The functionality and efficiency of any machinery depend significantly on its various components. Each part plays a crucial role in ensuring that the entire system operates smoothly and effectively. By gaining insight into the specific elements that make up a piece of equipment, users can better maintain, repair, or upgrade their machines as needed.

One valuable resource for understanding these components is a detailed schematic representation. Such a visual guide not only illustrates how parts are interconnected but also helps in identifying each element’s specific function. This knowledge is essential for anyone looking to enhance their skills in equipment management.

Whether you are a seasoned technician or a newcomer to machinery maintenance, familiarizing yourself with the individual components and their arrangement can lead to improved performance and longevity of the equipment. Emphasizing a thorough understanding of these elements empowers users to tackle any challenges that may arise during operation or maintenance.

This section will provide a comprehensive overview of a high-performance mowing machine, focusing on its essential components and how they contribute to the machine’s overall functionality. Understanding the structure and operation of this equipment is crucial for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Chassis | The main frame that supports all other components. |

| Engine | Drives the machine, providing necessary power for operation. |

| Deck | The housing that contains the cutting blades. |

| Transmission | Transfers power from the engine to the wheels. |

| Blades | Cut the grass to the desired height. |

| Wheels | Provide mobility and stability on various terrains. |

| Seat | Ensures operator comfort during extended use. |

| Controls | Allow the operator to manage speed and direction. |

| Fuel System | Stores and supplies fuel to the engine. |

| Cooling System | Maintains optimal engine temperature. |

| Battery | Provides electrical power for starting and accessories. |

| Safety Features | Includes mechanisms that protect the operator and machine. |

Key Features and Specifications

This section outlines the essential characteristics and technical details of the equipment, providing insights into its design and functionality. Understanding these attributes is crucial for users looking to optimize performance and maintenance.

- Robust construction for enhanced durability

- Advanced engine technology for superior efficiency

- Ergonomic controls for user-friendly operation

- Variety of cutting widths to suit different applications

- Adjustable height settings for versatile mowing

- Efficient fuel consumption for extended operation

- Integrated safety features to ensure user protection

Overall, the equipment is designed to meet the demands of professional landscaping while providing reliable performance and ease of use.

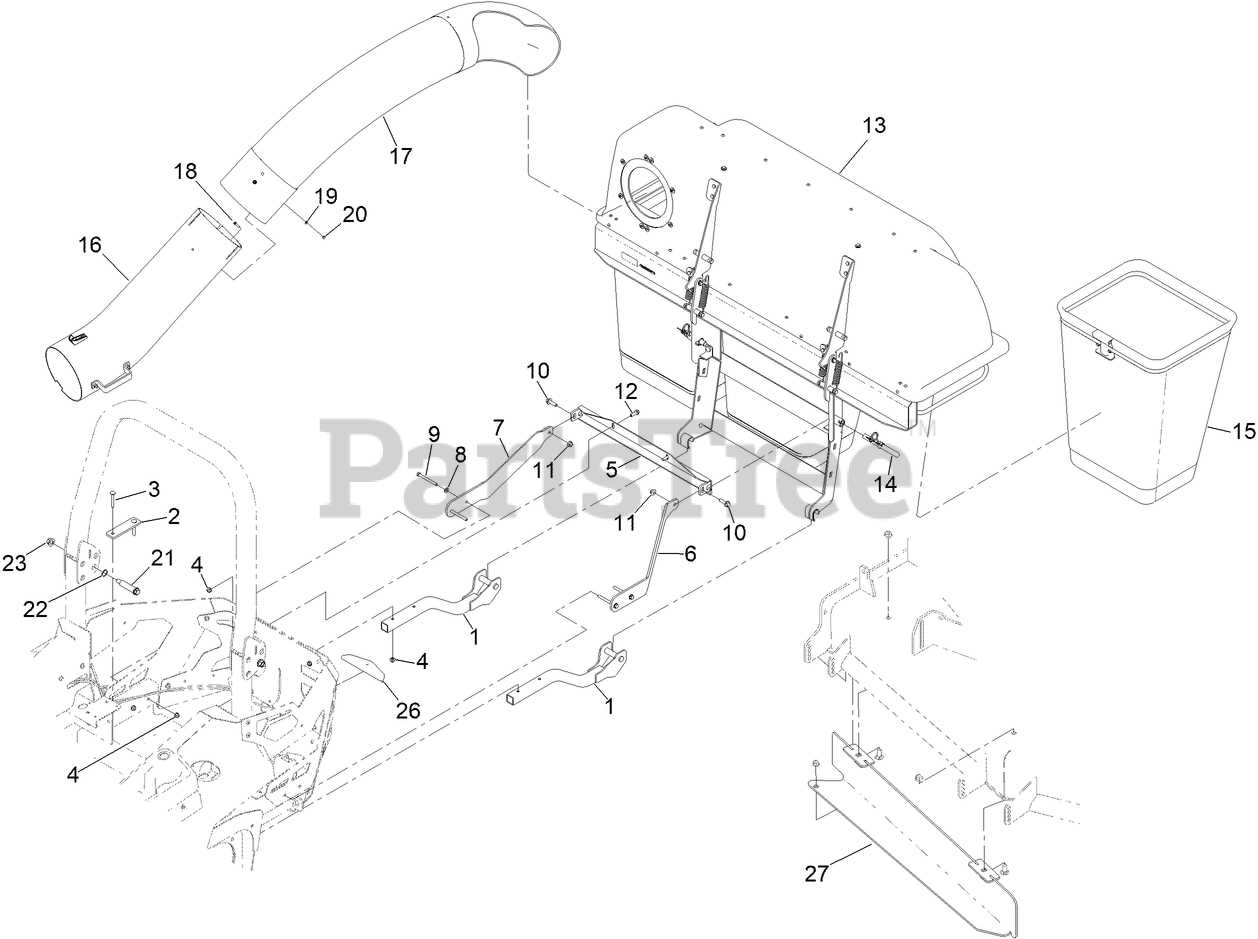

Understanding the Parts Diagram

Grasping the layout of a machinery assembly is essential for effective maintenance and troubleshooting. A well-structured representation showcases each component’s role, allowing users to visualize how various elements interact within the system. This foundational knowledge aids in identifying potential issues and facilitates repairs, ensuring optimal performance.

Components Overview

Every machinery assembly comprises several critical elements, each designed to perform specific functions. Recognizing these components and their placements enhances understanding of the overall operation. This familiarity can significantly improve one’s ability to maintain and service the equipment efficiently.

Interconnections and Functionality

The relationship between various elements is crucial for the machinery’s effective operation. Understanding how each part connects and functions together empowers users to diagnose problems and implement solutions quickly. This knowledge is invaluable for ensuring longevity and reliability in mechanical systems.

Components of the Toro Z Master

The functionality of any high-performance lawn care machine relies heavily on its individual components. Each element plays a crucial role in ensuring optimal operation and durability, contributing to the overall efficiency of the equipment.

Engine: The heart of the machine, responsible for powering all other parts. A robust engine ensures reliable performance and longevity.

Transmission: This system transmits power from the engine to the wheels, allowing for smooth and controlled movement. A well-designed transmission enhances maneuverability.

Deck: The cutting platform is where grass is trimmed. Its design impacts the quality of the cut and the machine’s ability to handle different terrains.

Wheels: Vital for stability and traction, these components allow for ease of movement across various surfaces, ensuring the machine remains effective in different conditions.

Controls: User-friendly controls enable precise operation, allowing the operator to manage speed, direction, and cutting height with ease.

Understanding these components can significantly enhance the user’s experience and maintenance practices, ultimately leading to better performance in lawn care tasks.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your equipment. By following a structured maintenance routine, you can prevent potential issues, enhance functionality, and achieve peak performance. This section outlines key practices that should be implemented to maintain your machinery effectively.

Routine Checks and Cleaning

Perform frequent inspections to identify any signs of wear or damage. Keeping the exterior clean prevents the accumulation of debris, which can hinder performance. Pay special attention to air filters, blades, and other critical components. Ensure they are free from obstructions and in good condition to facilitate optimal operation.

Lubrication and Adjustments

Regularly lubricate moving parts to reduce friction and wear. Proper lubrication extends the lifespan of components and enhances efficiency. Additionally, make necessary adjustments to ensure that all parts align correctly and function smoothly. This practice not only improves performance but also minimizes the risk of malfunctions.

Identifying Common Issues and Solutions

When dealing with lawn maintenance machinery, understanding potential problems can significantly enhance performance and longevity. Common challenges may arise due to wear and tear, improper usage, or environmental factors. Identifying these issues early allows for timely intervention, ensuring smooth operation.

One frequent issue is engine overheating, which can occur if the cooling system is obstructed or if there is insufficient lubrication. To mitigate this, regularly check and clean air filters, as well as ensure adequate oil levels are maintained.

Another common problem is the malfunction of cutting blades. Dull or damaged blades can result in uneven cutting and may stress the engine. Inspecting blades regularly and sharpening or replacing them as needed can resolve this issue effectively.

Furthermore, issues with the fuel system, such as clogged fuel lines or stale gasoline, can impede performance. It is advisable to use fresh fuel and periodically check the fuel filter for any blockages.

By being proactive and addressing these common concerns, operators can maintain their equipment in optimal condition, leading to better results in lawn care tasks.

Step-by-Step Assembly Instructions

Assembling your equipment requires careful attention to detail and a systematic approach. This guide outlines the essential steps to ensure that each component is correctly put together, facilitating optimal performance and longevity.

-

Gather all necessary components before starting the assembly process. Ensure that you have all tools required for assembly, including:

- Screwdriver

- Wrench

- Pliers

- Safety gloves

-

Begin by identifying the main base of the unit. Secure it on a flat, stable surface to prevent any movement during assembly.

-

Attach the frame components according to the included instructions, ensuring that each piece fits snugly into its designated position.

-

Install the wheels or tracks to the base. Make sure they rotate freely and are firmly secured to prevent any issues during operation.

-

Proceed to connect the engine or motor. Follow the specified order of assembly to avoid misalignment.

-

Once the engine is in place, attach the drive belt and ensure it is properly tensioned for efficient operation.

-

Finish by installing any additional components such as handles, control levers, or safety guards, verifying that each is securely fastened.

-

Conduct a thorough inspection of all connections and fasteners to ensure everything is properly assembled before use.

Following these steps will help you successfully assemble your equipment, readying it for operation while ensuring safety and reliability.

Recommended Replacement Parts

Maintaining the efficiency and longevity of your equipment often requires the use of quality components. Selecting the right substitutes is crucial for ensuring optimal performance and reliability. Below, we outline essential elements that should be considered for replacement to keep your machine running smoothly.

Essential Components

Key components that are commonly recommended for replacement include belts, blades, and filters. Regularly inspecting these parts can prevent potential breakdowns and enhance the overall functionality of your machine. Utilizing high-quality replacements ensures that your equipment continues to operate at peak performance.

Additional Recommendations

It is also advisable to consider items like spark plugs and oil filters, as they play a significant role in the maintenance of your system. Implementing these replacements at regular intervals can significantly extend the lifespan of your machinery and improve its efficiency.

Visual Representation of Assembly

Understanding the structure of a complex machine is essential for effective assembly and maintenance. A visual representation serves as a helpful guide, allowing users to see how various components fit together and interact. This aids in ensuring that every element is correctly positioned for optimal performance.

Key Components and Their Arrangement

In an assembly guide, it is crucial to highlight the primary elements and their layout. Each part plays a specific role, contributing to the overall functionality. Here are some common components typically featured in such representations:

- Chassis

- Engine assembly

- Transmission system

- Control panel

- Wheels and axles

Benefits of Visual Guides

Utilizing visual aids offers several advantages:

- Improved understanding of assembly processes.

- Quick identification of parts and their functions.

- Streamlined maintenance and repair efforts.

- Reduced assembly errors and increased efficiency.

Tools Needed for Repairs

When undertaking maintenance and repair tasks, having the right tools is essential for efficiency and effectiveness. This section outlines the necessary equipment that will facilitate the process, ensuring that all tasks can be performed smoothly.

Below is a list of common tools that are typically required for various repairs:

- Wrenches – Different sizes to accommodate various fasteners.

- Screwdrivers – A set of both flat-head and Phillips-head options.

- Pliers – Essential for gripping and manipulating components.

- Socket set – Useful for tightening or loosening bolts with ease.

- Torque wrench – Ensures that fasteners are tightened to the specified torque settings.

- Utility knife – Handy for cutting materials or removing old components.

- Measuring tape – For accurate measurements of parts and fittings.

- Safety goggles – To protect your eyes during repair work.

- Work gloves – To safeguard your hands from sharp edges and debris.

Having these tools readily available will make the repair process more efficient and effective, minimizing the risk of damage to components and enhancing overall safety.

Importance of Regular Maintenance

Regular upkeep is crucial for ensuring the longevity and optimal performance of machinery. Neglecting maintenance can lead to decreased efficiency, higher operational costs, and potential breakdowns. By implementing a consistent maintenance schedule, users can prevent minor issues from escalating into significant problems.

Routine inspections allow for the identification of wear and tear before it affects the equipment’s functionality. This proactive approach not only enhances the performance but also extends the lifespan of the machinery. Additionally, keeping equipment clean and lubricated reduces friction and wear, further contributing to its efficiency.

Moreover, regular maintenance can help maintain safety standards. Well-maintained machinery is less likely to experience sudden failures, reducing the risk of accidents and injuries. Therefore, investing time in routine upkeep is essential for both performance and safety.

Upgrading Components for Efficiency

Enhancing the functionality of machinery often involves optimizing various elements to achieve better performance and energy efficiency. By selecting high-quality alternatives or advanced technologies, users can significantly improve their equipment’s overall effectiveness.

Improving Performance: Upgrading specific components can lead to increased productivity. For instance, investing in superior blades or motors can result in faster operation and reduced downtime. These enhancements not only elevate the machinery’s output but also prolong its lifespan.

Energy Efficiency: Another critical aspect of upgrades is the potential for energy savings. Implementing components designed for lower power consumption can lead to significant reductions in operating costs. Additionally, optimizing hydraulic systems and control mechanisms can minimize waste and enhance overall efficiency.

Ultimately, thoughtful upgrades not only boost performance but also contribute to sustainability by reducing resource consumption. By prioritizing these enhancements, users can achieve both economic and environmental benefits.