assembly and control levers are crucial components that enhance the operator’s experience and ensure effective handling of the equipment. These elements provide the necessary leverage and accessibility to operate the machinery comfortably and efficiently, allowing users to maneuver with ease and precision.

Components Overview

Within the handlebar assembly, various elements work together to facilitate control and stability. Each part plays a specific role in ensuring the equipment functions optimally, contributing to both safety and usability.

| Component | Description | Function |

|---|---|---|

| Handlebar | The main structure that provides grip and control. | Allows the operator to steer and direct the equipment. |

| Throttle Lever | Controls the speed of the engine. | Enables adjustment of power according to the task. |

| Auger Control Lever | Engages and disengages the auger mechanism. | Facilitates snow throwing operations. |

| Safety Key | A critical safety feature that prevents accidental start-up. | Ensures safe operation by requiring the key to be in place. |

Maintenance Tips

Regular inspection and maintenance of the handlebar and control levers are essential for optimal performance. Ensure that all components are free from debris and damage, and lubricate moving parts as needed to prevent wear and tear. Proper care will enhance durability and reliability, allowing for smoother operation.

Common Replacement Parts for Maintenance

Regular upkeep of outdoor equipment is essential to ensure optimal performance and longevity. Identifying and replacing common wear items can significantly enhance functionality and reduce the risk of breakdowns. This section outlines frequently needed components that contribute to effective maintenance practices.

Belts are crucial for transferring power between various mechanical parts. Over time, these can wear down or become damaged, necessitating their replacement to maintain efficiency.

Blades are vital for achieving desired results during operation. Dull or chipped edges can hinder performance, so replacing them when they show signs of wear is advisable.

Filters, particularly air and fuel types, play a significant role in the cleanliness and efficiency of operation. Clogged or dirty filters can impede airflow or fuel flow, leading to decreased performance. Regular checks and replacements are essential.

Spark plugs are responsible for ignition in combustion engines. They can accumulate carbon deposits or wear out over time, impacting starting and efficiency. Regular replacement ensures reliable performance.

O-rings and gaskets are often overlooked but are critical in preventing leaks and maintaining proper seals. Over time, these components can degrade, leading to potential malfunctions. Regular inspection and replacement can prevent more significant issues.

By staying proactive with these common replacement items, users can maintain their equipment in peak condition, ensuring a reliable and efficient experience.

How to Identify Worn Out Parts

Recognizing signs of wear in mechanical equipment is crucial for maintaining optimal performance and prolonging its lifespan. Components that are worn out can lead to decreased efficiency and potential breakdowns. Regular inspections and understanding the common indicators of deterioration are essential for effective maintenance.

Here are some key signs that a component may need replacing:

- Unusual Noises: Listen for grinding, rattling, or squeaking sounds during operation. These noises often indicate that a part is damaged or excessively worn.

- Reduced Performance: Noticeable declines in efficiency, such as decreased power output or slower operation, can suggest that components are no longer functioning properly.

- Visible Damage: Inspect for cracks, breaks, or significant wear marks on parts. Physical signs of damage are often the most obvious indicators that a replacement is necessary.

- Leaks: Any fluid leakage from mechanical seals or joints may indicate that parts are failing and require immediate attention.

- Inconsistent Operation: If the equipment runs erratically or fails to start consistently, it may be a sign that internal components are worn out.

To ensure reliable performance, it’s advisable to conduct routine inspections and address any signs of wear promptly. Keeping a log of maintenance activities can help track the condition of components over time, aiding in timely replacements and repairs.

Genuine Honda HS55 Spare Parts Options

When it comes to maintaining outdoor equipment, choosing authentic components is crucial for optimal performance and longevity. Relying on original elements ensures compatibility and reliability, allowing users to operate their machines effectively in various conditions. Understanding the available options can significantly enhance the efficiency of your device.

Original components are designed specifically for your machinery, ensuring a perfect fit and functionality. These pieces are manufactured to meet rigorous quality standards, providing peace of mind and enhancing overall performance. From engines to belts, each component plays a vital role in the smooth operation of your equipment.

Utilizing genuine components not only preserves the warranty but also minimizes the risk of damage caused by inferior substitutes. Investing in authentic replacements guarantees that your machinery will continue to perform at its best, delivering consistent results for years to come. Always consult the manufacturer or authorized dealers to ensure that you are sourcing the right items for your specific model.

In summary, opting for genuine replacements is an investment in the reliability and efficiency of your outdoor equipment. By prioritizing quality, you can ensure that your machinery remains in top-notch condition, ready to tackle any task that comes its way.

Tips for Locating Hard-to-Find Parts

Finding elusive components for your equipment can be a daunting task. However, with the right strategies, you can streamline the search process and enhance your chances of success. This section provides valuable insights to help you navigate the often complicated world of sourcing specialized items.

Start by utilizing online resources such as manufacturer websites, online marketplaces, and forums dedicated to enthusiasts of your machinery. These platforms often provide detailed information on availability, pricing, and user reviews, which can guide you in making informed decisions.

| Strategy | Description |

|---|---|

| Join Online Forums | Engaging with communities of fellow users can lead to valuable recommendations for sourcing rare components. |

| Contact Authorized Dealers | Official distributors may have access to items not listed online, offering a direct path to procurement. |

| Use Social Media | Platforms like Facebook and Reddit can connect you with sellers or fellow users who might have the items you need. |

| Check Local Salvage Yards | These places often have a variety of equipment, increasing the likelihood of finding what you’re looking for. |

| Attend Trade Shows | Exhibitions can be an excellent opportunity to network with suppliers and discover hard-to-find items. |

By employing these tactics, you can increase your chances of locating those difficult-to-find components, ensuring your equipment remains in optimal working condition.