When it comes to maintaining and repairing outdoor machinery, having a clear understanding of the various components involved is crucial. This section delves into the intricate layouts that illustrate how different elements of the equipment are interconnected. By familiarizing yourself with these schematics, you can enhance your ability to troubleshoot and perform necessary maintenance tasks effectively.

These detailed representations provide invaluable insights into the assembly and functionality of the machinery, enabling users to identify specific components quickly. Each element plays a vital role in the overall operation, making it essential to comprehend how they fit together. Whether you’re a seasoned technician or a novice enthusiast, grasping the relationships between these components will empower you to address any issues that may arise.

Furthermore, understanding these layouts can significantly reduce the time and effort spent on repairs. With a clear visual reference, you can efficiently locate parts that require attention, ultimately leading to a more productive and enjoyable experience when working with your outdoor equipment. Embracing this knowledge not only improves your skills but also instills confidence in handling your machinery with care.

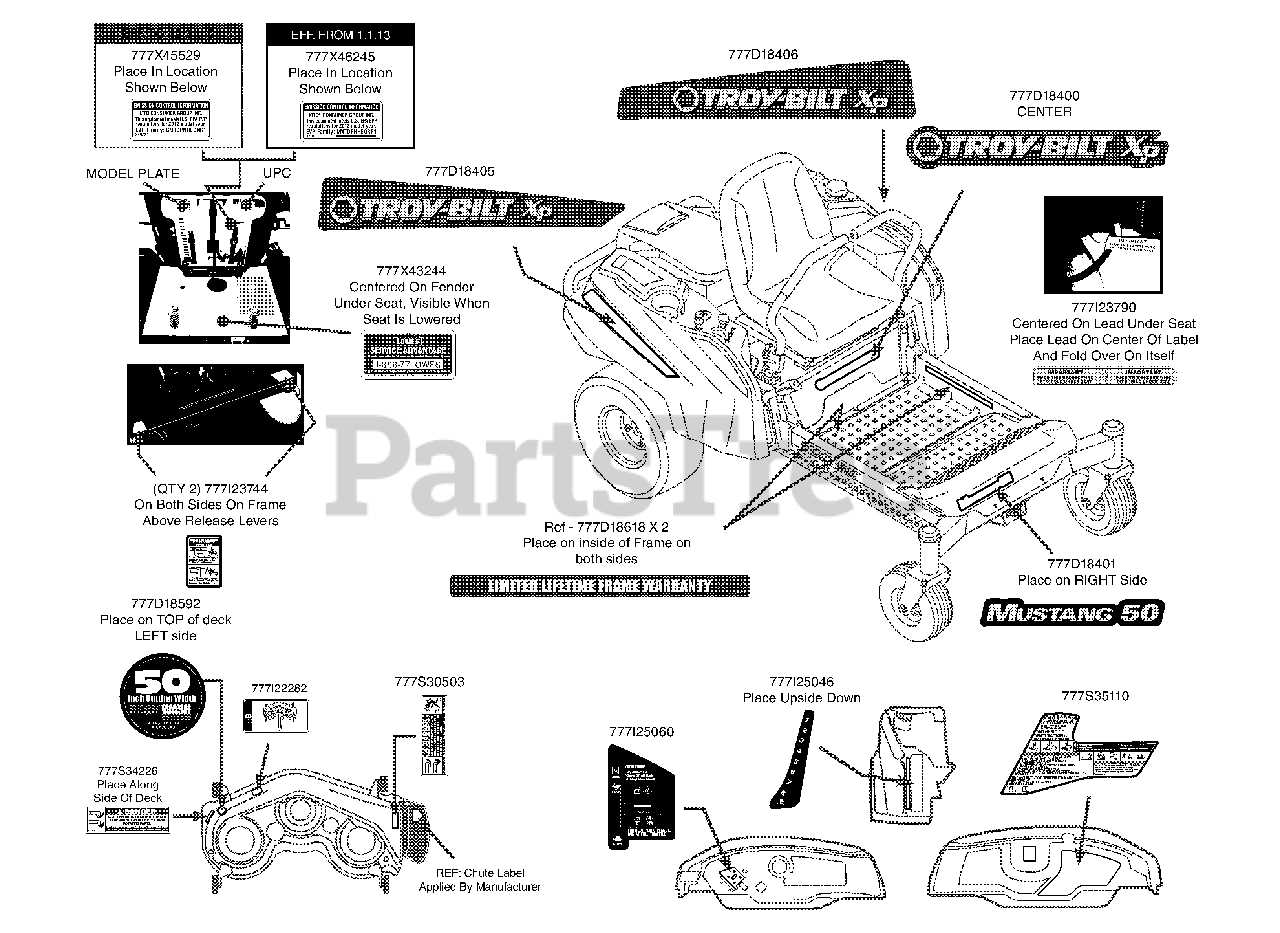

Troy Bilt Mustang Overview

This section provides a comprehensive examination of a well-regarded line of lawn maintenance equipment, highlighting its features, functionality, and user benefits. Designed for efficiency and ease of use, this range is suitable for both residential and commercial applications, making it a popular choice among landscapers and homeowners alike.

Key Features

- Robust construction for durability and long-lasting performance.

- Ergonomic design to enhance comfort during operation.

- Variety of attachments and accessories available to extend capabilities.

- Efficient engine performance for optimal cutting and trimming.

User Benefits

- Reduces time spent on yard work with advanced mowing technology.

- Offers ease of maneuverability in various terrains.

- Minimizes maintenance requirements, allowing for more time to enjoy the outdoors.

- Enhances property aesthetics through professional-grade results.

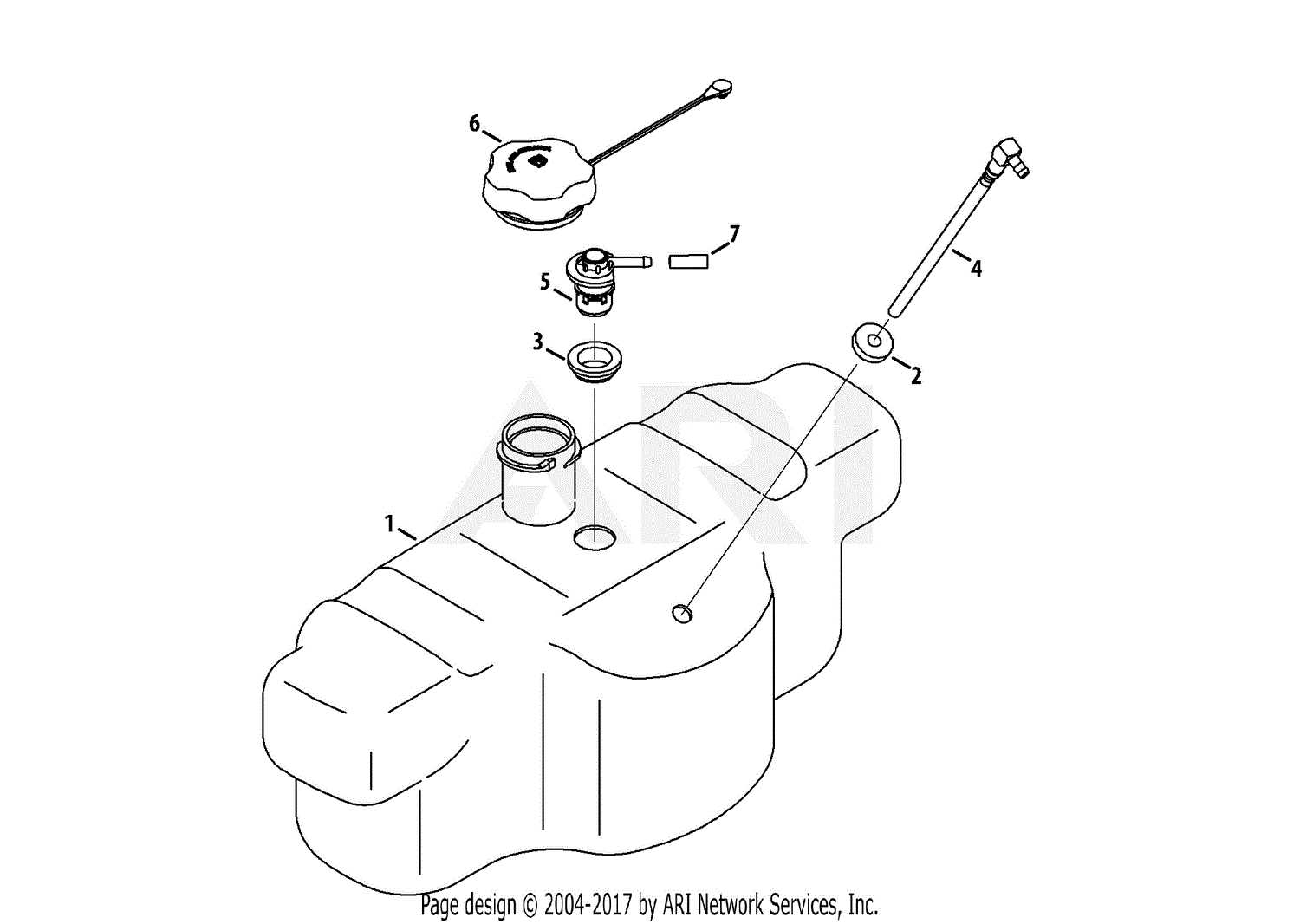

Common Parts and Their Functions

This section explores the essential components found in various lawn care equipment, focusing on their roles and significance in overall functionality. Understanding these elements is crucial for maintenance and effective operation.

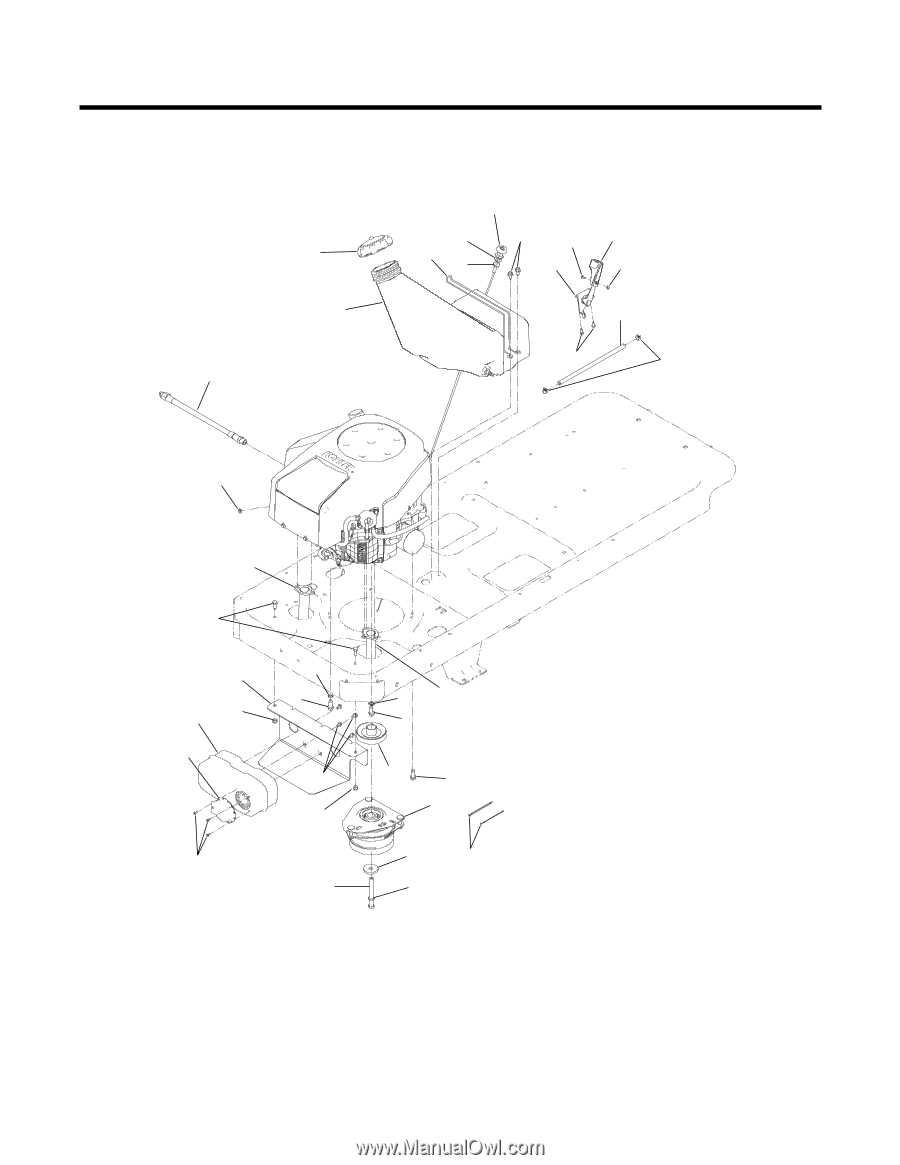

Engine Assembly

The engine assembly serves as the powerhouse of the equipment, converting fuel into mechanical energy. It is responsible for driving the blades and providing the necessary force for cutting and maneuvering. Regular maintenance of this unit ensures optimal performance and longevity.

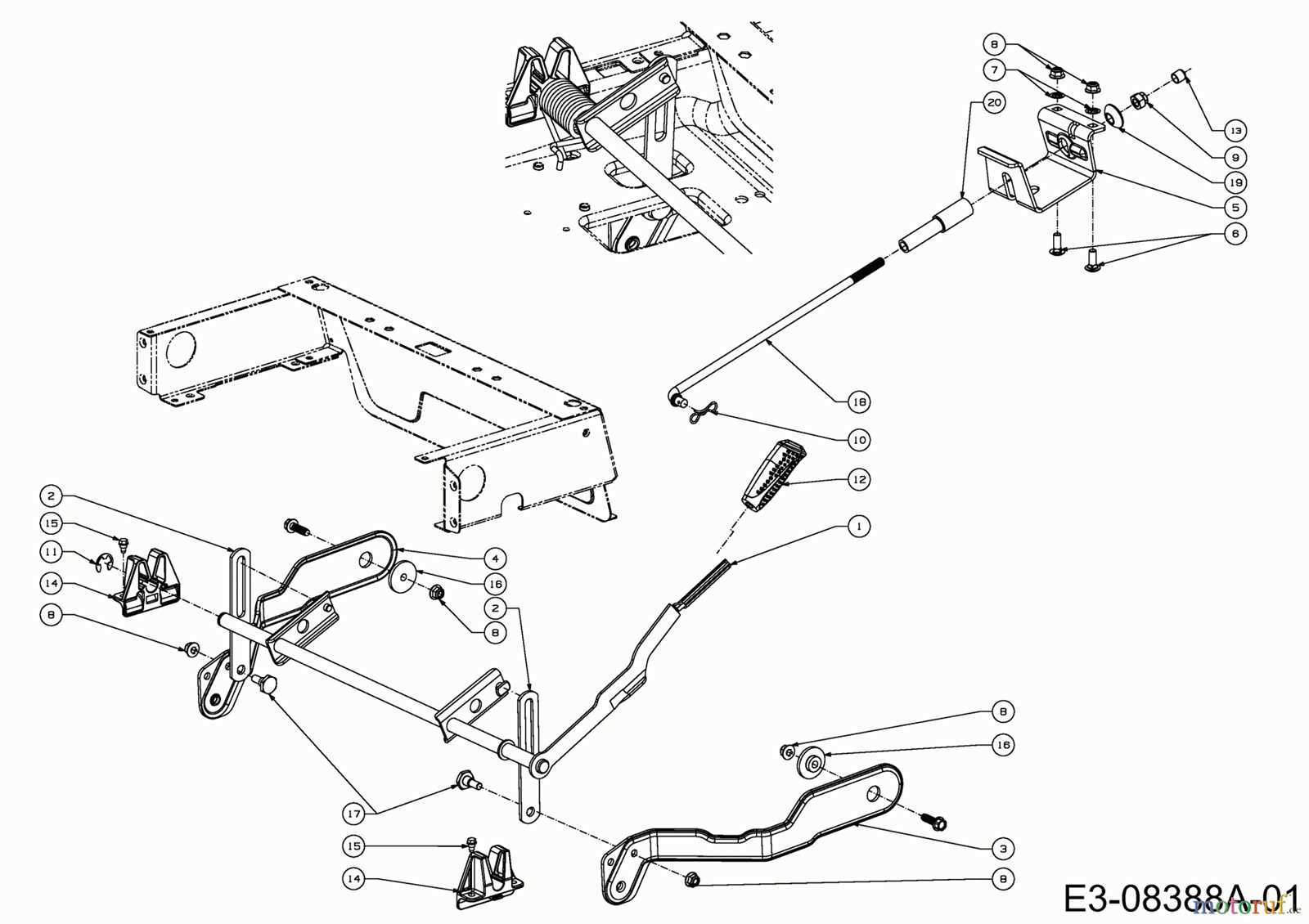

Transmission System

The transmission system transmits power from the engine to the wheels, allowing for smooth movement and speed adjustments. It consists of various gears and belts that enable operators to navigate different terrains effectively. Ensuring proper alignment and lubrication of this system is vital for efficient operation.

Other essential components include the cutting deck, control levers, and wheel assemblies, each contributing to the overall effectiveness of the machinery. Familiarity with these key elements can enhance user experience and facilitate troubleshooting when necessary.

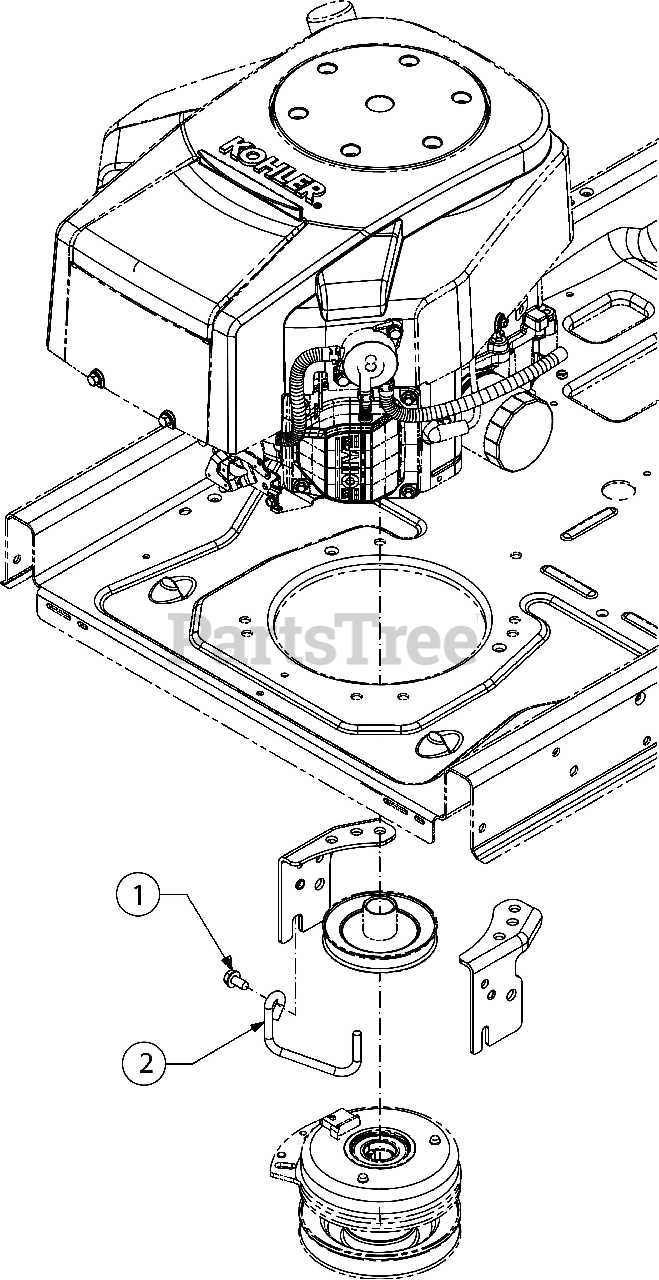

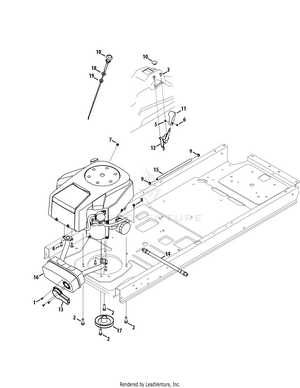

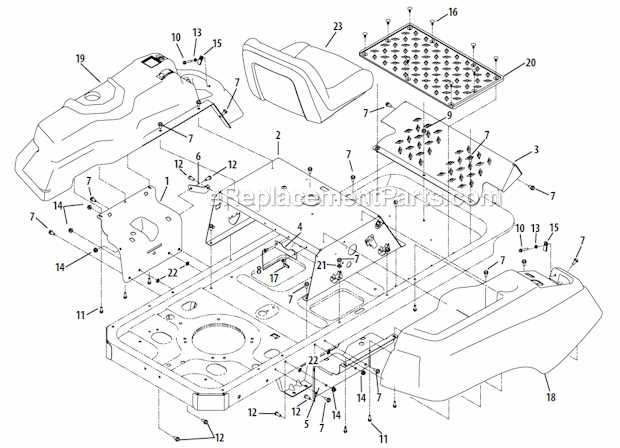

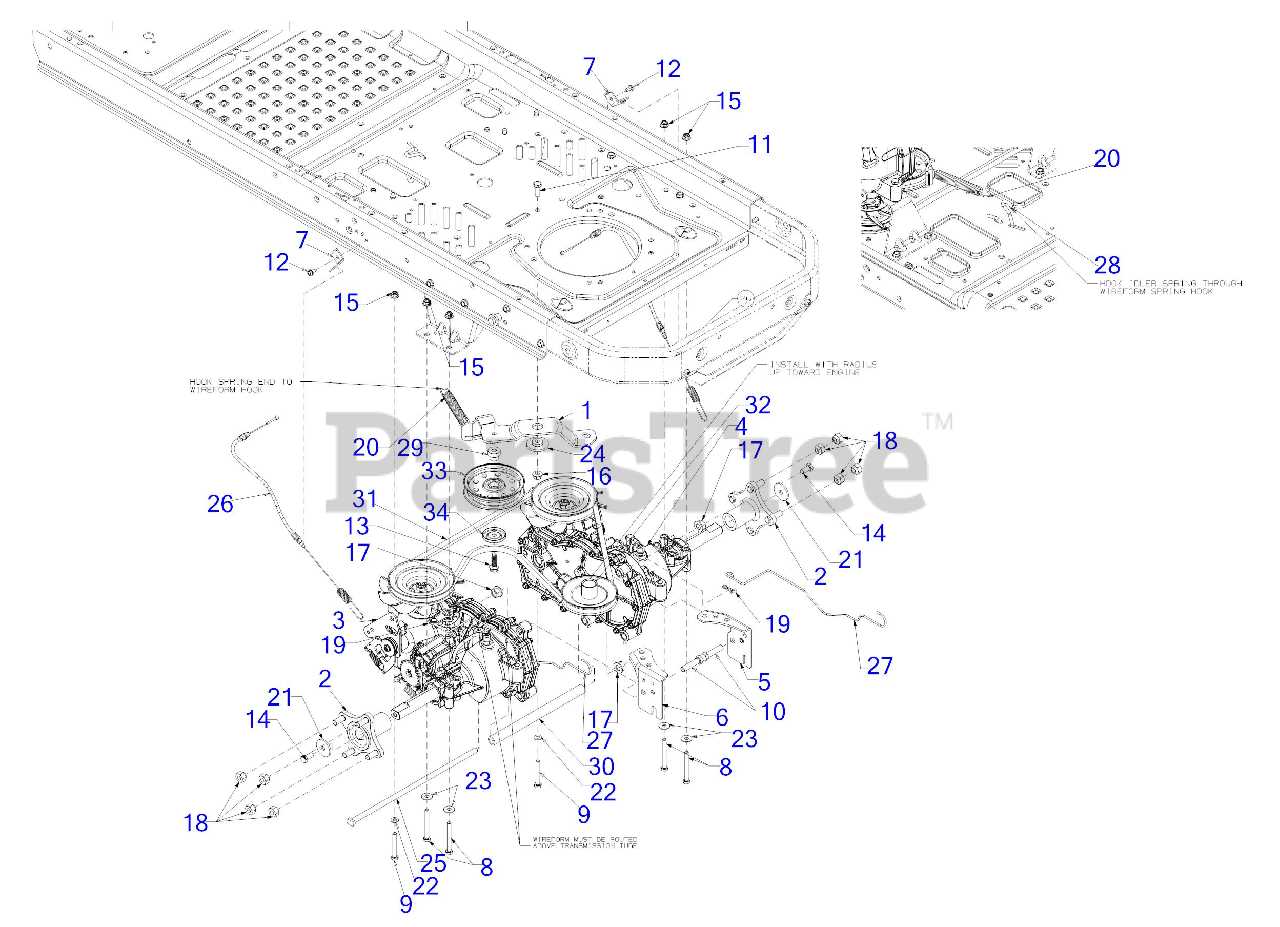

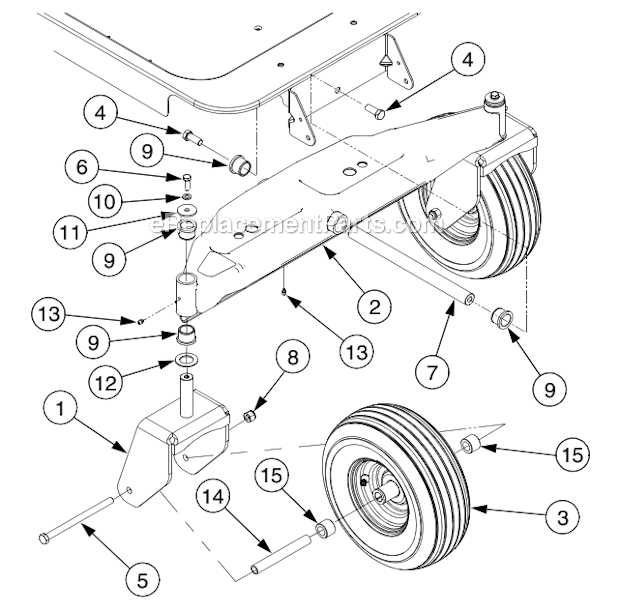

Understanding the Parts Diagram

Grasping the schematic representation of components is essential for effective maintenance and repair tasks. This visual guide serves as a reference to identify various elements, their functions, and interconnections within the equipment. Familiarity with this layout can enhance efficiency when troubleshooting issues or performing upgrades.

Key Components Overview

Each element within the illustration plays a crucial role in the overall operation. Below are some of the primary features you may encounter:

- Engine: The power source responsible for driving the entire system.

- Transmission: The mechanism that transfers power from the engine to the wheels.

- Chassis: The frame that supports all other components, providing stability and structure.

- Wheels: Critical for mobility, these elements must be maintained for optimal performance.

Utilizing the Schematic Effectively

To maximize the benefits of the visual representation, consider the following tips:

- Refer to the layout regularly during maintenance to ensure all components are accounted for.

- Cross-reference with your service manual for specific repair instructions related to each element.

- Use the schematic as a tool for identifying potential issues by observing wear and tear patterns on various parts.

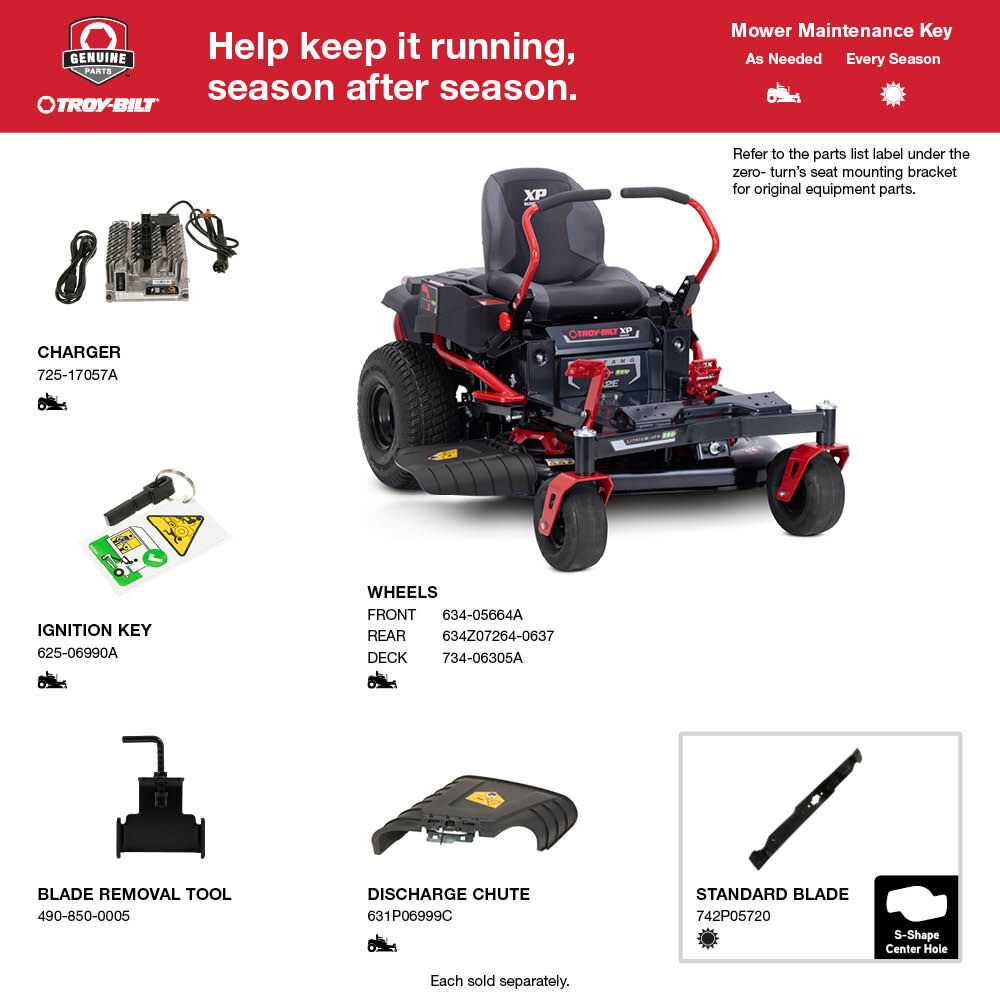

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its functionality and extend its lifespan. Numerous resources are available for acquiring the necessary items, whether for maintenance, repairs, or upgrades. Understanding where to look can save both time and money.

Online Retailers

Many online platforms specialize in selling various components. Here are some popular options:

- Amazon: A vast selection of components and accessories, often with customer reviews for guidance.

- eBay: A marketplace for both new and used items, perfect for those seeking rare or discontinued items.

- Manufacturer’s Website: The official site often provides genuine items and detailed specifications.

Local Suppliers

Visiting local stores can be beneficial for immediate needs. Consider checking:

- Home Improvement Stores: Chains like Home Depot or Lowe’s often stock basic components.

- Specialty Shops: Local dealers may offer specific items tailored to your equipment.

- Repair Services: Professional repair shops might have spare components available for purchase.

Maintenance Tips for Your Mustang

Proper upkeep is essential to ensure optimal performance and longevity of your machinery. Regular attention to key components can prevent breakdowns and enhance efficiency, providing a smoother experience during operation. This section outlines several crucial maintenance practices to keep your equipment in top condition.

Regular Inspections

Conducting routine examinations helps identify potential issues before they escalate. Focus on the following areas:

- Check the engine oil levels and quality, replacing it as needed.

- Inspect the air filter for dirt and debris, changing it regularly to maintain airflow.

- Examine belts and hoses for wear, replacing them if cracks or fraying are visible.

- Review the tire pressure and tread condition to ensure proper traction.

Cleaning and Lubrication

Keeping your machine clean and well-lubricated can significantly extend its lifespan. Follow these steps:

- Wash the exterior to remove dirt and debris, preventing corrosion.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Clear out any grass or debris from undercarriages and other hard-to-reach areas.

By following these simple yet effective maintenance strategies, you can enhance the reliability and functionality of your equipment for years to come.

Identifying Key Components

Understanding the essential elements of outdoor machinery is crucial for effective maintenance and operation. Each component plays a specific role in ensuring the equipment functions smoothly and efficiently. Familiarizing oneself with these elements can lead to better performance and longevity of the machinery.

Main Elements to Consider

- Engine: The powerhouse responsible for driving the entire system.

- Transmission: Facilitates the transfer of power from the engine to the wheels.

- Deck: The area that houses the cutting mechanism, critical for effective operation.

- Wheels: Essential for mobility and stability on various terrains.

- Control Panel: Allows the operator to manage different functions and settings.

Understanding Functional Groups

- Power System: Includes the engine and transmission, essential for generating and managing power.

- Cutting Mechanism: Comprises the deck and blades, pivotal for achieving the desired results during operation.

- Mobility Features: Encompasses wheels and axles, crucial for movement across different surfaces.

- Operator Interface: The control panel and related components that enhance usability.

Common Issues and Solutions

In the realm of outdoor equipment, various challenges can arise during operation and maintenance. Identifying these frequent problems is crucial for ensuring optimal functionality and longevity. This section explores typical issues encountered, along with effective strategies for resolution.

Engine Starting Problems: A common difficulty involves the engine failing to start. This may be due to a depleted battery or fuel-related issues. To troubleshoot, check the battery connections and ensure there is sufficient fuel in the tank. If the problem persists, consider examining the spark plug for wear or dirt.

Uneven Cutting: Another frequent concern is uneven cutting, which can lead to unsatisfactory results. This often occurs when the blades are dull or improperly adjusted. Regularly sharpen the blades and check their height settings to achieve an even cut across the lawn.

Excessive Vibration: Excessive shaking during operation can indicate misalignment or damage to components. Inspect the mower for loose parts, ensuring that all bolts and screws are tightened securely. Additionally, check the blade balance to minimize vibrations.

Clogged Deck: A clogged cutting deck can impede performance and efficiency. Regularly clean the deck after use to prevent grass buildup. Using a scraper or a pressure washer can help maintain a clear deck, promoting better airflow and cutting efficiency.

By addressing these common challenges with proactive solutions, users can enhance the reliability and performance of their outdoor equipment, ensuring a more enjoyable mowing experience.

How to Use the Diagram

Understanding the visual representation of components can significantly enhance your maintenance and repair efforts. This guide will help you navigate the illustration effectively, ensuring that you can identify each element and its function with ease.

Familiarize Yourself with the Key

Before diving into the visual aid, take a moment to review the accompanying legend. The key provides crucial information regarding symbols and labels used throughout the illustration. Recognizing these indicators will streamline your understanding and prevent confusion during the repair process.

Identify Components and Their Functions

Once you have grasped the symbols, begin pinpointing individual elements within the visual guide. Pay attention to the connections and relationships between various parts. This awareness will help you assess which components require attention and how they interact with one another. If you’re replacing or servicing a specific item, use the representation to locate it quickly, reducing the time spent searching.

Utilizing this visual reference effectively not only aids in the repair process but also enhances your overall knowledge of the machine’s structure and operation. Engaging with the representation fosters greater confidence when addressing maintenance tasks.

Parts Compatibility and Upgrades

Ensuring that components are compatible is crucial for optimal performance and longevity. When considering enhancements, it’s essential to explore which elements can be upgraded or replaced without compromising functionality. Understanding compatibility can lead to significant improvements in efficiency and effectiveness.

Evaluating Component Compatibility

Before making any modifications, assess the specifications and requirements of existing units. Each element must meet certain criteria to work seamlessly together. Referencing manufacturer guidelines can provide insights into compatible alternatives, helping to avoid potential issues during installation.

Enhancement Options

Upgrading specific components can yield enhanced performance. For example, replacing outdated engines with newer models can provide greater power and fuel efficiency. Additionally, considering aftermarket accessories can offer unique benefits, such as improved durability or advanced features. Always verify the compatibility of these upgrades to ensure a smooth transition.

Manufacturer Support and Resources

Accessing reliable assistance and informative materials is crucial for maintaining and repairing outdoor power equipment. Various resources are available to help users troubleshoot issues, acquire maintenance tips, and find compatible components. Whether it’s user manuals, instructional videos, or customer service contacts, these resources aim to enhance the overall user experience and ensure the longevity of the machinery.

Many manufacturers provide extensive online support, including downloadable manuals and FAQs. Users can benefit from community forums and discussion boards where they can share experiences and solutions. Additionally, customer support teams are typically reachable via phone or email, ready to address any inquiries or concerns.

Exploring authorized dealers and service centers can further assist users in locating the necessary resources. These locations often offer hands-on help, including repairs and parts sourcing, ensuring that equipment remains in optimal condition. Utilizing these support avenues can lead to efficient troubleshooting and a more enjoyable ownership experience.

DIY Repairs and Parts Installation

Engaging in home maintenance and equipment upkeep can be a rewarding experience. By understanding the components and their functions, individuals can tackle various repairs and install necessary items efficiently. This not only saves time but also enhances the longevity of the machinery.

Preparation is key to a successful project. Begin by gathering the right tools and materials needed for the task. A well-organized workspace will make the process smoother and minimize the risk of errors. Familiarizing oneself with the machinery’s structure and operational principles can greatly aid in diagnosing issues.

When it comes to installation, following a systematic approach ensures that each element is correctly fitted. Carefully read the instructions associated with new components, paying close attention to compatibility and specific requirements. It’s beneficial to refer to reliable resources or community forums for guidance on common challenges.

Finally, conducting regular maintenance checks after repairs or installations will help identify potential problems early. This proactive approach not only enhances performance but also ensures that the equipment remains in optimal condition for years to come.