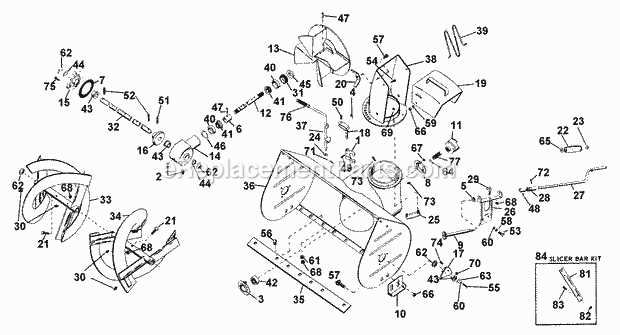

Maintaining your outdoor machinery is crucial for optimal performance during harsh winter conditions. Knowing the various elements that make up the equipment can significantly enhance its efficiency and longevity. This section delves into the intricate details of each component, providing insights into their functions and interrelationships.

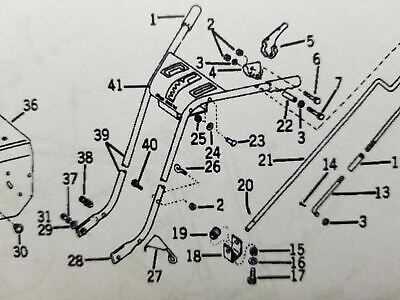

Recognizing the parts and how they interact is essential for effective maintenance and troubleshooting. Familiarity with the configuration of these components not only aids in identifying potential issues but also empowers you to make informed decisions when repairs are necessary. Understanding the assembly can also guide you in proper usage and care.

Furthermore, having a visual representation of the setup allows for a clearer comprehension of the machine’s functionality. By grasping how each element contributes to overall performance, you can ensure that your equipment operates smoothly and efficiently. This knowledge is invaluable for anyone looking to maximize their investment in outdoor machinery.

In the world of outdoor equipment, comprehending the visual representation of components is crucial for effective maintenance and repair. This guide will explore the essential elements that contribute to the overall functionality of the machinery.

Key Components Overview

Familiarizing yourself with the various elements will enhance your ability to troubleshoot issues. Below are some critical components to consider:

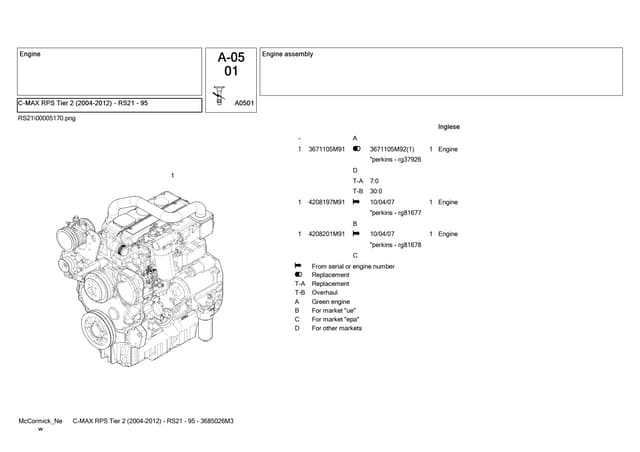

- Power Source: The engine or motor that drives the entire system.

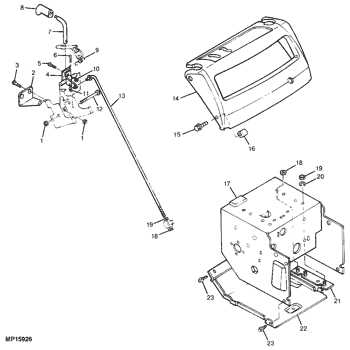

- Transmission: Mechanisms that transfer power from the engine to the moving parts.

- Control Systems: Handles and levers that allow the operator to manage the equipment’s operations.

- Chassis: The framework that supports all other components.

- Accessories: Optional features that can enhance performance and versatility.

Importance of Visual References

Having a clear visual reference aids in identifying and replacing worn or damaged elements. Utilizing this information can lead to:

- Increased efficiency in repairs.

- Better understanding of the machinery’s operation.

- Enhanced safety through proper handling of components.

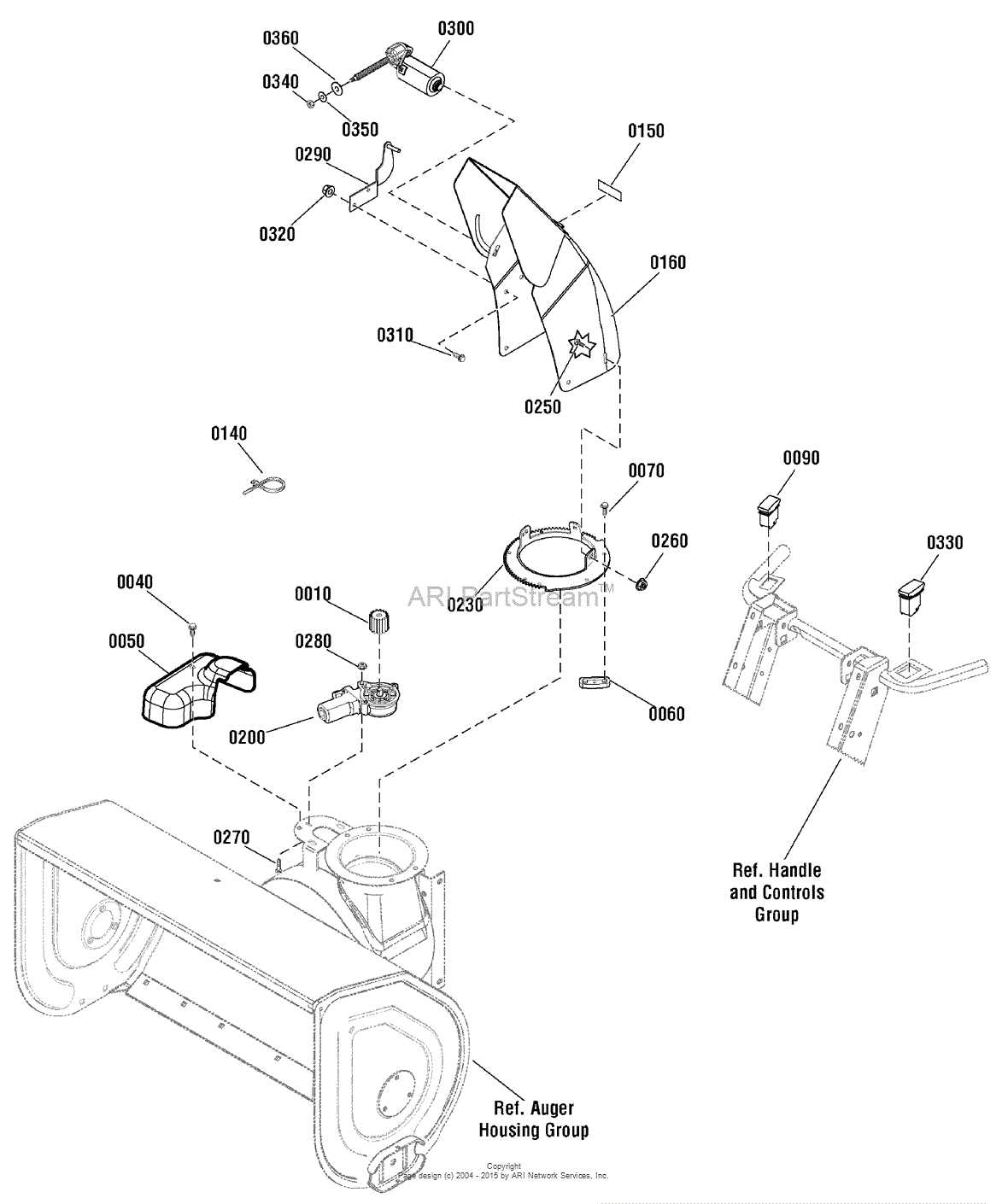

Essential Components of the Snowblower

Understanding the key elements of a snow-clearing machine is crucial for optimal performance and maintenance. Each component plays a significant role in the functionality and efficiency of the equipment, ensuring effective operation during winter conditions.

Here are the main components that contribute to the overall effectiveness of the machine:

- Auger: This part is responsible for gathering the snow and directing it towards the impeller.

- Impeller: It helps to propel the snow out of the chute once it has been collected by the auger.

- Chassis: The main structure that supports all other components and provides stability during operation.

- Engine: Powers the machine, providing the necessary energy to operate all moving parts.

- Controls: These allow the operator to adjust settings and manage the operation of the equipment effectively.

Each of these components must be maintained properly to ensure the machine operates efficiently throughout the winter months.

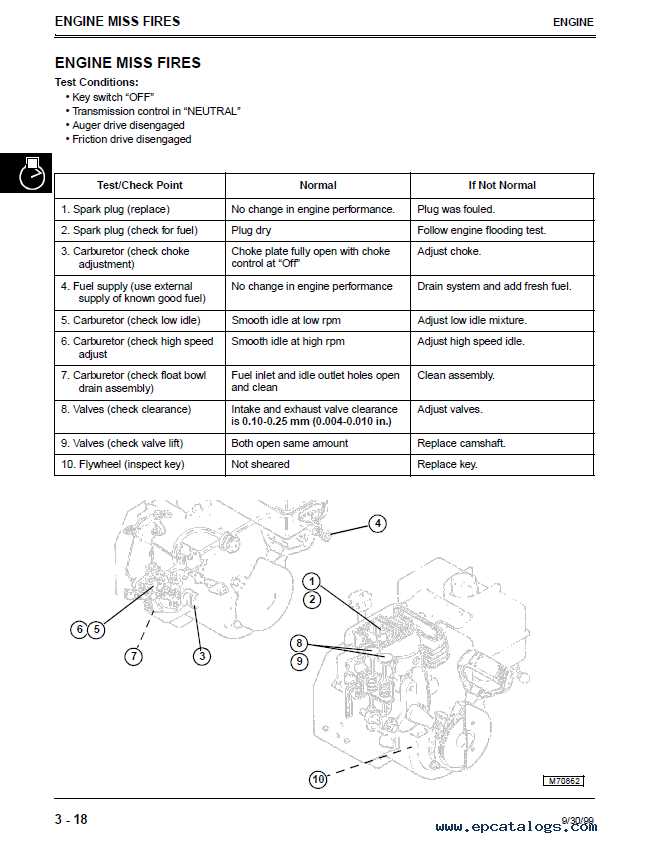

Common Issues with Snow Removal Equipment

When operating snow removal equipment, users may encounter a variety of common challenges that can affect performance and efficiency. Understanding these issues can help in troubleshooting and ensuring smooth operation during harsh winter conditions.

Frequent Mechanical Failures

Mechanical breakdowns are a significant concern for users. Components may wear out due to prolonged use, leading to decreased effectiveness. Regular maintenance is essential to identify wear signs early and replace affected components to maintain optimal functionality.

Fuel and Engine Problems

Fuel-related issues can also hinder performance. Old or contaminated fuel can cause starting difficulties or engine stalling. Ensuring that fuel is fresh and using high-quality products can mitigate these risks, prolonging the lifespan of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and effectiveness of your equipment requires regular care and attention. By following specific guidelines, you can significantly extend the lifespan of your machinery, allowing it to perform optimally throughout its usage. Proper maintenance not only enhances performance but also prevents costly repairs in the future.

Routine Inspections

Regularly checking various components for wear and tear is essential. Look for signs of damage or deterioration, and address any issues promptly. Ensuring that all parts are functioning correctly will prevent unexpected breakdowns and maintain efficiency.

Cleaning and Lubrication

Keeping your equipment clean is crucial for preventing buildup that can hinder performance. After each use, remove debris and dirt, especially from hard-to-reach areas. Additionally, applying appropriate lubricants to moving parts will reduce friction and ensure smooth operation.

Replacing Worn Out Parts

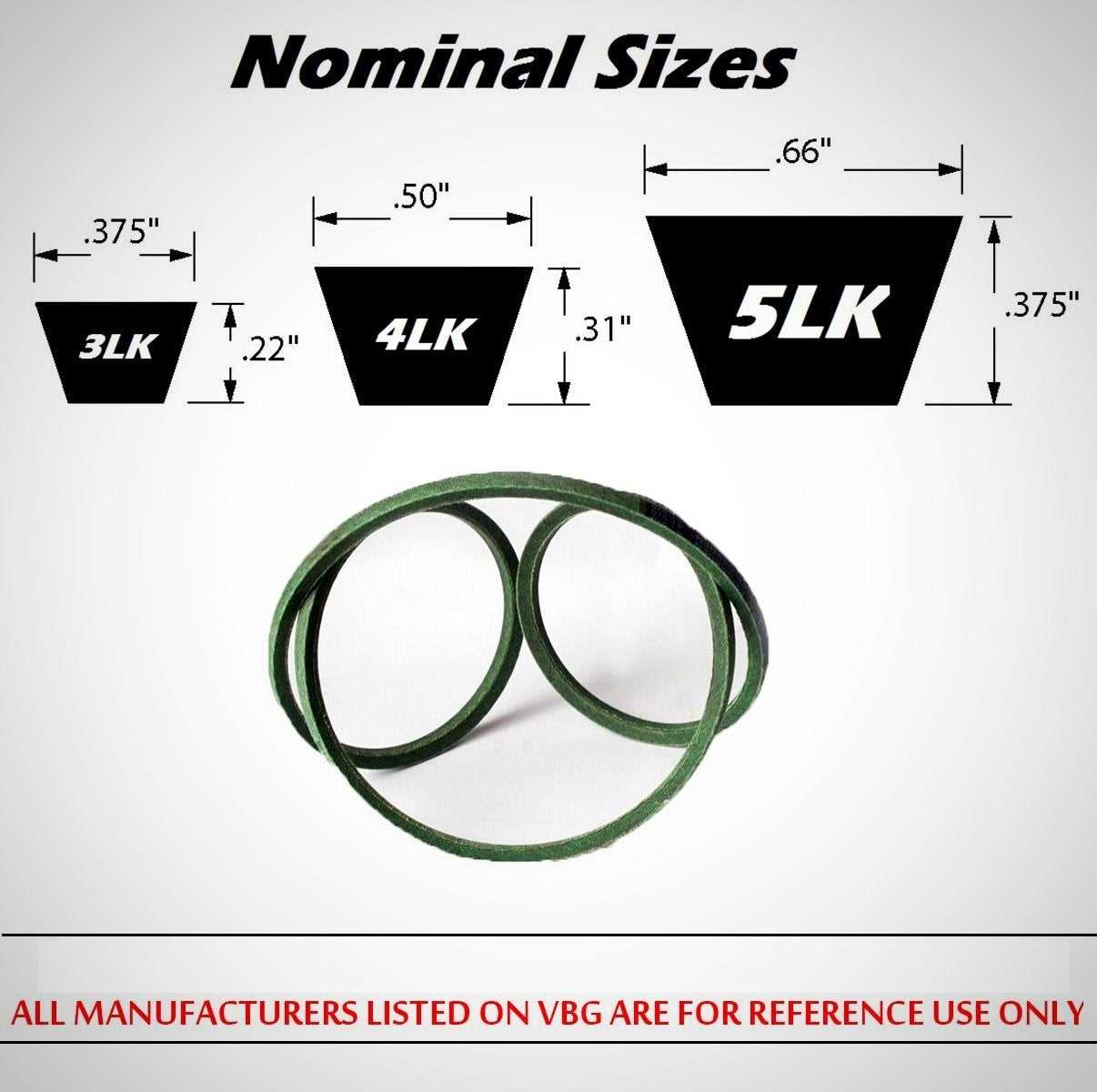

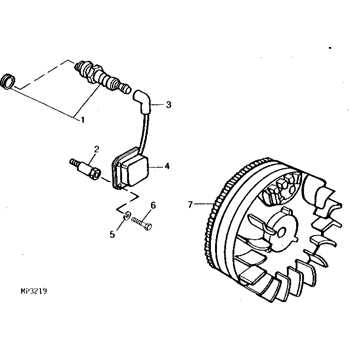

Maintaining optimal functionality in your equipment is crucial for achieving the best results. When components begin to show signs of wear, timely replacement becomes essential to ensure the machine operates efficiently and effectively. This section outlines the importance of recognizing and addressing worn-out elements to maintain performance and longevity.

Identifying Signs of Wear

It’s important to regularly inspect your machinery for any indications that components may need replacement. Look for the following signs:

- Increased noise during operation

- Reduced performance or efficiency

- Visible damage or wear on critical parts

- Frequent breakdowns or malfunctions

Replacement Process

Once you’ve identified which components are worn out, follow these steps for replacement:

- Gather necessary tools and replacement elements.

- Power off the machine and ensure it is safe to work on.

- Carefully remove the damaged components.

- Install the new elements, ensuring they fit correctly.

- Test the machine to confirm proper functionality.

By regularly replacing worn-out components, you not only improve the effectiveness of your equipment but also extend its lifespan, leading to better performance over time.

Identifying Compatible Replacement Parts

Finding suitable alternatives for equipment components is essential for maintaining optimal performance. Understanding how to choose the right replacements can save time and ensure efficiency during operation.

Understanding Component Compatibility

When selecting new elements for your machinery, consider the following factors:

- Model Specifications: Ensure the selected items align with the specific model requirements.

- Manufacturer Recommendations: Always refer to the guidelines provided by the original equipment manufacturer.

- Quality Standards: Opt for replacements that meet or exceed the quality standards set for the original components.

Sources for Finding Replacements

To locate the most appropriate alternatives, explore these options:

- Authorized dealers who specialize in equipment maintenance.

- Reputable online marketplaces that offer a wide range of compatible items.

- Local repair shops that provide expert advice and quality replacements.

Assembly and Disassembly Instructions

Understanding the procedure for putting together and taking apart equipment is essential for maintenance and repair. Proper knowledge of these processes ensures efficiency and prevents damage during handling. This section outlines the necessary steps for effectively assembling and disassembling the machinery, promoting a smoother workflow.

Preparation Steps

- Gather all necessary tools and equipment.

- Ensure that the workspace is clean and organized.

- Review any manuals or guides available for reference.

Disassembly Process

- Start by disconnecting all power sources.

- Remove any covers or protective casings.

- Carefully take apart the components, ensuring to keep track of screws and small parts.

- Label each part if necessary for easier reassembly.

Assembly Process

- Begin with the base components, securing them firmly.

- Gradually add each piece, ensuring proper alignment.

- Reattach covers and casings securely.

- Reconnect power sources and test the unit for proper function.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is crucial to prevent accidents and injuries. Proper precautions must be taken to create a secure working environment. This section outlines essential measures that should be followed during repair tasks.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Keep the workspace clean and free of obstructions to reduce the risk of slips and falls.

- Ensure proper lighting in the area to facilitate visibility and reduce hazards.

- Disconnect power sources before starting any repair to prevent accidental activation.

Handling Tools and Equipment

- Inspect tools and equipment for damage before use.

- Store tools in designated areas to avoid tripping hazards.

- Use tools as intended and follow manufacturer instructions to prevent misuse.

- Always keep a first-aid kit nearby to address minor injuries promptly.

Where to Find Genuine Parts

When seeking authentic components for your machinery, it’s essential to explore reliable sources that ensure quality and compatibility. Various avenues can lead you to trusted suppliers who specialize in these specific items.

One effective option is to visit authorized dealerships, where you can find a comprehensive selection of original components. These establishments often provide expert assistance, helping you identify the correct items for your needs.

Online marketplaces are another valuable resource, offering convenience and accessibility. Reputable websites dedicated to machinery supplies typically feature genuine items, accompanied by detailed descriptions and customer reviews.

Additionally, specialized repair shops may carry authentic components or be able to order them for you. Establishing a relationship with local technicians can lead to valuable recommendations for sourcing genuine items tailored to your equipment.