Maintaining outdoor equipment requires a clear understanding of how each element works together. Proper visualization of individual mechanisms can significantly enhance the efficiency and longevity of the machinery. Knowing how everything is arranged and operates is essential for ensuring reliable performance.

In the following sections, we will explore the crucial elements that contribute to the overall functionality of outdoor power tools. By understanding how each component connects and functions, you can ensure smoother operation and more effective upkeep of your equipment. This detailed breakdown will guide you through the important connections and assemblies.

Efficient maintenance is key to the long-term success of your equipment. Regular checks, combined with a thorough understanding of the internal structure, can help you keep your tools running smoothly. We will go through each aspect to ensure you’re equipped with the knowledge necessary for optimal care and repair.

Overview of the DeWalt DCST922 Trimmer

This powerful garden tool is designed to provide an efficient solution for maintaining outdoor spaces. Its lightweight construction and ergonomic design make it ideal for users looking for both convenience and performance during lawn care. It delivers consistent results while being easy to handle, ensuring a smooth experience for anyone using it.

Key Features

Equipped with advanced mechanisms, this device offers high durability and functionality. Its motor ensures optimal power output, while the adjustable shaft allows for greater flexibility during operation. These features come together to create a reliable tool for various types of garden work.

Performance and Usability

With its well-balanced weight and ergonomic handle, the device reduces fatigue even during prolonged use. Its intuitive controls make it accessible to users of all skill levels, allowing for precise operation in a variety of conditions. Whether for small yards or larger areas, this tool ensures excellent performance with minimal effort.

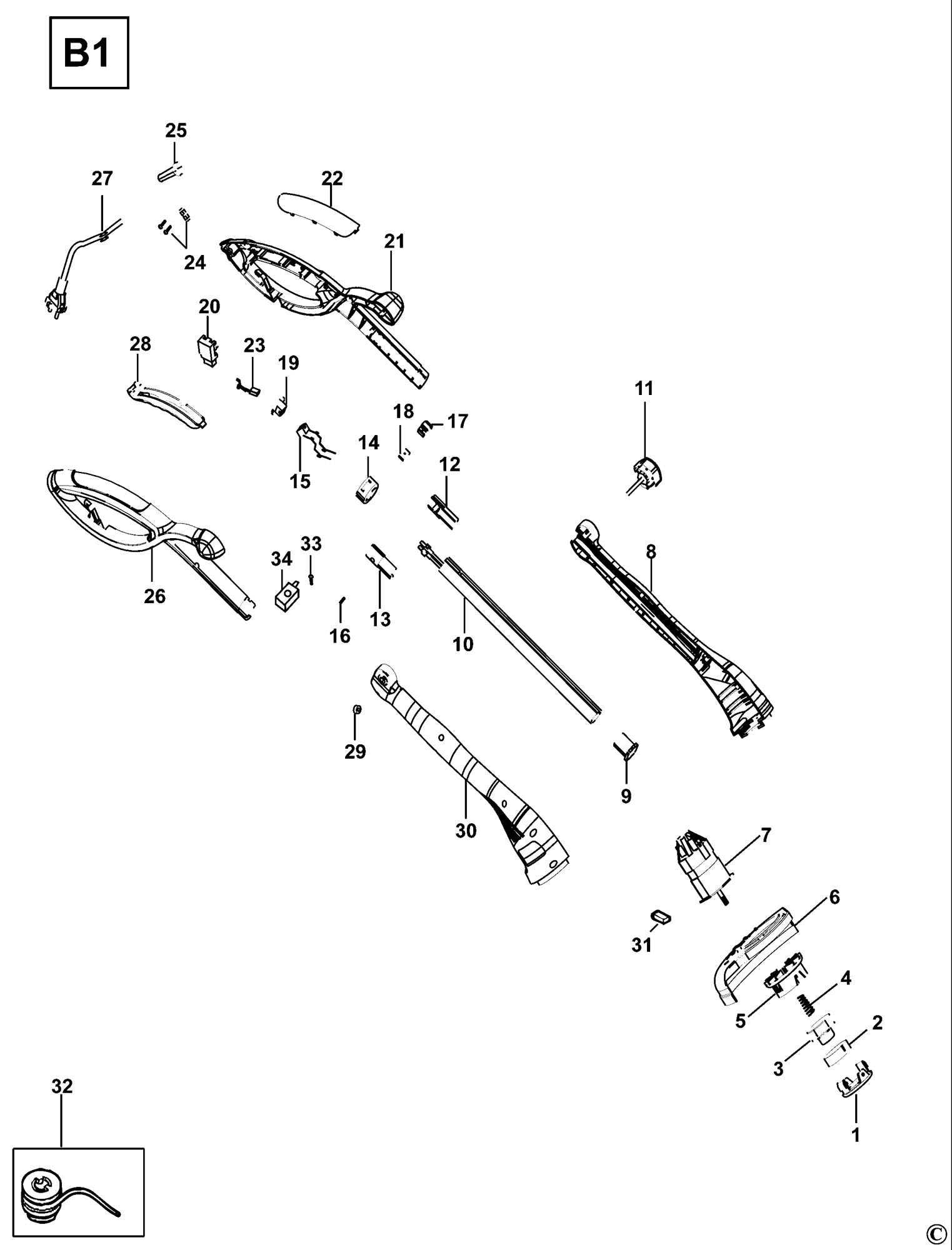

Main Components of the DeWalt DCST922

This tool consists of several key elements that ensure its efficiency and functionality. Each part plays a crucial role in delivering reliable performance, making it easier to handle and maintain. Below is a breakdown of the primary components that make up this model.

- Motor Housing: The core unit that powers the device, providing the energy required for smooth operation.

- Handle Assembly: Ergonomically designed for comfort, this section allows the user to maintain a firm and secure grip during use.

- Cutting

Exploring the Power Source and Motor

The efficiency and performance of modern cutting devices are largely determined by the type of power source and the motor technology they utilize. These components are crucial for providing the necessary energy to operate the tool effectively, ensuring it delivers consistent performance in various conditions.

Power Supply Options

Tools in this category can be powered by a range of energy sources, from battery-operated systems to electric alternatives. Battery-driven models offer enhanced mobility, while electric ones provide continuous operation without the need for recharging. Each power solution comes with its own advantages, such as flexibility or sustained power.

Motor Technology

The motor is the heart of any cutting device, transforming energy into mechanical force. Advanced brushless motors are known for their longer lifespan and reduced maintenance, allowing for smoother operation. This type of motor ensures greater efficiency, lower noise levels, and overall better user experience when tackling various tasks.

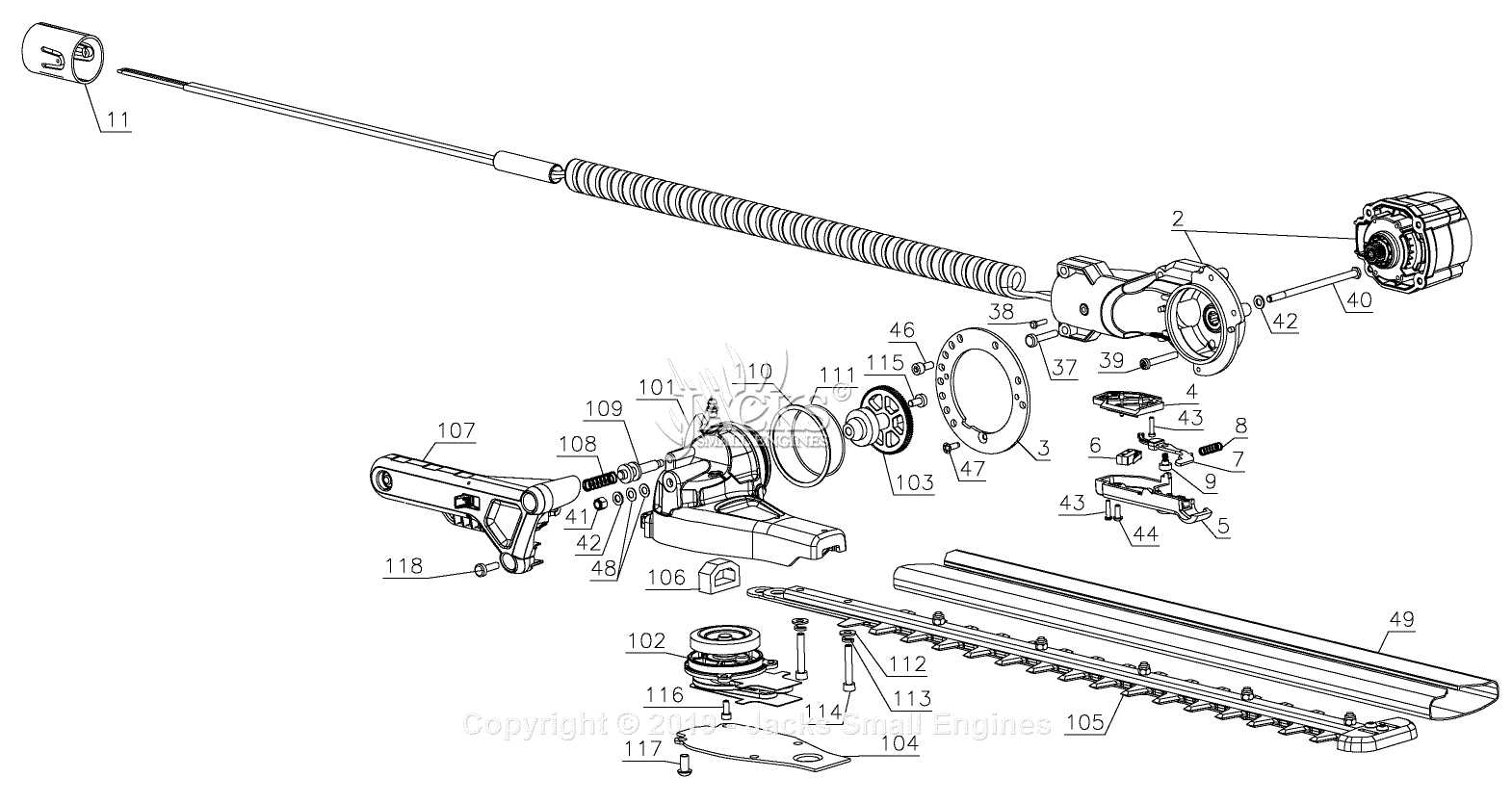

Trimmer Head Breakdown and Functionality

The head of a grass-cutting tool is designed to efficiently manage vegetation by utilizing a rotating mechanism. Its role is critical in ensuring smooth and precise cutting. This section will explore the structure and key components that contribute to its performance, offering insight into how the mechanism works and how each part interacts to deliver the desired outcome.

- Housing: The outer shell protects internal components while providing stability and durability.

- Spool: The central part responsible for holding and dispensing the cutting line. It ensures that the line feeds smoothly during operation.

- Cap: A removable cover that secures the spool in place and allows for easy replacement of the cutting line.

- Spring Mechanism: This helps in the automatic advancement of the cutting line, allowing it to maintain the right length as it wears down.

- Eyelets: Small openings through which the cutting line passes, directing it outside the head for trimming.

Each element of the head works together to ensure consistent performance, reducing wear and enhancing efficiency. Understanding these components allows for easier maintenance and troubleshooting when issues arise.

Guide to Shaft and Handle Assembly

Proper assembly of the shaft and handle ensures comfortable and safe operation of your outdoor tool. By following a structured approach, you can adjust the handle and attach the shaft securely, optimizing the balance and control during use.

Steps for Assembling the Shaft

- Begin by aligning the two sections of the shaft, ensuring that both ends fit smoothly into each other.

- Insert the provided locking pin or screw into the designated hole to secure the connection between the upper and lower sections.

- Check the tightness of the locking mechanism to avoid any movement during operation.

Attaching and Adjusting the Handle

- Locate the handle mounting area on the upper part of the tool.

- Place the handle at the most comfortable height for your grip, ensuring it is

Understanding the Guard and Safety Features

The guard and safety mechanisms of power equipment are essential components designed to protect users during operation. These features play a critical role in minimizing the risk of accidents and enhancing overall user safety.

The guard serves as a protective barrier, preventing debris from being ejected towards the operator and ensuring that the cutting area is contained. Its design is crucial for maintaining visibility while effectively shielding the user from potential hazards.

Safety features also include mechanisms that automatically shut down the equipment when certain conditions are met, such as overheating or when the operator releases the control handle. These systems are vital for preventing injuries and extending the life of the equipment.

Moreover, understanding how to properly use the guard and safety features not only enhances safety but also improves the efficiency of the tool. Users are encouraged to familiarize themselves with these components to ensure optimal performance and protection during use.

Maintenance of Cutting Blades and Line

Proper upkeep of cutting components is essential for the efficient operation of outdoor power equipment. Regular maintenance not only extends the lifespan of these elements but also enhances performance, ensuring that the device operates at its best during use. This section provides guidelines on maintaining the blades and line to achieve optimal results.

Sharpening Blades

Maintaining sharp edges on cutting tools is crucial for effective cutting. Dull blades require more effort, leading to potential strain on the equipment. To sharpen the blades, follow these steps:

Step Action 1 Ensure the equipment is powered off and disconnected from any power source. 2 Use a sharpening stone or file to carefully sharpen the edges, maintaining the original angle. 3 Clean the blades with a cloth to remove debris and residue. 4 Inspect for any signs of damage or excessive wear and replace if necessary. Line Replacement

Regularly replacing the cutting line is vital to maintaining efficiency. A worn or broken line can hinder performance and may lead to unnecessary wear on the machine. Here are the steps to replace the line:

Step Action 1 Power off the equipment and disconnect from any power source. 2 Remove the spool from the device, following the manufacturer’s instructions. 3 Cut a new length of line according to specifications and wind it onto the spool. 4 Reassemble the spool and ensure it is securely attached before testing the equipment. Battery and Charging System Explanation

The performance of any outdoor power tool heavily relies on its energy source and the efficiency of its charging mechanism. Understanding how these systems function is crucial for optimal usage and maintenance.

In many modern tools, the battery serves as a primary energy reservoir. Key aspects include:

- Battery Type: Most devices utilize lithium-ion batteries due to their lightweight, high energy density, and minimal memory effect.

- Voltage Rating: The voltage influences the power output. Higher voltage typically translates to increased performance.

- Capacity: Measured in amp-hours (Ah), this indicates how long the battery can sustain operation before needing a recharge.

Charging systems are equally essential for ensuring long-lasting performance:

- Charger Design: An effective charger is designed to regulate current and voltage to optimize battery health.

- Charge Time: The duration required to fully replenish the battery varies, influenced by the charger type and the battery’s current state.

- Maintenance Features: Many advanced chargers come with features like temperature control and automatic shut-off to prevent overheating.

Understanding these elements allows users to enhance the lifespan of their tools and ensure reliable operation during outdoor tasks.

Troubleshooting Common Part Issues

When working with outdoor equipment, it’s common to encounter various problems related to individual components. Identifying these issues can significantly enhance the efficiency of your tool and extend its lifespan. Below are some common concerns and their potential solutions.

1. Performance Problems

- Engine Not Starting: Ensure that the fuel is fresh and the spark plug is in good condition. Check for any clogs in the air filter.

- Uneven Cutting: Inspect the cutting mechanism for wear and tear. Replace any damaged blades or accessories as needed.

2. Vibration and Noise

- Excessive Vibration: Look for loose components or damaged parts that may need tightening or replacement.

- Unusual Noises: Identify the source of the noise, as it could indicate a failing bearing or misaligned parts.

3. Fuel System Issues

- Fuel Leaks: Examine hoses and connections for cracks or damage. Replace any faulty components immediately.

- Fuel Flow Problems: Clear any obstructions in the fuel lines and check the filter for blockages.

Regular maintenance and careful observation can help prevent many of these issues. Keeping your equipment in optimal condition ensures that it operates smoothly and effectively.

Replacement Options for DeWalt DCST922 Parts

Maintaining your equipment in optimal condition is essential for ensuring its longevity and performance. When components become worn or damaged, exploring available alternatives can be beneficial. This section will outline various options for sourcing replacements, focusing on quality and compatibility.

Aftermarket Components: Numerous manufacturers produce aftermarket items that may offer comparable or superior quality compared to the original. These options often provide cost savings without sacrificing performance. Always verify compatibility with your specific model before purchasing.

Original Equipment Manufacturer (OEM): For those seeking guaranteed fit and performance, OEM replacements are an excellent choice. These items are produced by the original manufacturer and typically match the specifications of the original components, ensuring seamless integration.

Refurbished Options: Consider refurbished items as a sustainable alternative. Many suppliers offer thoroughly inspected and repaired components at reduced prices. This can be an environmentally friendly choice, contributing to reduced waste while maintaining performance standards.

Local Retailers: Local hardware stores or specialized gardening equipment shops often carry a selection of replacement components. Consulting with knowledgeable staff can help identify suitable options and provide insights into the best choices for your equipment’s needs.

By exploring these various avenues, you can ensure your equipment remains functional and efficient, ready to tackle any task.