When winter descends and snow blankets the landscape, having a reliable machine at your disposal can make all the difference. Knowing the various elements that comprise your snow clearing equipment is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring efficiency and durability, enabling you to tackle harsh weather conditions with confidence.

In this exploration, we will delve into the intricate relationships between the different parts that make up your snow removal device. From the engine to the auger system, every section contributes to the overall functionality. Understanding these elements not only aids in troubleshooting but also empowers you to make informed decisions regarding repairs and replacements.

Moreover, familiarizing yourself with these components can enhance your overall experience, allowing you to operate your machine effectively and safely. Whether you’re a novice or a seasoned user, having a clear grasp of how each element interacts will ensure that you’re prepared to face whatever winter may bring.

Poulan Pro Snowblower Overview

This section provides an insightful look into a popular brand of winter equipment designed for efficient snow removal. Known for its reliability and robust performance, this machinery has become a favored choice for both homeowners and professionals alike. Understanding its features and components is essential for optimal usage and maintenance.

Key Features

- Powerful engine for superior snow-clearing capabilities

- Durable construction to withstand harsh winter conditions

- Multiple speed settings for adjustable performance

- Ergonomic design for user comfort during operation

- Easy maneuverability, even in heavy snowfall

Maintenance Tips

- Regularly check the fuel and oil levels before each use.

- Inspect the blades for wear and damage after heavy snowfall.

- Clear any debris from the intake area to ensure optimal performance.

- Store the unit in a dry place to prevent rust and corrosion.

- Follow the manufacturer’s guidelines for seasonal maintenance checks.

Importance of Replacement Parts

Ensuring the longevity and efficiency of outdoor equipment relies heavily on the timely substitution of essential components. Over time, various elements can wear out, leading to decreased performance and potential breakdowns. Understanding the significance of these replacements can help users maintain their machinery effectively.

- Performance Optimization: New components can restore optimal functionality, enhancing overall performance.

- Safety Assurance: Worn or damaged parts can pose safety risks. Replacing them mitigates potential hazards.

- Cost-Effectiveness: Timely replacements can prevent more significant issues that might require costly repairs.

- Extended Lifespan: Regular updates of critical elements contribute to the durability of the equipment.

- Efficiency Improvement: New components often enhance fuel efficiency and reduce energy consumption.

Neglecting the need for these substitutions can lead to diminished functionality and increased repair costs. Prioritizing the replacement of worn components ensures the machinery remains reliable and effective over time.

Common Snowblower Issues

Operating a snow-clearing machine can sometimes lead to various challenges that hinder performance. Understanding these frequent problems can help users maintain efficiency and extend the lifespan of their equipment.

Starting Difficulties

One of the most common frustrations is trouble with ignition. Issues may stem from fuel quality, spark plug condition, or battery status. Regular checks and maintenance can mitigate these problems.

Clogging Issues

Another prevalent concern is blockage in the discharge chute. This can occur due to wet or heavy snow, leading to inefficient clearing. Keeping the chute clean and clear of obstructions is essential for optimal operation.

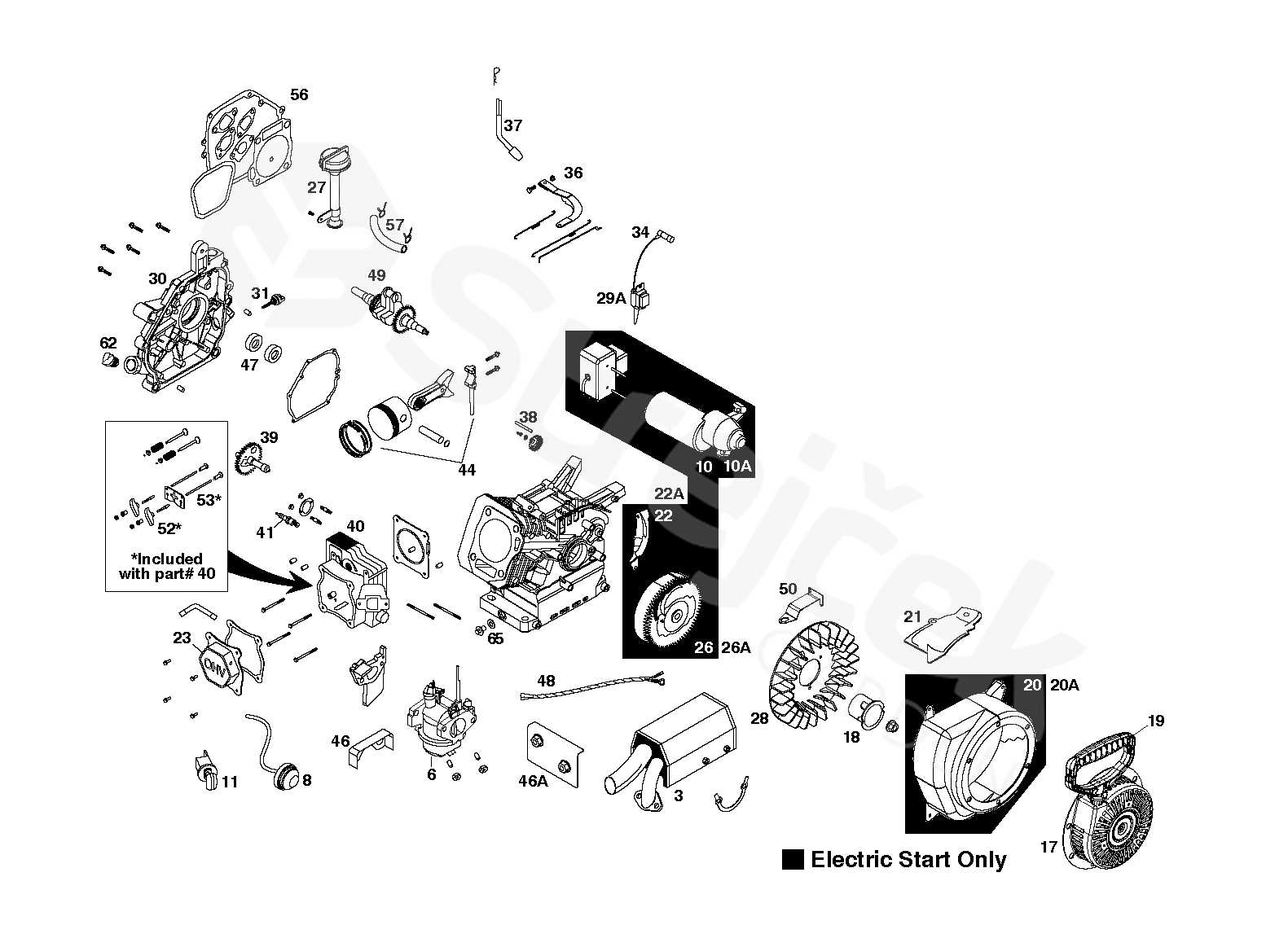

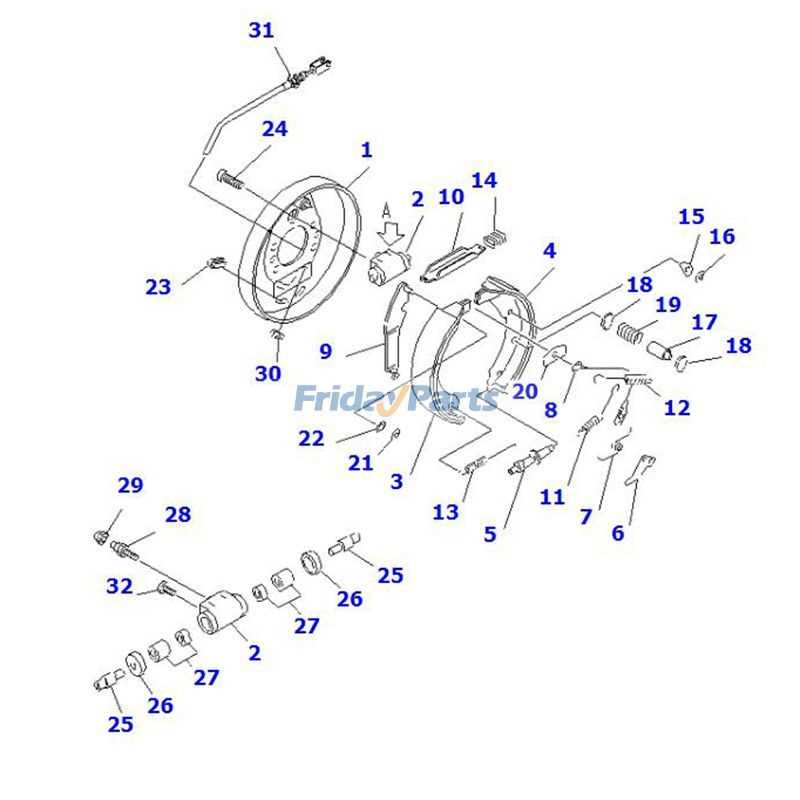

Key Components Explained

Understanding the essential elements of any outdoor clearing machine is crucial for effective operation and maintenance. Each component plays a vital role in the overall functionality, ensuring optimal performance during challenging weather conditions.

Primary Elements

- Engine: The powerhouse that drives the entire system, providing the necessary force for movement and operation.

- Auger: This part efficiently gathers and directs snow towards the discharge chute.

- Chassis: The structural framework that houses and supports all major components, ensuring stability.

Additional Features

- Discharge Chute: Directs the expelled material away from the machine, allowing for controlled clearing.

- Control Panel: Centralized interface for operating various functions, enhancing user experience.

- Skid Shoes: Adjustable elements that protect the base while providing stability on uneven surfaces.

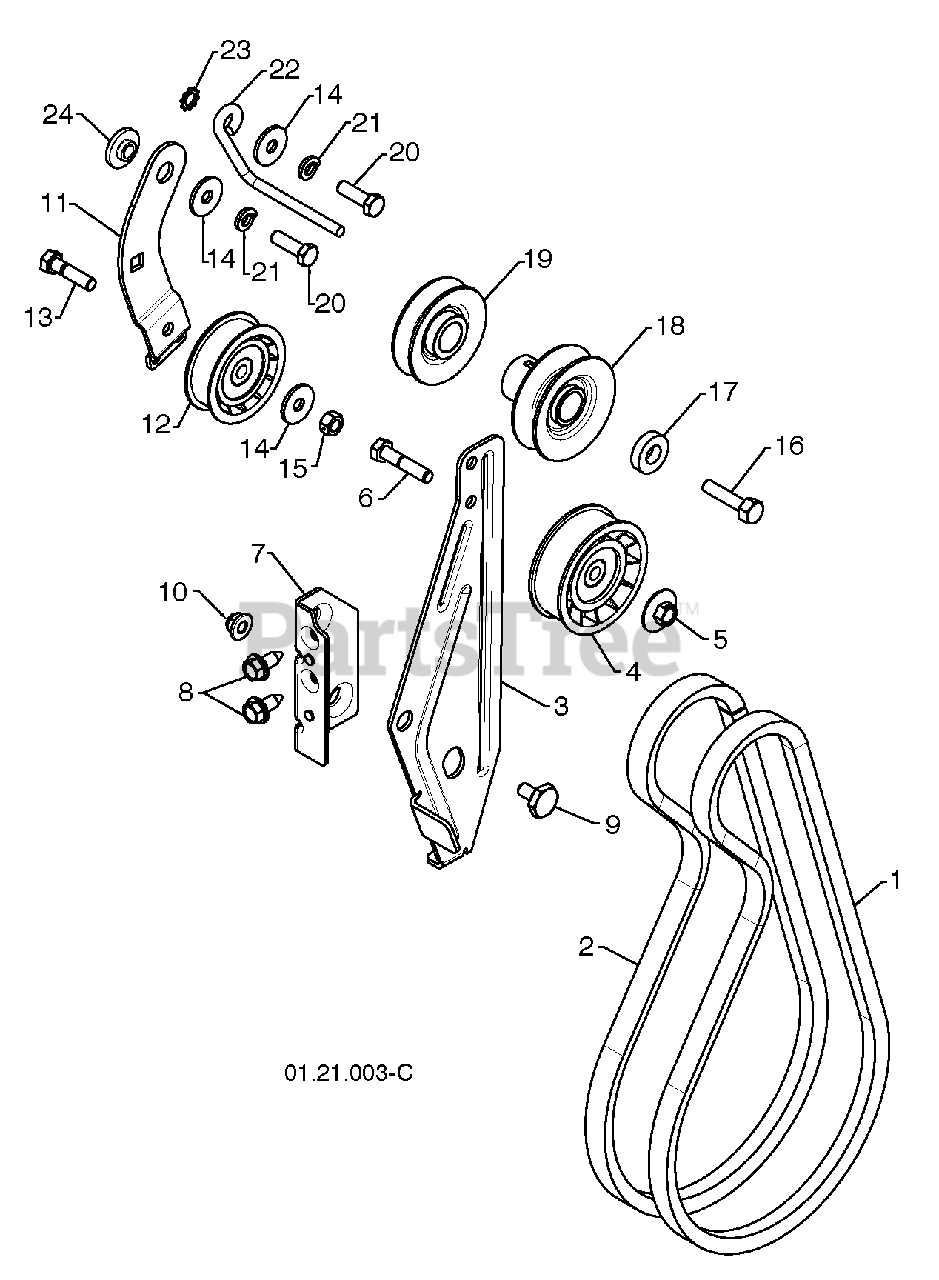

Understanding the Parts Diagram

Grasping the layout of various components is essential for effective maintenance and troubleshooting. A clear representation of these elements aids users in identifying and replacing specific sections, ultimately enhancing the machine’s performance.

Key aspects to consider include:

- Identification of each component and its function.

- Understanding how parts interact with one another.

- Locating the necessary tools for assembly or disassembly.

Familiarity with the visual guide ensures that users can:

- Quickly locate issues within the system.

- Efficiently perform repairs or upgrades.

- Extend the lifespan of the equipment through proper care.

By delving into the details, users can achieve the ultimate level of operational efficiency.

How to Access the Diagram

Gaining insight into the assembly and components of your equipment is crucial for effective maintenance and repairs. This section outlines the steps to locate and utilize visual references that illustrate the structure and individual elements of your machine.

Online Resources

Many manufacturers offer detailed visual aids on their websites. By visiting the official site, you can often find downloadable PDFs or interactive models that provide clear representations of various assemblies.

User Manuals

Your user manual is another invaluable resource. It typically contains a section dedicated to illustrations, showcasing the layout and components of your equipment, which can greatly assist in troubleshooting and repair tasks.

Where to Find Genuine Parts

Finding authentic components for your outdoor machinery is crucial for maintaining optimal performance and longevity. Whether you need replacements or upgrades, sourcing these items from reliable vendors ensures quality and compatibility, making your maintenance tasks more effective.

Authorized Retailers

One of the best ways to obtain genuine components is through authorized retailers. These stores often carry a wide selection of original items, backed by manufacturer warranties and support. Checking online directories or visiting local shops can lead you to trusted options.

Manufacturer Websites

Another excellent source is the official websites of the manufacturers. These platforms typically offer detailed catalogs, direct purchase options, and customer service resources to help you identify the right items for your needs. Always verify the website’s authenticity to ensure you are buying legitimate products.

DIY Repair Tips

When tackling repairs on outdoor machinery, having a solid approach can make all the difference. Understanding how components interact allows for efficient troubleshooting and resolution of issues. Whether you’re a seasoned expert or a novice, these tips can enhance your repair experience.

1. Gather Tools and Supplies: Before starting, ensure you have the necessary tools at hand. A well-organized workspace can significantly streamline the process.

2. Reference Manuals: Always consult your equipment’s manual. It contains vital information that can help you delve into specific repairs with confidence.

3. Take Notes: Document your steps during disassembly. This practice is invaluable for reassembly and can prevent confusion later.

4. Test Parts: If possible, test components before replacing them. Sometimes, cleaning or adjusting a piece can resolve the problem without the need for a new part.

5. Seek Online Resources: Explore forums and video tutorials. Engaging with a community can provide insights and tips that enhance your repair skills.

6. Safety First: Always prioritize safety. Use gloves and protective eyewear, and ensure the machinery is turned off before beginning any work.

With the right mindset and preparation, you’ll find that most repairs are manageable, turning challenges into satisfying accomplishments.

Tools Needed for Repairs

When tackling maintenance tasks, having the right instruments can significantly ease the process and enhance the effectiveness of repairs. This section outlines essential tools that will facilitate your efforts, ensuring a smooth experience as you work through various challenges.

Essential Hand Tools

Basic hand tools are crucial for any repair job. Here are some of the must-haves:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts. |

| Screwdriver Set | To drive screws and fasteners. |

| Pliers | For gripping and manipulating objects. |

| Socket Set | For accessing hard-to-reach fasteners. |

Power Tools for Efficiency

In addition to hand tools, power tools can greatly improve efficiency. Consider including the following:

| Tool | Purpose |

|---|---|

| Drill | For creating holes and driving screws quickly. |

| Impact Wrench | For removing stubborn bolts with ease. |

| Angle Grinder | For cutting and grinding metal parts. |

| Multimeter | For electrical testing and diagnostics. |

Maintenance Best Practices

Proper upkeep of your outdoor equipment ensures optimal performance and longevity. By following a few essential guidelines, you can keep your machinery in excellent condition and avoid costly repairs.

Regular Inspection

Frequent checks of your equipment help identify potential issues before they escalate. Look for wear and tear, and ensure all components are functioning correctly.

Cleaning and Storage

Keeping your equipment clean and stored appropriately protects it from environmental damage. Regularly remove debris and store in a dry place when not in use.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every season | Use manufacturer-recommended oil. |

| Filter Replacement | Every season | Check for clogging and replace as needed. |

| Inspect Belts | Monthly | Look for cracks or fraying. |

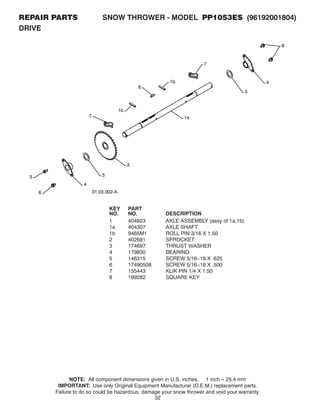

Identifying Compatibility with Models

When maintaining or repairing outdoor equipment, understanding the compatibility of components with various models is crucial for optimal performance. This process involves recognizing the specific requirements and specifications that different machines have, ensuring that any replacements or upgrades align perfectly with the intended model.

Key Considerations

Start by examining the model number of your equipment. This number is often located on the machine itself and serves as a vital reference for finding suitable replacements. Cross-referencing this number with manufacturer catalogs can reveal compatible components designed for your specific model. Additionally, pay attention to the year of manufacture, as compatibility can vary even among models with similar names.

Consulting Manufacturer Resources

Utilizing manufacturer resources such as manuals or online databases can greatly aid in identifying the right components. These resources often provide detailed specifications and compatibility charts that highlight which components can be used interchangeably. Consulting these references before making a purchase can save time and ensure that the chosen replacements will function effectively with your machine.

Ordering Parts: A Step-by-Step Guide

Acquiring components for your equipment can seem daunting, but with a clear approach, it becomes manageable. This guide aims to simplify the process, ensuring you receive the right items swiftly and efficiently.

Step 1: Identify the Component

Before making any purchases, ascertain the exact item needed. Check the model number and any identifying marks on your machine. This information is crucial for accuracy.

Step 2: Find a Reliable Supplier

Research reputable vendors who specialize in the necessary components. Look for customer reviews and ensure they offer a return policy. Trustworthy suppliers often have extensive catalogs and knowledgeable staff to assist you.

Tip: Keep your model number handy during your search for a smoother experience.

Following these steps will help you navigate the ordering process confidently, leading to successful repairs and maintenance.