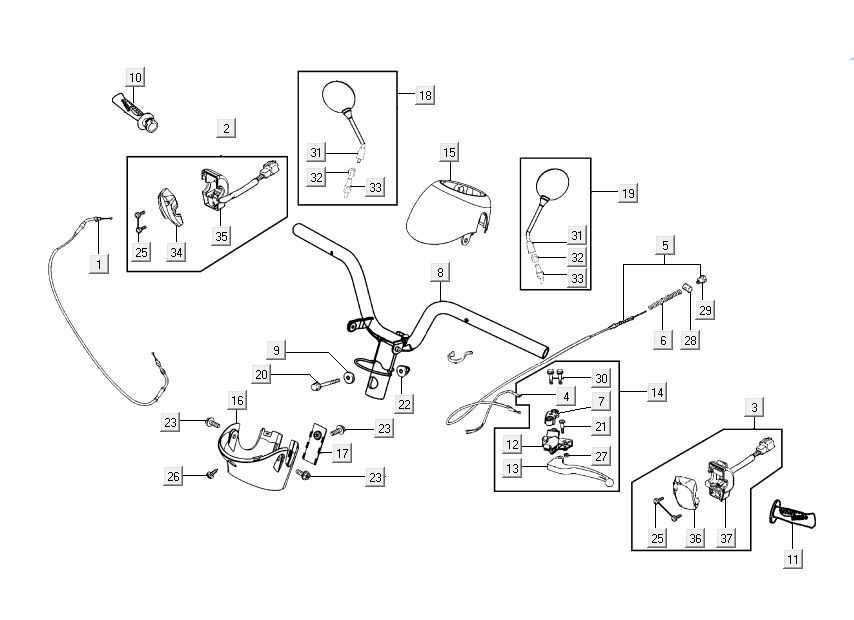

The functionality of a lawn care machine relies heavily on its maneuverability and precision. Proper management of these control elements ensures a smooth operation and enhances the user experience. For those looking to maintain or troubleshoot their equipment, a thorough understanding of the various components involved is essential.

Recognizing how these mechanisms interact can significantly impact the efficiency of the machine. Each element plays a vital role in translating the operator’s intentions into tangible movements. By familiarizing yourself with the layout and specifics of these components, you can identify issues more easily and perform necessary adjustments or replacements.

This guide aims to provide clarity on the intricate relationships between different control components, highlighting key features and functionalities. Whether you’re a seasoned user or a newcomer, gaining insight into these crucial aspects will empower you to enhance the performance of your machinery.

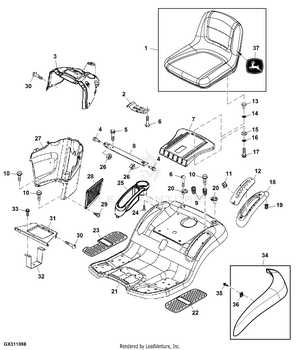

Understanding John Deere L130 Components

This section delves into the essential elements that contribute to the functionality and maneuverability of a popular riding mower. By comprehending these components, users can enhance their maintenance skills and ensure optimal performance.

Key elements include:

- Control mechanisms

- Transmission systems

- Wheel assembly

- Support structures

- Power transmission components

Each part plays a vital role in delivering a seamless user experience, making it crucial to understand how they interact with one another.

- Control mechanisms: These allow the operator to direct movement effectively.

- Transmission systems: These transfer power from the engine to the wheels.

- Wheel assembly: This affects traction and stability on various terrains.

- Support structures: These provide the necessary framework for all components.

- Power transmission components: These ensure efficient energy transfer for optimal operation.

Understanding the interplay between these elements will empower users to maintain their equipment and troubleshoot any issues that arise effectively.

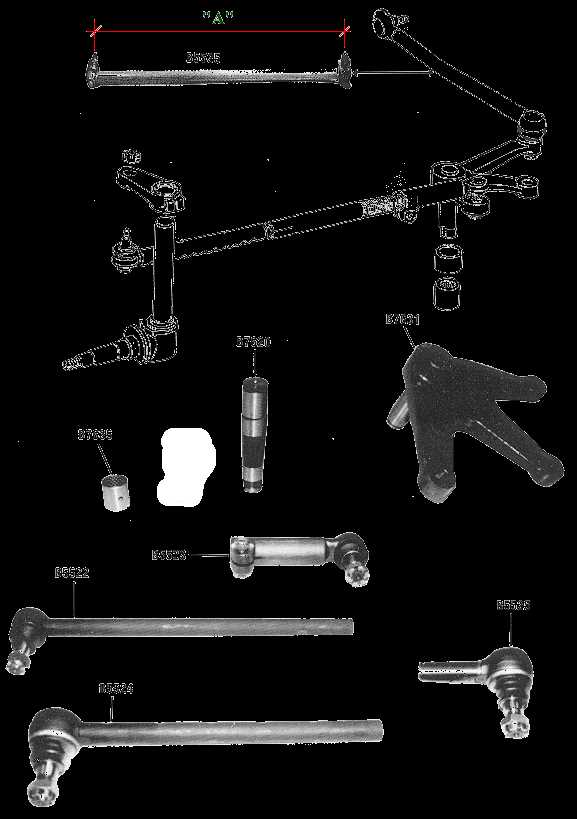

Importance of Steering Mechanisms

The functionality of any vehicle greatly relies on its maneuvering systems. These systems play a crucial role in ensuring precision and control, enabling operators to navigate various terrains effectively. A well-designed mechanism not only enhances performance but also contributes to overall safety and user experience.

Effective navigation is essential for achieving optimal efficiency, especially in challenging environments. Robust mechanisms allow for swift adjustments and responsiveness, ensuring that the vehicle can adapt to sudden changes in direction or terrain. This adaptability is vital for maintaining stability and control during operation.

Moreover, reliable mechanisms reduce the risk of wear and tear, extending the lifespan of the vehicle. Regular maintenance and understanding of the inner workings can prevent costly repairs and downtime. Consequently, a thorough grasp of these systems ensures that operators can keep their machinery in peak condition.

In summary, the significance of maneuvering systems cannot be overstated. Their impact on efficiency, safety, and longevity makes them a fundamental aspect of vehicle design and operation.

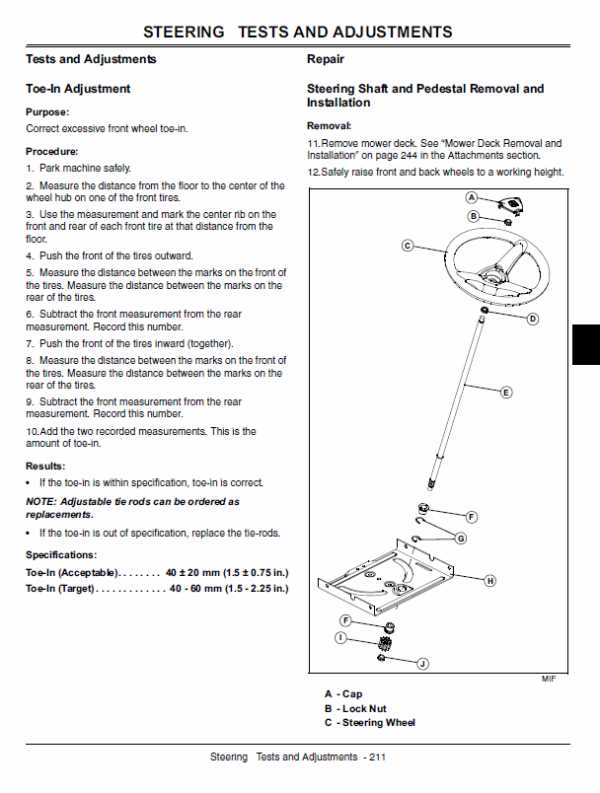

Common Issues with L130 Steering

Maintaining proper control over your machinery is crucial for optimal performance. Various challenges can arise, impacting maneuverability and overall functionality. Identifying these concerns early can save time and reduce repair costs.

Typical Challenges

Several factors can contribute to difficulties in control, including wear and tear on components, improper alignment, and fluid leaks. Each issue can lead to decreased responsiveness, making operation less efficient.

Signs of Trouble

| Issue | Symptoms |

|---|---|

| Worn Components | Loose handling and unresponsive turns |

| Poor Alignment | Drifting to one side while moving straight |

| Fluid Leaks | Visible puddles under machinery |

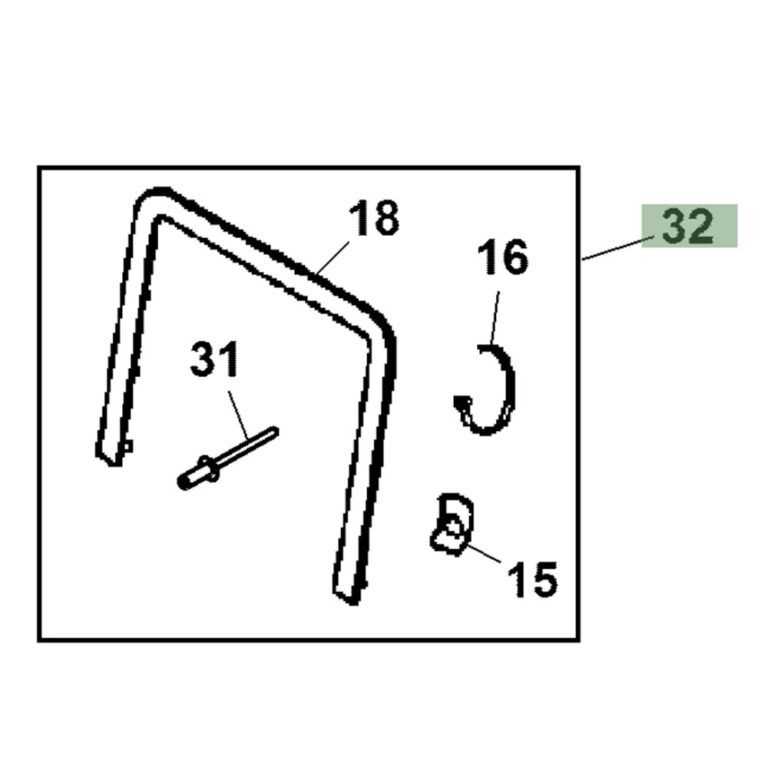

Identifying Parts in Diagrams

Understanding visual representations is essential for effective maintenance and repair tasks. Recognizing individual components within these illustrations allows users to troubleshoot issues and make informed decisions. This section provides insights on how to decode and identify elements in such graphical layouts.

Common Symbols and Notations

Many illustrations employ standardized symbols and notations to convey specific meanings. Familiarity with these can significantly enhance comprehension. Here are some typical examples:

- Lines: Indicate connections or pathways between components.

- Shapes: Represent different types of elements, such as circles for fasteners or rectangles for housing.

- Labels: Often used to provide additional context or identify specific elements.

Steps to Identify Components

To effectively interpret and recognize elements in visual layouts, follow these steps:

- Examine the overall structure and layout to understand the relationship between components.

- Identify any labels and their corresponding symbols for clarification.

- Look for accompanying legends or keys that explain the meanings of various notations.

- Take note of the scale and proportions to gauge the size of each element relative to others.

By following these guidelines, users can improve their ability to analyze and utilize visual resources effectively, leading to better maintenance outcomes. Understanding these illustrations is a vital skill for anyone involved in the upkeep and repair of machinery.

Maintenance Tips for Steering System

Proper upkeep of your vehicle’s guidance mechanism is crucial for optimal performance and longevity. Regular inspections and timely interventions can prevent minor issues from escalating into significant problems, ensuring a smooth and reliable operation.

Regular Inspections

Conduct routine checks on all components associated with the guidance system. Look for signs of wear, such as fraying or cracks, and ensure that all fasteners are securely tightened. Monitoring fluid levels is also essential, as low levels can impact performance.

Lubrication Practices

Applying the appropriate lubricants to moving elements reduces friction and wear. Consult the manufacturer’s guidelines for recommended products and intervals. Consistent lubrication not only enhances functionality but also extends the life of the mechanism.

How to Read Technical Diagrams

Understanding technical illustrations is essential for anyone involved in mechanical maintenance or assembly. These visual representations serve as a guide to help users identify components, their functions, and how they interact within a system. Familiarity with these visuals can significantly enhance efficiency and accuracy in repair and assembly tasks.

Key Elements to Identify

Before diving into a technical illustration, it’s crucial to recognize the fundamental elements that are commonly present. These include labels, symbols, and lines that indicate connections and movements. Here’s a brief overview of these components:

| Element | Description |

|---|---|

| Labels | Text that identifies each component or section, often accompanied by numbers. |

| Symbols | Standardized icons representing specific parts or functions, such as electrical or mechanical elements. |

| Lines | Connective paths that illustrate how components interact, including arrows for direction of movement. |

Tips for Effective Interpretation

To effectively interpret these visuals, take your time to study each element and understand its relationship to others. Cross-referencing the illustration with the accompanying documentation can provide additional context and clarity. Practice will improve your skills in reading and utilizing these diagrams efficiently.

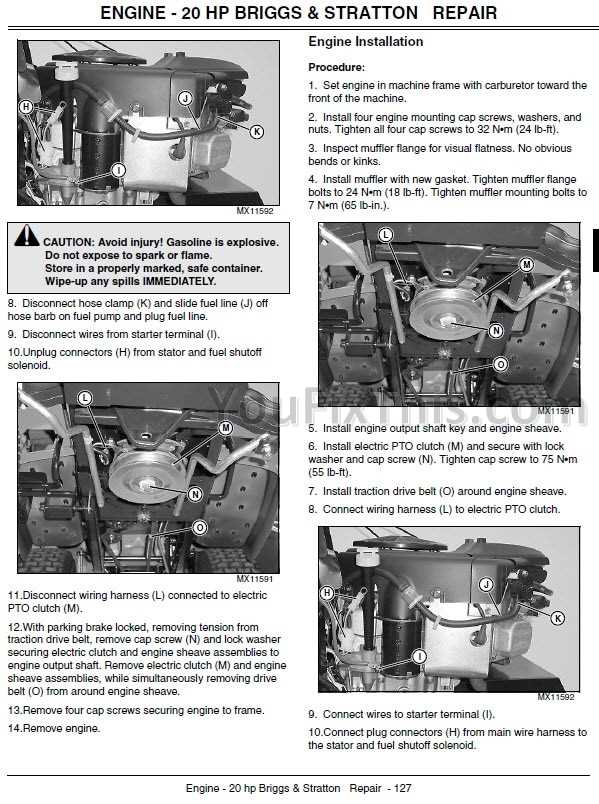

Tools Needed for Repairs

When undertaking any repair project, having the right equipment is essential for efficiency and effectiveness. Proper tools not only facilitate the task at hand but also ensure safety and precision throughout the process.

To begin, a basic set of hand tools is crucial. This includes wrenches, pliers, and screwdrivers of various sizes. These tools allow for easy access to components and enable the technician to tighten or loosen fasteners as needed.

Next, consider investing in specialized tools. Depending on the complexity of the repairs, items such as a torque wrench or a puller may be necessary. These tools help achieve specific outcomes and can prevent damage during the repair process.

Additionally, having a reliable work surface is important. A sturdy bench or platform allows for organized workspace, minimizing the risk of losing small parts and improving overall efficiency.

Finally, don’t overlook the value of safety equipment. Items like gloves and goggles are vital for personal protection, ensuring that the repair process can be carried out without unnecessary risks.

Replacing Steering Parts Effectively

Ensuring smooth navigation requires understanding the components that influence control and direction. Proper replacement of these elements can significantly enhance performance and extend the lifespan of your machinery. Knowing the right approach and necessary tools is crucial for a successful upgrade.

Start by gathering essential tools and replacement components before beginning the process. Familiarize yourself with the assembly by consulting detailed guides or visual aids, which will help you identify each component’s function. This knowledge is vital for a seamless transition and avoids any complications during installation.

Carefully remove the existing elements, taking note of their arrangement for accurate reassembly. Cleaning the mounting areas will help ensure a secure fit for the new components. After placing the replacements, double-check connections and adjustments to achieve optimal functionality.

Finally, conduct a test run to evaluate the effectiveness of your replacements. Observing the machinery’s behavior will confirm whether the new elements have been integrated successfully and if further adjustments are needed. Consistent maintenance will also play a key role in ensuring longevity and reliability.

Safety Precautions During Maintenance

Proper upkeep of machinery is essential for ensuring safe and efficient operation. Adhering to specific safety guidelines can significantly reduce the risk of accidents and injuries during maintenance tasks.

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Ensure the machine is turned off and completely cool before starting any work.

- Disconnect the battery to prevent accidental starts while servicing.

- Use tools that are in good condition and suitable for the task at hand.

Implementing these practices not only safeguards the individual performing the maintenance but also extends the lifespan of the equipment.

Finding Replacement Parts Online

Locating components for your machinery can be a straightforward process with the right approach. The internet offers a vast array of resources that cater to your needs, allowing you to source the necessary items efficiently. From specialized retailers to broader marketplaces, there are multiple avenues to explore for acquiring what you require.

Start by identifying reliable websites that focus on equipment maintenance and accessories. Utilize search engines to find vendors that specialize in the specific type of machinery you own. Be sure to compare prices and check customer reviews to ensure you are getting quality products. Additionally, exploring online forums and communities can provide insights into where to find the best deals and reliable suppliers.

It’s also wise to have your machine’s model information handy. This will help filter your search results, making it easier to find the exact components that fit your needs. In some cases, manufacturers’ official websites offer a direct route to obtain genuine items, ensuring compatibility and performance.

Lastly, consider using online databases that list various suppliers, enabling you to compare options quickly. By leveraging these resources, you can effectively secure the components you need to keep your equipment running smoothly.

Comparing L130 with Similar Models

When exploring various models in the same category, it’s essential to examine their features, capabilities, and overall performance. This comparison helps potential users identify which option best suits their needs and preferences.

One key aspect to consider is the engine performance, which significantly affects productivity and efficiency. Models in this range typically offer similar horsepower, yet subtle differences in design can lead to varied operational experiences.

Another important factor is the comfort and ease of use. While many machines provide basic functionalities, some include enhanced ergonomic features that can greatly improve the user experience during prolonged usage.

Finally, durability plays a crucial role in the long-term satisfaction of users. Comparing build quality and materials used can provide insights into how well each model withstands wear and tear over time.

Resources for Further Learning

For those looking to deepen their understanding of machinery components and their assembly, a wealth of resources is available. Engaging with comprehensive materials can enhance your knowledge of operational systems, troubleshooting techniques, and maintenance procedures.

Online platforms, including forums and educational websites, offer valuable insights through articles and videos. Additionally, manuals and technical guides can provide in-depth information regarding specific models and their configurations.

Participating in community groups or workshops allows for hands-on experience and expert guidance. Local libraries and bookstores may also have extensive collections related to machinery care and repair, making them excellent places to further your education.