The proper functioning of any cutting tool relies heavily on the precise arrangement and interaction of its various components. Having a clear understanding of how these elements fit together not only aids in effective maintenance but also enhances the overall performance of the tool. In this section, we will explore the intricacies of these layouts, providing insights that can assist both new users and seasoned professionals alike.

By familiarizing oneself with the configuration of a chain saw, one can easily identify potential areas for improvement or necessary repairs. This knowledge empowers users to make informed decisions regarding the upkeep of their equipment, ensuring longevity and reliability. The following descriptions will offer a detailed examination of essential components, emphasizing their roles and interrelationships.

Whether you’re a hobbyist or a professional, understanding the assembly of your cutting tool is crucial for optimal usage. A comprehensive grasp of how each part contributes to the overall functionality allows for enhanced efficiency and safety during operation. Let’s delve into the essential aspects of this vital equipment.

Understanding the essential components of the Stihl MS261C involves exploring its intricate parts and their functions. This section of the article breaks down the key elements that make up this powerful tool, offering a detailed overview without delving into specific technical details. By grasping the fundamental components, users can gain a clearer understanding of how each part contributes to the overall functionality and performance of the MS261C.

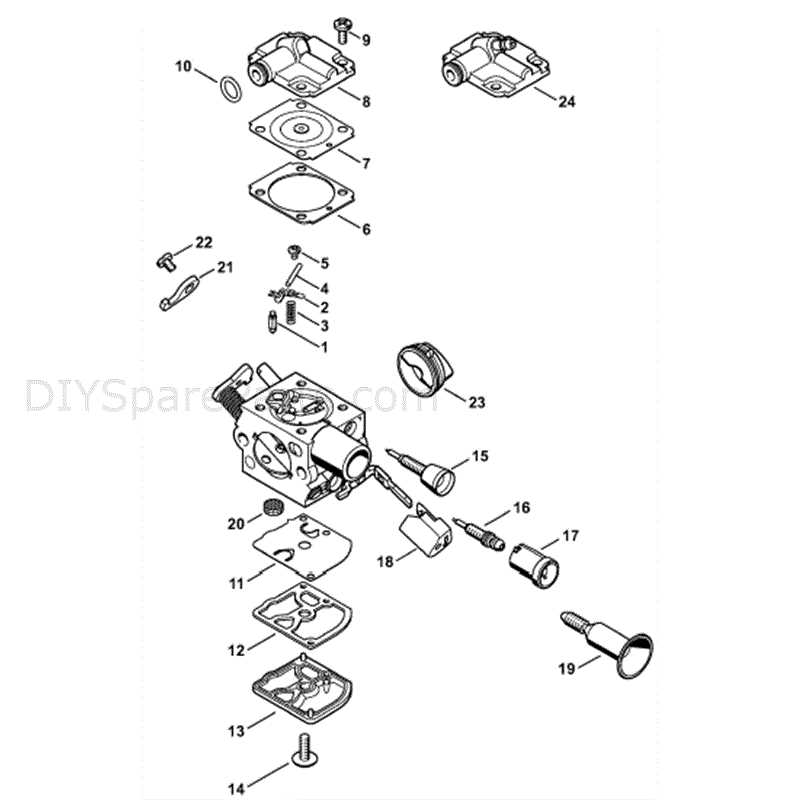

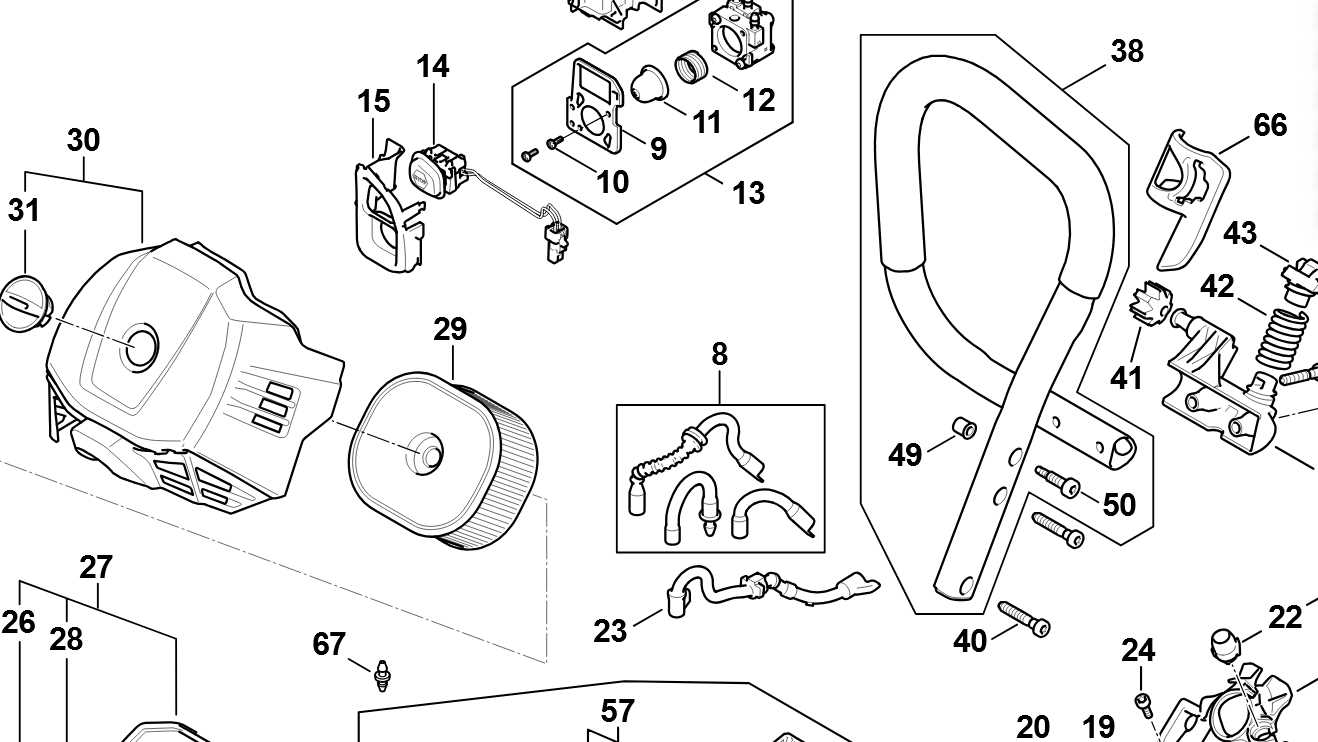

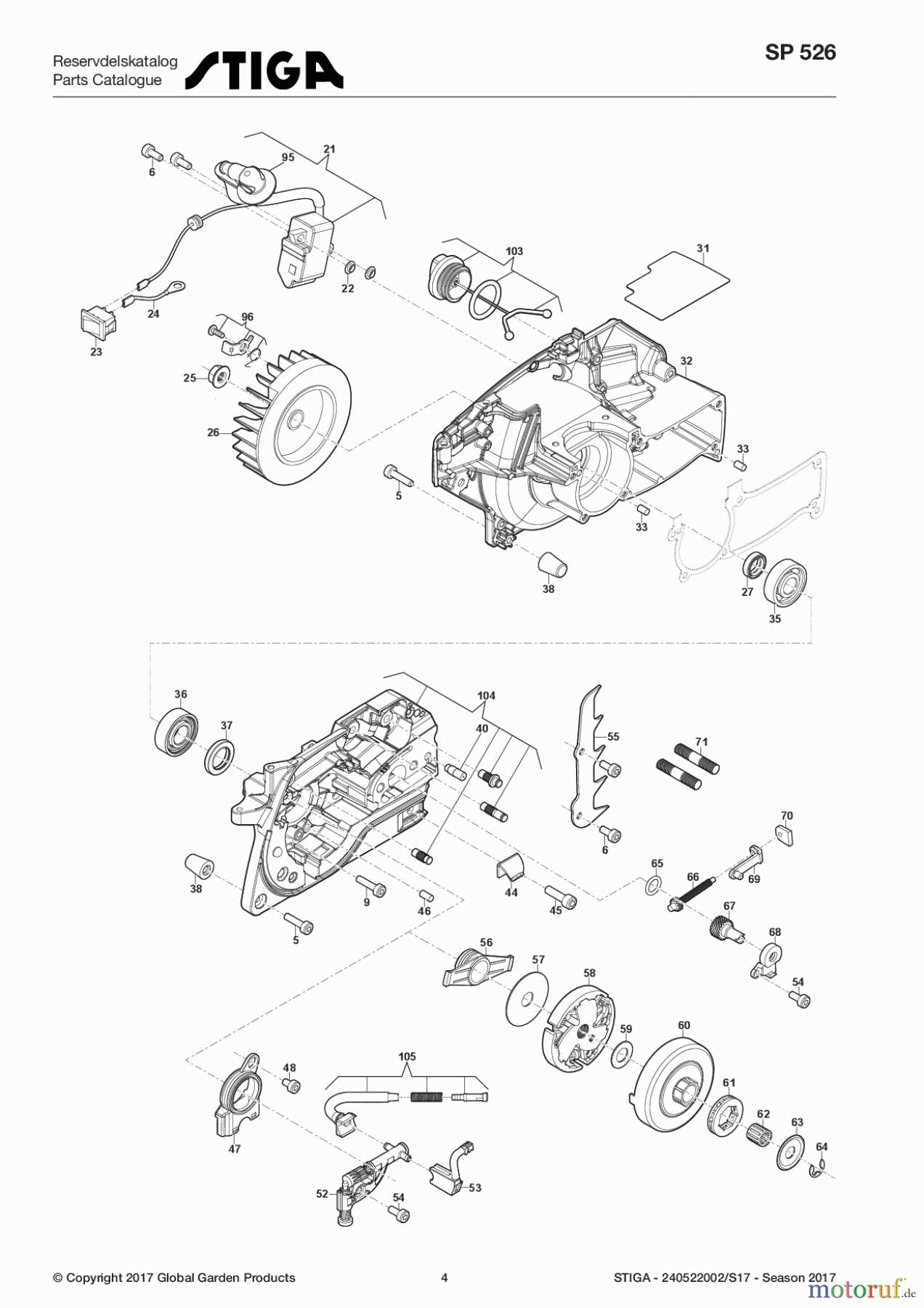

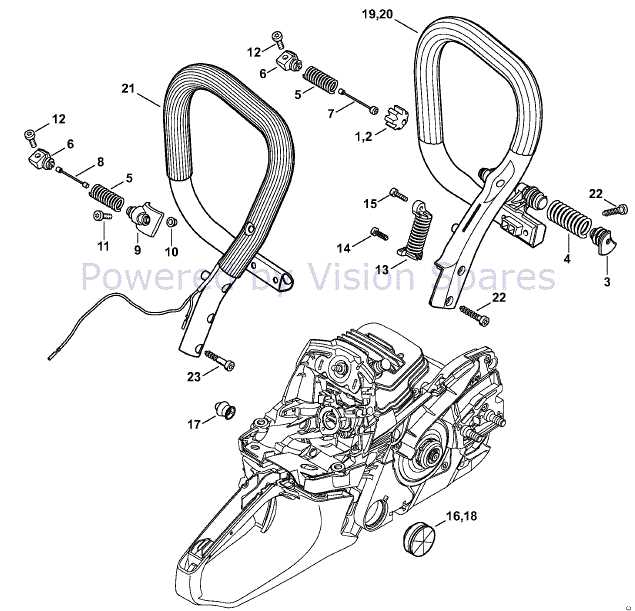

Importance of a Parts Diagram

Understanding the components of a tool is essential for effective maintenance and repair. A visual representation of these elements provides clarity, making it easier to identify each section and its function. This knowledge can enhance efficiency and prolong the lifespan of the equipment.

Utilizing a schematic can significantly improve the repair process. It allows users to pinpoint specific areas that may require attention, ensuring that nothing is overlooked. Furthermore, having a clear reference can save time, reducing the likelihood of errors during assembly or disassembly.

| Benefit | Description |

|---|---|

| Enhanced Clarity | A visual aid simplifies understanding complex machinery. |

| Time Efficiency | Quickly locate components, minimizing downtime during repairs. |

| Improved Accuracy | Reduces chances of mistakes by providing a clear reference. |

| Prolonged Equipment Life | Regular maintenance guided by a visual reference helps prevent premature wear. |

Overview of Stihl MS261C Model

The Stihl MS261C chainsaw represents a versatile and robust tool designed for professional and demanding residential use. It embodies a combination of power, efficiency, and ergonomic design, making it suitable for a wide range of cutting tasks.

With its innovative features and durable construction, this model ensures reliable performance in various environmental conditions. It integrates advanced technology aimed at enhancing user comfort and operational efficiency, thereby maximizing productivity.

The design emphasizes user safety and ease of maintenance, offering intuitive controls and accessible components for straightforward operation and upkeep. Its engineering focuses on durability, ensuring longevity and consistent performance throughout its lifespan.

Overall, the MS261C stands out as a preferred choice among professionals seeking reliability, performance, and durability in a high-performance chainsaw.

Main Parts of the Chainsaw

The efficiency and functionality of a cutting tool rely heavily on its key components. Understanding these essential elements allows users to appreciate how the tool operates and maintain it effectively. Each part plays a vital role in ensuring that the equipment performs its intended tasks with precision.

Essential Components

- Engine: The heart of the chainsaw, responsible for providing the necessary power to operate.

- Guide Bar: This long metal piece supports the chain and guides its movement during cutting.

- Chain: A series of interlinked metal segments that rotate around the guide bar to perform cutting.

- Handle: The part that provides grip and control, allowing the user to maneuver the tool effectively.

- Air Filter: This component prevents debris from entering the engine, ensuring optimal performance.

Additional Elements

- Fuel Tank: Stores the mixture of fuel and oil needed for the engine to run.

- Chain Brake: A safety feature that stops the chain quickly in case of kickback.

- Clutch: Engages and disengages the chain from the engine, allowing for safe operation.

- Oiler: Distributes lubricant to the chain, reducing friction and extending its lifespan.

Locating Replacement Parts Easily

Finding the right components for your equipment can often feel overwhelming. However, by utilizing effective strategies, you can streamline the process and ensure that you obtain the necessary items without hassle.

Start by consulting the user manual, as it typically includes valuable information on compatible components and maintenance guidelines. Additionally, many manufacturers offer online resources that feature exploded views and detailed descriptions of each element, which can significantly aid in your search.

Utilizing online marketplaces is another efficient way to locate essential items. Websites dedicated to selling spare components often provide search filters that allow you to narrow down your options based on your specific needs. Moreover, reading customer reviews can help you gauge the reliability of the products and sellers.

Finally, consider reaching out to local dealers or repair shops. They usually have a wealth of knowledge regarding the specific equipment you own and can assist in identifying and ordering the correct components quickly.

Tools Required for Repairs

When it comes to performing maintenance and fixing issues with outdoor power equipment, having the right tools is essential. Proper tools not only ensure efficiency but also help prevent damage to the machine during repairs. A well-equipped toolkit can make the process smoother and more effective.

To begin with, a set of basic hand tools is necessary, including wrenches, screwdrivers, and pliers. These items are fundamental for loosening and tightening various components. Additionally, having a socket set can provide greater leverage and access to hard-to-reach areas.

For more intricate tasks, specialized tools such as chain saw files and feeler gauges may be required. These instruments aid in precise adjustments and maintenance, ensuring optimal performance. Furthermore, safety equipment, including gloves and goggles, should always be on hand to protect the user during repairs.

Finally, organizing tools in a toolbox or workstation can significantly enhance efficiency. A tidy workspace allows for easy access to necessary items and minimizes the time spent searching for specific tools.

Common Issues and Solutions

This section addresses frequent challenges encountered with chain saws and provides practical solutions to enhance performance and longevity. Understanding these common problems can help users maintain their equipment more effectively and reduce downtime.

1. Engine Starting Difficulties

If the engine fails to start or struggles to ignite, consider the following factors:

- Check the fuel quality; stale or contaminated fuel can hinder performance.

- Inspect the spark plug for wear and replace it if necessary.

- Examine the air filter for clogs; cleaning or replacing it may improve airflow.

2. Poor Cutting Performance

When the cutting efficiency decreases, it may be due to several issues:

- Ensure that the chain is sharp; a dull chain requires excessive effort and increases wear.

- Verify the chain tension; improper tension can cause binding and reduce effectiveness.

- Inspect the bar for wear; a damaged or bent guide bar can lead to uneven cuts.

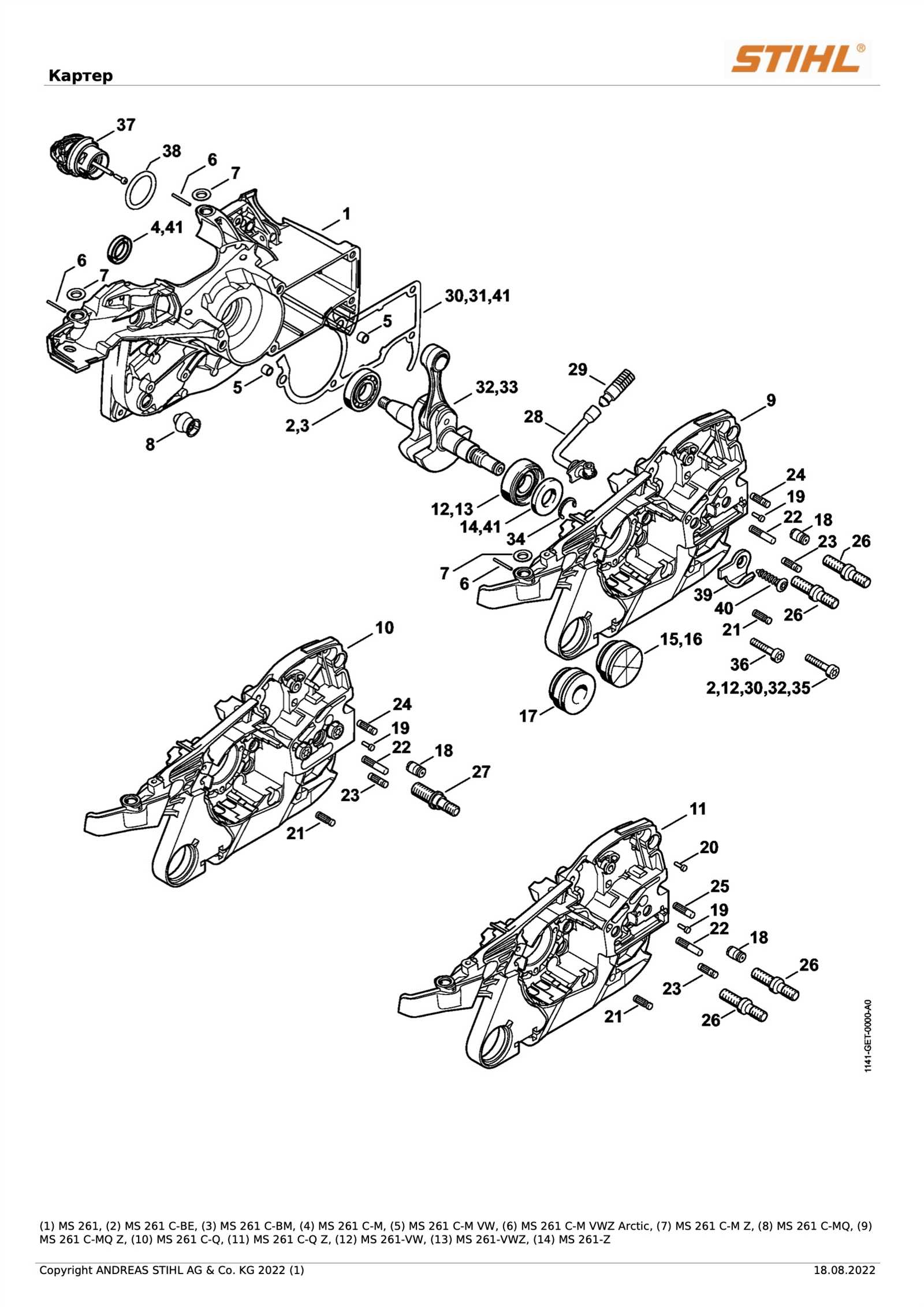

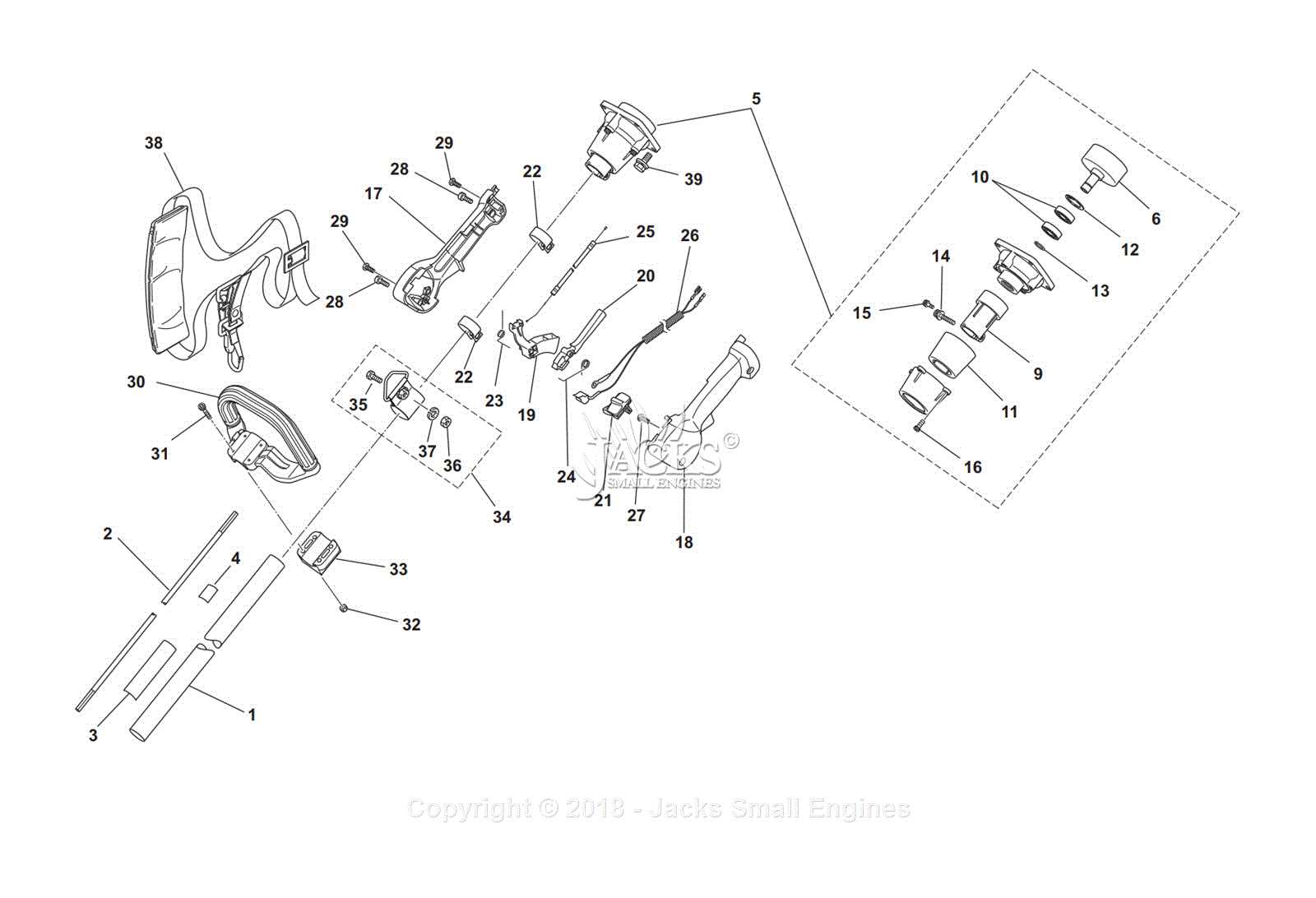

How to Interpret the Diagram

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual aids provide a comprehensive overview of components, helping users identify parts and their functions. By familiarizing yourself with these illustrations, you can streamline your repair processes and ensure optimal performance of your equipment.

Familiarize Yourself with Symbols

Most technical illustrations include specific symbols and labels that represent various elements. Take the time to learn these icons, as they convey critical information about each part’s role within the assembly. Understanding these symbols will enable you to quickly navigate the visual representation and locate the necessary components.

Follow the Flow of the Assembly

Technical illustrations often display the assembly sequence or flow of parts. Observe the connections and arrangements carefully to understand how components interact with one another. This knowledge is crucial for disassembly and reassembly tasks, ensuring that everything fits together correctly and functions as intended.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-lasting performance of your equipment. By adhering to specific care guidelines, you can enhance efficiency, prevent breakdowns, and extend the lifespan of your tools. Here are some practical maintenance strategies to keep your machinery running smoothly.

Regular Cleaning

Keeping your equipment clean is crucial for optimal performance. Dust, debris, and other contaminants can hinder functionality and cause wear over time. Follow these steps for effective cleaning:

- Use a soft brush to remove dirt and debris from the exterior.

- Inspect and clean air filters regularly to ensure proper airflow.

- Check for any buildup in the engine compartment and remove it.

Routine Inspections

Conducting regular inspections helps identify potential issues before they escalate. Pay attention to the following:

- Examine belts and chains for signs of wear or damage.

- Check fluid levels, including oil and fuel, to ensure they are within recommended ranges.

- Inspect moving parts for proper lubrication and functionality.

By implementing these maintenance practices, you can significantly improve the reliability and longevity of your equipment, ensuring it performs efficiently for years to come.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. There are several reliable avenues to explore when looking for original elements that fit your specific model, ensuring that your machine operates smoothly and efficiently.

Authorized Dealers

Visiting authorized retailers is one of the best ways to ensure you are getting genuine items. These dealers are recognized by the manufacturer and typically carry a comprehensive selection of components tailored for your machine. Additionally, they often provide expert advice and support, helping you select the right replacements.

Online Marketplaces

Another convenient option is to browse reputable online platforms. Many websites specialize in offering authentic components, complete with detailed descriptions and specifications. Before making a purchase, verify the seller’s credibility by checking reviews and ratings to ensure a trustworthy transaction.

DIY Repairs: A Step-by-Step Guide

When it comes to maintaining your equipment, understanding how to perform basic repairs can save you time and money. This guide will walk you through the essential steps needed to troubleshoot and fix common issues, ensuring your tools remain in optimal condition. With a little patience and the right approach, you can tackle many repairs yourself, making the process both rewarding and empowering.

Identifying Common Issues

The first step in any repair process is to accurately identify the problem. Listen for unusual sounds, watch for irregular operation, and take note of any visual signs of wear or damage. These observations will help you pinpoint the issue more effectively. Creating a checklist can also aid in tracking the symptoms and potential causes.

Gathering Necessary Tools

Before you begin the repair, ensure you have the appropriate tools at your disposal. Basic tools may include wrenches, screwdrivers, and pliers. Depending on the specific issue, you may need specialized equipment. Preparation is key; having everything ready will streamline the process and reduce the chances of interruption.

With the right knowledge and tools, you can confidently approach repairs and maintain the longevity of your equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring personal safety and the protection of equipment is paramount. Proper precautions can prevent accidents and injuries, allowing for a more efficient repair process. By adhering to established safety guidelines, individuals can create a secure working environment, facilitating the successful completion of necessary repairs.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential during any maintenance procedure. This includes wearing safety goggles to shield the eyes from debris, gloves to protect the hands, and sturdy footwear to ensure stability. Additionally, using ear protection can help minimize the risk of hearing damage from loud machinery.

Work Area Organization

Maintaining a tidy work area is crucial for safety. A clutter-free environment reduces the risk of trips and falls, allowing for smooth movement while working. Ensure all tools and parts are stored properly, and keep hazardous materials away from the workspace. This not only enhances safety but also improves efficiency during the repair process.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and accessories related to outdoor equipment. Understanding these elements can enhance the maintenance and efficiency of your tools, ensuring they function optimally for various tasks.

What should I consider when replacing components?

When replacing any element, it is essential to check compatibility with your specific model. Additionally, assess the quality and durability of the replacement to ensure it meets your operational needs. Regular maintenance and timely replacements can prolong the lifespan of your equipment.

Where can I find reliable information on components?

Reliable information can be obtained from manufacturer websites, authorized dealers, and user manuals. These sources often provide detailed insights and specifications, helping you make informed decisions about necessary replacements and upgrades.